1. Introduction

Partially molten rock is a physical system that is central to many geological and planetary processes. It is a densely packed, melt-saturated, granular medium, but it has seldom been considered in these terms. Continuum models of partially molten rock treat the solid and liquid phases as interpenetrating fluids in a poro-viscous, zero-Reynolds-number theory (e.g. McKenzie Reference McKenzie1984; Fowler Reference Fowler1990). In such models, effects arising from the discrete grains are neglected, except insofar as they affect the creep viscosity. For example, during Coble creep, the melt phase provides a fast pathway for mass diffusion around grains (e.g. Takei & Holtzman Reference Takei and Holtzman2009; Rudge Reference Rudge2018). Deformation experiments on partially molten rock are typically parameterised in terms of an isotropic flow law with a weakening factor that depends on the volume fraction of melt within pores (e.g. Kohlstedt & Zimmerman Reference Kohlstedt and Zimmerman1996; Kelemen et al. Reference Kelemen, Hirth, Shimizu, Spiegelman and Dick1997). These physics were reviewed by Katz et al. (Reference Katz, Rees Jones, Rudge and Keller2022).

It is less commonly noted, however, that deformation of partially molten rock inevitably includes a component of sliding along grain boundaries (e.g. Hansen, Zimmerman & Kohlstedt Reference Hansen, Zimmerman and Kohlstedt2011; Rudge Reference Rudge2021). The granular origins and importance of such sliding in partially molten rock were recognised by Paterson (Reference Paterson1995) and elaborated by Paterson (Reference Paterson2001). In these works, the geometric grain-compatibility problem arising from grain-boundary sliding is assumed to be entirely resolved by shape change of the grains, which occurs by diffusion or lattice dislocations (Langdon Reference Langdon2006). A third possibility is noted by Paterson (Reference Paterson2001) but then neglected: that incompatibility is resolved by relative motion of undeforming grains in a granular flow. This mechanism is fundamental in the physics of athermal granular media (e.g. Forterre & Pouliquen Reference Forterre and Pouliquen2008); it gives rise to dilatancy and non-local granular fluidity.

In this paper we extend the continuum theory of partially molten rock to incorporate the physics of a granular medium. As a hypothesis for the essential granular physics, we adapt and include theory for dilatancy and non-local fluidity. We test this hypothesis by modelling published laboratory experiments in which partially molten rock is subjected to torsional deformation. The deformation drives liquid–solid segregation and yields robust patterns of melt localisation. We show that the inclusion of granular physics brings model predictions into agreement with laboratory data.

The laboratory experiments, detailed in King, Zimmerman & Kohlstedt (Reference King, Zimmerman and Kohlstedt2010) and reviewed in § 2 below, are conducted on synthetic rocks comprising solid olivine grains and liquid basaltic melt. Hot-pressed, nominally uniform, cylindrical samples of this aggregate are sheared in a torsion apparatus at high temperature and confining pressure. During shear, two modes of liquid–solid segregation occur simultaneously. The first is a pattern-forming localisation of the liquid into high-porosity sheets that form at 15–20![]() $^\circ$ to the shear plane (Holtzman et al. Reference Holtzman, Groebner, Zimmerman, Ginsberg and Kohlstedt2003). The sheets are typically measured in their cross-section, where they appear as bands with a characteristic spacing. The second is a radially inward porous flow of liquid, accommodated by a radially outward flow of solid (Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015).

$^\circ$ to the shear plane (Holtzman et al. Reference Holtzman, Groebner, Zimmerman, Ginsberg and Kohlstedt2003). The sheets are typically measured in their cross-section, where they appear as bands with a characteristic spacing. The second is a radially inward porous flow of liquid, accommodated by a radially outward flow of solid (Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015).

A satisfactory physical understanding of these flow phenomena has been elusive, though much has been learned through theoretical analysis. Localisation of the liquid phase into sheets at 45![]() $^\circ$ to the shear plane was predicted by Stevenson (Reference Stevenson1989) and Spiegelman (Reference Spiegelman2003) to be a consequence of a porosity-weakening viscosity of the solid aggregate. Katz, Spiegelman & Holtzman (Reference Katz, Spiegelman and Holtzman2006) and Rudge & Bercovici (Reference Rudge and Bercovici2015) showed that if this viscosity is (effectively) non-Newtonian with a power-law exponent of

$^\circ$ to the shear plane was predicted by Stevenson (Reference Stevenson1989) and Spiegelman (Reference Spiegelman2003) to be a consequence of a porosity-weakening viscosity of the solid aggregate. Katz, Spiegelman & Holtzman (Reference Katz, Spiegelman and Holtzman2006) and Rudge & Bercovici (Reference Rudge and Bercovici2015) showed that if this viscosity is (effectively) non-Newtonian with a power-law exponent of ![]() $\sim$6, the angle is reduced to match the observations. However, this exponent was measured by King et al. (Reference King, Zimmerman and Kohlstedt2010) to be

$\sim$6, the angle is reduced to match the observations. However, this exponent was measured by King et al. (Reference King, Zimmerman and Kohlstedt2010) to be ![]() ${\sim }1.5\pm 0.3$ at 95 % confidence – almost Newtonian. Furthermore, these isotropic theories cannot explain the radial melt segregation in torsion experiments. In contrast, a theory of anisotropic Coble creep with Newtonian viscosity can explain the radial segregation (Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015). This theory was derived by Takei & Holtzman (Reference Takei and Holtzman2009) from grain-scale considerations of anisotropic solid contiguity under deviatoric stress. It predicts that viscous resistance to deformation is reduced in the direction of minimum contiguity. It also predicts the emergence of porosity bands and, if the contiguity tensor aligns with the principal stress directions, that the bands grow fastest at low angles, consistent with experiments (Takei & Katz Reference Takei and Katz2013). However, in laboratory experiments that produce bands, the grain-scale contiguity is misaligned by about 15

${\sim }1.5\pm 0.3$ at 95 % confidence – almost Newtonian. Furthermore, these isotropic theories cannot explain the radial melt segregation in torsion experiments. In contrast, a theory of anisotropic Coble creep with Newtonian viscosity can explain the radial segregation (Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015). This theory was derived by Takei & Holtzman (Reference Takei and Holtzman2009) from grain-scale considerations of anisotropic solid contiguity under deviatoric stress. It predicts that viscous resistance to deformation is reduced in the direction of minimum contiguity. It also predicts the emergence of porosity bands and, if the contiguity tensor aligns with the principal stress directions, that the bands grow fastest at low angles, consistent with experiments (Takei & Katz Reference Takei and Katz2013). However, in laboratory experiments that produce bands, the grain-scale contiguity is misaligned by about 15![]() $^\circ$ (Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015; Qi & Kohlstedt Reference Qi and Kohlstedt2018), which corresponds to a theoretical prediction of high-angle porosity bands (this discrepancy is resolved by better measurement of contiguity, according to Seltzer et al. Reference Seltzer, Peč, Zimmerman and Kohlstedt2023). Nonetheless, viscous anisotropy theory gives rise to an effective dilatancy that we discuss in § 6.1, below.

$^\circ$ (Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015; Qi & Kohlstedt Reference Qi and Kohlstedt2018), which corresponds to a theoretical prediction of high-angle porosity bands (this discrepancy is resolved by better measurement of contiguity, according to Seltzer et al. Reference Seltzer, Peč, Zimmerman and Kohlstedt2023). Nonetheless, viscous anisotropy theory gives rise to an effective dilatancy that we discuss in § 6.1, below.

Another challenge is to explain the characteristic wavelength of the high-porosity bands observed in experiments. All of the theories noted above lack mode selection; instead, they predict the rate of band growth to plateau at decreasing wavelength. Several studies have invoked processes driven by interfacial energy to regularise the growth-rate spectrum. Bercovici & Rudge (Reference Bercovici and Rudge2016) incorporated capillary effects in a diffuse-interface approximation of a sharp porosity interface (Sun & Beckermann Reference Sun and Beckermann2004) – however, sharp interfaces emerge in experiments only long after the onset of instability. Takei & Hier-Majumder (Reference Takei and Hier-Majumder2009) and King, Hier-Majumder & Kohlstedt (Reference King, Hier-Majumder and Kohlstedt2011) hypothesised that variation of surface tension drives dissolution/precipitation reactions. When coupled with chemical diffusion in the melt phase, these reactions damp instability growth at small wavelengths.

The theory of dense granular suspensions, as reviewed by Guazzelli & Pouliquen (Reference Guazzelli and Pouliquen2018), holds promise in providing a simple and unified explanation for all of these observed patterns. A central feature is the anisotropic compressive stress between solid particles caused by shearing flow (Bagnold Reference Bagnold1954). The coupling between shear and compression is the consequence of the microphysical interaction of suspended particles (Brady & Morris Reference Brady and Morris1997). This behaviour is demonstrated empirically in various studies, but Deboeuf et al. (Reference Deboeuf, Gauthier, Martin, Yurkovetsky and Morris2009) provide a particularly fascinating example and discussion. If the suspended solid phase is not rigidly confined, it can undergo a net dilatation due to shear (Reynolds Reference Reynolds1885; Boyer, Guazzelli & Pouliquen Reference Boyer, Guazzelli and Pouliquen2011).

In a suspension contained within a constant volume, net dilatancy is prohibited but the solid fraction can vary internally. Besseling et al. (Reference Besseling, Isa, Ballesta, Petekidis, Cates and Poon2010) shows that shearing, dense suspensions are susceptible to a banding instability; this instability is modelled in terms of a suspension viscosity that increases with solid fraction. Their results run parallel to the theory for band emergence in partially molten rock (Stevenson Reference Stevenson1989) except that in a suspension, the growth rate of bands also depends on the dilatancy. Moreover, Morris & Boulay (Reference Morris and Boulay1999) shows that for suspension flows in cylindrical geometry (i.e. pipe flow, parallel-plate or cone-and-plate torsion), radial segregation of liquid and solid phases is predicted, consistent with experiments. Again, there is a parallel with results for partially molten rock in torsion (Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015; Qi & Kohlstedt Reference Qi and Kohlstedt2018) and pipe-flow (Quintanilla-Terminel et al. Reference Quintanilla-Terminel, Dillman, Pec, Diedrich and Kohlstedt2019) configurations. In all of these flowing suspensions, the dilatancy stress plays a central role.

Another aspect of granular physics that may be relevant here is non-local fluidity (inverse viscosity). This concept was developed in the context of emulsions (e.g. Goyon et al. Reference Goyon, Colin, Ovarlez, Ajdari and Bocquet2008; Bocquet, Colin & Ajdari Reference Bocquet, Colin and Ajdari2009) and adapted to granular suspensions (Kamrin & Koval Reference Kamrin and Koval2012). The theory states that the flow response to stress at a point in the granular medium is sensitive to the fluidity in a neighbourhood around that point. This neighbourhood has a typical size, ![]() $\xi$, of order

$\xi$, of order ![]() $10$ times the grain size and decreasing with the square root of shear stress. Henann & Kamrin (Reference Henann and Kamrin2013) demonstrate that simulated shear zones, forced by a spatial discontinuity in boundary velocity, are regularised by non-local fluidity to a width that is consistent with experiments. Hence, non-local fluidity appears promising in regularising the growth spectrum of shear bands in experiments on partially molten rock.

$10$ times the grain size and decreasing with the square root of shear stress. Henann & Kamrin (Reference Henann and Kamrin2013) demonstrate that simulated shear zones, forced by a spatial discontinuity in boundary velocity, are regularised by non-local fluidity to a width that is consistent with experiments. Hence, non-local fluidity appears promising in regularising the growth spectrum of shear bands in experiments on partially molten rock.

The fundamentally granular nature of partially molten rock and the relevant predictions from theories of dense granular suspensions motivate the present work. Our aims are to develop a theory for partially molten rock that incorporates granular dilatancy and non-local fluidity, and to compare predictions of that theory to the results of laboratory experiments. We note that in doing so, we are applying granular physics at solid fractions above what is typically considered the jamming fraction, at which the solid phase becomes immobile. However, in crystalline materials at high homologous temperatures, grain boundaries behave as a viscous fluid that allows grains to slide past each other (Ashby Reference Ashby1972). In this context, the solid phase can still be mobilized if sufficient shear stress is applied (Heussinger & Barrat Reference Heussinger and Barrat2009). Moreover, in-situ observations of polycrystalline aggregates deforming at high solid fraction show a clear link between grain-boundary sliding and dilatancy (Walte, Bons & Passchier Reference Walte, Bons and Passchier2005; Kareh et al. Reference Kareh, O'Sullivan, Nagira, Yasuda and Gourlay2017). Hence, we assert that although the grains of partially molten rocks are not rigid, they nonetheless undergo grain-boundary sliding that is associated with a compressive intergranular stress and may lead to dilatancy.

Mechanical decreases in solid fraction, including by dilatancy, are here referred to as decompaction. The poro-viscous theory of partially molten rock relates the decompaction rate to the pressure difference between the liquid and solid phases in a viscous constitutive law (McKenzie Reference McKenzie1984). This approach differs from suspension theory, in which the solid phase exerts zero resistance to changes in solid fraction (Guazzelli & Morris Reference Guazzelli and Morris2011). It also differs from theories for dry granular media, where the solid fraction is a decreasing function of the shear-strain rate (Forterre & Pouliquen Reference Forterre and Pouliquen2008), and from soil mechanics, where the solid fraction is predicted to evolve toward a critical state as a function of the total strain (Oda & Iwashita Reference Oda and Iwashita2020). However, it seems that these isotropic dynamics may be incompletely understood. For example, Kabla & Senden (Reference Kabla and Senden2009) found empirical evidence that dilatancy and shear-independent compaction compete in the evolution of solid fraction. By combining poro-viscous decompaction with dilatancy stress, our theory may provide new insight in this regard.

Previous authors have incorporated granular dilatancy into discussions and models of geological materials, going back at least to Mead (Reference Mead1925). It has been invoked in crystal-rich deforming magma (e.g. Smith Reference Smith1997; Petford, Koenders & Clemens Reference Petford, Koenders and Clemens2020), in lower-crustal shear zones (Menegon et al. Reference Menegon, Fusseis, Stünitz and Xiao2015) and in gouge-filled fault zones (e.g. Marone, Raleigh & Scholz Reference Marone, Raleigh and Scholz1990; Segall et al. Reference Segall, Rubin, Bradley and Rice2010). Dilatation has been considered in competition with compaction (Paterson Reference Paterson2001; Niemeijer & Spiers Reference Niemeijer and Spiers2007) and as a microphysical mechanism responsible for rate-and-state friction (Chen & Spiers Reference Chen and Spiers2016). It may play a role in regulating glacial sliding (Warburton, Hewitt & Neufeld Reference Warburton, Hewitt and Neufeld2023) and in a range of geomorphological processes (Jerolmack & Daniels Reference Jerolmack and Daniels2019). Dilatation is associated with Riedel shear zones (e.g. Dresen Reference Dresen1991; Bedford & Faulkner Reference Bedford and Faulkner2021), which appear at the same angle as bands in partially molten rock. It might be expected that partially molten rock shares certain behaviours with other granular, geological materials. In the present work we find that incorporation of granular dilatancy and non-local fluidity brings predictions of a poro-viscous compaction theory into quantitative agreement with experimental results.

The paper is organised as follows. In § 2 we review torsion experiments on partially molten rocks and highlight their key results. We present our rheological model in § 3. Then, in § 4 we provide the governing equations and analyse them in terms of radial segregation and band formation. This analysis is followed by quantitative comparison with experiments in § 5 and a discussion in § 6.

2. Laboratory experiments and key observations

Previously described laboratory experiments provide a motivation and context for testing the theory developed here. We focus on experiments conducted on partially molten rock, typically synthesized from mixtures of ![]() $\sim$95 % olivine grains and

$\sim$95 % olivine grains and ![]() $\sim$5 % mid-ocean ridge basalt, sometimes with a small percentage of chromite (e.g. Holtzman et al. Reference Holtzman, Groebner, Zimmerman, Ginsberg and Kohlstedt2003; King et al. Reference King, Zimmerman and Kohlstedt2010; Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015). The olivine grains are polydisperse, typically with a mean diameter of

$\sim$5 % mid-ocean ridge basalt, sometimes with a small percentage of chromite (e.g. Holtzman et al. Reference Holtzman, Groebner, Zimmerman, Ginsberg and Kohlstedt2003; King et al. Reference King, Zimmerman and Kohlstedt2010; Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015). The olivine grains are polydisperse, typically with a mean diameter of ![]() $\sim$10

$\sim$10 ![]() $\mathrm {\mu }$m. Samples are hydrostatically hot pressed to remove gas-filled bubbles prior to deformation. After hot pressing, they have a nominally uniform melt fraction,

$\mathrm {\mu }$m. Samples are hydrostatically hot pressed to remove gas-filled bubbles prior to deformation. After hot pressing, they have a nominally uniform melt fraction, ![]() $\phi _0$.

$\phi _0$.

The experiments are conducted in a gas-medium, triaxial-deformation apparatus (Paterson Reference Paterson1990) with a confining pressure of 300 MPa and temperatures of ![]() ${\sim }1225\,^\circ$C. The samples are jacketed to separate them from the confining gas. Under these conditions, the basalt is molten and the olivine (and chromite) grains are solid. Torsional deformation is imposed on the sample, although some experiments have also been conducted in direct shear (Holtzman et al. Reference Holtzman, Groebner, Zimmerman, Ginsberg and Kohlstedt2003; Holtzman & Kohlstedt Reference Holtzman and Kohlstedt2007). The distribution of porosity within the sample is not measured in situ. Rather, the experiment is quenched, sectioned and imaged at high resolution to calculate the porosity field.

${\sim }1225\,^\circ$C. The samples are jacketed to separate them from the confining gas. Under these conditions, the basalt is molten and the olivine (and chromite) grains are solid. Torsional deformation is imposed on the sample, although some experiments have also been conducted in direct shear (Holtzman et al. Reference Holtzman, Groebner, Zimmerman, Ginsberg and Kohlstedt2003; Holtzman & Kohlstedt Reference Holtzman and Kohlstedt2007). The distribution of porosity within the sample is not measured in situ. Rather, the experiment is quenched, sectioned and imaged at high resolution to calculate the porosity field.

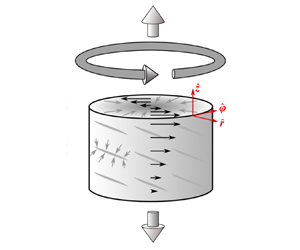

The essential characteristics of these torsional experiments are outlined in figure 1(a). Cylindrical samples with height ![]() $H$ and outer radius

$H$ and outer radius ![]() $R$ are deformed by a circular plate that turns with angular velocity

$R$ are deformed by a circular plate that turns with angular velocity ![]() $\dot {\varOmega }\hat {\boldsymbol {z}}$ about the axis of the cylinder. At low strains, when the sample remains nominally uniform, the imposed twist induces an azimuthal velocity field

$\dot {\varOmega }\hat {\boldsymbol {z}}$ about the axis of the cylinder. At low strains, when the sample remains nominally uniform, the imposed twist induces an azimuthal velocity field ![]() $U(r,z)\hat {\boldsymbol {\varphi }}$ that is axisymmetric. The velocity component

$U(r,z)\hat {\boldsymbol {\varphi }}$ that is axisymmetric. The velocity component ![]() $U$ increases linearly in the

$U$ increases linearly in the ![]() $\hat {\boldsymbol {z}}$ and

$\hat {\boldsymbol {z}}$ and ![]() $\hat {\boldsymbol {r}}$ directions. On cylindrical surfaces, the deformation is approximately that of simple shear; the magnitude of the shear strain (and its rate) increase from zero at the twist axis to a maximum value at the outer boundary of the sample.

$\hat {\boldsymbol {r}}$ directions. On cylindrical surfaces, the deformation is approximately that of simple shear; the magnitude of the shear strain (and its rate) increase from zero at the twist axis to a maximum value at the outer boundary of the sample.

Figure 1. Experimental configuration and representative results. (a) Schematic diagram of a deforming experimental sample and the emergent patterns of melt segregation. Experiments are conducted at high confining pressure and high temperature. After achieving a specified twist, the sample is quenched, sectioned and polished to reveal the distribution of melt (solidified to glass) and crystalline, granular solid. (b) A tangential section showing high-porosity bands (black) at low angle to the shear plane (![]() $\phi _0=0.04, \gamma =1.5$; King et al. Reference King, Zimmerman and Kohlstedt2010). (c) A transverse section showing radially inward migration of melt (

$\phi _0=0.04, \gamma =1.5$; King et al. Reference King, Zimmerman and Kohlstedt2010). (c) A transverse section showing radially inward migration of melt (![]() $\phi _0=0.10, \gamma =5.0$; Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015). Cracks visible in (b) and (c) are a consequence of the rapid quench and decompression after deformation.

$\phi _0=0.10, \gamma =5.0$; Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015). Cracks visible in (b) and (c) are a consequence of the rapid quench and decompression after deformation.

The outer boundary of the sample is sealed in an impermeable, nickel jacket. The radial normal stress at the jacket is maintained constant by the confining gas pressure. At the temperatures of the experiments, the viscosity of nickel is greater than that of the basaltic liquid and less than the granular olivine aggregate. This viscosity contrast enables the jacket to shear with negligible resistance, but discourages its intrusion into the pore space of the sample. Hence, its effect on the sample falls somewhere between two limiting cases. In one limit, the jacket inhibits all radial flow at the boundary by isolating the volume of the sample. In the other limit, it transmits the full confining pressure into the pore space between olivine grains. There is empirical evidence that the reality is closer to the first of these limits, but the details have not been measured or quantified.

Two critical observations have arisen from torsion experiments on partially molten rocks. The first is the emergence of high-porosity sheets separated by compacted, low-porosity lenses after a shear strain of ![]() $\gamma \sim 1$ (Holtzman et al. Reference Holtzman, Groebner, Zimmerman, Ginsberg and Kohlstedt2003). These sheets are usually measured in cross-section, as in figure 1(b), and hence, referred to as bands. They have a characteristic spacing and form at 15–20

$\gamma \sim 1$ (Holtzman et al. Reference Holtzman, Groebner, Zimmerman, Ginsberg and Kohlstedt2003). These sheets are usually measured in cross-section, as in figure 1(b), and hence, referred to as bands. They have a characteristic spacing and form at 15–20![]() $^\circ$ to the shear plane (Holtzman & Kohlstedt Reference Holtzman and Kohlstedt2007). This angle is similar to that of Riedel shear zones (Dresen Reference Dresen1991), but significantly lower than what would be expected if the bands were normal to the direction of maximum tension (45

$^\circ$ to the shear plane (Holtzman & Kohlstedt Reference Holtzman and Kohlstedt2007). This angle is similar to that of Riedel shear zones (Dresen Reference Dresen1991), but significantly lower than what would be expected if the bands were normal to the direction of maximum tension (45![]() $^\circ$). Furthermore, individual bands are embedded in a nominally simple-shear flow and, hence, with time, they are rotated to higher angles. However, despite this necessary rotation, the band-angle distribution remains roughly unchanged with increasing strain (King et al. Reference King, Zimmerman and Kohlstedt2010).

$^\circ$). Furthermore, individual bands are embedded in a nominally simple-shear flow and, hence, with time, they are rotated to higher angles. However, despite this necessary rotation, the band-angle distribution remains roughly unchanged with increasing strain (King et al. Reference King, Zimmerman and Kohlstedt2010).

The second critical observation is that with progressive twist, liquid melt segregates from the solid grains and migrates toward the centre of the cylinder (Qi & Kohlstedt Reference Qi and Kohlstedt2018). This migration leads to azimuthally averaged porosity, measured over the transverse section shown in figure 1(c), that decreases with radius. Experiments to increasing values of total twist (reported as shear strain ![]() $\gamma$ at the outer radius) exhibit greater segregation and a steeper radial porosity gradient (Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015).

$\gamma$ at the outer radius) exhibit greater segregation and a steeper radial porosity gradient (Qi et al. Reference Qi, Kohlstedt, Katz and Takei2015).

The present study aims to explain these observations in terms of the physics of dense granular suspensions.

3. Rheological model

Our rheological model of a two-phase aggregate, comprising a contiguous matrix of solid grains and its melt-saturated, permeable pore space, is based on the poro-viscous theory derived by McKenzie (Reference McKenzie1984) and reviewed by Katz (Reference Katz2022). The melt is present with volume fraction ![]() $\phi$ (the porosity) that varies in space and time. This variation is accommodated by (de)compaction of the solid matrix, but both phases are incompressible. To incorporate dilatancy effects, we take inspiration from theories of suspensions (Brady & Morris Reference Brady and Morris1997; Fang et al. Reference Fang, Mammoli, Brady, Ingber, Mondy and Graham2002; Guazzelli & Pouliquen Reference Guazzelli and Pouliquen2018) and append a term that hypothetically quantifies the normal stresses generated by grain–grain interactions during shearing flow. The constitutive law for the effective stress is then

$\phi$ (the porosity) that varies in space and time. This variation is accommodated by (de)compaction of the solid matrix, but both phases are incompressible. To incorporate dilatancy effects, we take inspiration from theories of suspensions (Brady & Morris Reference Brady and Morris1997; Fang et al. Reference Fang, Mammoli, Brady, Ingber, Mondy and Graham2002; Guazzelli & Pouliquen Reference Guazzelli and Pouliquen2018) and append a term that hypothetically quantifies the normal stresses generated by grain–grain interactions during shearing flow. The constitutive law for the effective stress is then

where ![]() $\zeta _\phi$,

$\zeta _\phi$, ![]() $\eta _\phi$ and

$\eta _\phi$ and ![]() $D_\phi$ are dynamic viscosities for isotropic, deviatoric and dilatational deformation, respectively,

$D_\phi$ are dynamic viscosities for isotropic, deviatoric and dilatational deformation, respectively, ![]() $\boldsymbol {I}$ is the identity tensor, and where

$\boldsymbol {I}$ is the identity tensor, and where

\begin{equation} \mathcal{C} \equiv \boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{v}^s,\quad \dot{\boldsymbol{\varepsilon}} \equiv \frac{1}{2}\left[\boldsymbol{\nabla}\boldsymbol{v}^s + (\boldsymbol{\nabla}\boldsymbol{v}^s)^T - \frac{2}{3}\mathcal{C}\boldsymbol{I}\right]\!,\quad \boldsymbol{\varLambda}\equiv \left(\begin{array}{@{}ccc@{}} 1 & 0 & 0 \\ 0 & \varLambda_\perp & 0 \\ 0 & 0 & \varLambda_\times \end{array}\right)\!, \end{equation}

\begin{equation} \mathcal{C} \equiv \boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{v}^s,\quad \dot{\boldsymbol{\varepsilon}} \equiv \frac{1}{2}\left[\boldsymbol{\nabla}\boldsymbol{v}^s + (\boldsymbol{\nabla}\boldsymbol{v}^s)^T - \frac{2}{3}\mathcal{C}\boldsymbol{I}\right]\!,\quad \boldsymbol{\varLambda}\equiv \left(\begin{array}{@{}ccc@{}} 1 & 0 & 0 \\ 0 & \varLambda_\perp & 0 \\ 0 & 0 & \varLambda_\times \end{array}\right)\!, \end{equation}

are the decompaction rate, deviatoric strain-rate tensor and particle-stress anisotropy tensor, respectively. We have introduced ![]() $\boldsymbol {v}^s$, the solid velocity field, and

$\boldsymbol {v}^s$, the solid velocity field, and ![]() $\dot {\varepsilon }_{II} \equiv \sqrt {\dot {\boldsymbol {\varepsilon }}:\dot {\boldsymbol {\varepsilon }}/2}$ is the second invariant of the deviatoric strain-rate tensor. Deboeuf et al. (Reference Deboeuf, Gauthier, Martin, Yurkovetsky and Morris2009) provides theoretical context, insightful commentary and empirical justification for the dilatancy term in (3.1).

$\dot {\varepsilon }_{II} \equiv \sqrt {\dot {\boldsymbol {\varepsilon }}:\dot {\boldsymbol {\varepsilon }}/2}$ is the second invariant of the deviatoric strain-rate tensor. Deboeuf et al. (Reference Deboeuf, Gauthier, Martin, Yurkovetsky and Morris2009) provides theoretical context, insightful commentary and empirical justification for the dilatancy term in (3.1).

The particle-stress anisotropy tensor ![]() $\boldsymbol {\varLambda }$ is used to model the normal stresses generated by a particle-laden flow that is locally approximated as simple shear (Guazzelli & Morris Reference Guazzelli and Morris2011; Guazzelli & Pouliquen Reference Guazzelli and Pouliquen2018). It is written with reference to a coordinate system aligned with the simple shear. The

$\boldsymbol {\varLambda }$ is used to model the normal stresses generated by a particle-laden flow that is locally approximated as simple shear (Guazzelli & Morris Reference Guazzelli and Morris2011; Guazzelli & Pouliquen Reference Guazzelli and Pouliquen2018). It is written with reference to a coordinate system aligned with the simple shear. The ![]() $\varLambda _{11}$ direction is taken to be the direction of flow (indicated by

$\varLambda _{11}$ direction is taken to be the direction of flow (indicated by ![]() $\parallel$); the

$\parallel$); the ![]() $\varLambda _{22}$ direction is normal to the shear plane (hence, we denote it

$\varLambda _{22}$ direction is normal to the shear plane (hence, we denote it ![]() $\varLambda _\perp$); the

$\varLambda _\perp$); the ![]() $\varLambda _{33}$ direction is the direction of the vorticity vector (and, hence, denoted

$\varLambda _{33}$ direction is the direction of the vorticity vector (and, hence, denoted ![]() $\varLambda _\times$). The

$\varLambda _\times$). The ![]() $\varLambda _{11}$ entry is factored out and lumped with

$\varLambda _{11}$ entry is factored out and lumped with ![]() $D_\phi$. Therefore,

$D_\phi$. Therefore, ![]() $\varLambda _\perp$ and

$\varLambda _\perp$ and ![]() $\varLambda _\times$ are dimensionless particle-normal-stress ratios. Previous work has shown that the values of these parameters may be constrained by comparison of model predictions with carefully designed experiments (Morris & Boulay Reference Morris and Boulay1999; Fang et al. Reference Fang, Mammoli, Brady, Ingber, Mondy and Graham2002; Guazzelli & Pouliquen Reference Guazzelli and Pouliquen2018). In the flow geometries considered below (Cartesian or cylindrical), the particle-stress anisotropy tensor can be straightforwardly aligned with the experimental deformation geometry; in general, it must be aligned with respect to the principal axes of the flow (Miller, Singh & Morris Reference Miller, Singh and Morris2009).

$\varLambda _\times$ are dimensionless particle-normal-stress ratios. Previous work has shown that the values of these parameters may be constrained by comparison of model predictions with carefully designed experiments (Morris & Boulay Reference Morris and Boulay1999; Fang et al. Reference Fang, Mammoli, Brady, Ingber, Mondy and Graham2002; Guazzelli & Pouliquen Reference Guazzelli and Pouliquen2018). In the flow geometries considered below (Cartesian or cylindrical), the particle-stress anisotropy tensor can be straightforwardly aligned with the experimental deformation geometry; in general, it must be aligned with respect to the principal axes of the flow (Miller, Singh & Morris Reference Miller, Singh and Morris2009).

The isotropic part of the effective stress is where dilatancy modifies the physics. We see this by taking ![]() $-1/3$ the trace of the effective stress tensor in (3.1),

$-1/3$ the trace of the effective stress tensor in (3.1),

where ![]() $P^j = -\text {tr}\left (\boldsymbol {\sigma }^j\right )/3$ is the pressure of phase

$P^j = -\text {tr}\left (\boldsymbol {\sigma }^j\right )/3$ is the pressure of phase ![]() $j$. This equation states that the shear-strain rate has two possible consequences for isotropic deformation. If

$j$. This equation states that the shear-strain rate has two possible consequences for isotropic deformation. If ![]() $\zeta _\phi =0$, there is no viscous resistance to compaction and shear generates a positive effective pressure. This is equivalent to suspension theory (e.g. Deboeuf et al. Reference Deboeuf, Gauthier, Martin, Yurkovetsky and Morris2009). If, in contrast, there is zero effective pressure (

$\zeta _\phi =0$, there is no viscous resistance to compaction and shear generates a positive effective pressure. This is equivalent to suspension theory (e.g. Deboeuf et al. Reference Deboeuf, Gauthier, Martin, Yurkovetsky and Morris2009). If, in contrast, there is zero effective pressure (![]() ${\rm \Delta} P=0$), then shear causes dilatation. This has a parallel in soil mechanics, where the dilatancy angle

${\rm \Delta} P=0$), then shear causes dilatation. This has a parallel in soil mechanics, where the dilatancy angle ![]() $\psi$ gives the kinematic relationship between shear strain and dilatation (e.g. Oda & Iwashita Reference Oda and Iwashita2020). In the present context, we can compute the dilatancy angle as

$\psi$ gives the kinematic relationship between shear strain and dilatation (e.g. Oda & Iwashita Reference Oda and Iwashita2020). In the present context, we can compute the dilatancy angle as ![]() $\tan \psi \equiv D_\phi \text {tr}\left (\boldsymbol {\varLambda }\right )/3\zeta _\phi$. The more general case, of interest here, is where both the effective pressure and the compaction viscosity are non-zero.

$\tan \psi \equiv D_\phi \text {tr}\left (\boldsymbol {\varLambda }\right )/3\zeta _\phi$. The more general case, of interest here, is where both the effective pressure and the compaction viscosity are non-zero.

To complete the rheological model, we require expressions for the dependency of the three viscosities on melt fraction ![]() $\phi$. Empirical constraints and theoretical models of the shear viscosity

$\phi$. Empirical constraints and theoretical models of the shear viscosity ![]() $\eta _\phi$ and compaction viscosity

$\eta _\phi$ and compaction viscosity ![]() $\zeta _\phi$ are summarised by Katz et al. (Reference Katz, Rees Jones, Rudge and Keller2022). Shear viscosity has been measured over a range of melt fractions; Kelemen et al. (Reference Kelemen, Hirth, Shimizu, Spiegelman and Dick1997) showed that it is well described by an exponential decrease with liquid fraction

$\zeta _\phi$ are summarised by Katz et al. (Reference Katz, Rees Jones, Rudge and Keller2022). Shear viscosity has been measured over a range of melt fractions; Kelemen et al. (Reference Kelemen, Hirth, Shimizu, Spiegelman and Dick1997) showed that it is well described by an exponential decrease with liquid fraction ![]() $\phi$. Theory for Coble creep, where compaction is accommodated by diffusion of grain mass along grain boundaries and through the melt-filled pores, indicates that the compaction viscosity is a multiple of

$\phi$. Theory for Coble creep, where compaction is accommodated by diffusion of grain mass along grain boundaries and through the melt-filled pores, indicates that the compaction viscosity is a multiple of ![]() $\sim$5/3 larger than the shear viscosity (Takei & Holtzman Reference Takei and Holtzman2009; Rudge Reference Rudge2018). There are no empirical measurements of the dilitation viscosity

$\sim$5/3 larger than the shear viscosity (Takei & Holtzman Reference Takei and Holtzman2009; Rudge Reference Rudge2018). There are no empirical measurements of the dilitation viscosity ![]() $D_\phi$ of partially molten rock, nor are there are microstructural models. Experiments on particle suspensions by Deboeuf et al. (Reference Deboeuf, Gauthier, Martin, Yurkovetsky and Morris2009) show an exponential weakening of particle normal stress with liquid fraction. On this basis, and for simplicity in the absence of further information, we take

$D_\phi$ of partially molten rock, nor are there are microstructural models. Experiments on particle suspensions by Deboeuf et al. (Reference Deboeuf, Gauthier, Martin, Yurkovetsky and Morris2009) show an exponential weakening of particle normal stress with liquid fraction. On this basis, and for simplicity in the absence of further information, we take ![]() $D_\phi$ to be an unknown multiple of

$D_\phi$ to be an unknown multiple of ![]() $\eta _\phi$. Hence, the viscosities are given by

$\eta _\phi$. Hence, the viscosities are given by

where ![]() $\eta _0$ is a reference value of shear viscosity at reference melt fraction

$\eta _0$ is a reference value of shear viscosity at reference melt fraction ![]() $\phi _0$,

$\phi _0$, ![]() $\lambda \approx 27$ is the porosity-weakening factor and

$\lambda \approx 27$ is the porosity-weakening factor and ![]() $D_0$ is an unknown, dimensionless constant.

$D_0$ is an unknown, dimensionless constant.

We obtain a constraint on ![]() $D_0$ by requiring positive entropy production under any combination of shear and isotropic deformation. The dissipation-rate density arising from (3.1) is

$D_0$ by requiring positive entropy production under any combination of shear and isotropic deformation. The dissipation-rate density arising from (3.1) is

where ![]() $\dot {\varepsilon }_\parallel, \dot {\varepsilon }_\perp, \dot {\varepsilon }_\times$ are the normal components of the strain-rate tensor in a coordinate system aligned with simple shear. Assuming isotropic dilatancy

$\dot {\varepsilon }_\parallel, \dot {\varepsilon }_\perp, \dot {\varepsilon }_\times$ are the normal components of the strain-rate tensor in a coordinate system aligned with simple shear. Assuming isotropic dilatancy ![]() $\boldsymbol {\varLambda } = \boldsymbol {I}$, (3.5) becomes

$\boldsymbol {\varLambda } = \boldsymbol {I}$, (3.5) becomes ![]() $\varPsi = \zeta _\phi \mathcal {C}^2 + 4\eta _\phi \dot {\varepsilon }_{II}^2 - D_\phi \dot {\varepsilon }_{II}\mathcal {C}$, and into this we substitute the viscosities of (3.4a–c). We find that

$\varPsi = \zeta _\phi \mathcal {C}^2 + 4\eta _\phi \dot {\varepsilon }_{II}^2 - D_\phi \dot {\varepsilon }_{II}\mathcal {C}$, and into this we substitute the viscosities of (3.4a–c). We find that ![]() $\varPsi$ is positive definite if

$\varPsi$ is positive definite if ![]() $0 \le D_0 < 4\sqrt {5/3} \approx 5$ and, therefore, limit consideration to values of

$0 \le D_0 < 4\sqrt {5/3} \approx 5$ and, therefore, limit consideration to values of ![]() $D_0$ within this range.

$D_0$ within this range.

Finally, in combining our rheological model with conservation equations governing the flow, we consider the granular physics discussed by Kamrin & Koval (Reference Kamrin and Koval2012), which adopts a model for emulsions by Goyon et al. (Reference Goyon, Colin, Ovarlez, Ajdari and Bocquet2008). They show that macroscopic, irreversible shear is accommodated by grain-rearrangement events at the microscopic scale. In partially molten rock, geometric compatibility of the grain packing dictates that grains cannot rotate freely; their rotations must be compatible with those of neighbouring grains (Rudge Reference Rudge2021). Hence, deformation is necessarily dispersed by grain–grain interaction during rearrangement events. This non-local interaction means that the viscosity at a point in the medium is influenced by the viscosity at points within a distance ![]() $\xi$, known as the cooperativity length. Kamrin & Koval (Reference Kamrin and Koval2012) express this interaction in terms of a non-local fluidity – the inverse of the non-local shear viscosity

$\xi$, known as the cooperativity length. Kamrin & Koval (Reference Kamrin and Koval2012) express this interaction in terms of a non-local fluidity – the inverse of the non-local shear viscosity ![]() $\tilde {\eta }_\phi$. We rewrite their fluidity equation in terms of a non-local viscosity,

$\tilde {\eta }_\phi$. We rewrite their fluidity equation in terms of a non-local viscosity,

Evidently, if ![]() $\xi =0$ then the non-local viscosity reduces to

$\xi =0$ then the non-local viscosity reduces to ![]() $\eta _\phi$. For

$\eta _\phi$. For ![]() $\xi >0$, this equation imposes a minimum scale of viscosity variation. Goyon et al. (Reference Goyon, Colin, Ovarlez, Ajdari and Bocquet2008) measure

$\xi >0$, this equation imposes a minimum scale of viscosity variation. Goyon et al. (Reference Goyon, Colin, Ovarlez, Ajdari and Bocquet2008) measure ![]() $\xi$ as a function of

$\xi$ as a function of ![]() $1-\phi$ and find that it increases to about 5 times the grain diameter at a solid fraction of 85 %. We shall see below in § 4.2 that

$1-\phi$ and find that it increases to about 5 times the grain diameter at a solid fraction of 85 %. We shall see below in § 4.2 that ![]() $\xi >0$ serves to regularise the spectrum of instability growth.

$\xi >0$ serves to regularise the spectrum of instability growth.

4. Analysis

To explore the consequences of the hypothesised rheological model, we adopt the formulation of mass and momentum conservation for a partially molten rock deforming at zero Reynolds number (McKenzie Reference McKenzie1984). We make a Boussinesq approximation, taking density as constant for both phases, assume zero mass transfer between phases and neglect gravitational body forces on the basis that they are much weaker than the shear tractions imposed in experiments. With these assumptions, the phase densities vanish from the equations. The coupled system of conservation equations becomes

The first, known as the compaction equation, is obtained from Darcy's law by eliminating the liquid velocity using the two-phase continuity equation. It includes the fluid mobility ![]() $M_\phi = M_0 (\phi /\phi _0)^n$, which represents the ratio of the porosity-dependent permeability and the constant liquid viscosity. The second equation is a statement of force balance in the two-phase aggregate. The third equation is mass conservation for the solid phase (porosity is transported by the solid velocity). These equations are standard (Katz Reference Katz2022), except for two modifications. The first modification is use of the non-local viscosity

$M_\phi = M_0 (\phi /\phi _0)^n$, which represents the ratio of the porosity-dependent permeability and the constant liquid viscosity. The second equation is a statement of force balance in the two-phase aggregate. The third equation is mass conservation for the solid phase (porosity is transported by the solid velocity). These equations are standard (Katz Reference Katz2022), except for two modifications. The first modification is use of the non-local viscosity ![]() $\tilde {\eta }_\phi$ in (4.1b), which couples it to (3.6) governing the non-local viscosity. For consistency, we use the non-local viscosity in (3.4a–c) to compute non-local compaction

$\tilde {\eta }_\phi$ in (4.1b), which couples it to (3.6) governing the non-local viscosity. For consistency, we use the non-local viscosity in (3.4a–c) to compute non-local compaction ![]() $\tilde {\zeta }_\phi$ and dilitation

$\tilde {\zeta }_\phi$ and dilitation ![]() $\tilde {D}_\phi$ viscosities. The second modification is the last term on the right-hand side of (4.1b), which captures the hypothesised dilatancy effects. The classical model is recovered for

$\tilde {D}_\phi$ viscosities. The second modification is the last term on the right-hand side of (4.1b), which captures the hypothesised dilatancy effects. The classical model is recovered for ![]() ${\xi,D_0\to 0}$.

${\xi,D_0\to 0}$.

In the subsections below, we investigate the consequences of these two modifications. We do so in the context of torsional deformation and boundary conditions that mimic the laboratory experiments described in § 2.

4.1. Radial segregation in parallel-plate torsion

Torsional flow embeds simple shear into a cylindrical geometry with the potential for hoop stress. The experiments described in § 2 demonstrate that parallel-plate torsional flow drives solid radially outward and liquid radially inward. This phenomenon is consistent with the behaviour of dense suspensions undergoing parallel-plate torsional flow (Merhi et al. Reference Merhi, Lemaire, Bossis and Moukalled2005) but in contrast to the Poiseuille flow of Appendix D. We consider cone-and-plate torsional flow (where the plates are not parallel) in Appendix C.

To understand the radially outward transport of solid grains in terms of dilatancy and particle-stress anisotropy, we work in a cylindrical geometry with coordinates (![]() $r,\varphi,z$), as shown in figure 1(a). We consider a cylinder of partially molten rock with outer radius

$r,\varphi,z$), as shown in figure 1(a). We consider a cylinder of partially molten rock with outer radius ![]() $R$, azimuthal symmetry in

$R$, azimuthal symmetry in ![]() $\varphi$ and, instantaneously at

$\varphi$ and, instantaneously at ![]() $t=0$, with uniform porosity

$t=0$, with uniform porosity ![]() $\phi _0$. At this instant, the solid flow is assumed to have zero

$\phi _0$. At this instant, the solid flow is assumed to have zero ![]() $\hat {\boldsymbol {z}}$ component, a fixed azimuthal component and an unknown radial component. This flow is described by

$\hat {\boldsymbol {z}}$ component, a fixed azimuthal component and an unknown radial component. This flow is described by

\begin{equation} \boldsymbol{v}^s = V\hat{\boldsymbol{r}} + \frac{\dot{\varOmega}\,r z}{H}\hat{\boldsymbol{\varphi}}, \quad\mathcal{C}=\frac{1}{r}\frac{\partial{}}{\partial{r}}rV,\quad\dot{\boldsymbol{\varepsilon}} = \left(\begin{array}{@{}ccc@{}} \displaystyle \dfrac{\partial{V}}{\partial{r}} - \dfrac{\mathcal{C}}{3} & 0 & 0 \\ 0 & \dfrac{V}{r} - \dfrac{\mathcal{C}}{3} & \dfrac{\dot{\varOmega r}}{2H} \\ 0 & \dfrac{\dot{\varOmega r}}{2H} & -\dfrac{\mathcal{C}}{3} \end{array}\right)\!, \end{equation}

\begin{equation} \boldsymbol{v}^s = V\hat{\boldsymbol{r}} + \frac{\dot{\varOmega}\,r z}{H}\hat{\boldsymbol{\varphi}}, \quad\mathcal{C}=\frac{1}{r}\frac{\partial{}}{\partial{r}}rV,\quad\dot{\boldsymbol{\varepsilon}} = \left(\begin{array}{@{}ccc@{}} \displaystyle \dfrac{\partial{V}}{\partial{r}} - \dfrac{\mathcal{C}}{3} & 0 & 0 \\ 0 & \dfrac{V}{r} - \dfrac{\mathcal{C}}{3} & \dfrac{\dot{\varOmega r}}{2H} \\ 0 & \dfrac{\dot{\varOmega r}}{2H} & -\dfrac{\mathcal{C}}{3} \end{array}\right)\!, \end{equation}

where ![]() $V(r)$ is the unknown radial component of the solid velocity field,

$V(r)$ is the unknown radial component of the solid velocity field, ![]() $\dot {\varOmega }$ is the constant twist rate and

$\dot {\varOmega }$ is the constant twist rate and ![]() $H$ is the uniform gap between the parallel plates. We linearise the strain-rate intensity under the assumption that dilatancy is driven by the forced shear such that

$H$ is the uniform gap between the parallel plates. We linearise the strain-rate intensity under the assumption that dilatancy is driven by the forced shear such that

This choice eliminates a feedback whereby the anisotropic part of the dilatancy drives additional dilatancy. While it may be physically reasonable, it will reduce the predicted dilatancy at a given value of ![]() $D_0$ relative to the case where the feedback is included.

$D_0$ relative to the case where the feedback is included.

We use ![]() $\dot {\varepsilon }_{II}$ in the radial component of force-balance equation (4.1b) to write

$\dot {\varepsilon }_{II}$ in the radial component of force-balance equation (4.1b) to write

We then combine this with the compaction equation (4.1a) to eliminate the liquid pressure and integrate once. Rescaling ![]() $r$ with the outer radius

$r$ with the outer radius ![]() $R$ and

$R$ and ![]() $V$ with the characteristic scale

$V$ with the characteristic scale

we obtain the dimensionless equation

Here we have introduced

the ratio of the compaction length to the outer radius. The compaction length is an emergent length scale over which perturbations to the solid–liquid pressure difference are relaxed by decompaction (McKenzie Reference McKenzie1984; Spiegelman Reference Spiegelman1993; Katz Reference Katz2022).

The normal-stress difference on the right-hand side of (4.6) arises from the particle-stress anisotropy tensor ![]() $\boldsymbol {\varLambda }$, with the coordinates aligned such that the flow direction is

$\boldsymbol {\varLambda }$, with the coordinates aligned such that the flow direction is ![]() $\hat {\boldsymbol {\varphi }}$ and the vorticity direction is

$\hat {\boldsymbol {\varphi }}$ and the vorticity direction is ![]() $\hat {\boldsymbol {r}}$. The boundary condition at the centre of the cylinder is

$\hat {\boldsymbol {r}}$. The boundary condition at the centre of the cylinder is ![]() $V(0)=0$. With this constraint, (4.6) admits the solution

$V(0)=0$. With this constraint, (4.6) admits the solution

where ![]() $I_n(z)$ is the modified Bessel function of the first kind,

$I_n(z)$ is the modified Bessel function of the first kind, ![]() $L_n(z)$ is the modified Struve function and

$L_n(z)$ is the modified Struve function and ![]() $A$ is a constant to be determined by matching the boundary condition at the dimensionless outer radius

$A$ is a constant to be determined by matching the boundary condition at the dimensionless outer radius ![]() $r=1$. Two end-member cases can be considered for this outer boundary condition.

$r=1$. Two end-member cases can be considered for this outer boundary condition.

4.1.1. Outer boundary condition: no normal flow

In this case, a rigid outer cylinder requires that at ![]() $r=R$, the radial component of velocity is

$r=R$, the radial component of velocity is ![]() $V(R)=0$. Then the analytical solution to dimensionless equation (4.6) is

$V(R)=0$. Then the analytical solution to dimensionless equation (4.6) is

This result demonstrates that the sign of ![]() $V(r)$ is determined by the size of

$V(r)$ is determined by the size of ![]() $\varLambda _\times$. In figure 2(a) we have chosen

$\varLambda _\times$. In figure 2(a) we have chosen ![]() $\varLambda _\times = 0.45$ such that

$\varLambda _\times = 0.45$ such that ![]() $V(r)>0$. This choice is qualitatively consistent with experimental results (§ 2) where the solid is observed to move outward with progressive twist. Evidently, for the outer boundary condition

$V(r)>0$. This choice is qualitatively consistent with experimental results (§ 2) where the solid is observed to move outward with progressive twist. Evidently, for the outer boundary condition ![]() $V(1)=0$, any choice of

$V(1)=0$, any choice of ![]() $\varLambda _\times$ satisfying

$\varLambda _\times$ satisfying

is also qualitatively consistent. For this range of ![]() $\varLambda _\times$, the hoop stress generated by dilatancy in the flow direction is stronger than the dilatant normal stress in the radial (vorticity) direction. As noted by Takei & Katz (Reference Takei and Katz2013), a compressive hoop stress drives solid radially outward.

$\varLambda _\times$, the hoop stress generated by dilatancy in the flow direction is stronger than the dilatant normal stress in the radial (vorticity) direction. As noted by Takei & Katz (Reference Takei and Katz2013), a compressive hoop stress drives solid radially outward.

Figure 2. Parallel-plate torsion flow at ![]() $t=0$. Non-dimensional solutions of (4.6) with uniform

$t=0$. Non-dimensional solutions of (4.6) with uniform ![]() $\eta _\phi =\eta _0$. Panels (a,b) have the outer boundary condition

$\eta _\phi =\eta _0$. Panels (a,b) have the outer boundary condition ![]() $V(R)=0$; panels (c,d) have the zero-effective-stress outer boundary condition given in (4.12). (a) Analytical solutions (4.9) with the outer boundary condition

$V(R)=0$; panels (c,d) have the zero-effective-stress outer boundary condition given in (4.12). (a) Analytical solutions (4.9) with the outer boundary condition ![]() $V(R)=0$ and with

$V(R)=0$ and with ![]() $\varLambda _\times =0.45$. In the limit of

$\varLambda _\times =0.45$. In the limit of ![]() $\mathcal {R} \gg 1$, the dimensionless solution is asymptotic to

$\mathcal {R} \gg 1$, the dimensionless solution is asymptotic to ![]() $V(r)\sim (2\varLambda _\times - 1) (r^2-r)/3$. In the other limit,

$V(r)\sim (2\varLambda _\times - 1) (r^2-r)/3$. In the other limit, ![]() $\mathcal {R}\ll 1$, the matched asymptotic solution is

$\mathcal {R}\ll 1$, the matched asymptotic solution is ![]() $V(r)\sim \mathcal {R}^2(2\varLambda _\times - 1)[-1+\exp (-r/\mathcal {R}) + \exp (-(1-r)/\mathcal {R})]$. (b) Decompaction rate with

$V(r)\sim \mathcal {R}^2(2\varLambda _\times - 1)[-1+\exp (-r/\mathcal {R}) + \exp (-(1-r)/\mathcal {R})]$. (b) Decompaction rate with ![]() $\varLambda _\times =0.45$. (c) Analytical solution (4.13) with outer boundary condition (4.12) and with

$\varLambda _\times =0.45$. (c) Analytical solution (4.13) with outer boundary condition (4.12) and with ![]() $\mathcal {R}=0.3$. (d) Decompaction rate with

$\mathcal {R}=0.3$. (d) Decompaction rate with ![]() $\mathcal {R}=0.3$.

$\mathcal {R}=0.3$.

4.1.2. Outer boundary condition: no normal effective stress

Alternatively, we can consider the case where the partially molten cylinder is surrounded by an inviscid fluid, held at a dimensional confining pressure ![]() $P_c$. This pressure must be balanced by the phase-averaged traction at the boundary and, therefore,

$P_c$. This pressure must be balanced by the phase-averaged traction at the boundary and, therefore, ![]() $\hat {\boldsymbol {r}} \boldsymbol {\cdot } \bar {\boldsymbol {\sigma }}\boldsymbol {\cdot } \hat {\boldsymbol {r}} = -P_c$. Assuming that the liquid pressure is continuous at

$\hat {\boldsymbol {r}} \boldsymbol {\cdot } \bar {\boldsymbol {\sigma }}\boldsymbol {\cdot } \hat {\boldsymbol {r}} = -P_c$. Assuming that the liquid pressure is continuous at ![]() $r=R$, we obtain the boundary condition

$r=R$, we obtain the boundary condition

Expanding this condition using (3.1) and the approximate second invariant (4.3), then non-dimensionalising ![]() $r$ with

$r$ with ![]() $R$ and

$R$ and ![]() $V$ with

$V$ with ![]() $[V]$, we obtain the dimensionless boundary condition

$[V]$, we obtain the dimensionless boundary condition

This condition yields a different value of ![]() $A$ and the general solution (4.8) becomes

$A$ and the general solution (4.8) becomes

\begin{align} V(r) &= {\rm \pi}\mathcal{R}^2\left(\frac{1}{2}-\varLambda_\times\right)\notag\\ &\quad\times \left[\frac{3L_0\left(\dfrac{1}{\mathcal{R}}\right) - 2\mathcal{R} L_1 \left(\dfrac{1}{\mathcal{R}}\right)+\dfrac{3}{{\rm \pi}\mathcal{R}} \dfrac{\varLambda_\times}{1/2-\varLambda_\times}}{\displaystyle 3I_0 \left(\dfrac{1}{\mathcal{R}}\right) - 2\mathcal{R} I_1\left(\dfrac{1}{\mathcal{R}}\right)}I_1 \left(\frac{r}{\mathcal{R}}\right)-L_1\left(\frac{r}{\mathcal{R}}\right)\right]. \end{align}

\begin{align} V(r) &= {\rm \pi}\mathcal{R}^2\left(\frac{1}{2}-\varLambda_\times\right)\notag\\ &\quad\times \left[\frac{3L_0\left(\dfrac{1}{\mathcal{R}}\right) - 2\mathcal{R} L_1 \left(\dfrac{1}{\mathcal{R}}\right)+\dfrac{3}{{\rm \pi}\mathcal{R}} \dfrac{\varLambda_\times}{1/2-\varLambda_\times}}{\displaystyle 3I_0 \left(\dfrac{1}{\mathcal{R}}\right) - 2\mathcal{R} I_1\left(\dfrac{1}{\mathcal{R}}\right)}I_1 \left(\frac{r}{\mathcal{R}}\right)-L_1\left(\frac{r}{\mathcal{R}}\right)\right]. \end{align} This function is plotted in figure 2(c,d); the curves are computed with ![]() $\mathcal {R}=0.3$ and values of

$\mathcal {R}=0.3$ and values of ![]() $\varLambda _\times$ that span

$\varLambda _\times$ that span ![]() $1/2$. The radial component of solid velocity

$1/2$. The radial component of solid velocity ![]() $V$ is generally positive, indicating outward solid flow and decompaction across all radii. This outward flow is again driven by the compressive hoop stress. Distinct from the rigid outer boundary condition, however, condition (4.12) allows the solid to move outward at the outer boundary. Hence, in this case, torsion with any

$V$ is generally positive, indicating outward solid flow and decompaction across all radii. This outward flow is again driven by the compressive hoop stress. Distinct from the rigid outer boundary condition, however, condition (4.12) allows the solid to move outward at the outer boundary. Hence, in this case, torsion with any ![]() $\varLambda _\times$ causes the solid cylinder to expand radially, imbibing liquid across the outer boundary.

$\varLambda _\times$ causes the solid cylinder to expand radially, imbibing liquid across the outer boundary.

The pattern of flow in figure 2(c) is slightly different for ![]() $\varLambda _\times =0.75$, where there is a region of

$\varLambda _\times =0.75$, where there is a region of ![]() $V<0$ at inner radii. The inner part of this region is associated with compaction

$V<0$ at inner radii. The inner part of this region is associated with compaction ![]() $\mathcal {C}<0$, as shown by the solid curve in (d). The driving force is again dilatancy, but in this case with

$\mathcal {C}<0$, as shown by the solid curve in (d). The driving force is again dilatancy, but in this case with ![]() $\varLambda _\times >1/2$, the radial dilatant normal stress plays a significant role. As is the case for Poiseuille flow in Appendix D, faster shear at larger radii drives solid inward. But with zero radial effective stress at the outer boundary, dilatancy also drives outward solid flow, radial expansion of the cylinder and radial imbibition of liquid.

$\varLambda _\times >1/2$, the radial dilatant normal stress plays a significant role. As is the case for Poiseuille flow in Appendix D, faster shear at larger radii drives solid inward. But with zero radial effective stress at the outer boundary, dilatancy also drives outward solid flow, radial expansion of the cylinder and radial imbibition of liquid.

4.1.3. Outward force on pistons due to dilatancy

The results depicted in figure 2 for both outer boundary conditions are valid instantaneously at ![]() $t=0$, when all properties are uniform with radius. At this initial instant, we compute an axial force outward on the plates, parallel to

$t=0$, when all properties are uniform with radius. At this initial instant, we compute an axial force outward on the plates, parallel to ![]() $\hat {\boldsymbol {z}}$, that arises from dilatancy. This calculation provides a prediction to be compared with laboratory measurements. Details of the calculation are in Appendix A. The main result is that the axial force is dominated by the direct effect of dilatancy in the flow-perpendicular direction, and hence, scales as

$\hat {\boldsymbol {z}}$, that arises from dilatancy. This calculation provides a prediction to be compared with laboratory measurements. Details of the calculation are in Appendix A. The main result is that the axial force is dominated by the direct effect of dilatancy in the flow-perpendicular direction, and hence, scales as

where ![]() $\mathcal {T}$ is the torque that causes a twist rate of

$\mathcal {T}$ is the torque that causes a twist rate of ![]() $\dot \varOmega$ at

$\dot \varOmega$ at ![]() $t=0$. Here

$t=0$. Here ![]() ${\rm \Delta} F$ is the outward force in excess of that due to the confining pressure surrounding the sample. Using typical laboratory values for

${\rm \Delta} F$ is the outward force in excess of that due to the confining pressure surrounding the sample. Using typical laboratory values for ![]() $\mathcal {T}$ and

$\mathcal {T}$ and ![]() $R$ in (4.14) (Appendix A), we find that the excess force is of the order of 10 % of the force due to the typical confining pressure.

$R$ in (4.14) (Appendix A), we find that the excess force is of the order of 10 % of the force due to the typical confining pressure.

In detail, the excess force ![]() ${\rm \Delta} F$ can deviate from the simple prediction of (4.14). Figure 8 in Appendix A plots this deviation for both outer-boundary-condition cases over a range of

${\rm \Delta} F$ can deviate from the simple prediction of (4.14). Figure 8 in Appendix A plots this deviation for both outer-boundary-condition cases over a range of ![]() $\mathcal {R}$ and

$\mathcal {R}$ and ![]() $\varLambda _\times$. When the outer boundary is closed to solid flow (

$\varLambda _\times$. When the outer boundary is closed to solid flow (![]() $V(R)=0$), the excess force is close to the simple scaling above; when the outer boundary has zero effective stress (4.12), dilatancy in the radial direction leads to a net decompaction of the sample and a reduction in the excess axial force by approximately one half.

$V(R)=0$), the excess force is close to the simple scaling above; when the outer boundary has zero effective stress (4.12), dilatancy in the radial direction leads to a net decompaction of the sample and a reduction in the excess axial force by approximately one half.

4.1.4. Finite time and steady state

The analysis of parallel-plate torsion to this point has considered the instantaneous problem at ![]() $t=0$, when the domain is uniform in porosity. The instantaneous flow requires that this uniform state is subsequently lost by radial segregation of solid and liquid (and, as shown empirically and below in § 4.2, by a banding instability). Appendix B derives the system of equations, simplified from (4.1), that governs the finite-time evolution of the radial distribution of porosity. The non-uniform porosity

$t=0$, when the domain is uniform in porosity. The instantaneous flow requires that this uniform state is subsequently lost by radial segregation of solid and liquid (and, as shown empirically and below in § 4.2, by a banding instability). Appendix B derives the system of equations, simplified from (4.1), that governs the finite-time evolution of the radial distribution of porosity. The non-uniform porosity ![]() $\phi (r)$ leads to a radial dependence of mobility

$\phi (r)$ leads to a radial dependence of mobility ![]() $M_\phi$ and aggregate viscosity

$M_\phi$ and aggregate viscosity ![]() $\tilde {\eta }_\phi$.

$\tilde {\eta }_\phi$.

A series of time-dependent numerical solutions are plotted in figure 3(a), coloured according to the shear strain ![]() $\gamma$ at the outer radius of the domain

$\gamma$ at the outer radius of the domain ![]() $R$. Details of the numerical method are in Appendix B; the code is available in an online repository (Katz, Rudge & Hansen Reference Katz, Rudge and Hansen2023). This calculation uses

$R$. Details of the numerical method are in Appendix B; the code is available in an online repository (Katz, Rudge & Hansen Reference Katz, Rudge and Hansen2023). This calculation uses ![]() $\mathcal {R}=0.3$ and

$\mathcal {R}=0.3$ and ![]() $\varLambda _\times =0.4$ with boundary condition

$\varLambda _\times =0.4$ with boundary condition ![]() $V(R)=0$. At the smallest finite strains, the porosity distribution has the shape of the

$V(R)=0$. At the smallest finite strains, the porosity distribution has the shape of the ![]() $t=0$ solution for

$t=0$ solution for ![]() $\mathcal {C}(r)$, shown in figure 2(b). With increasing strain (time), the porosity contrast between the centre and outer radius increases. However, the evolution slows and ceases as the porosity distribution approaches a steady state.

$\mathcal {C}(r)$, shown in figure 2(b). With increasing strain (time), the porosity contrast between the centre and outer radius increases. However, the evolution slows and ceases as the porosity distribution approaches a steady state.

Figure 3. Parallel-plate torsion at ![]() $t\ge 0$ and

$t\ge 0$ and ![]() $t\to \infty$. Coloured curves show the time-dependent, numerical solution to the system (B3) for porosity

$t\to \infty$. Coloured curves show the time-dependent, numerical solution to the system (B3) for porosity ![]() $\phi (r,t)/\phi _0$. Black curves show the analytical, steady-state solution (4.16) for

$\phi (r,t)/\phi _0$. Black curves show the analytical, steady-state solution (4.16) for ![]() $\xi =0$. Both panels use empirically motivated values

$\xi =0$. Both panels use empirically motivated values ![]() $\lambda =27$ and

$\lambda =27$ and ![]() $\phi _0=0.07$. (a) Solutions with

$\phi _0=0.07$. (a) Solutions with ![]() $\varLambda _\times =0.4$,

$\varLambda _\times =0.4$, ![]() $\mathcal {R}=0.3$ and

$\mathcal {R}=0.3$ and ![]() $\xi /R=0.03$ at various outer-radius strains

$\xi /R=0.03$ at various outer-radius strains ![]() $\gamma (R)$. (b) Steady solutions for four values of

$\gamma (R)$. (b) Steady solutions for four values of ![]() $\varLambda _\times$.

$\varLambda _\times$.

In the steady state and with ![]() $\xi =0$, the radial component of the solid velocity is zero and radial force-balance equation (4.1b) reduces to

$\xi =0$, the radial component of the solid velocity is zero and radial force-balance equation (4.1b) reduces to ![]() $\hat {\boldsymbol {r}}\boldsymbol {\cdot } (\boldsymbol {\nabla }\boldsymbol {\cdot } D_\phi \boldsymbol {\varLambda }\dot {\varepsilon }_{II}) = 0$ or, after expanding and rearranging,

$\hat {\boldsymbol {r}}\boldsymbol {\cdot } (\boldsymbol {\nabla }\boldsymbol {\cdot } D_\phi \boldsymbol {\varLambda }\dot {\varepsilon }_{II}) = 0$ or, after expanding and rearranging,

where ![]() $D_\phi '$ is the derivative of the dilatation viscosity with respect to its argument,

$D_\phi '$ is the derivative of the dilatation viscosity with respect to its argument, ![]() $\phi$. In solutions to this equation, a steady state is reached when the force of the hoop stress (left-hand side) balances the force of the radial normal stresses (right-hand side). The compressive hoop force, associated with a coefficient of unity in

$\phi$. In solutions to this equation, a steady state is reached when the force of the hoop stress (left-hand side) balances the force of the radial normal stresses (right-hand side). The compressive hoop force, associated with a coefficient of unity in ![]() $\boldsymbol {\varLambda }$, is due to azimuthal dilatancy that pushes solid radially outward. The radial normal force, associated with the coefficient

$\boldsymbol {\varLambda }$, is due to azimuthal dilatancy that pushes solid radially outward. The radial normal force, associated with the coefficient ![]() $\varLambda _\times$ in

$\varLambda _\times$ in ![]() $\boldsymbol {\varLambda }$, has two causes: first, the gradient in radial dilatancy due to the torsional shear (

$\boldsymbol {\varLambda }$, has two causes: first, the gradient in radial dilatancy due to the torsional shear (![]() $\dot {\varepsilon }_{II}\propto r$), and second, the gradient in radial dilatancy due to the steady-state radial gradient in porosity.

$\dot {\varepsilon }_{II}\propto r$), and second, the gradient in radial dilatancy due to the steady-state radial gradient in porosity.

Laboratory experiments that impose torsional deformation, discussed in § 2, have an azimuthally averaged porosity that decreases with radius. On the basis of the predicted compaction rate at ![]() $t=0$, shown in figure 9, we can infer that this porosity structure is consistent with the no-normal-flow boundary condition and

$t=0$, shown in figure 9, we can infer that this porosity structure is consistent with the no-normal-flow boundary condition and ![]() $\varLambda _\times < 1/2$. It is unclear whether these experiments approach a steady-state radial porosity profile, or would do so at larger strains. If a steady state can be achieved, then (4.15) requires that

$\varLambda _\times < 1/2$. It is unclear whether these experiments approach a steady-state radial porosity profile, or would do so at larger strains. If a steady state can be achieved, then (4.15) requires that ![]() $D_\phi '<0$ independent of the specific form of

$D_\phi '<0$ independent of the specific form of ![]() $D_\phi$; in other words, it requires that the dilatancy stress at fixed strain rate decreases as porosity increases.

$D_\phi$; in other words, it requires that the dilatancy stress at fixed strain rate decreases as porosity increases.

In (3.4a–c) we specified that ![]() $D_\phi$ has the form

$D_\phi$ has the form ![]() $D_\phi =D_0\eta _\phi$. Given the exponential dependence of

$D_\phi =D_0\eta _\phi$. Given the exponential dependence of ![]() $\eta _\phi$ on

$\eta _\phi$ on ![]() $\phi$, it follows that

$\phi$, it follows that ![]() $D_\phi ' = -\lambda D _\phi$. With this we can solve (4.15) to give

$D_\phi ' = -\lambda D _\phi$. With this we can solve (4.15) to give

where ![]() $r$ has been non-dimensionalised with the outer radius

$r$ has been non-dimensionalised with the outer radius ![]() $R$ and we have used global conservation of liquid mass to determine the constant of integration (see Appendix B for details). This function is plotted as black curves in figure 3 for various values of

$R$ and we have used global conservation of liquid mass to determine the constant of integration (see Appendix B for details). This function is plotted as black curves in figure 3 for various values of ![]() $\varLambda _\times$; in § 5 we compare it with measurements from laboratory experiments. The logarithmic singularity in (4.16) for

$\varLambda _\times$; in § 5 we compare it with measurements from laboratory experiments. The logarithmic singularity in (4.16) for ![]() $r \to 0$ is removed by non-local viscosity when cooperativity length

$r \to 0$ is removed by non-local viscosity when cooperativity length ![]() $\xi >0$. This is evident in figure 3(a) by comparison between the numerical solution at late time (red curve;

$\xi >0$. This is evident in figure 3(a) by comparison between the numerical solution at late time (red curve; ![]() $\xi =0.1\delta$) and the steady solution (black curve;

$\xi =0.1\delta$) and the steady solution (black curve; ![]() $\xi =0$).

$\xi =0$).

4.2. Simple shear between parallel plates

Here, following the analysis of Spiegelman (Reference Spiegelman2003), we investigate the stability of a two-dimensional simple-shear flow with initial melt fraction ![]() $\phi _0 + \phi _1(\boldsymbol {x},t)$, where

$\phi _0 + \phi _1(\boldsymbol {x},t)$, where ![]() $\vert \phi _1\vert \ll \phi _0$ is a perturbation. A schematic diagram is shown in figure 4(a). The coordinate system is oriented such that

$\vert \phi _1\vert \ll \phi _0$ is a perturbation. A schematic diagram is shown in figure 4(a). The coordinate system is oriented such that ![]() $\hat {\boldsymbol {x}}$ is in the flow direction and

$\hat {\boldsymbol {x}}$ is in the flow direction and ![]() $\hat {\boldsymbol {y}}$ is in the direction perpendicular to the shear plane. We assume invariance in the

$\hat {\boldsymbol {y}}$ is in the direction perpendicular to the shear plane. We assume invariance in the ![]() $\hat {\boldsymbol {z}}$ (vorticity) direction and take the

$\hat {\boldsymbol {z}}$ (vorticity) direction and take the ![]() $x$–

$x$–![]() $y$ plane to be infinite; hence, there is no need to impose boundary conditions. The procedure is a standard linearised stability analysis, detailed in Katz (Reference Katz2022, Chapter 7) and sketched in the next paragraph. Alisic et al. (Reference Alisic, Rhebergen, Rudge, Katz and Wells2016) provides a three-dimensional analysis for torsion in cylindrical coordinates, but this adds mathematical complexity without additional physical insight.

$y$ plane to be infinite; hence, there is no need to impose boundary conditions. The procedure is a standard linearised stability analysis, detailed in Katz (Reference Katz2022, Chapter 7) and sketched in the next paragraph. Alisic et al. (Reference Alisic, Rhebergen, Rudge, Katz and Wells2016) provides a three-dimensional analysis for torsion in cylindrical coordinates, but this adds mathematical complexity without additional physical insight.

Figure 4. Growth rate of sinusoidal perturbations under a simple-shear flow from (4.17). (a) Schematic diagram showing a finite region of the infinite domain. The grey scale shows the perturbed porosity field.(b) Growth rate as a function of wavenumber ![]() $k$ for

$k$ for ![]() $D_0=0$ at

$D_0=0$ at ![]() $\theta =45^\circ$. Circles represent the growth rate computed at

$\theta =45^\circ$. Circles represent the growth rate computed at ![]() $k^*=\epsilon ^{-1/2}$. (c) Growth-rate angular factor as a function of

$k^*=\epsilon ^{-1/2}$. (c) Growth-rate angular factor as a function of ![]() $\theta$ with

$\theta$ with ![]() $\varLambda _\perp = 1$, and values of

$\varLambda _\perp = 1$, and values of ![]() $D_0$ given in the legend. (d) Growth-rate angular factor as a function of

$D_0$ given in the legend. (d) Growth-rate angular factor as a function of ![]() $\theta$ with

$\theta$ with ![]() $D_0=2$, and values of

$D_0=2$, and values of ![]() $\varLambda _\perp$ given in the legend.

$\varLambda _\perp$ given in the legend.

We use (4.1b) to eliminate the pressure gradient from (4.1a) and obtain an equation governing the irrotational part of the velocity field. Then we take the curl of (4.1b) to obtain an equation governing the solenoidal part. These are coupled to (3.6) and (4.1c) for viscosity and solid mass. We expand variables into a steady, background state and a time-dependent perturbation that is arbitrarily small at ![]() $t=0$. The perturbations are assumed to be proportional to

$t=0$. The perturbations are assumed to be proportional to ![]() $\exp [{\rm i}\boldsymbol {k}(t)\boldsymbol {\cdot } \boldsymbol {x} + {s}(t)]$, where

$\exp [{\rm i}\boldsymbol {k}(t)\boldsymbol {\cdot } \boldsymbol {x} + {s}(t)]$, where ![]() $\boldsymbol {k}(t)$ is a time-dependent wave vector that changes direction and magnitude with the background flow. After linearising the governing equations, we solve the leading-order balance for the base state. This is a simple-shear flow with velocity gradient

$\boldsymbol {k}(t)$ is a time-dependent wave vector that changes direction and magnitude with the background flow. After linearising the governing equations, we solve the leading-order balance for the base state. This is a simple-shear flow with velocity gradient ![]() $\dot \gamma$ and zero compaction rate. Using the base-state solution, we solve the perturbation equations to obtain the dimensionless growth rate

$\dot \gamma$ and zero compaction rate. Using the base-state solution, we solve the perturbation equations to obtain the dimensionless growth rate ![]() $\dot {s}$ as a function of dimensionless wave-vector magnitude

$\dot {s}$ as a function of dimensionless wave-vector magnitude ![]() $k$ and wavefront angle to the shear plane

$k$ and wavefront angle to the shear plane ![]() $\theta \equiv \tan ^{-1}k_x/k_y$. In the present case, we obtain

$\theta \equiv \tan ^{-1}k_x/k_y$. In the present case, we obtain

\begin{equation} \dot{s} = (1-\phi_0)\frac{\lambda}{3}\frac{k^2}{(1+k^2)(1+\epsilon^2 k^2)}\left[\sin 2\theta - \frac{D_0}{2}\frac{(\sin^2\theta + \varLambda_\perp\cos^2\theta)\sin^2 2\theta}{1-\dfrac{D_0}{4}(1-\varLambda_\perp)\sin 4\theta}\right]\!. \end{equation}

\begin{equation} \dot{s} = (1-\phi_0)\frac{\lambda}{3}\frac{k^2}{(1+k^2)(1+\epsilon^2 k^2)}\left[\sin 2\theta - \frac{D_0}{2}\frac{(\sin^2\theta + \varLambda_\perp\cos^2\theta)\sin^2 2\theta}{1-\dfrac{D_0}{4}(1-\varLambda_\perp)\sin 4\theta}\right]\!. \end{equation}

In this equation, ![]() $\dot {s}$ has been made dimensionless by scaling with the background rate of shear

$\dot {s}$ has been made dimensionless by scaling with the background rate of shear ![]() $\dot {\gamma }$. Wavenumber

$\dot {\gamma }$. Wavenumber ![]() $k$ has been made dimensionless by scaling with the compaction length

$k$ has been made dimensionless by scaling with the compaction length ![]() $\delta \equiv \sqrt {3 M_0 \eta _0}$. We have introduced the ratio