1. Introduction

Innovation is critical in driving business and economic development (Schumpeter Reference Schumpeter1934; Porter Reference Porter1990). Companies, whether small startups or large established corporations, increasingly claim to be innovative (Kwoh Reference Kwoh2012). Innovation has become a buzzword in news articles, book titles, and company reports. Innovation studies have also recently emerged as a scientific field (Fagerberg & Verspagen Reference Fagerberg and Verspagen2009). Despite the consensus on its importance, ‘innovation’ has been variously defined by its different advocates. In academia, Schumpeter (Reference Schumpeter1934) first defined innovation as ‘new combinations’ or ‘the setting up of a new production function’. In practice, innovation often refers to the introduction of new products, improvements in quality, and new production methods (Hagedoorn Reference Hagedoorn1996).

The diverse meanings, interpretations, and uses of the term ‘innovation’ provide but limited guidance on the necessary actions to successfully innovate (Luo et al. Reference Luo, Baldwin, Whitney and Magee2014). To enhance innovation, a process-based view of innovation appears to be more prescriptive and actionable. The ‘innovation process’ that is commonly studied in the existing literature, however, only concerns the applied research, product design, and development activities that can be managed within single companies (Otto & Wood Reference Otto and Wood2000; Pavitt Reference Pavitt, Fagerberg, Mowery and Nelson2005). Meanwhile, there is a growing belief that innovation is most likely to emerge in a highly entrepreneurial regional ecosystem where complementary activities are conducted across organizations (Saxenian Reference Saxenian1996; Kenny Reference Kenny2000; Blank Reference Blank2008) and that basic sciences are valuable for innovation (Jaffe & Trajtenberg Reference Jaffe and Trajtenberg1996; Fleming & Sorenson Reference Fleming and Sorenson2004; Dugan & Gabriel Reference Dugan and Gabriel2013); however, we still know little about what activities are desirable and how they should be organized in an ecosystem.

In this paper, our analysis expands the traditionally defined boundaries of innovation processes and examines the diverse innovation-relevant activities that originate with the creation of scientific knowledge and end with the successful implementation or diffusion of an invention. The expansion of the boundary of analysis illuminates which activities are relevant and how they are connected to nurturing and enhancing innovation. Specifically, the analysis identifies three sub-processes that contribute to innovation, including science, design, and entrepreneurshipFootnote 1 , their complementarity, and the value added from uniting them. Properly promoting and uniting these three specific sub-processes will produce more actionable results than the narrative of innovation as a phenomenon, design, or invention. The shared creative, uncertain, and costly nature of the three sub-processes is also analyzed, and suggests that existing knowledge about managing design processes can be leveraged to understand and guide the science and entrepreneurship processes.

Different models of uniting the sub-processes at different levels, e.g., organizational, regional, and global levels, are further presented and analyzed. First, the examples of Robert Langer, Defense Advanced Research Projects Agency (DARPA), Bell Labs, Google, and IBM, among others, are used to illustrate different models of uniting innovation sub-processes primarily within organizational boundaries. Then, the value of regional ecosystems for uniting all three sub-processes across organizational boundaries is discussed, and demonstrated by a case study on how the Boston/MIT ecosystem nurtured the innovation of Brontes Technologies. In addition, the challenges of and strategies for building local innovation ecosystems are analyzed, and suggest the value of linkages to remotely located complementary sub-processes across different regions. A detailed case is analyzed to illustrate the value of such cross-border linkages for uniting the sub-processes. The case is about how private solar photovoltaic (PV) ventures in China in the early 2000s were started and grown by uniting relevant scientific, design, and entrepreneurial activities across regions, when there was previously no PV ecosystem in China.

In general, the united view of the innovation process presented here contributes to the academic literature on innovation. It also gives prescriptive guidance for scientists, engineers, and designers, as well as business managers, entrepreneurs, and policy makers to elevate their innovation-oriented efforts through a united innovation process.

The remainder of the paper is organized as follows. Section 2 reviews the various perspectives and studies of innovation, which justifies our goal of a more united view. Section 3 identifies and analyzes the science, design, and entrepreneurship sub-processes. Section 4 focuses on the benefits from uniting them. Sections 5–7 discuss different models and examples of uniting the sub-processes within and across organizations and ecosystems. Section 8 concludes the paper.

2. Literature review

2.1. Innovation as a phenomenon

Writing on innovation is becoming more frequent and is growing to include many perspectives and levels of analysis (Fagerberg & Verspagen Reference Fagerberg and Verspagen2009). A main strand of the innovation literature analyzes innovation as a phenomenon. Numerous studies provide empirical evidence of the patterns of innovation across nations, industry sectors, firms, and technology classes (Furman, Porter & Stern Reference Furman, Porter and Stern2002; Castellacci Reference Castellacci2007; Griliches Reference Griliches1990; Scherer Reference Scherer1965; Pavitt Reference Pavitt1985; Koh & Magee Reference Koh and Magee2006). Other studies reveal and define types of innovation, such as architectural and modular innovation (Henderson & Clark Reference Henderson and Clark1990; Baldwin & Clark Reference Baldwin and Clark2000), radical and incremental innovation (Daft & Becker Reference Daft and Becker1978; Hage Reference Hage1980), product versus process innovation (Abernathy & Utterback Reference Abernathy and Utterback1978), and recently, disruptive innovation (Christensen Reference Christensen1997), open innovation (Chesbrough Reference Chesbrough2003), and distributed innovation (Anderson & Joglekar Reference Anderson and Joglekar2012; Baldwin Reference Baldwin2012). Despite being useful for analyzing the subsequent competitive implications of innovation (Abernathy & Clark Reference Abernathy and Clark1985), such studies of innovation as phenomena are naturally limited to explaining how innovation arises.

Meanwhile, since Schumpeter (Reference Schumpeter1934), scholars (primarily economists) have sought to understand the contexts and factors that influence the success and failure of innovation (Schmookler Reference Schmookler and Nelson1962; Freeman Reference Freeman1974). Studied factors include R&D spending and manpower (Arrow Reference Arrow and Nelson1962; Nelson Reference Nelson1962; Mowery & Rosenberg Reference Mowery and Rosenberg1998), industrial and competitive dynamics (Rosenberg Reference Rosenberg1963; Porter Reference Porter1990), institutional environments (Lundvall Reference Lundvall1992; Nelson Reference Nelson1993; Freeman Reference Freeman1995), regional ecosystems (Saxenian Reference Saxenian1996; Kenny Reference Kenny2000; Blank Reference Blank2008; Delgado, Porter & Stern Reference Delgado, Porter and Stern2010), culture (Florida Reference Florida2004; Senor & Singer Reference Senor and Singer2009), venture capital (Samila & Sorenson Reference Samila and Sorenson2010), intellectual property protection (Merges & Nelson Reference Merges and Nelson1990), and employment law (Marx, Strumsky & Fleming Reference Marx, Strumsky and Fleming2009), among others. Alternately, psychologists have examined cognitive, individual, team, organizational, and cultural factors that may restrict or empower creativity (Weisberg Reference Weisberg2006; Hennessey & Amabile Reference Hennessey and Amabile2010).

Management scholars have particularly focussed on firm-level organizational capabilities for learning and experiments that enable firms to continually innovate (Cohen & Levinthal Reference Cohen and Levinthal1990; Teece & Pisano Reference Teece and Pisano1994). The structural dimensions of organizations, such as the decentralization of decision making, loose links among divisions, and vertical integration versus disintegration, are associated with different types of firm innovation capabilities (Sanchez & Mahoney Reference Sanchez and Mahoney1996; Fang, Lee & Schilling Reference Fang, Lee and Schilling2010; Kapoor Reference Kapoor2013). Studies of inventor networks (Sorenson, Rivkin & Fleming Reference Sorenson, Rivkin and Fleming2006; Singh & Fleming Reference Singh and Fleming2010), inter-firm alliances and collaboration networks (Gulati Reference Gulati1998; Schilling & Phelps Reference Schilling and Phelps2007), and transaction networks (Luo, Olechowski & Magee Reference Luo, Olechowski and Magee2012) have shed light on how firms access and leverage complementary resources and knowledge in a larger ecosystem to pursue innovation opportunities. Taking the ecosystem and network perspective to the national level are studies on ‘national innovation systems’ (Lundvall Reference Lundvall1992; Nelson Reference Nelson1993; Freeman Reference Freeman1995), which emphasize the interactions of different institutions, such as companies, universities, government agencies, and intermediary organizations, to collectively nurture innovation.

2.2. Innovation as a process

Innovation scholars who are interested in operations have focussed on the process of new product development (NPD) (Ulrich & Eppinger Reference Ulrich and Eppinger2001; Krishnan & Ulrich Reference Krishnan and Ulrich2001; Cagan & Vogel Reference Cagan and Vogel2002). The NPD process is often referred to as the ‘innovation process’. This process has been conceptualized, analyzed, and organized as the sequential stages of opportunity identification, concept generation, product design, development, and commercial production (Clark & Wheelwright Reference Clark and Wheelwright1993; Otto & Wood Reference Otto and Wood2000; Schilling Reference Schilling2010). Managers often make go/kill decisions on whether to move a project from one completed stage to the next (Cooper Reference Cooper2000). This is often referred to as a ‘stage-gate process’ and is well accepted by researchers and practitioners. A survey shows that nearly 60% of firms use some type of stage-gate process to control project quality and reduce development costs (Schilling Reference Schilling2010, pp. 249).

In contrast, partially parallel development processes, in which a later stage is initiated before an earlier stage is finalized, have received much attention because this approach may enable close coordination, prevent costly iterations between stages, and shorten overall development time (de Meyer & van Hooland Reference de Meyer and van Hooland1990). With advanced technology and high market uncertainty, however, the tight coupling of stages may result in frequent and costly reworking of both the product and the process (Eisenhardt & Tabrizi Reference Eisenhardt and Tabrizi1995; Terwiesch & Loch Reference Terwiesch and Loch1999). Research has also suggested that involving customers and suppliers in the NPD process can often help match NPD efforts with potential demands and needs (Herstatt & von Hippel Reference Herstatt and von Hippel1992; Bonaccorsi & Lipparini Reference Bonaccorsi and Lipparini1994). Concrete frameworks and methods have been proposed to aid in understanding customers with regard to social–economic–technological trends and identifying new product design opportunities based on this understanding (Cagan & Vogel Reference Cagan and Vogel2002).

Recent studies have called for the utilization of design and creative thinking techniques to ensure the novelty of the outcome of the product development process (Seidel & Fixson Reference Seidel and Fixson2013). Such techniques may include the theory of inventive problem solving (TRIZ; Altshuller and Shapiro Reference Altshuller and Shapiro1956; Cascini & Russo Reference Cascini and Russo2007), design by analogy (Chan et al. Reference Chan, Fu, Schunn, Cagan, Wood and Kotovsky2011; Fu et al. Reference Fu, Chan, Cagan, Kotovsky, Schunn and Wood2013), and the crowdsourcing of design features (Burnap et al. Reference Burnap, Ren, Papalambros, Gonzalez and Gerth2015). Design theoreticians have created several formal models of innovative design processes, such as function–behavior–structure (Gero Reference Gero1990), infused design (Shai & Reich Reference Shai and Reich2004), concept–knowledge (C–K) theory (Hatchuel & Weil Reference Hatchuel and Weil2009), idea matrixes, and creativity operators (Tang & Luo Reference Tang and Luo2013). Such formal models may guide the development of new design tools and creativity methods. These models emphasize knowledge management and creativity in design processes.

The design literature has developed a fruitful understanding of a broad set of human activities that begin with abstraction and end with useful novelty in the design process (Antonsson & Cagan Reference Antonsson and Cagan2001; Magee et al. Reference Magee, Wood, Frey and Moreno2013). Such activities include conception, problem definition, idea generation and evaluation, prototyping, experimentation, and refining. Empirical and theoretical research has shown that flexibly structured processes, rather than rigidly structured ones, yield greater design success (Frey et al. Reference Frey, Herder, Wijnia, Subrahmanian, Katsikopolous and Clausing2009; Brooks Reference Brooks2010). Creative processes often require iterations between divergent and convergent thinking (Dym et al. Reference Dym, Agogino, Frey, Eris and Leifer2005; Hennessey & Amabile Reference Hennessey and Amabile2010). Design expertise, which comprises domain-specific knowledge plus the ability to transform it to derive novelty, is a fundamental enabler of creative design outcomes (Reyna Reference Reyna, Mio and Katz1996; Weisberg Reference Weisberg2006; Luo et al. Reference Luo, Baldwin, Whitney and Magee2014).

As indicated in these diverse but related studies, innovation results from a broad range of relevant activities and factors. The brief review above was not intended to cover all innovation studies, but to reveal the limited scope in individual studies and coupling of the existing understanding of concepts related to innovation. Such limitations may lead to oversight regarding valuable collective actions for enhancing innovation. This paper aims to reveal and connect the broadly relevant sub-processes that contribute to innovation, and then develop a more united view of the innovation process.

3. Disentangling the innovation process: science, design, and entrepreneurship

3.1. Three sub-processes of innovation

An innovation is recognized or acknowledged when its associated invention is successfully implemented (Hennessey & Amabile Reference Hennessey and Amabile2010); that is, when the invention has successfully diffused into broad use, received massive public recognition, and achieved real economic or social impacts (Utterback Reference Utterback1974; Rogers Reference Rogers2003; Luo et al. Reference Luo, Baldwin, Whitney and Magee2014). Inventions, however, do not necessarily lead to innovations. Despite their useful novelty, many noticeable inventions fail to move from R&D labs to markets to become recognized as innovations (Times Magazine 2010); the Segway and Google Glass are just two examples. Additionally, many inventors fail to capture the profits from their own inventions; an example is the computer graphic user interface (GUI), initially invented at Xerox Palo Alto Research Center (PARC). Although the GUI later became a standard, Xerox made little revenue from its invention. The first successful commercial GUI product was the Apple Macintosh, which was inspired by the inventive work at PARC. Microsoft also gained phenomenal profit from its Windows operating system, also GUI-based. The varied degrees and pathways of the implementation and diffusion of inventions indicate that the process through which inventions become innovations is highly relevant to the eventual realization of innovation.

The process by which new inventions reach the market and ultimately the users is the ‘entrepreneurship process’. It is the effort of entrepreneurship that matches inventions with market opportunities and needs. Entrepreneurship has been considered a pivotal element of innovation over time (Wennekers & Thurik Reference Wennekers and Thurik1999). Schumpeter (Reference Schumpeter1934) was the first to add the concept of entrepreneurship to innovation and to consider entrepreneurs as the agents who push creative destruction. Stevenson & Gumpert (Reference Stevenson and Gumpert1985) explicitly distinguished the entrepreneurial process from the administrative process and defined entrepreneurship as ‘the pursuit of opportunity beyond the resources you currently control’. Note that while general entrepreneurship does not necessarily involve technology or invention (Stevenson Reference Stevenson2006; Shane Reference Shane2008), an entrepreneurial process is required to turn an invention into innovation.

The novel nature of inventions implies the resulting uncertainty about markets, demand, and supporting ecosystems, and thus determines that the process of nurturing, commercializing, or implementing inventions is always an entrepreneurial one, but to varied degrees. Higher novelty in an invention demands greater entrepreneurial effort to nurture it and further drive it to enter and penetrate the market, where it becomes an innovation. For example, Steve Jobs created and managed a highly entrepreneurial process that was separate from Apple’s main operations to design and market the Macintosh when Apple I and Apple II were the successful main product lines of Apple in the early 1980s (Wasserman Reference Wasserman2011). Entrepreneurship is needed for the innovation-oriented practices of not only new venture startup firms but also established companies, where it is called ‘corporate entrepreneurship’ or ‘intrapreneurship’ (Pinchot Reference Pinchot and Katz1997; Wolcott & Lippitz Reference Wolcott and Lippitz2007).

The sub-process that results in invention is the ‘creative design process’. Design is the process of applying knowledge to create artifacts that are novel and useful to others (Simon Reference Simon1996; Luo et al. Reference Luo, Baldwin, Whitney and Magee2014). Design processes often include a series of activities, such as conception, problem definition, idea evaluation, prototyping, and refining. Design does not guarantee the achievement of an invention, although it creates the possibility. Some design processes may result in only limited novelty that is insufficient to be considered an invention, or limited usefulness that is insufficient to drive the entrepreneurial process. Such design processes are less relevant to innovation. This paper focuses on the creative design process that delivers sufficient novelty for invention and further innovation.

The design process requires knowledge as inputs. Some knowledge concerns the natural phenomena related to design problems: this is scientific knowledge. Other knowledge is related to the practices, solutions, methods, tools, social contexts, and any other existing artifacts in a specific design domain: this is design knowledge. For example, the design of piston engines requires a large volume of domain-specific design knowledge about the existing artifacts (including existing engine designs, tools, methods, processes, regulations, etc.), in addition to the basic scientific knowledge about the physical phenomenon of combustion.

Design knowledge is generated and accumulated through continual design and learning activities in the design process, as suggested by the C–K theory (Hatchuel & Weil Reference Hatchuel and Weil2009). In contrast, scientific knowledge is normally created in the ‘scientific process’, preceding the design process that uses knowledge to create new artifacts. Continual scientific knowledge creation enables new design opportunities and the creation of novel artifacts. For example, the creation of scientific knowledge of photoelectric effect and an improved understanding of silicon materials enabled the invention of solar PV cells. Despite providing knowledge ingredients for the design process, scientific processes are not typically aimed at designing artifacts, but at the discovery of unknown truths in the natural world. Scientists are mainly driven by curiosity. For example, Galileo Galilei discovered gravitation and Isaac Newton formulated the law of universal gravitation without thought to applications. These types of discoveries and theories from scientists allowed many useful artifacts based on them to be designed later.

The creative design processes that aim for highly novel and path-breaking inventions may need to rely more on scientific knowledge than on design knowledge because by definition, little relevant design knowledge (e.g., existing solutions, relevant tools/equipment, regulations, and policies) exists prior to the path-breaking invention. After an invention has opened a new design path, related design knowledge will be generated and accumulated. In fact, related design knowledge will increasingly be required in further design iterations along the same trajectory. Later activities in the same trajectory would be more oriented for incremental improvements and optimization rather than invention. Therefore, the goal of achieving innovation suggests the value of scientific knowledge for creative design, and the relevance of the scientific process that continually creates new scientific knowledge to enable creative design opportunities.

Earlier studies have shown that scientific research increases the rate and quality of related technological inventions (Jaffe Reference Jaffe1989; Jaffe & Trajtenberg Reference Jaffe and Trajtenberg1996), and engineers can benefit from reading the relevant scientific literature to solve difficult technical problems (Gibbons & Johnston Reference Gibbons and Johnston1974; Allen Reference Allen1977). Dugan & Gabriel (Reference Dugan and Gabriel2013) attribute the success of DARPA in producing many path-breaking inventions to its uniting of scientists and engineers. At DARPA, scientists and engineers collaborate in the same project teams, which seek to solve challenging engineering design problems that require pushing the frontiers of basic science. Fleming & Sorenson (Reference Fleming and Sorenson2004) theoretically argued that scientific knowledge acts as a ‘map’ that can help inventors perceive and explore a wider space of design possibilities and identify the directions and shortest paths to better solutions. His empirical analysis of patent data showed that the contribution of science to invention is greater when the technologies or design problems are more complex and that the use of scientific knowledge in design can mitigate the negative effect of the difficulty of interdisciplinary knowledge integration on the value of invention. These statistical and case studies have suggested the value of uniting scientific research and engineering design efforts.

3.2. Characteristics of the sub-processes

Thus far, we have identified three sub-processes that contribute to innovation—science, design, and entrepreneurship. Despite their differences, these three sub-processes also share certain characteristics in common (Table 1). First, they are all creative processes. Science is about creating previously unknown understanding and knowledge of the natural world. Design creates new artifacts that did not exist previously. Entrepreneurship establishes new businesses, uses, or installments that did not exist previously. Creativity distinguishes these three processes from production or service delivery processes, for which precise repetition is essential.

Table 1. Common characteristics of scientific, design, and entrepreneurial processes

Second, science, design, and entrepreneurship processes are all uncertain. The output from such processes is unpredictable and idiosyncratic by nature. To cope with uncertainty, scientists, engineering designers, and entrepreneurs must continually experiment, collect feedback, and learn through trial and error. As a consequence, the success of experimental processes often comes after many failures and experiential learning. To fail cheaply and adjust quickly, flexibility is important in the design and management of all three sub-processes (Rajan et al. Reference Rajan, van Wie, Wood, Campbell and Otto2005; Frey et al. Reference Frey, Herder, Wijnia, Subrahmanian, Katsikopolous and Clausing2009; de Neufville & Scholtes Reference de Neufville and Scholtes2011). In brief, experimentation and learning are the core activities of all three sub-processes, and a flexible process and mindset facilitates experimentation and learning. In contrast, rule-based mindsets and organizations are inappropriate for such creative and uncertain processes.

Furthermore, the required experiments and anticipated failures determine that all three processes are costly. To sustain experimentation for learning and afford the necessary failures requires economic resources. Therefore, to succeed in their respective processes, scientists, engineering designers, and entrepreneurs need to search for resources to sustain their activities. An entrepreneurial process is often funded by external venture capital funds, or the internal venture funds of large companies in the case of corporate entrepreneurship. The economic returns of new ventures or corporate ventures can be used to compensate and sustain their upstream creative design activities, which in turn, are expected to consider market and customer needs. The scientific process is mainly funded and sustained by public resources, such as the National Science Foundation, partly because science does not directly generate economic returns. When relevant scientific, design, and entrepreneurial activities are closely united to result in innovation, however, the contribution of science to invention and innovation will be straightforward and visible. Thus, the related scientific research may be better rewarded, appropriating a portion of the economic return from the resulting innovation.

Because of the shared creative, uncertain, and costly nature of the three sub-processes, scientists, engineering designers, and entrepreneurs can learn from one another to improve their respective processes. In particular, design scientists have developed rich theories and methods that can potentially be leveraged to improve the understanding, design, and management of scientific and entrepreneurship processes. For instance, design scholars have shown that C–K theory and infused design can indeed support scientific discoveries (Shai, Reich & Hatchuel Reference Shai, Reich and Hatchuel2013). Recently, scholars and practitioners advocated the adoption of design thinking and ideation methods to improve creativity in broader business practices (Beckman & Barry Reference Beckman and Barry2007; Verganti Reference Verganti2008; Brown Reference Brown2009; Seidel & Fixson Reference Seidel and Fixson2013). Brainstorming processes and techniques are a focus for ideation methods in different contexts (Osborn Reference Osborn1953; Taylor, Berry & Block Reference Taylor, Berry and Block1958; Sutton & Hargadon Reference Sutton and Hargadon1996; Girotra, Terwiesch & Ulrich Reference Girotra, Terwiesch and Ulrich2010). Additional theories and methods developed for design process (e.g., the flexibility principle, design by analogy, and creativity operators) may also inspire or guide scientists and entrepreneurs in undertaking their respective creative activities. The growing design science research may continually benefit scientific and entrepreneurial processes.

4. Value added by uniting the sub-processes for innovation

We have now understood the complementary contributions of science, engineering design, and entrepreneurship to innovation. Uniting the sub-processes creates value-added for enhancing innovation. This section explains the specific benefits from uniting them.

First, uniting the scientific and design processes facilitates the immediate use of the latest findings and discoveries from scientific research in design efforts. Exposing engineering designers to a newer, wider space of design possibilities empowers them to create novel solutions to complex technical problems or come up with path-breaking inventions (Gibbons & Johnston Reference Gibbons and Johnston1974; Fleming 2001; Dugan & Gabriel Reference Dugan and Gabriel2013). In other words, uniting scientific and design processes enables creative design opportunities. In contrast, those design processes that do not draw on the newest scientific knowledge are constrained in the traditional design opportunity space, seeing limited chances of breakthrough inventions. Common design outputs with limited novelty will not lead to innovation, even if they can be successfully commercialized and implemented.

In turn, the novel solutions or path-breaking inventions from creative design process are opportunities for entrepreneurial individuals, teams, and organizations to disrupt existing markets and create new trends. That is, they can offer first-mover advantages to the entrepreneurial process that is closely united with them. Furthermore, if the recognized innovation is based on cutting-edge scientific findings, it incurs a naturally high barrier to imitation and imitators. Without deep field-specific scientific knowledge, layperson engineers may find it difficult to comprehend the latest scientific results or newly understood mechanisms behind the new products that they wish to imitate or replicate. In such cases, the first-moving entrepreneurial individuals and firms will enjoy a sustainable competitive advantage. In the language of Peter Thiel (Thiel Reference Thiel2014), an innovation based on the latest scientific discovery or knowledge may establish a sustainable monopoly power on the part of the entrepreneurs, startups, or companies that commercialize it.

In addition to the value of science for engineering design in terms of nurturing path-breaking inventions, as well as the value of science-based invention for entrepreneurship in terms of creating first-moving advantage and sustainable monopoly, the integration of these three sub-processes also allows design to create value for science, and allows entrepreneurship to benefit coupled engineering design and scientific activities in a reverse direction. First, solving challenging problems and exploring path-breaking inventions in the design process may require advancing the understanding of related natural phenomena and thus simulate relevant scientific activities to push the frontiers of scientific knowledge. Evidence can be found in the successes of basic science research at Bell Labs and DARPA, which focussed on challenging engineering design problems that required an advanced scientific understanding of natural phenomena coupled with relevant technology design efforts (Gertner Reference Gertner2012; Dugan & Gabriel Reference Dugan and Gabriel2013). Likewise, entrepreneurial activities may also illuminate important and challenging design problems, thus stimulating both scientific research and engineering design activities to seek creative solutions to the problems.

In innovation processes that tightly couple complementary scientific, design, and entrepreneurial efforts, the contribution of science to invention and innovation is more direct and visible than that of stand-alone scientific activities. In such united innovation processes, the contributing scientific activities can be better appreciated and supported and scientists better compensated and rewarded by appropriating some of the profits from the innovation as a result of the united efforts. In contrast, it is unlikely for the entrepreneurs who successfully commercialize inventions based on public or common scientific knowledge to recognize and appreciate the scientists and scientific activities that created such knowledge in separate processes.

Table 2 summarizes the benefits of uniting the three sub-processes for each sub-process and for eventual innovation. To harvest these benefits for innovation, we advocate a united innovation process in which the scientific, design, and entrepreneurship sub-processes are closely coupled and/or partially parallel, as depicted in Figure 1. The overlapping of the sub-processes in the figure implies that the united innovation process is nonlinear by nature, due to the mutually beneficial coupling of the sub-processes. In addition to the benefits to individual sub-processes, the united innovation process as a whole may enhance the rates, radicalness, and significance of the resulting innovation. In contrast, the existing literature has not considered the scope of sub-processes of innovation or the value added for innovation from uniting them.

Table 2. Benefits of the united innovation process

Figure 1. The united innovation sub-processes: science, design, and entrepreneurship.

The united view of innovation process can be formulated as follows:

This formula implies that the missing or weakness of any of three sub-processes in a process that aims for innovation will limit the chance and degree of innovation success. Although design and entrepreneurship coupled together may be sufficient to produce some innovation, the likelihood of this limited integration achieving breakthrough, path-breaking, and significant innovations will be much improved if science activities are also tightly engaged with them. In such cases, cutting-edge scientific knowledge is created for and immediately utilized in design and implemented via entrepreneurship. The formula also indicates the multiplicative effect of the degree of creativity of each of the three sub-processes in co-determining the rates, radicalness, and significance of eventual innovation. For instance, the integration of newer science, a more creative design process, and more entrepreneurial activities may give rise to more radical and impactful innovation. On the contrary, if the design efforts only utilize common and old knowledge and are followed by routine commercialization approaches, the chances of leading to innovation and especially significant innovation will be limited.

Now, we have clarified several benefits of uniting the science, design, and entrepreneurial sub-processes. On this basis, the following sections further explore different models and levels, i.e., individuals, organizations, ecosystems, or the globe, in which the sub-processes can be united.

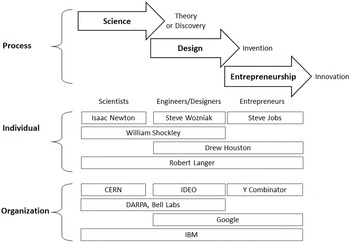

5. Integration of innovation sub-processes within organizations

Sub-process specialists, such as scientists, engineers, and entrepreneurs, are the main actors and drivers of the scientific, design, and entrepreneurship sub-processes. Figure 2 provides some examples of specialized individuals or organizations involved in the science, design, and entrepreneurship sub-processes. For instance, some entrepreneurs, such as Bill Gates and Steve Jobs, were mostly responsible for creating and managing the entrepreneurial process of commercializing inventions, but did not invent the products they sold. Steve Wozniak designed the Apple I and II personal computers. Wozniak was a designer rather than an entrepreneur because he was neither interested nor involved in business activities (Wasserman Reference Wasserman2011). In some cases, the inventors are also entrepreneurs. Good examples are Drew Houston of Dropbox and Mark Zuckerberg of Facebook, who are both the initial designers of their inventions and the entrepreneurs who created and continue to run the entrepreneurial processes that commercialize their inventions. Steve Jobs also became more involved in the design process after he returned to Apple in the late 1990s.

Figure 2. Examples of sub-process specialists and integrators.

Most scientists, such as Isaac Newton and Albert Einstein, are primarily motivated by curiosity and the desire for better understanding natural phenomena. Due to their separation of interests and activities from design and entrepreneurship, they are seldom considered as contributing to any innovation, although many engineers later adopted the fundamental knowledge created by those scientists in engineering design. There are exceptions. One notable exception is William Shockley, who was simultaneously a physicist (Nobel Prize Laureate in Physics in 1956) and an inventor. During his years at Bell Labs, Shockley published a number of fundamental scientific papers about solid state physics and also received many patents related to the design of electronics and semiconductors. His most notable invention was junction transistor. Shockley was also somewhat involved in entrepreneurship: he started Shockley Semiconductor Laboratory in Palo Alto, California, as a division of Beckman Instruments in 1956, but ran the lab unsuccessfully.

Robert Langer presents another exception to the general truth that a single person cannot integrate the roles of scientist, inventor, and entrepreneur. Langer is a chemical engineering professor at MIT, and his lab at MIT hosts approximately 100 researchers. Langer has published thousands of scientific papers, including many in Nature and Science. He is also a (co-) inventor of more than one thousand patents and a (co-) founder of more than two dozen companies that commercialize science-based inventions from his lab. According to his personal account published in Nature Biotechnology (Langer Reference Langer2013), in his experience, he found the large pharmaceutical companies that licensed inventions from his lab were ineffective in pushing his discoveries to users and achieving real impact. Thus, he chose to form and run companies with his Ph.D. students, postdocs, and colleagues at MIT to develop and commercialize the inventions based on the scientific discoveries made in his MIT lab. For example, a paper that Langer’s group published in Science in 1997 (Edwards et al. Reference Edwards, Hanes, Caponetti, Hrkach, Ben-Jebria, Eskew, Mintzes, Deaver, Lotan and Langer1997) led to a patent and a successful company called Advanced Inhalation Research, Inc., which focussed on developing commercial pharmaceutical products based on proprietary pulmonary drug delivery technologies. In brief, Robert Langer takes a united approach, integrating science, design, and entrepreneurship to pursue innovation and impact.

It is rare, however, for a single person to comprehensively unite scientific, design, and entrepreneurship sub-processes to effectively nurture innovation. Even Langer or Shockley needed to work within organizations, such as MIT, Bell Labs, or their own startup companies, to pursue innovation. Formal organizations that house inventors and scientists together may enrich their interactions, to allow for the simultaneous exploration of new scientific discoveries and related breakthrough inventions, as well as potential commercial products and services based on them.

A good organizational example is DARPA, which successfully nurtured many breakthrough inventions, such as reduced instruction set computers (RISC), microelectromechanical systems (MEMS), global positioning system (GPS), drones, and carbon fibers, generating broad economic and societal impacts beyond the initial military applications. DARPA formulates and executes R&D projects that simultaneously advance both science and technology in solving pressing real-world problems. The project teams typically comprise both scientists and engineers. The chosen problems must be sufficiently challenging that they cannot be solved without pushing the frontiers of related sciences. This implies a problem-driven approach to stimulate scientific research and allows for the immediate application of scientific discoveries to creating solutions to real-world challenges. For example, the DARPA program that designed MEMS also created new fundamental knowledge in plasma physics, fluid dynamics, and materials. DARPA was indeed considered a major funding source and driver for basic science research. In brief, DARPA’s success in producing breakthrough innovations on a sustained basis has been attributed to its purposefully uniting basic scientific research that aims to create new understanding of phenomena, with the engineering design efforts aiming to address pressing societal problems (Dugan & Gabriel Reference Dugan and Gabriel2013).

In the private sector, an example of the successful integration of scientific research and engineering design is Bell Labs. The fundamental scientific research at Bell Labs led to several Nobel prizes in physics and chemistry as well as the Turing Prize in Computer Science. Notable works include radio astronomy and information theory. The in-house scientific work at Bell Labs enabled many important path-breaking inventions, such as transistors, lasers, solar PV cells, and the UNIX operating system (Gertner Reference Gertner2012) through the continual exploration of creative design opportunists using cutting-edge scientific discoveries. Neither DARPA nor Bell Labs participated in massive commercialization and entrepreneurial activities. The US government funded DARPA. Bell Labs had ample funding from AT&T, which derived revenues mainly from its legal monopoly on phone services in the most productive years of Bell Labs.

Large integrated corporations such as IBM may have the capacity and capability to integrate and unite scientific, design, and corporate entrepreneurship sub-processes in-house. This integration has likely given IBM the integrative capabilities to continually introduce and realize innovations in the market (Helfat & Raubitschek Reference Helfat and Raubitschek2000; Kapoor Reference Kapoor2013; Luo et al. Reference Luo, Baldwin, Whitney and Magee2014) and the dynamic capabilities to rapidly respond to technological and market changes over time (Teece, Pisano & Shuen Reference Teece, Pisano and Shuen1997; Eisenhardt & Martin Reference Eisenhardt and Martin2000); however, such comprehensive corporations are rare. Most technology firms, including Google and Apple, tend to integrate product design and entrepreneurial processes in-house (Mowery Reference Mowery, Lamoreaus and Raff1995). Companies that appear innovative normally create and manage highly entrepreneurial internal procedures, processes, and cultures to nurture innovation deviating from their established product lines. Instead of conducting fundamental scientific research in-house, such companies often choose to collaborate with universities and public basic research institutions to stay connected with the frontiers of scientific advances.

At the same time, some organizations focus on single specific sub-processes of innovation. For instance, incubators such as Y Combinator and TechStars focus on the entrepreneurial sub-process. Design firms such as IDEO choose to specialize in the design sub-process but work closely with the firms that actually develop, produce, and market products. Pure scientific organizations such as the European Organization for Nuclear Research (CERN) are created to discover the unknown and develop a new understanding of nature. Such pure scientific organizations often intentionally protect their scientists and activities from commercial and applied interests. Many purely scientific activities are conducted at universities.

A sub-process specialist’s oversight of or disconnection from the complementary actors and activities in the united innovation process may limit his or her potential to contribute to innovation. Design, which is the middle stage of the united innovation process, is often appreciated by both scientific and entrepreneurial organizations; but entrepreneurial organizations often overlook the value of science, have limited access to scientific activities, or are incapable of understanding sciences. In sum, it is important for sub-process specialists, either individuals or organizations, to understand that their own activities can better contribute to innovation by being united with their complementary scientific, design, and entrepreneurial sub-processes.

6. Integration of innovation sub-processes in local ecosystems

Very few single persons or organizations can afford to possess, control, and integrate all three sub-processes (science, design, and entrepreneurship) in-house. Many of the examples provided above are successful in closely uniting two of the three sub-processes, either Science

![]() $\times$

Design or Design

$\times$

Design or Design

![]() $\times$

Entrepreneurship. In the past few decades, regional innovation ecosystems such as Silicon Valley have played an increasingly visible role in fostering innovation (Saxenian Reference Saxenian1996; Kenny Reference Kenny2000; Blank Reference Blank2008), and the most successful ecosystems often integrate the relevant scientific, design, and entrepreneurship sub-processes for innovation in certain domains.

$\times$

Entrepreneurship. In the past few decades, regional innovation ecosystems such as Silicon Valley have played an increasingly visible role in fostering innovation (Saxenian Reference Saxenian1996; Kenny Reference Kenny2000; Blank Reference Blank2008), and the most successful ecosystems often integrate the relevant scientific, design, and entrepreneurship sub-processes for innovation in certain domains.

Recently, the joint Committee on Science, Engineering, and Public Policy (COSEPUP) of the National Academy of Sciences (NAS), National Academy of Engineering (NAE), and Institute of Medicine (IoM)Footnote 2 organized two high-level workshops on key factors and trends of innovation ecosystems (COSEPUP 2013). The workshop participants emphasized the value of interactions among research universities and industry for innovation, and shared and debated different models of interactions, such as technology licensing, free/public knowledge sharing, spinoffs, consultation, and other new and emerging methods. Such interactions can be facilitated by the co-location of scientists, engineers, and entrepreneurs, and their respective organizations, such as universities, national labs, and companies, in a geographically proximate region.

In an innovation-oriented ecosystem, scientists, designers, and entrepreneurs, as well as their organizations, interact and collaborate to co-create innovation while also maintaining their own interests and specialties. The interaction is what engages complementary specialists in an ecosystem and allows them to build their own successes on the success of others. Innovation ecosystem is not a totally new paradigm, but much of the existing ecosystem literature is focussed on the networks of suppliers, customers, and complementors in the supply chains (Saxenian Reference Saxenian1991; Iansiti & Levien Reference Iansiti and Levien2004; Adner & Kapoor Reference Adner and Kapoor2010; de Meyer & Williamson Reference de Meyer and Williamson2012). Such ecosystems may be better referred to as business ecosystems rather than innovation ecosystems. Based on the united view of innovation process, the present paper considers the co-location of complementary science, design, and entrepreneurship sub-processes, and corresponding actors, as well as their synchronized collaborative and united efforts, as the key constituents of an innovation ecosystem.

In the following, the case example of Brontes Technologies is analyzed in detail to illustrate how an innovation ecosystem centered around MIT (Cambridge, Massachusetts) can nurture innovation by closely uniting science, design, and entrepreneurship sub-processes in a local region.

6.1. Case exampleFootnote 3

The research group of MIT mechanical engineering professor Douglas Hart works on fluid diagnostics, optics, and image processing. Professor Hart and Janos Rohaly, a senior lecturer, invented a single lens 3D imaging technology in 2002 on the basis of many years of scientific research. Their technology uses a single lens with a rotating, off-axis aperture to generate 3D surface images in real time, supplanting dual-lens cameras that imaged an object from different angles. This applied development effort was supported by a commercialization-oriented grant from the MIT Deshpande Center for Technology Innovation. The center funds applied development efforts to move MIT inventions to the market.

Later, at a networking event of the MIT $50K business plan competition, Professor Hart met two Harvard Business School MBA students, Eric Paley and Micah Rosenbloom, who eventually became the CEO and COO of the company they later founded. At the time, the startup team also included MIT research scientists, postdoctoral scholars, and doctoral students. Since then, they have explored the market potential of various specific applications of the 3D imaging technology, from facial recognition for security and 3D animation for entertainment to medical applications. They presented alternative application and commercialization ideas at the Cambridge Enterprise Forum Concept Clinic. That experience helped them to formulate their business plan for the MIT $50K business plan competition, where they were selected as a runner-up.

While developing prototypes, they discovered a significant need in dental imaging. With a clear target market, Brontes Technologies was incorporated in June 2003 with the mission of providing technology for dentists to scan the inside of the mouth in real time; the technology was licensed through the MIT technology licensing office. They returned to present at the Enterprise Forum Startup Clinic and received two rounds of seed capital from the audience, followed by venture capital funds from David Frankel, Flybridge Capital, Charles River Ventures, and Bain Capital Ventures in 2004. In October 2006, 3M acquired Brontes Technologies for $95 million and the company delivered its first products in 2007.

This story demonstrates how the innovation ecosystem around MIT integrates and unites the relevant scientific, design, and entrepreneurial sub-processes for innovation, as well as their respective supporting activities, to nurture innovation. As illustrated in Figure 3, the researchers at the MIT lab were responsible for the scientific sub-process. Some postdocs and students later left the lab and joined the startup company to focus on the engineering design of applications and commercial products. The two MBA students from Harvard University drove the entrepreneurial process. Scientists, engineers, and entrepreneurs worked closely to pursue innovation.

Figure 3. United innovation sub-processes in the Boston/MIT innovation ecosystem.

Meanwhile, supporting organizations also helped unite the sub-processes. For instance, the MIT Deshpande Center supported commercialization-oriented engineering design efforts. The MIT Technology Licensing Office was responsible for generating the financial returns from the invention, which would, in turn, be reallocated to support basic research activities at MIT. And, the MIT $50K Business Plan Competition and the Cambridge Enterprise Forum connected researchers, entrepreneurs, investors, and potential clients, and synchronized their complementary activities.

Clearly, more than just hosting the diverse actors in its local community, the MIT ecosystem was also able to motivate and drive the actors to think and act beyond their specialties to connect, interact, and collaborate to incorporate deep and advanced sciences in technology applications, and, in turn, take inventions from the lab to the market. The MIT innovation ecosystem is not only comprehensive, but the co-located actors are also closely connected. As a result, relevant science, design, and entrepreneurship sub-processes are united for innovation.

6.2. Building an innovation ecosystem: challenges and strategies

Inspired by the success of the MIT and Stanford innovation ecosystems (Roberts & Eesley Reference Roberts and Eesley2009; Eesley & Miller Reference Eesley and Miller2012), many cities and governments around the world have attempted to build their own ‘science parks’, ‘innovation clusters’, or ‘ecosystems’. According to the COSEPUP report of NAS, NAE, and IoM (COSEPUP 2013), there are now over 460 science parks worldwide, although very few have succeeded. In practice, although it is straightforward to use financial and policy incentives to attract industrial firms, startups, and research and education institutions to reside in a specific science park, it is also naturally difficult to foster fluid and intensive communication, interaction, and cooperation among individuals and organizations specializing in the distinct science, design, and entrepreneurship sub-processes.

The specialized individuals and organizations required for science, design, and entrepreneurship have distinctive goals and interests. Scientists are driven by curiosity, creating gadgets fascinates engineers, and entrepreneurs are keen on economic and social impacts. Such differences may limit the incentives to collaborate and unite activities Starbuck & Farjoun (Reference Starbuck and Farjoun2005). In addition, scientists, engineers/designers, and entrepreneurs receive different types of education and develop different types of personalities, knowledge bases, skill sets, capabilities, work habits, and communication styles along their respective career paths. Scientific institutions and commercial firms also require and often develop different cultures, codes of conduct, and organizational routines over time. For these reasons, the effectiveness of communication and cooperation between different types of groups for science, design, and entrepreneurship may be limited. Without necessary interactions and effective cooperation, the mechanistic aggregation of scientists, designers, and entrepreneurs in a geographically proximate region may not result in an innovation ecosystem.

What can incentivize scientists, designers (or inventors), and entrepreneurs to reach out to each other and interact, thereby effectively collaborating with and learning from each other? At the 2013 workshops organized by COSEPUP of NAS, NAE, and IoM, speakers repeatedly highlighted culture as key to the success of innovation ecosystems, as opposed to operational methods (COSEPUP 2013). Generally, culture may imply the shared expectations among a group of people about how they and others will interact. As for the innovation culture, it should center on the shared understanding that innovation is a result of collective efforts ranging from science through design to entrepreneurship and the shared belief that the value from the co-created innovation can be shared. Such a culture may motivate scientists, designers, and entrepreneurs to accommodate others’ differences and specialties and to interact, collaborate, and unite their activities. The motivated interactions and influences will further facilitate confluence and the emergence of a coherent innovative culture, which in turn, facilitates organic interactions and seamless integration.

The importance of culture for uniting the sub-processes of innovation in a local ecosystem has been implied in previous studies on Silicon Valley and Israel (Saxenian Reference Saxenian1996; Florida Reference Florida2004; Senor & Singer Reference Senor and Singer2009). In the case example of Brontes Technologies, the self-driven interactions among individuals specializing in science, design, and entrepreneurship were largely facilitated by the entrepreneurial culture of the MIT community at large. In brief, to foster the possible emergence of a culture that nurtures innovation, ecosystem builders may evangelize the united view of the innovation process and its value added for enhancing innovation.

7. Integration of innovation sub-processes across regions

An ecosystem offers clear advantages for innovation via the integration of the science, design, and entrepreneurship sub-processes; however, it may take many years, enormous effort, and an idiosyncratic pathway for an innovation ecosystem to emerge in a region. Successful examples of innovation ecosystems exist in the world, but are rare. When a sub-process for science, design, or entrepreneurship is missing or weak in a local region, linkages to remote competitive parties carrying out the locally missing or weak sub-processes will become crucial, based on the united view of the innovation process. In other words, scientists, designers, or entrepreneurs may need to cross geographical boundaries to connect and unite remotely based science, design, and entrepreneurship sub-processes relevant to their domains to drive innovation. Very often, such cross-border connections need to be created on a global scale.

In the following case example, the emergence process of the Chinese PV industry in the early 2000s illustrates the importance of such global linkages for the integration of relevant innovation sub-processes, when no single region has competitiveness in all three sub-processes for solar PV technologies.

7.1. Case exampleFootnote 4

In the late 1990s, a few Chinese entrepreneurs were keen to drive the wide adoption of solar-PV-generated electricity by reducing the cost of PV cells via large-scale manufacturing; however, the scientific knowledge base, design capability, supply chains, and market needs for solar PV cells were lacking in China at the time. Facing local constraints, Shi Zhengrong started Suntech Power in 2001, which later became one of the global leaders in the solar industry, and developed it rapidly through successful global engagement and integration of required resources. For instance, Suntech’s research and development mainly relied on the University of New South Wales (UNSW) in Australia (where the founder studied and worked for many years). Suntech sought and imported used equipment from Italy, Japan, and the United States, procured key raw materials from Germany and the United States, supplied its products to customers in Europe, and also received investments from international venture capitalists and private equity firms (Zhang, Luo & White Reference Zhang, Luo and White2014).

This global integration model fueled the rapid growth of Suntech without comprehensive R&D capacities in-house and without being part of a comprehensive local ecosystem for solar PV technologies. Suntech became the world’s first solar company to list on New York Stock Exchange (NYSE) in 2005 and is the global industry leader with shipments of 1.6 GW PV products in 2010. Its radical growth and successful NYSE initial public offering, which raised US$2.3 billion, attracted several other China-based solar ventures to imitate its growth model characterized by building global linkages, which also allowed them to rapidly grow into world-class technology-based businesses (see Table 3).

Table 3. Top 10 solar cell companies by shipments in 2010

![]() $^{+}$

Source: PV Insights.

$^{+}$

Source: PV Insights.

![]() $^{\ast }$

Source: Breyer et al.

Reference Breyer, Birkner, Kersten, Gerlach, Goldschmidt, Stryi-Hipp, Montoro and Riede2010.

$^{\ast }$

Source: Breyer et al.

Reference Breyer, Birkner, Kersten, Gerlach, Goldschmidt, Stryi-Hipp, Montoro and Riede2010.

Interestingly, Suntech’s entrepreneurship and engineering design activities were closely linked to the fundamental research conducted at the Solar Photovoltaics Research Group of the UNSW in Australia, led by Professor Martin Green, and the applied research at Pacific Solar Pty, a spinoff and affiliate of Martin Green’s group. Shi Zhengrong, the founder and CEO (2001–2011) of Suntech, was a Ph.D. student of Professor Green from 1992 to 1995 and a research scientist, and later deputy director of research at Pacific Solar Pty Ltd from 1995 to 2000. As a scientist, Shi had published extensively about multicrystalline silicon thin film solar technologies and accumulated a number of patents. Having spent 15 years in scientific research, he has the cutting-edge scientific knowledge of solar PV technologies and the ability to comprehend the latest scientific advances in the field.

Since its founding in 2001, Suntech has maintained close ties with the R&D activities at UNSW. In 2002, Suntech signed a cooperation agreement with the Centre of Excellence for Advanced Silicon Photovoltaics and Photonics (CEASPP) at UNSW. The collaboration covered a full spectrum of activities from basic research to technology development and commercialization. One example was the jointly developed ‘semiconductor finger’ technology (Wenham et al. Reference Wenham, Mai, Tjahjono, Jia and Shi2005; Wenham, Mai & Tjahjono Reference Wenham, Mai and Tjahjono2006), which achieved 18% efficiency, compatibility with Suntech’s manufacturing infrastructure, and immediate commercialization by Suntech in 2007. The basic research grounding the semiconductor finger technology was conducted at UNSW and received some funding from Suntech. The resultant patent was jointly held by UNSW and Suntech.

In addition to directly funding scientific research at UNSW in Australia, Suntech also sponsored the visits of UNSW researchers and students to Suntech and sent its own engineers to visit UNSW laboratories. Such interactions facilitated intensive informal learning and synchronized scientific, design, and entrepreneurship efforts across regional borders. A few R&D personnel from UNSW also joined Suntech later (see Table 4). Among them, Professor Stuart Wenham split his time as the director of the CEASPP at UNSW and the CTO of Suntech. Over time, the scientific research at UNSW continually served as a main source of scientific and technological knowledge required for the product design and entrepreneurship activities of Suntech. To access the broader cutting-edge scientific knowledge relevant to solar technologies, Suntech also collaborated with other universities in China, Europe, and the United States.

Table 4. Suntech’s connections with UNSW

This case demonstrates how Suntech united the relevant scientific, design, and entrepreneurship sub-processes for solar innovation on a global scale, which is illustrated in Figure 4. Scientists at the UNSW research lab contributed to the scientific sub-process. UNSW and Suntech engineers collaborated and contributed to the engineering design of solar cells and modules. Suntech, together with its international suppliers and investors, drove the entrepreneurship sub-process. Clearly, Suntech played a central role in coupling and uniting sub-processes across regional borders.

Figure 4. United innovation sub-processes across regions for solar photovoltaic innovation.

As Suntech cultivated local suppliers and generated spinoffs, much of its technical knowledge spilled over to other local firms over time, resulting in a cluster of globally competitive solar companies in China. Some of these Chinese companies were also founded by UNSW researchers and students and former Suntech executives, and have grown by uniting science, design, and entrepreneurship activities across regional borders. Photovoltaic shipments from Chinese firms grew rapidly from 3% of the global total in 1997 to 54% in 2010 (Mints Reference Mints2011; National Research Council 2012). As shown in Table 2, of the top 10 global PV firms by shipment in 2010, 5 were based in China. The top 10 Chinese solar PV firms are all publically listed on either the NYSE or the NASDAQ. In particular, none of these firms are state-owned companies or receive state subsidies. Policy support from the Chinese government was absent until 2007. Without the linkages that successfully united globally distributed science, design, and entrepreneurship activities, the Chinese solar firms would not have been able to grow to their current scales so quickly and, as a result, drive the diffusion and implementation of solar PV technologies across the globe.

Today, the capacity for basic research on the PV effect; the design and development of solar PV cells and application modules; and the manufacturing, sales, and installation of solar power systems are globally distributed. The leading firms in the solar industry operate and compete globally, maintaining strong ties with universities and research institutionsFootnote 5 , which continually advances the scientific understanding of the PV effect. The global integration of relevant scientific research, application design, and entrepreneurial activities enabled solar PV innovations via the immediate use of the latest scientific knowledge for solar PV technology design and implementation.

8. Conclusion

This paper contributes to the general innovation literature by proposing a united view of the innovation process, which specifies the science, design, and entrepreneurship sub-processes. The common creative, uncertain, and costly nature of these three sub-processes is explicated, which suggests that the growing design science literature may also benefit the scientific and entrepreneurial processes. The specific emphasis of the paper is on the complementarity of the three sub-processes and the value added by closely uniting them to enhance innovation. The various benefits from the united innovation process were discussed in detail in Section 4 and summarized in Table 2.

Specifically, within a united innovation process, the scientific sub-process generates new discoveries and knowledge, the timely use of which in the design process may enable design opportunities for novel solutions, breakthroughs, and path-breaking inventions. This in turn provides first-mover advantages and sustainable monopoly to the entrepreneurial sub-process that closely follows. The united design sub-process may stimulate relevant scientific research and seek immediate applications of science in search of creative design opportunities, and provide inventions as inputs for the entrepreneurship sub-process to implement and commercialize them into impactful innovation. The entrepreneurial sub-process may also illuminate important and challenging design problems, which in turn, stimulate creative design activities and relevant scientific research activities. The entrepreneurship sub-process can also appropriate the economic returns from innovation to support and reward the united design and scientific sub-processes. As a whole, the united innovation process will enhance the rates, radicalness, and significance of innovation.

For specialized scientists, designers, and entrepreneurs, overlooking each other’s complementarity may limit their potential contributions to innovation. In guiding the sub-process specialists who aim for innovation, the united view of innovation is more systematic and actionable than the design theories that consider the importance of science but ignore the role of entrepreneurship, as well as the entrepreneurship theories that seldom consider either design or science in depth. The united view of the innovation process also leads to practical implications and guidance for the actions of individuals and organizations that aim for innovation.

As shown in the variety of cases and examples that we discussed, the integration of the three sub-processes can be achieved to different extents at alternative organizational, regional, and global levels. The variety of integration models, extents, and scopes suggests that the individuals and organizations aiming for innovation need to analyze their idiosyncratic situations to make explicit decisions regarding (1) whether to integrate science, design, and entrepreneurship in-house or across organizations and (2) if not, how to efficiently unite their in-house sub-processes with external complementary sub-processes across organizational, ecosystem, or regional borders. In brief, the united view of the innovation process is generic and level flexible.

In particular, the role of ecosystems for innovation is increasingly appreciated because it is naturally difficult for individuals and single organizations to integrate all of the relevant science, design, and entrepreneurial sub-processes, whereas ecosystems provide a high-level integration mechanism. In contrast to traditional ecosystem theories, the united view of innovation processes emphasizes that effective innovation ecosystems integrate the science, design, and entrepreneurship sub-processes relevant to their respective technological domains. For ecosystem builders, evangelizing and building an innovation-oriented culture based on the belief of the shared value creation and capture from uniting the scientific, design, and entrepreneurial sub-processes may drive actors in scientific, design, and entrepreneurship specialties to connect and collaborate, allowing an effective innovation ecosystem to emerge.

Despite the understanding of these mechanisms, it will be always difficult to build or foresee effective innovation ecosystems because it may yet take many years, enormous effort, and idiosyncratic pathways for an innovation ecosystem to emerge in a region. Individuals and organizations that must live outside any comprehensive ecosystem may still pursue the integration of the sub-processes for innovation. In this case, it becomes crucial to create and maintain cross-border connections to unite external complementary sub-processes in remote regions, especially when some of the complementary sub-processes and activities cannot be conducted competitively in one’s local ecosystem.

The present paper opens up many avenues of empirical research based on more detailed case studies or the statistical analysis of large-scale quantitative data at various levels. Future research is expected to develop testable hypotheses, e.g., how different modes or degrees of the integration of science, design, and entrepreneurship activities in different technological domains may affect innovation outcomes at different organizational or regional levels, and collect activity and performance data to test them. For instance, the same degree of integration of the three sub-processes may yield varied innovation returns in different technology domains, conditioned by the institutional factors in particular domains, organizations, or regions. In sum, this article can be seen as an invitation for broader and more in-depth studies of the modes, strategies, conditions, scopes, levels, and returns of uniting science, design, and entrepreneurship activities.

Acknowledgments

SUTD-MIT International Design Centre (IDC) and Singapore Ministry of Education Tier 2 Academic Research Grants provided funding for this research. The author is especially grateful to the editor and three anonymous referees for detailed comments and criticism that greatly improved the article. The author alone is responsible for any errors and oversights.