1. Introduction

Sustainable development has been identified as a focus for current and future generations; considering economic development, social impact and environmental sustainability (Sonego, Echeveste & Debarba Reference Sonego, Echeveste and Debarba2018). Interest in sustainability has increased over the past four decades due to international agendas and policies regarding the environment (Gao et al. Reference Gao, Xiao, Wei and Zhou2018). This has led to higher customer awareness of sustainability issues as well as changes in purchasing behaviour, resulting in increased pressure on firms and designers to implement sustainable factors during New Product Development (NPD) (Buchert et al. Reference Buchert, Halstenberg, Bonvoisin, Lindow and Stark2017; Turkson et al. Reference Turkson, Acquaye, Liu and Papadopoulos2020). It is therefore crucial that product design actively incorporates sustainability into NPD, achieving optimal function with minimal sustainable impact on products.

There are various definitions of sustainability throughout literature, among which the most prominent and commonly used is defined by Brundtland (Reference Brundtland1987, p. 16) as the ‘development that meets the needs of the present without compromising the ability of future generations to meet their own needs’. Sustainability is also defined through the three pillars of sustainability, environment, social and economic factors, which collectively determine what is sustainable (Purvis, Mao & Robinson Reference Purvis, Mao and Robinson2019). An alternative definition states that humanity must adapt and transform so that environmental and social conditions can be maximised; supporting human security, well-being and health (Turkson et al. Reference Turkson, Acquaye, Liu and Papadopoulos2020). Throughout product design literature there is a range of terminology regarding sustainability, adopting terms such as cleaner production, eco-design and green design (Glavič & Lukman Reference Glavic and Lukman2007). Different perspectives are also apparent throughout product design literature regarding the implementation of sustainable approaches. Venkata Rao (Reference Venkata Rao2009) suggests that all environmental standards and requirements must be satisfied from the early design stages to the end of life of the product. Design for Sustainability outlines various methodologies for enabling sustainable improvements, based on social, economic and environmental factors, to products through life cycle thinking (Clark et al. Reference Clark, Kosoris, Hong and Crul2009). Design for the environment is concerned with reducing the overall environmental impact of a product throughout its entire life cycle (Graedel, Comrie & Sekutowski Reference Graedel, Comrie and Sekutowski1995). There is not a clear or cohesive direction in which the designer should be working towards, this could be an issue when aiming to enable sustainable product development.

This study will be directly focusing on environmental sustainability during the product design process, the two remaining pillars of sustainability may also be discussed briefly during this review. Environmental sustainability can be defined as the maintenance of ecosystems through efficient management (Moldan, Janoušková & Hák Reference Moldan, Janoušková and Hák2012), which is also connected to social and economic sustainability. Environmental Sustainability is also described as the ‘condition of balance, resilience, and interconnectedness that allows human society to satisfy its needs while neither exceeding the capacity of its supporting ecosystems to continue to regenerate the services necessary to meet those needs nor by our actions diminishing biological diversity’ (Morelli Reference Morelli2011, p. 5). This covers a large scope of topics such as pollution, energy efficiency and others, which need to be considered to ensure environmental sustainability within NPD. This can be complex for the designer to know which of these elements are relevant to their project as well as how and when to implement them. Traditionally designers have focused on elements such as aesthetics, cost, performance and manufacturability of their designs (Graedel et al. Reference Graedel, Comrie and Sekutowski1995). The recent demand for sustainability to be more integrated into product development requires designers to be equipped with these skills so that they can evaluate economic, social and environmental aspects of their decisions (Raoufi et al. Reference Raoufi, Park, Khan, Haapala, Psenka, Jackson, Kremer and Kim2019). The product design stage has been recognised throughout literature as important and has been suggested to influence between 70 and 80% of sustainability impacts (Yang & Song Reference Yang and Song2006; Waage Reference Waage2007; Ahmad et al. Reference Ahmad, Wong, Tseng and Wong2018; Hub Reference Hub2018). The product design phase and the designer should therefore become central to the implementation of environmental sustainability within NPD.

This article aims to review the state-of-the-art research on environmental sustainability within the product design field. By critically reviewing these approaches from the perspective of the designer it will aid towards the understanding of how environmental sustainability should be integrated into the current design process. The article focuses on (a) the integration of environmental sustainability within the current design process, (b) the progression of environmental sustainability within product design over time and (c) if there are any other external factors that need to be considered in the design process for eco-design to be successful. This will provide a holistic view of environmental sustainability throughout the design process. Section 2 presents the methods that were used to systematically review the literature. Section 3 summarises the current status of environmental sustainability in the product design domain. This is followed by a new conceptual framework (NCF), proposed in Section 4, considering environmental sustainability from the perspective of the designer, this will be the primary contribution of the study, highlighting the product designer’s role in environmental sustainability integration during NPD. The discussion and suggestions for future research are presented in Sections 5 and 6.

2. Method

2.1. Method of data collection

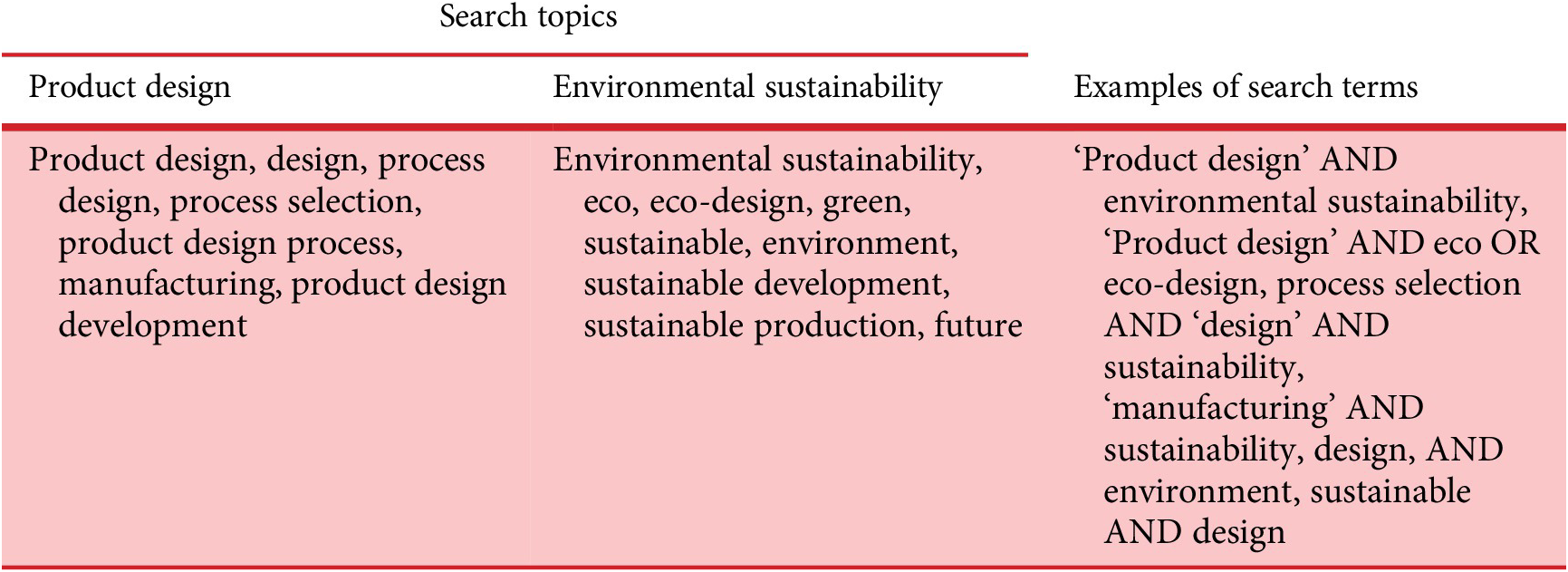

Articles exploring the relationship between environmental sustainability and product design have been published across a wide range of journals in the areas of designing for sustainability, life cycle analysis (LCA) and environmentally conscious manufacturing. This has required a systematic strategy to select and process the most relevant literature to provide a quality critical review. This has been completed using the methodology for completing a systematic review outlined by Tranfield, Denyer & Smart (Reference Tranfield, Denyer and Smart2003). Following the methodology, keywords and search terms were selected from the scope of the study, see Table 1. A combination of these words was used in multiple searches to locate the relevant literature. The search was conducted through Academic Libraries powered by EBSCO, Scopus, Ei Compendex and Google Scholar databases to select suitable literature.

Table 1. Keywords for literature identification

To ensure that the literature review was completed to assist designers and to understand how to effectively implement environmental sustainability into the design process during NPD, it was important that the literature selected was relevant. Relevant literature included information on sustainability, environmental sustainability, environmental sustainability in relation to product design and the product design process. Literature was discussed among the authors during the data collection process, to identify key and common themes throughout the literature. The relevant literature was located by systematically looking at 10-year intervals, starting at the year 1980 and working up to the present day, this enabled a clear view of the evolution of environmental sustainability within product design. This date was selected due to the start of relevant sources available from this period onwards as well as the publication in 1987 of the Brundtland Commission (Brundtland Reference Brundtland1987) which highlighted the need for sustainable development. Outside of this timeframe was also investigated for literature such as United Nations (UN) agendas created prior to 1980 in relation to sustainability. This initial search found 989 studies. Second, literature that had little to no relevance to the research subject, for example, forest conservation, studies in other languages and any duplicates found were eliminated, this reduced the number of studies to 730. Literature was further refined by reading the abstract and the table of contents, if available, of each article. Similar methods have previously been adopted by Blizzard & Klotz (Reference Blizzard and Klotz2012) and Easterby-Smith et al. (Reference Easterby-Smith, Thorpe, Jackson and Jaspersen2018); this ensured that each article was relevant to the study, resulting in 455 studies. A final detailed evaluation of the text was conducted, this involved reading the papers in full and assessing whether they had relevant information to the study, which totalled 140 studies to be reviewed for this critical review. See Figure 1 for a summary of the literature review selection methodology. The final selection of literature included journal articles, conference papers and books. Critical literature reviews have been conducted previously to investigate sustainability within the product design industry, such as is in the analysis and review of product design tools to aid with sustainability (Ahmad et al. Reference Ahmad, Wong, Tseng and Wong2018) and the investigation of sustainable innovation in small and medium-sized enterprises (Klewitz & Hansen Reference Klewitz and Hansen2014). Therefore, this critical review adopted this methodology to review the current status of environmental sustainability within product design.

Figure 1. Literature review selection methodology flowchart.

2.2. Data analysis

Data extraction and synthesis were conducted whilst reading the papers in full (Tranfield et al. Reference Tranfield, Denyer and Smart2003), identifying the key factors of environmental sustainability in relation to product design. Factors were identified by searching each paper for word repetitions and keywords within the context of environmental sustainability. Once the keywords had been identified, they were grouped to create factors. The term ‘factors’ include principles that designers can apply to enable environmental sustainability, elements that have an impact on the environment during use or in production, socioeconomic elements that could also impact the product design process and principles that designers must follow to ensure lawful environmentally sustainable production. This screening process led to questions regarding when the designer considered the identified factors and if there were any additional factors involved in monitoring environmentally sustainable development within product design, such as software. A secondary screening of all literature was performed to resolve these questions and to identify any additional gaps within this field; this was completed by directly searching each article to identify the author’s interpretations of these objectives. This methodology enabled environmental sustainability factor identification, the understanding of the evolution of environmental sustainability within product design, the observation of where literature suggests the identified factors should be considered and current methods of integration within the product design process. Concluding with the development of a NCF to aid the designer in the implementation of sustainability during NPD.

3. Literature review

3.1. Overview of environmental sustainability

There has been a substantial increase in publications on environmental sustainability over the last 20 years (Purvis et al. Reference Purvis, Mao and Robinson2019). However, environmental sustainability has been a key factor in development before this. Sustainable development was originally defined by Brundtland (Reference Brundtland1987, p. 16) and literature has continued to investigate environmental sustainability following this statement. Prior to Brundtland (Reference Brundtland1987, p. 16) the UN discussed environmental conservation and the ecological world; where they proposed that development could not exist without considering the environment or being sure that development did not lead to adverse side effects (Thacher Reference Thacher1978). The UN further discussed the importance of communication with policy makers regarding the environment and development (Thacher Reference Thacher1978); this has continued to develop, and it is now argued that government involvement is a key factor in ensuring environmentally sustainable development (Gao et al. Reference Gao, Xiao, Wei and Zhou2018).

3.2. Major research areas of environmental sustainability in relation to product design

The literature is divided into 17 subsections, each representing an identified factor of environmental sustainability in relation to product design. These are the factors that have been recognised as a reoccurring theme throughout the reviewed literature as having a distinct contribution in the improvement of the environmental sustainability of a product. The following factors have been established throughout the past 40 years and are described in the succeeding subsections.

6Rs

The 6Rs represent six areas for environmentally sustainable improvement: reduce, reuse, recycle, recover redesign and remanufacture (Metta & Badurdeen Reference Metta and Badurdeen2013; Yan & Feng Reference Yan and Feng2014; Go, Wahab & Hishamuddin Reference Go, Wahab and Hishamuddin2015; Hapuwatte & Jawahir Reference Hapuwatte and Jawahir2019). The 6Rs are an example of an identified factor which is a principle that product designers can apply during their process to enable environmental sustainability. All six areas aim to reduce resources throughout the entire product lifecycle without compromising the functionality of the product (Glavič & Lukman Reference Glavic and Lukman2007; Metta & Badurdeen Reference Metta and Badurdeen2013). It is argued that the 6R concept should be considered throughout all stages of the product life cycle (Devanathan et al. Reference Devanathan, Ramanujan, Bernstein, Zhao and Ramani2010). Turkson et al. (Reference Turkson, Acquaye, Liu and Papadopoulos2020) suggested that there is a dependency on the use of recycled materials and reduction of consumption due to the need of technology and resources by society, therefore designers are required to maximise their implementation of the 6Rs during the product lifecycle to facilitate this. Additionally, it is suggested that where possible designers should specify the use of recycled material as opposed to virgin material (Graedel et al. Reference Graedel, Comrie and Sekutowski1995). Modularity is proposed to support the 6R methodology as it can increase the ease of repair as well as enabling reuse and recycle at the end of life due to easy disassembly (Graedel et al. Reference Graedel, Comrie and Sekutowski1995; Hata, Kato & Kimura Reference Hata, Kato and Kimura2001; Yan & Feng Reference Yan and Feng2014). Remanufacture is described as the reprocessing of used products to restore them into a new condition without loss of the functionality (Glavič & Lukman Reference Glavic and Lukman2007; Metta & Badurdeen Reference Metta and Badurdeen2013), which can save energy and prolong product life. Remanufacturing is a rising trend within the industry regarding improving environmental sustainability. It is critical that the designer implements the 6R concept into their design process as the concept aims to tackle environmental sustainability throughout the entire product lifecycle of NPD.

Resource utilisation

Natural resources are finite, and this has resulted in concerns within the product design industry (Glavič & Lukman Reference Glavic and Lukman2007). Ceschin & Gaziulusoy (Reference Ceschin and Gaziulusoy2016) define resource utilisation as the efficient use of resources during NPD, without limiting the functionality of the final product. This factor is identified to be a principle that designers can apply to enable environmental sustainability. It is argued that the 6R concept should be applied during the product design stage to reduce the overall consumption of resources (Metta & Badurdeen Reference Metta and Badurdeen2013). Structural features of designs, such as assembly requirements, can also be optimised to reduce resource consumption (Fiksel, Mcdaniel & Spitzley Reference Fiksel, Mcdaniel and Spitzley1998).

Material selection

Material selection as a factor of environmental sustainability is defined as the consideration of the environmental sustainability impacts of the materials selected to significantly improve the environmental benefits of the entire product (Eddy et al. Reference Eddy, Krishnamurty, Grosse, Wileden and Lewis2015). This is a factor that designers can consider during their process to enable environmental sustainability. It is suggested that designers need to consider the functional requirement, the estimated product lifetime and the disposal process of a product when selecting a material (Graedel & Guth Reference Graedel and Guth1990; Sampaio et al. Reference Sampaio, Sousa, Simões and Pontes2018). There has been a focus within the literature for designers to focus on selecting ‘eco-friendly’ materials (Clark et al. Reference Clark, Kosoris, Hong and Crul2009), such as selecting materials that are recyclable (Graedel & Guth Reference Graedel and Guth1990; Graedel et al. Reference Graedel, Comrie and Sekutowski1995; Sampaio et al. Reference Sampaio, Sousa, Simões and Pontes2018). Ansys Granta MI Materials Gateway are tools that provide a database of materials, which can assist the designer or design engineer in a deeper understanding of the material performance, enabling them to make a more informed decisions when selecting materials (Nelson Reference Nelson2016). Tools such as this should be considered if expected to improve understanding of material properties to improve environmental sustainability. Gallimore & Cheung (Reference Gallimore and Cheung2016) elaborated on the interrelationship between material selection and process selection, which needs to be considered during NPD (Alkhazraji et al. Reference Alkhazraji, Saldana, Donghuan and Kumara2013). While environmental sustainability factors of material selection are important, Alkhazraji et al. (Reference Alkhazraji, Saldana, Donghuan and Kumara2013) urged designers not to disregard consumer satisfaction when selecting materials.

Transport and logistics

All stages of the product life cycle need to be considered regarding environmental sustainability, including transportation and logistics (de Ron Reference De Ron1998). Transport and logistics is defined as the consideration of environmental sustainability whilst selecting transportation methods as well as manufacturing and distribution locations, within the context of environmental sustainability (Singh, Goodyer & Popplewell Reference Singh, Goodyer and Popplewell2007; Venkata Rao Reference Venkata Rao2009). This is a factor that designers should consider in order to reduce the overall environmental impact of the product. Additionally, transportation has been highlighted as a stage within the product life cycle that causes waste; it is advised that transportation distance is reduced to improve environmental sustainability (Singh et al. Reference Singh, Goodyer and Popplewell2007). It is therefore important that the designer considers material selection, the location of manufacture and the overall transportation of the product throughout the lifecycle as these all impact the overall environmental sustainability of NPD.

Durability and/or longevity

Zhang et al. (Reference Zhang, Zhang, Fung, Bakshi and Ng2020) defined durable products as those which last a long time whilst remaining in the same product form and functionality (de Ron Reference De Ron1998; Tseng, Lin & Han Reference Tseng, Lin and Han2012; Yan & Feng Reference Yan and Feng2014; Vimal et al. Reference Vimal, Vinodh, Brajesh and Muralidharan2016; Kuo & Wang Reference Kuo and Wang2019). Durability and/or longevity describe a factor that designers can apply during the product design process to enable environmental sustainability. de Ron (Reference De Ron1998) argued that designers should consider quality over quantity in relation to material selection and use, to enable a longer usage period. It is suggested that products that focus on environmentally sustainable factors, such as durability, add value for the customer as they can be deemed to be of better quality, which influences consumer purchasing behaviour (Clark et al. Reference Clark, Kosoris, Hong and Crul2009). Yan & Feng (Reference Yan and Feng2014) and Go et al. (Reference Go, Wahab and Hishamuddin2015) stated that product modularity can have a positive effect on durability of a product as products can be easily maintained, thus extending their lifecycle. Bernard (Reference Bernard2019) reported that durability could be a trade-off with other environmental sustainability factors; for example, designing a more durable product could add production steps and consequently increase emissions. This will have to be evaluated by the designer based on factors such as material and process selection to ensure the development of an environmentally sustainable product.

Structural and functional considerations

Structural and functional considerations describe the adaptation of structural or functional properties of a product or service to improve environmental sustainability. This factor is a principle that designers can employ during their design process to aid environmental sustainability. Easy disassembly can aid the consumer when separating materials for recycling. This also enables easy repair, refurbishment and reuse of products, which will extend the product lifetime, reducing material consumption through the manufacture of a replacement product (Graedel et al. Reference Graedel, Comrie and Sekutowski1995; Eddy et al. Reference Eddy, Krishnamurty, Grosse, Wileden and Lewis2013; Kuo & Wang Reference Kuo and Wang2019). Additionally, structural and functional considerations can reduce unnecessary usage of materials and energy during production and use. If the product is designed with dividable parts, it can be easily repaired, recovered and recycled (Fiksel et al. Reference Fiksel, Mcdaniel and Spitzley1998). This further supports the environmental factor of the 6Rs as it suggests there is a need for designers to consider the structural and functional constraints of a product to fulfil 6R requirements. Products that have increased functionality and ease of use are suggested to have longer life spans, easier disposal methods and lower environmental impacts; this could aid the designer or business financially as well as improving material sourcing, which can positively affect social sustainability (Clark et al. Reference Clark, Kosoris, Hong and Crul2009). Less material usage, a key element in reducing waste through functional and structural considerations, is suggested to be easier through the use of additive manufacturing (AM) (Despeisse & Ford Reference Despeisse and Ford2015). Customization, which is one of the major advantages of AM, can also enable a product to be more structurally or aesthetically appealing to a consumer, due to an increased emotional attachment and lifetime (Despeisse & Ford Reference Despeisse and Ford2015).

Process selection

The selection of manufacturing processes whilst considering environmental sustainability during product development defines the factor of process selection. It has been identified as a key factor when considering environmental sustainability as it can determine how easily a product can be repaired, assembled, what materials are suitable and what waste throughout the process; all of which have an impact on the environment (Stuart, Ammons & Turbini Reference Stuart, Ammons and Turbini1999; He, Luo & Huang Reference He, Luo and Huang2019). This factor is a principle that designers should consider in order to enable environmental sustainability, but it is also an element that could impact the environment during the production phase of NPD. Generally, the manufacturing engineer reviews the product design to select a process to achieve the desired functions (Alkhazraji et al. Reference Alkhazraji, Saldana, Donghuan and Kumara2013). However, this is contradicted by Zhang et al. (Reference Zhang, Zhang, Fung, Bakshi and Ng2020) who stated that the selection of a process is a design variable, which should be carefully considered by the design in product design. Clark et al. (Reference Clark, Kosoris, Hong and Crul2009) suggest that designers need to consider a broader spectrum of environmental sustainability issues during process selection to enable cleaner production. Processes have varying benchmarks of sustainability, Alkhazraji et al. (Reference Alkhazraji, Saldana, Donghuan and Kumara2013) outlined a need for a standard level to compare processes to provide a clear structure for designers to compare and select processes during the product design process. Furthermore, process selection is often completed once the design has been finalised, however, Liu, Zhu & Yu (Reference Liu, Zhu and Ye2020) found that integrating process selection into the product design process allows for greater design potential. This methodology may also aid environmental sustainability as the designer would have greater understanding of the environmental sustainability focused manufacturing benefits during the design stage and accordingly.

Modularity

Modular structures can be used to reorganise a product family, sharing common modules through a family product line (Hata et al. Reference Hata, Kato and Kimura2001). The factor of modularity describes the facilitation of upgrades, adaptations, modifications and increase in variety during NPD, all of which reduce energy use and increase environmental sustainability benefits of the product (Hata et al. Reference Hata, Kato and Kimura2001; Sonego et al. Reference Sonego, Echeveste and Debarba2018). This factor is a principle that designers can implement to enable environmental sustainability, it may also have some benefits during the use and production phase. Designing for modularity has a positive impact during the manufacturing stage as it decreases cost as well as environmental impact by using the same tooling and equipment (Yan & Feng Reference Yan and Feng2014). Additionally, modularity positively impacts the use phase of a product in relation to the environment due to the ability to maintain and upgrade a product, consequently extending a product’s lifetime (Sonego et al. Reference Sonego, Echeveste and Debarba2018). Go et al. (Reference Go, Wahab and Hishamuddin2015) stated that designing for modularity may enable and improve remanufacture of products, this again improves the environmental sustainability of the overall product by using a cradle-to-cradle methodology. A limitation of modularity is user acceptance, Sonego et al. (Reference Sonego, Echeveste and Debarba2018) claimed that user’s perceive modular products to be less durable, reliable and safe. This may impact the purchasing behaviour in two ways, one being that the consumer chooses not to purchase at all and the other being that if a module breaks or needs upgrading that the consumer is more likely to replace the entire product rather than a singular module, which would eliminate the original sustainable impact.

Packaging

The factor of packaging is defined as the development of the packaging whilst also considering the environmental sustainability of the product life cycle, it is an additional element of a product to which designers need to apply environmentally sustainability considerations. Packaging of a product can affect production during NPD, designers need to consider the additional density and weight of packaging and the environmental impacts of those (Chan, Wang & Raffoni Reference Chan, Wang and Raffoni2014). Graedel et al. (Reference Graedel, Comrie and Sekutowski1995) suggested that designers should consider the following factors: if there is a need for packaging, to use minimal packaging, to consider returnable/refillable/reusable packaging options and to use recyclable materials. Designers need to inform the user about how to dispose or recycle the packaging of the product responsibly (Graedel et al. Reference Graedel, Comrie and Sekutowski1995). Post-packaging also needs to be considered as there may be opportunity for reusability of packaging or reusability from packaging waste (Singh et al. Reference Singh, Goodyer and Popplewell2007).

Greenhouse gas emissions

Greenhouse gas emissions describe a factor of environmental sustainability often referred to as global warming or the greenhouse effect throughout the literature (Graedel & Guth Reference Graedel and Guth1990). There are four main categories of the greenhouse gas emissions factor, namely greenhouse, ozone depletion, acidification and oxidation potentials (Khan, Sadiq & Veitch Reference Khan, Sadiq and Veitch2004). When considering how to quantify greenhouse gas emissions, carbon footprint is often discussed as a key quantifiable factor of environmental impact (Sadiq & Khan Reference Sadiq and Khan2006; Kiong et al. Reference Kiong, Lee, Chong, Azlan and Muhd Nor2013). The phenomenon of global warming has been linked to product design and development since the 1980s (Gardner & Roseland Reference Gardner and Roseland1989; Rosemarin Reference Rosemarin1989) and is still a prominent theme within world media, and can influence how businesses and stakeholders make their decisions regarding environmental sustainability in product design (Short et al. Reference Short, Lee-Mortimer, Luttropp and Johansson2012). Greenhouse gas emissions are an example of a factor of an element, which can have an impact on the environment in use or during the production of the product. The rise of CO2 emissions has been reported as a driver in the development of renewable resources (Glavič & Lukman Reference Glavic and Lukman2007), this is a responsibility of the designer as they can implement these changes during the product design phase. However, to effectively consider greenhouse gas emissions as a factor of environmental sustainability during the design process, Ma & Kremer (Reference Ma and Kremer2016) suggest that designers should consider all variants of emissions and aim to reduce them throughout the design process. The consideration of greenhouse gas emissions could prove difficult for designers, especially if there is a lack of knowledge and time to complete the product development process. ISO 14000 (Sarkis, Meade & Presley Reference Sarkis, Meade and Presley2006) is a set of sustainable regulation tools to guide designers and should be used to satisfy requirements regarding emissions, to both control and manage greenhouse gas emissions during the design process (Singh et al. Reference Singh, Goodyer and Popplewell2007). The continuous focus on greenhouse gas emissions may be a result of government policies such as carbon caps for manufacturers (Gao et al. Reference Gao, Xiao, Wei and Zhou2018). This is important for manufacturers and design firms to recognise and manage product development accordingly, informing the designer on greenhouse gas emission based regulations, which they must adhere to during NPD.

Waste

Waste describes a factor that has an impact on the environment throughout the entire life cycle of the product, from production, during use, to end-of-life. Environmentally sustainable production requires all kinds of waste to be reduced to a minimum level whenever possible (de Ron Reference De Ron1998). Stuart et al. (Reference Stuart, Ammons and Turbini1999) defined waste into multiple categories: process, packaging, assembly or disassembly and defect. Waste minimization is highlighted by Glavič & Lukman (Reference Glavic and Lukman2007) as a fundamental process to ensure environmentally sustainable production as it can aid toxicity, cost and risk reduction during the product life cycle. In 2000, the UK government introduced the Waste Strategy that provides a framework for waste management to ensure the reduction, reuse and recovery and only then disposal of waste (Chick & Micklethwaite Reference Chick and Micklethwaite2004); this ensures responsible consumption and disposal during production. Designers must ensure they are aiming to follow this framework to be more environmentally sustainable (de Ron Reference De Ron1998; Chick & Micklethwaite Reference Chick and Micklethwaite2004). Graedel & Guth (Reference Graedel and Guth1990) identified the factors that could aid the designer recognise where improvement is needed throughout the product life. Venkata Rao (Reference Venkata Rao2009) and Monteiro et al. (Reference Monteiro, Silva, Ramos, Campilho and Fonseca2019) explained that alongside process waste, packaging waste must also be considered by the designer and reduced to ensure environmentally sustainable production. Deutz, Neighbour & Mcguire (Reference Deutz, Neighbour and Mcguire2010) discussed possible ways of integrating environmentally sustainable waste management systems into product design as a functional requirement; this could aid designers to ensure waste is reduced throughout NPD.

Energy

Sustainable production is defined by Glavič & Lukman (Reference Glavic and Lukman2007) as creating goods using processes, which conserve energy in a safe and healthy way. Energy is an identified factor of environmental sustainability, which is an element that can have an impact on the use and the production phase during NPD. Energy usage is the energy used in all phases of the product life cycle; therefore, to be more environmentally sustainable energy should be reduced throughout (de Ron Reference De Ron1998). Graedel & Guth (Reference Graedel and Guth1990) support this by stating that for a design to be energy efficient, energy use should be minimised at each manufacturing step; designers need to consider this throughout the product lifecycle. Furthermore, it is suggested that if a designer develops a product with prolonged lifetime this will reduce mass flows, reducing energy need related to production, distribution, collection of used products and recycling (Persson Reference Persson1999). This requires the designer to consider the positives and negatives when designing for a manufacturing process to ensure that the product is environmentally sustainable in relation to energy. Energy also includes renewable energy and resources, these have been defined as resources that are in a continually renewing state, supplying materials and energy in continuous ways; renewable resources do not rely on fossil fuels as there is a finite supply (Glavič & Lukman Reference Glavic and Lukman2007). Due to the invisibility of energy, consumers can disregard their consumption patterns and have a negative impact on the environment; consequently, designers need to conceive creative solutions during NPD to improve consumer behaviour patterns (Tang & Bhamra Reference Tang and Bhamra2008).

User behaviour

The factor of user behaviour describes the decisions designers make to consider the users’ concerns regarding sustainability issues as well as preventing the unsustainable behaviour patterns of users when using the product. User behaviour is a factor that can have an effect during the use phase, and the designer must be aware of it during the product design process to improve environmental sustainability. Environmental awareness of consumers has put pressure on manufacturers and designers, this has encouraged the development of environmentally sustainable products as well as having an environmentally sustainable disposal process (Chen Reference Chen2001; Venkata Rao Reference Venkata Rao2009). However, Tang & Bhamra (Reference Tang and Bhamra2008) argued that although consumers are concerned by the environmental impacts of their behaviour, their actions do not reflect this; for example, due to the invisibility of electricity and other resources in the home users are not conscious of the impact they have. It is therefore the designer’s role to research and generate creative concepts to improve energy efficiency and change consumption behaviour of users (Tang & Bhamra Reference Tang and Bhamra2008). Environmentally sustainable product design cannot depend on technology alone, user behaviour is a factor that needs to be considered by designers (Person Reference Persson1999). It is important to understand user behaviour and why they may dispose of products or consume unnecessary energy in the home to design products that aid the change in behaviour (Van Nes & Cramer Reference Van Nes and Cramer2005). Creating a user-product attachment can be key to extending product lifetime and therefore the environmental sustainability of a product; the qualities identified for increasing product attachment are self-expression, group affiliation, memories and enjoyment (Ceschin & Gaziulusoy Reference Ceschin and Gaziulusoy2016). It is suggested that collaboration with consumers is necessary for environmentally sustainable product design (Hoffman Reference Hoffmann2007; Gaziulusoy Reference Gaziulusoy2015; Sonego et al. Reference Sonego, Echeveste and Debarba2018) as they can help identify key actions within their own behaviour which need to be focused on to improve environmental sustainability during the use phase of the product lifecycle.

Resource depletion

Consumers are increasingly aware of the impact on the environment and the depletion of resources, and this is the main driver of the increase in environmentally sustainable product design and development (Laverne et al. Reference Laverne, Marquardt, Segonds, Koutiri and Perry2019). The factor of resource depletion describes the consideration of global depleting resources during NPD (Khan et al. Reference Khan, Sadiq and Veitch2004), although resource depletion is larger than one product development it is important that designers and firms are aware of this factor and accommodate it through material selection or structural considerations to reduce resource usage (Sakao Reference Sakao2007). Resource depletion is an element that will affect the choices of designers during the production phase of NPD, it also has some socioeconomic elements. The quantification of resource depletion is determined by the consumption of resources per unit production (Khan et al. Reference Khan, Sadiq and Veitch2004). Through the strategic designing of new products, resource depletion can be managed; the 6R concept can be implemented by designers with the aim to reduce and reuse resources for environmentally sustainable improvement (Metta & Badurdeen Reference Metta and Badurdeen2013; Yan & Feng Reference Yan and Feng2014; Go et al. Reference Go, Wahab and Hishamuddin2015; Hapuwatte & Jawahir Reference Hapuwatte and Jawahir2019). Resource depletion is further supported via new technology initiatives such as Industry 4.0. which addresses resource depletion through smart production systems (Kamble, Gunasekaran & Gawankar Reference Kamble, Gunasekaran and Gawankar2018); new technologies need to be considered by designers as implementing them will have positive effects on the environmental sustainability of NPD. Resource utilisation is a previously identified factor that could potentially have a positive impact on resource depletion through the efficiency of resources and reduction of waste.

Toxicity and hazardous production

Toxicity and hazardous production are identified as a factor of environmental sustainability which considers the by-products of production that can cause harm to the environment (Kiong et al. Reference Kiong, Lee, Chong, Azlan and Muhd Nor2013). They are elements that can have an impact on the environment during production or use as well as having some socioeconomic elements, such as the potential harm it could inflict on local communities. Glavič & Lukman (Reference Glavic and Lukman2007) stated that to be successful in environmental performance hazardous or toxic substances, resources and energy need to be minimised during the product design process. It is important to consider both toxic content within a product but also toxic waste (Rosemarin Reference Rosemarin1989; Overby Reference Overby1991; Chen Reference Chen2001). Designers need to consider how a product or process can be improved to reduce the overall dependency of potential toxic materials and emissions (Graedel & Guth Reference Graedel and Guth1990). Sakao (Reference Sakao2007) suggests that material selection should be considered due to their toxicity and to minimise hazardous production. The toxicity of material and production can also have the potential to damage human health, which is important to consider for human risk and societal sustainability (Khan et al. Reference Khan, Sadiq and Veitch2004; Glavič & Lukman Reference Glavic and Lukman2007; Vimal et al. Reference Vimal, Vinodh, Brajesh and Muralidharan2016; Zhang et al. Reference Zhang, Zhang, Fung, Bakshi and Ng2020).

Eco-business

Eco-business describes a socioeconomic factor that could impact the design process. The factor describes when a designer or a business chooses to implement environmental sustainability within their NPD process, they could also benefit economically. Environmental sustainability can impact economic growth as sustainability focuses on environmental and societal need, this enables social relevance, increasing consumer purchases (Pieroni, Mcaloone & Pigosso Reference Pieroni, Mcaloone and Pigosso2019). Gaziulusoy (Reference Gaziulusoy2015) argued that the successful addressing of social and environmental issues and changing the business mindset to fulfil this has become one of the fundamental requirements for business success. Examples of factors that influence the business are lower energy as this is cost-saving as well as the reduction of material in the product and packaging as this aids management and cost (Brezet, Stevels & Rombouts Reference Brezet, Stevels and Rombouts1999), these are factors of environmental sustainability that can be influenced through design. Circular economy (CE), which is discussed in detail in Section 3.7, has been identified as a business model with increasing interest and support. Focusing on the ideology of closing loops (Pieroni et al. Reference Pieroni, Mcaloone and Pigosso2019), and although a separate concept to sustainability, there are sustainable benefits to implementing this business model.

Government regulations, laws and guidelines

Government regulations, laws and guidelines have been prominent within environmentally sustainable product design literature and play a role in promoting environmentally sustainable development (Wang et al. Reference Wang, Ghadimi, Lim and Tseng2019). This factor can be described as a set of principles that designers have to follow to ensure that their product is lawfully environmentally sustainable. Gardner & Roseland (Reference Gardner and Roseland1989) argued that sustainability was first brought to the attention of governments by Brundtland (Reference Brundtland1987). Governments offer environmentally sustainable design motivation through grants or government regulations (de Ron Reference De Ron1998). This requires and motivates designers and firms to implement environmental sustainability into NPD. European governments have set targets for the recycling of consumer products (Chen Reference Chen2001; Alayón, Säfsten & Johansson Reference Alayón, Säfsten and Johansson2017) and the recovery, reuse and recycling of waste (Mellor et al. Reference Mellor, Williams, Stevens, Clift and Azapagic2001). It has also been discussed that government subsidies are provided to stimulate product recycling and that the government has regulations so that the whole product or specific product contents must be recovered (Zhang et al. Reference Zhang, Zhang, Fung, Bakshi and Ng2020). Designers should therefore design products with this legislation in mind and consider the 6R concept during NPD. Gao et al. (Reference Gao, Xiao, Wei and Zhou2018) proposed that government guidelines and legislation can aid manufacturers in making strategic decisions when setting the product green degree. Although, it may be disputed that designers or design teams should set these targets as the product design phase can impact up to 80% of the sustainability impacts (Yang & Song Reference Yang and Song2006; Waage Reference Waage2007; Ahmad et al. Reference Ahmad, Wong, Tseng and Wong2018; Hub Reference Hub2018). The ISO 14000 standards were developed to encourage environmental management (Sarkis et al. Reference Sarkis, Meade and Presley2006); they do not prescribe performance targets but provide tools to aid with the control of environmental impacts of products or services (Glavič & Lukman Reference Glavic and Lukman2007). Although this tool is subjective to the designer or firm it provides guidance on how to implement environmental sustainability during NPD. Government regulations are prominent within environmentally sustainable product development and can change over time, the designer and firm must be aware of these to ensure that their designs are complying with the various restrictions and to also benefit financially by adhering to them.

3.3. The evolution of environmental sustainability in product design

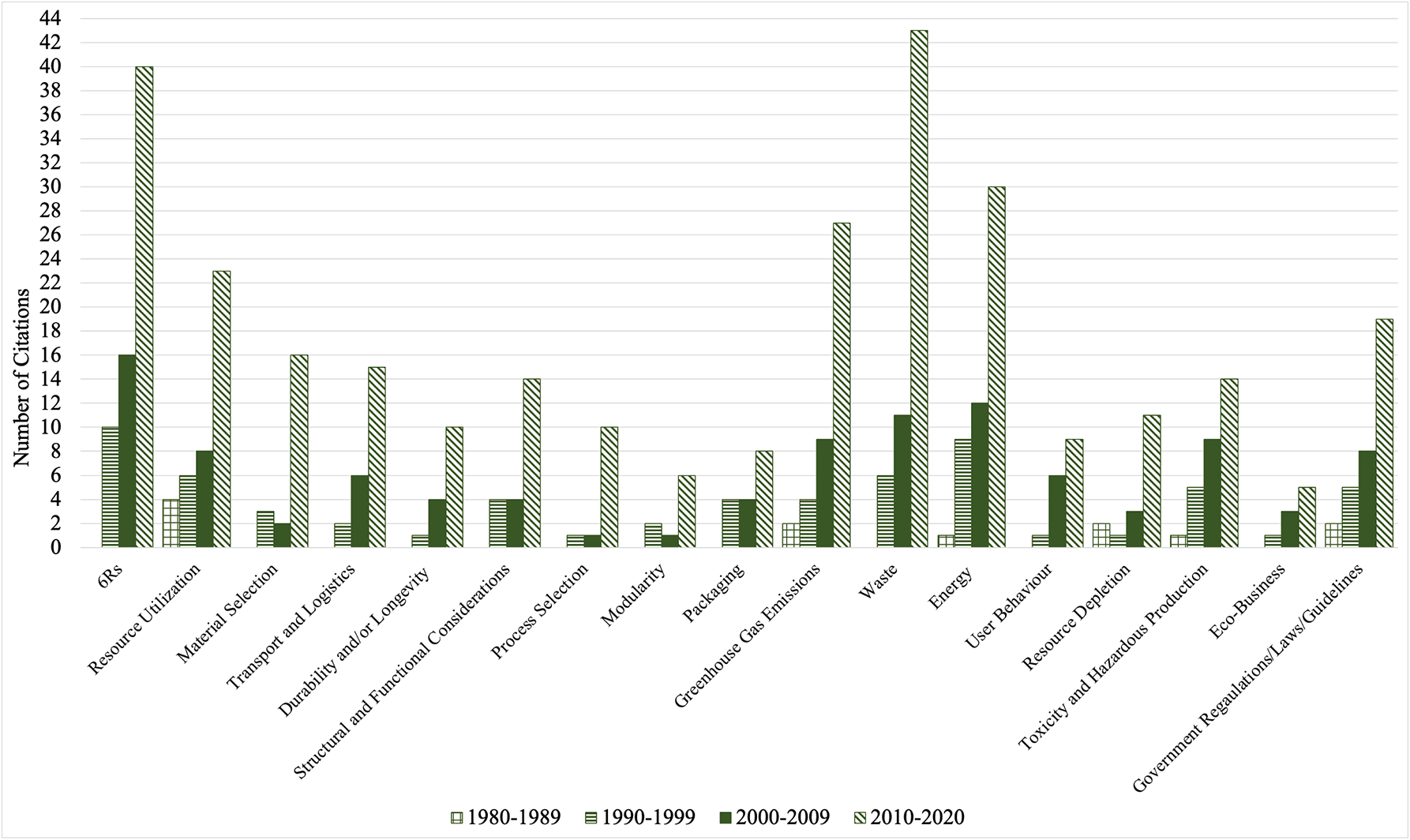

Section 3.3 showcases the development of environmental factors over the last four decades. Figure 2 and Table A1 present the summary of the 17 factors of environmental sustainability highlighted previously. The figure and table are divided into the relevant decades, allowing for an observation of the popularity and variety of environmental sustainability factors during each decade investigated and how environmental sustainability has developed over time. Table A1 presents a summary of all the factors identified by literature as well as the relevant sources that support each factor. This illustrates the extensive review undertaken into each factor and highlights the value of each factor due to the growing interest over the four decades. When investigating the literature and collating the data of each factor, it was important to select factors that were established over the past four decades or showing the growth in research interest. This enabled the identification of a collection of factors that are suggested to aid in the development and implementation of environmental sustainability during the product design process.

Figure 2. The development of environmental sustainability.

Figure 2 presents the development of environmental sustainability as well as further illustrating Table A1 to emphasise and summarise the current state as well as the progression of literature regarding the factors of environmental sustainability to be considered during the product design process.

Figure 2 identifies that there is a substantial increase in the number of research papers focused on environmental sustainability in the past 10 years. Indicating that environmental sustainability has become increasingly important within product design literature.

-

(i) The Brundtland Report was released in 1987, and from Figure 2, the first factors of environmental sustainability within product design were being recognised during the 1980s.

-

(ii) By the 1990s, all the identified factors had been reported in literature.

-

(iii) Between 1990 and 2009, literature discussing the factors of environmental sustainability increased, however within the last decade literature has quickly grown showcasing the importance of each factor in relation to product design.

-

(iv) Both 6Rs and Waste have been considered as key factors within product design as both have been discussed throughout a 30-year period. This could also be due to the increase of CE literature and research, especially in the past decade.

-

(v) Resource utilisation and energy also appear to have a sharp increase during the last decade and are being considered more frequently throughout literature as the 40-year period has progressed.

-

(vi) A possible instigator of the increase in popularity of environmental sustainability is the increase of literature highlighting government laws, regulations and legislations, especially in the last decade along with the seventeen sustainable development goals being announced by the UN in 2015 (United Nation 2015; Ameli, Mansour & Ahmadi-Javid Reference Ameli, Mansour and Ahmadi-Javid2019). With the increase of stricter polices and regulations regarding environmentally sustainable design, it has become essential that research has investigated the importance of these from the perspective of designers and manufacturers during NPD for designers and manufacturers to adhere to the more important this has become within research.

-

(vii) Consumer behaviour and awareness regarding environmental sustainability have also increased (Chen Reference Chen2001; Venkata Rao Reference Venkata Rao2009); this could be a driver in the general increase of all the identified environmental factors discussed throughout product design literature over time.

Literature regarding environmental sustainability within product design is becoming more significant and impacts on a variety of factors within the industry. Research continues to aid designers to understand and implement design for environmental sustainability principles throughout NPD.

3.4. The current state of integration of environmental sustainability in product design

Environmental sustainability is recognised within the product design industry and there are multiple methods that designers can use to integrate this into their work, including various assessment methods and software packages. This can aid the designer to evaluate their current work and highlight improvements to maximise environmental sustainability during NPD. The following subsections discuss three tools that have been identified to aid environmental sustainability implementation, these tools were selected due to the volume of product design literature discussing the integration of these tools. This is of particular interest to this study as it has aided in the understanding of the current status as well as the development of the conceptual framework, discussed in Section 4.

Life cycle analysis

LCA tools are used to validate green design options in relation to energy, material application and process-related aspects (Brezet et al. Reference Brezet, Stevels and Rombouts1999). LCA is also described by Stuart et al. (Reference Stuart, Ammons and Turbini1999) as a three-step design evaluation methodology, which is composed of inventory measures, environmental impact assessment and a methodology for improvement of the product life cycle. Traditionally LCA’s are product-focused, however more recently there have been efforts towards process design considering economic, technological and environmental constraints (Sadiq & Khan Reference Sadiq and Khan2006). LCA’s were originally standardised by ISO (1997) (Sakao Reference Sakao2007), but were later updated (Devanathan et al. Reference Devanathan, Ramanujan, Bernstein, Zhao and Ramani2010). This methodology is suggested to be relatively objective by Sakao (Reference Sakao2007) due to the requirement of quantitative data. Cradle-to-grave analysis is also used to describe LCA by Glavič & Lukman (Reference Glavic and Lukman2007). Additionally, LCA’s have been integrated into some product design curricular (Delaney & Liu Reference Delaney and Liu2021), this could make the application of LCA tools more accessible to product designers progressing into the industry. However, it has been found that LCA tools require an expert to be successful during use as well as needing detailed information to quantify the environmental factors to be assessed (Raoufi et al. Reference Raoufi, Park, Khan, Haapala, Psenka, Jackson, Kremer and Kim2019). This can limit their success and efficiency when assessing environmental impact throughout the life cycle. Furthermore, LCA’s have been highlighted to require more detailed information and would arguably be best implemented during the detailed design phase of the product design process opposed to the early stages (Sakao Reference Sakao2007; Devanathan et al. Reference Devanathan, Ramanujan, Bernstein, Zhao and Ramani2010). This is a limitation as it has previously been found that environmental sustainability is best implemented during the early stages of the product design process as this is where the greatest impacts are made (Yang & Song Reference Yang and Song2006; Waage Reference Waage2007; Ahmad et al. Reference Ahmad, Wong, Tseng and Wong2018). The use of CAD integrated with LCA is a rising trend within industry, which aims to assist the designer in the evaluation of environmental aspects during the design stage (Morbidoni et al. Reference Morbidoni, Favi and Germani2011; Chen, Tao & Yu Reference Chen, Tao and Yu2017), however, there are still limitations as this is a new technology and will need further research to be totally effective.

Sustainability checklists

Sustainability checklists are used within industry to assess a product from an environmental perspective; this method highlights areas for improvement throughout the product lifecycle (Sakao Reference Sakao2007). The checklist method can also be used to check areas of deviation and causes of environmental issues, which could affect the production chain (de Ron Reference De Ron1998). Examples of factors considered during a sustainability checklist are material selection, material usage, waste characteristics, energy, recyclability and disposal (de Ron Reference De Ron1998; Sakao Reference Sakao2007; Zhang et al. Reference Zhang, Zhang, Fung, Bakshi and Ng2020). The use of this environmental sustainability tool is arguably more subjective in comparison to other methods such as LCA’s (Devanathan et al. Reference Devanathan, Ramanujan, Bernstein, Zhao and Ramani2010). The measures of a checklist can be subjective to business goals opposed to an objective environmental sustainability assessment (Sakao Reference Sakao2007). Schöggl, Baumgartner & Hofer (Reference Schöggl, Baumgartner and Hofer2017) argued that checklists can be too general, this could be disadvantageous as there may be lack of clarity of what the designer is working towards or assessing. Sustainability checklists can ask the designer questions regarding the factors selected to assess such as ‘Is the product harder to be degraded naturally?’ (Zhang et al. Reference Zhang, Zhang, Fung, Bakshi and Ng2020, p. 8), although this is relevant this method is potentially completed post-design and previous selections may be hard to undo once selected.

Sustainability software packages

The primary aim of sustainability software packages is to assess environmental impacts of a design on behalf of the designer. Softwares such as EcoFit, EcoCAD and EcologiCAD aim to assist the designer in the enhancements of design capabilities and to assess environmental impacts during the design phase (Raoufi Reference Raoufi, Park, Khan, Haapala, Psenka, Jackson, Kremer and Kim2019). The most frequent software package discussed throughout the literature analysed was the SolidWorks Sustainability package. The software quantifies and assesses environmental impacts using the CAD model of a given designed product (Raoufi et al. Reference Raoufi, Park, Khan, Haapala, Psenka, Jackson, Kremer and Kim2019); and focuses on four elements of sustainability: carbon footprint, water eutrophication, air acidity and total energy used (Kiong et al. Reference Kiong, Lee, Chong, Azlan and Muhd Nor2013; Gallimore & Cheung Reference Gallimore and Cheung2016). More recently, Autodesk Fusion 360, has been developed and uses generative design to help product designers or design engineers with sustainability goals such as material and energy reduction using CAD models (Bezpalko Reference Bezpalko2019), although it is unclear whether it assesses the entire spectrum of environmental sustainability factors outlined in this review.

3.5. Stakeholders to environmental sustainability

Several stakeholders have been identified to aid the designer in implementing environmental sustainability within the product design process. Schöggl et al. (Reference Schöggl, Baumgartner and Hofer2017) argued that internal communication and collaboration across different departments during the product design stage would optimise the environmental sustainability of the final product. Buchert et al. (Reference Buchert, Kaluza, Halstenberg, Lindow, Hayka and Stark2014) considered stakeholders throughout the design process; suggesting that design managers, sustainability experts and design engineers are key at the product planning stage and design engineers are key during the concept and embodiment stage. It has also been suggested that during post-production the firm’s environmental manager should be in control of the reduction of waste and emissions (Singh et al. Reference Singh, Goodyer and Popplewell2007). Kuo & Wang (Reference Kuo and Wang2019) discussed the use of environmental specialists working alongside designers during the product design phase, but it is not clear at what point in the design process they should be involved. Users have also been highlighted as stakeholders within the product design process as they are identified as being influential to environmental sustainability and business success (Gaziulusoy Reference Gaziulusoy2015), users can provide an insight into the use of the product, which may have been previously overlooked in relation to sustainability. Therefore, users could be integrated into the design process more frequently in the future or they could be in control of the design process with methods like customization to aid environmental sustainability. Other literature states that managerial, policy and engineering perspectives should be considered throughout the development of new products (Stuart et al. Reference Stuart, Ammons and Turbini1999). Managers of firms may also be considered as stakeholders of the product design process as they have a clear view of the economic benefits of implementing environmental sustainability within NPD (Short et al. Reference Short, Lee-Mortimer, Luttropp and Johansson2012). Lofthouse (Reference Lofthouse2004) suggested that during the detailed design phase the design team will hand over the project to design engineers dependent on the complexity of the project. A wide range of industry professionals as well as users have been identified as potential stakeholders to the design process to aid in the effective implementation of environmental sustainability. This suggests a more collaborative design process is needed to be successful in the development of environmentally sustainable products. This may require a restructure of the design process to facilitate a more collaborative style of work across departments within the NPD process. However, although the literature has identified these potential stakeholders, it is unclear who designers currently interact with during the design process and whether those professionals specifically aid with environmental sustainability, further investigation is required to determine this.

3.6. Additive manufacturing

AM is a group of over 10 manufacturing processes that, opposed to traditional subtractive manufacturing techniques, produce products layer-by-layer to enable production on demand (Ford & Despeisse Reference Ford and Despeisse2016). AM has been identified as an emerging technology that has the potential to enable environmentally sustainable manufacture such as the reduction in waste material generated during production compared with material removal processes (Liu, Moultrie & Ye Reference Liu, Moultrie and Ye2019; Liu, Zhu & Ye Reference Liu, Zhu and Ye2019). Energy consumption and reduction in transportation due to having more localised production are also benefits of AM. Additionally, inventory waste is reduced as spare parts and orders can be designed and made on demand (Despeisse & Ford Reference Despeisse and Ford2015; Ford & Despeisse Reference Ford and Despeisse2016; Laverne et al. Reference Laverne, Marquardt, Segonds, Koutiri and Perry2019). Reuse and recycling of by-products such as waste are also enabled through AM (Despeisse & Ford Reference Despeisse and Ford2015; Laverne et al. Reference Laverne, Marquardt, Segonds, Koutiri and Perry2019). However, Faludi et al. (Reference Faludi, Bayley, Bhogal and Iribarne2015) dispute that there is a higher amount of energy used during AM. In addition, AM also permits for product development with less assembly steps, which is implied to reduce environmental impact due to the minimization of logistics (Despeisse & Ford Reference Despeisse and Ford2015). It should be noted that the reduced assembly steps do not naturally come with AM, this is the responsibility of the designer, and they should be designed into the product itself. Despeisse & Ford (Reference Despeisse and Ford2015) argued that AM allows for easier customization which can extend a product’s lifetime due to the emotional attachment of the consumer. AM is still a relatively new technology; it is unclear how this technology will be integrated into the design process, but it is expected to have a positive impact on environmental sustainability. As AM continues to develop it may be used more frequently during NPD opposed to rapid prototyping purposes only. It may also allow for users to produce products at home, enabling a more on-demand service, which reduces the impact of transport and logistics. The potential and acceptance of the technology (by industry and users) has yet to be fully explored and requires further investigation.

3.7. Circular economy

CE is quickly becoming a trend within the literature as a potential solution to foster environmental protection without limiting economic growth (Ceschin & Gaziulusoy Reference Ceschin and Gaziulusoy2016; Rocha, Antunes & Partidário Reference Rocha, Antunes and Partidário2019). The Ellen MacArthur Foundation defines CE as ‘an industrial system that is restorative or regenerative by intention and design’ (MacArthur Reference Macarthur2013, p. 7). It has also been described as an umbrella concept that aims for the achievement of a more resource effective and efficient economic system through narrowing, slowing and closing material and energy flows (Pieroni et al. Reference Pieroni, Mcaloone and Pigosso2019). The loop economy is suggested to enable industrial strategies, which aid waste prevention, job creation, resource efficiency and dematerialization within the industrial economy (Geissdoerfer et al. Reference Geissdoerfer, Savaget, Bocken and Hultink2017; Kirchherr, Reike & Hekkert Reference Kirchherr, Reike and Hekkert2017). Contemporary elements of CE such as the cradle-to-cradle methodology (Bocken et al. Reference Bocken, De Pauw, Bakker and Van Der Grinten2016; Kirchherr et al. Reference Kirchherr, Reike and Hekkert2017) are also featured within design for sustainability literature so there is some cross over in the two fields of research, suggesting that some CE methodologies are already being integrated into the product design process. There are further similarities between the CE and sustainability, design and innovations are argued to be the main drivers for reaching their ambitions and stakeholders are implied to be imperative to reach their expectations (Geissdoerfer et al. Reference Geissdoerfer, Savaget, Bocken and Hultink2017). The difference between sustainability and CE is described by Geissdoerfer et al. (Reference Geissdoerfer, Savaget, Bocken and Hultink2017) as sustainability aims to improve the environment, economy and the society from a wide perspective. Whereas CE is implied to be the economic actors with consequential benefits for sustainability. However, the crossovers between the two ideologies could enable benefits for one when implementing the other. CE, due to the business focus, may be more appealing to businesses, which would encourage their teams to implement CE methodologies. This would have benefits to the environmental sustainability of the product. It is unclear whether the design process, in its typical state, is suitable to facilitate these closed-loop concepts, and therefore must be developed to accommodate this in a more effective way.

4. New product design conceptual framework

4.1. Environmental sustainability in the design process

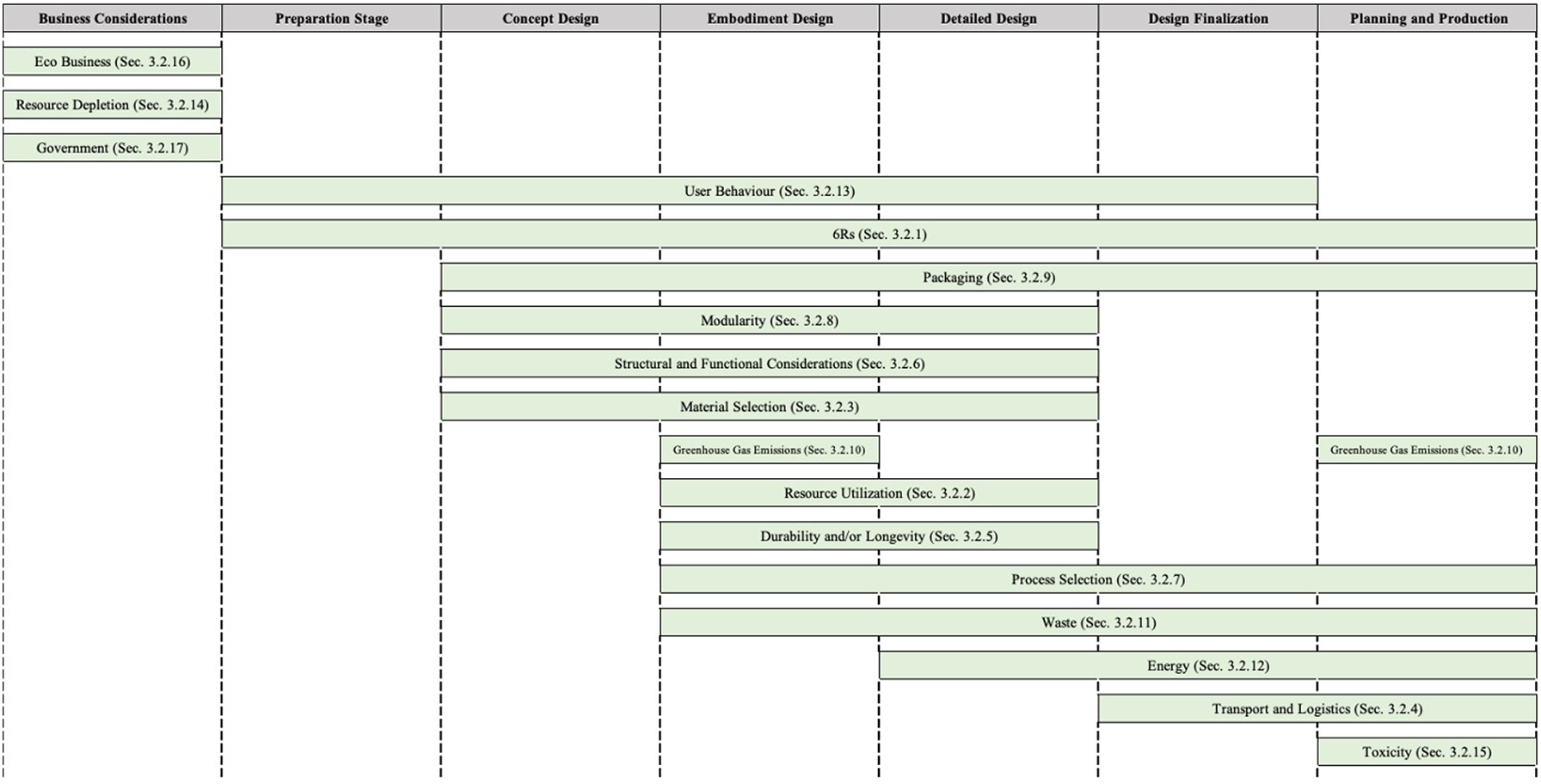

The typical design process, as depicted in Figure 3, generally contains six key stages, namely, the preparation stage, concept design, embodiment design, detailed design, design finalisation and planning and production (Wright Reference Wright1998; Chiu & Chu Reference Chiu and Chu2012). It has been highlighted that environmental sustainability should be considered during the product design process due to the high impact that this phase has on the overall environmental sustainability of the product (Yang & Song Reference Yang and Song2006; Waage Reference Waage2007; Ahmad et al. Reference Ahmad, Wong, Tseng and Wong2018; Hub Reference Hub2018). The product design stage enables the designer to assess the lifecycle of a product prior to the manufacture and development (Go et al. Reference Go, Wahab and Hishamuddin2015), which can enable a comprehensive review of the environmental sustainability impact. Additionally, there is an increasing awareness of the importance of the product design phase in relation to environmental sustainability factors as it can optimise the overall environmentally sustainable performance throughout the product lifecycle (Yang & Song Reference Yang and Song2009). Furthermore, environmentally sustainable considerations of previous designs can have a positive impact on future designs and should be continued when developing a new product (Brundage et al. Reference Brundage, Bernstein, Hoffenson, Chang, Nishi, Kliks and Morris2018).

Figure 3. The typical design process adapted from Wright (Reference Wright1998) and Chiu & Chu (Reference Chiu and Chu2012).

Although environmental sustainability impacts should be considered during the design process it is unclear at which stage of the process each factor should be specified. Gaziulusoy (Reference Gaziulusoy2015) argued that environmental sustainability issues such as recyclability and reusability should be considered at the very early stages of the product development to bring design improvements early in the production process. However, the concept stage is highlighted to lack necessary information to analyse the environmental impact of a product. It is therefore suggested that environmental sustainability should be a focus during the detailed design phase as it has clearer specifications and quantitative data, which can be used to assess and estimate the environmental impact to locate improvements (Brundage et al. Reference Brundage, Bernstein, Hoffenson, Chang, Nishi, Kliks and Morris2018). Sadiq & Khan (Reference Sadiq and Khan2006) and Chang, Lee & Chen (Reference Chang, Lee and Chen2014) also supported this claim that environmental considerations should be a focus later within the product design process. In contrast Go et al. (Reference Go, Wahab and Hishamuddin2015) suggested that product design plays a vital part in improving environmental sustainability and should be considered during the concept and embodiment stage as these stages have the greatest impact on materials, geometry and product structure. de Almeida Souza & de Barros Pereira (Reference De Almeida Souza and De Barros Pereira2006) and Yang & Song (Reference Yang and Song2006) discussed how toxicity and hazardous production needs to be considered during the manufacturing and production stages of NPD. Buchert et al. (Reference Buchert, Kaluza, Halstenberg, Lindow, Hayka and Stark2014) considered carbon emissions at both the embodiment and production stage to ensure that goals for environmental sustainability are being met; highlighting how certain environmental sustainability factors need to be considered more than once during the product design phase.

More recent literature suggests that environmental sustainability should be considered throughout the entire product design phase (Chiu & Chu Reference Chiu and Chu2012; Ahmad et al. Reference Ahmad, Wong, Tseng and Wong2018). Ahmad et al. (Reference Ahmad, Wong, Tseng and Wong2018) discuss that sustainability should be incorporated along all stages of the product design process as long as the designer determines the sustainability issues, generates advice regarding sustainability during early stages of the design using relevant tools and resources, evaluates the performance of the product in regard to sustainability and generates a method to track sustainability all whilst meeting user needs and product functions; this should also be assumed for environmental sustainability. Chiu & Chu (Reference Chiu and Chu2012) proposed that sustainability should be considered across the preparation stage, preliminary design stage and the detailed design stage; supporting others who suggested that environmental sustainability should be considered throughout the product design process.

4.2. New conceptual framework

This section outlines the NCF following the analysis of literature. The new contribution to the field provided by the NCF is a theoretical framework from the perspective of a product designer on how and when they should consider the identified key factors of environmental sustainability during their design process. This format is adapted from the current design process, seen previously in Figure 3, this was important as designers are already familiar with this process and can therefore effectively embed these factors into their work. Existing work has previously discussed the importance of certain stages of the typical design process, such as the detailed design stage (Sadiq & Khan Reference Sadiq and Khan2006). Frameworks have also been previously developed highlighting how design for environmental sustainability should be integrated during the design process (Eppinger & Ulrich Reference Eppinger and Ulrich2015). Focusing on setting an agenda, identifying environmental impacts, setting guidelines, applying those guidelines, assessing, refining and reflecting. However, no paper has covered such an extensive review of factors of environmental sustainability and discussed how they should be integrated across all stages of the design process. The NCF will enable a thorough and effective review of environmental sustainability throughout all stages of the product design process.

The NCF, as depicted in Figure 4, proposes to integrate the 17 environmental sustainability factors throughout the typical design process. It represents how factors often need to be considered continually throughout multiple product design stages.

Figure 4. The NCF that shows how the identified 17 factors in Section 3.2 should be considered during product design.

The first adaptation of the current product design process, Figure 3, is a preliminary stage identified as ‘Business Considerations’, this was due to literature identifying that business managers need to be considered during the design process as they have a holistic view of how environmental sustainability could benefit the company (Short et al. Reference Short, Lee-Mortimer, Luttropp and Johansson2012). Business considerations feature eco-business, resource depletion and government regulations; these factors are nonexclusive to a singular product development and should be reviewed continuously by the firm to inform designers of developments, which are out of their control.

The NCF combines the concept of considering environmental sustainability throughout all stages of the design process suggested by Chiu & Chu (Reference Chiu and Chu2012) and Ahmad et al. (Reference Ahmad, Wong, Tseng and Wong2018) as well as combining research from other authors who advise certain factors should be considered at specific stages.

Literature identified conflicting information on where the 6Rs should be considered within the design process, with Gaziulusoy (Reference Gaziulusoy2015) arguing that it should be considered in the early stages and Chang et al. (Reference Chang, Lee and Chen2014) stating that any factor should be considered at later stages where there is more detail. As the 6Rs consist of six subfactors as well as literature highlighting that it should be considered at the beginning and the end of the product design process, the 6Rs are considered throughout all stages in the NCF. User behaviour is often a factor considered during the development of a design specification, often in the preparation stage, and considered greatly in the concept stages for initial concepts. However, literature argues that user behaviour should be considered throughout the product design process (Gaziulusoy Reference Gaziulusoy2015; Sonego et al. Reference Sonego, Echeveste and Debarba2018). Therefore, user behaviour has been considered from the preparation stage to the design finalisation during the NCF, this incorporates the tasks of a designer as well as literature recommendations. Packaging has been identified as having individual design criteria as well as affecting logistics (Chan et al. Reference Chan, Wang and Raffoni2014); therefore, this factor has been implemented from the concept design stage to planning and production during the NCF. Modularity, as well as structural and functional considerations, focus on the structure and body of the design; therefore, it has been categorised within the concept, embodiment and detailed design phases as these are the key areas where functionality is determined (Wright Reference Wright1998; Devanathan et al. Reference Devanathan, Ramanujan, Bernstein, Zhao and Ramani2010). Graedel et al. (Reference Graedel, Comrie and Sekutowski1995) identified that designers should consider material selection during the initial design stages, as this can prevent an unnecessary variety of materials used in a singular product, avoiding the need to separate product components at the end of the product life cycle. Material selection is also dependent on the design specification developed during the preparation stage, and would be further developed during the concept, embodiment and detailed design phase based on the requirements of the typical design process aside from environmental sustainability (Wright Reference Wright1998; Devanathan et al. Reference Devanathan, Ramanujan, Bernstein, Zhao and Ramani2010), this is reflected in the NCF. Greenhouse gas emissions feature at both the embodiment and the production stage. The embodiment stage was selected as this is where the product will be developed greatly, here designers should be considering how their decisions could impact greenhouse gas emissions. The production stage is anticipated to be the stage where greenhouse gas emissions will be produced, and therefore should be monitored during this stage. These placements are echoed by Buchert et al. (Reference Buchert, Kaluza, Halstenberg, Lindow, Hayka and Stark2014). Resource utilisation and durability and/or longevity are both factors that need an initial concept to develop before focusing on environmental sustainability; therefore, these factors have been placed at the embodiment and detailed design phase as they require more specifications to make improvements (Wright Reference Wright1998; Devanathan et al. Reference Devanathan, Ramanujan, Bernstein, Zhao and Ramani2010). Process selection can determine design features (Stuart et al. Reference Stuart, Ammons and Turbini1999; He et al. Reference He, Luo and Huang2019) and should therefore be considered from the embodiment stage onwards so that the design fulfils these requirements through to the planning and production stages. Waste can occur at all stages of the product life cycle and should be considered during the product design process to achieve environmental sustainability (Glavič & Lukman Reference Glavic and Lukman2007). Waste needs initial concepts before waste can be minimised; therefore, waste is considered throughout multiple phases including and from the embodiment design stage. Energy has been identified as having many variables with detail being required, this factor is therefore considered from the detailed design stage onwards, this is supported by de Ron (Reference De Ron1998). Transport and Logistics have been considered from the design finalisation phase onwards, due to the organisation required from this phase to produce a product on time and to the correct standard as well as following the current demands from the typical design process (Devanathan et al. Reference Devanathan, Ramanujan, Bernstein, Zhao and Ramani2010; Chiu & Chu Reference Chiu and Chu2012). The factor of toxicity and hazardous production is considered during the planning and production phase as this is the stage where toxicity and hazardous production would be the greatest risk to environmental sustainability. Additionally, this is the stage where there would be a position for designers or stakeholders to assess the toxicity and hazardous production and to find potential solutions to minimise the environmental sustainability damage. This placement is further supported by de Almeida Souza & de Barros Pereira (Reference De Almeida Souza and De Barros Pereira2006) and Yang & Song (Reference Yang and Song2006).

5. Discussion