Introduction

The gas composition of air bubbles in ice which was formed by dry sintering is to a good approximation atmospheric. Already Reference Scholander, Scholander, Hemmingsen, Coachman and NuttScholander and others (1961) have analysed air extracted from ice samples with known or estimated age to study the history of atmospheric gas composition. Reliable results, especially concerning the CO2 concentration, were only obtained after ice samples from very cold regions were selected and after dry extraction techniques had been applied Reference Berner, Berner, Oeschger and Stauffer(Berner and others, 1980; Reference Delmas, Delmas, Ascencio and LegrandDelmas and others, 1980). According to measurements with these techniques on such samples, the CO2 concentration shows several significant variations during the past 40000 years. It is of great interest to study in parallel with the CO2 concentration other trace gases and the 13C/12C ratio of the CO2 in the extracted air. Measurements for these purposes require a minimal sample size of about 500 g of ice. Up to now, no dry extraction system for such large samples has been available.

Although dry extraction methods drastically reduce contamination by CO2 formed from carbonates, there remains the risk of a smaller contamination by gases desorbed from the walls of the extraction system. In particular CO2 desorption depends on the water-vapour pressure Reference Zumbrunn, Zumbrunn, Neftel and Oeschger(Zumbrunn and others, 1982) and shows an almost linear increase with the extraction time. There is also the possibility of losing gas by adsorption on newly formed surfaces of crushed or ground ice Reference Ocampo and Klinger(Ocampo and Klinger, 1982).

To minimize these risks of contamination by desorption and of loss by adsorption, the gases have to be extracted at low temperature (and therefore low water-vapour pressure), the extraction time must be kept short, and the surface area of crushed ice should be minimal.

We met these conditions by constructing an extraction system based on a milling cutter working at −20° C, which allows us to crush a sample of 500 g of ice in only 2 min into chips of approximately 1 mm3. The air from the bubbles is collected by condensation at 15 K in less than 10 min.

Description of the Extraction System

Principle

The extraction system is schematically shown in Figure 1. It consists mainly of a crushing device, which by milling the ice sample opens the air bubbles, and a gas collection device.

Fig. 1. Diagram of the extraction system. • gasket (gold or aluminium O-ring.

-

1 milling cutter (diameter: 100 mm; number of teeth: 8).

-

2 magnetic coupling for driving the milling cutter.

-

3 silver-coated ball bearings.

-

4 magnetic coupling for the feed of the ice sample.

-

5 ice sample (100 g to 800 g).

-

6 gas-sample container (volume: 9.5 cm3).

-

7 cold head.

-

8 sample container.

-

9 chips container.

Crushing device

The ice sample is crushed in an evacuated container by a milling cutter. The milling cutter is driven by magnetic coupling with a crank outside the evacuated container, so that any dynamic vacuum seals can be avoided. All parts which may get into contact with the ice samples or the extracted air are made from stainless steel. The different parts are sealed by metal gaskets. Gold is used for permanent seals, aluminium for seals which have to be replaced after each extraction. The milling cutter runs in greaseless silver-coated ball bearings. The ice sample is pressed against the milling cutter by its own weight plus an additional force exerted form the outside with the help of a second magnetic coupling. This coupling allows the force to be adjusted during the milling process. The size of the ice chips varies within certain limits, depending on the applied force. The permanent magnets inside the evacuated container (for the milling cutter and the sample feed) are packed in stainless steel. The crushing device is operated in a cold room at −20° C.

Gas collection device

The gas extracted from the opened bubbles is collected by condensation at 15 K in a small gas-sample container cooled by a helium closed-cycle refrigerator, Leybold Heraeus CRYOGEN R210. Water vapour is removed by a cold trap, located between the crushing device and the gas-sample container and cooled with liquid nitrogen. With an adjustable heater the temperature of the cold trap can be regulated between −196° C and −40° C, for the measurements presented here it was operated at −80° C. The duration of an extraction is determined by the condensation time of the gases and not by the time needed to crush the ice. In Figure 2 a typical pressure-decrease diagram during collection of 54 cm3 of gas at S.T.P. is shown.

Fig. 2. A typical pressure decrease in the crushing device during gas collection in a lest run. 54 cm3 STP of standard gas, but no ice, were filled into the crushing device.

Extraction procedure

To insert an ice sample into the crushing device, the evacuated apparatus is flushed with CO2-free nitrogen before opening the cover. The ice sample is lowered slowly into the sample container attached to a metal wire, which is removed after the sample is in place on top of the milling cutter. The inner part of the sample feed coupling is inserted. Afterwards the sample container is sealed vacuum-tight with an aluminium O-ring. The extraction device is then evacuated to the dynamic pressure of water vapour of about 30 Pa, and pumping is continued at this pressure for at least one hour to remove possible impurities adsorbed at the ice surface. After that the crushing device is closed off from the vacuum pump and the valve to the evacuated small gas-sample container, which has already been cooled down to 15 K, is opened. Milling is now started. With the milling cutter working at a rate of about 1–2 revolutions per second, a sample of 500 g is crushed in about 2 min. Collection of gases has to be continued for approximately 10 min to avoid losses by incomplete condensation.

The total efficiency of the extraction is about 90%, if we assume that the total air content in ice from South Pole is 90.3 cm3 S.T.P. kg−1, calculated according to Reference Raynaud and WhillansRaynaud and Whillans (1982). Most of the remaining gas is still trapped in bubbles which were not opened during crushing. We estimate that only a minor part of the losses is due to incomplete condensation.

After the crushing process, the crushing device is again flushed with CO2-free nitrogen, and the chips container is opened to remove the crushed ice.

Test results

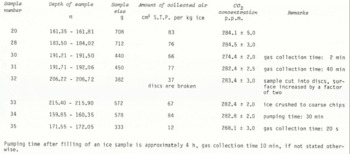

Tests were made by analyzing fractions of the extracted and collected gas using a gas chromatograph, Hewlett Packard 5880 A. To estimate the order of magnitude of the contamination by CO2 from leaks and especially by desorption of CO2 from the walls of the system, we made some tests with bubble-free single crystals, which were grown from super-pure water as described by Reference Schwander, Schwander, Neftel, Oeschger and StaufferSchwander and others (1983). The extraction procedure with single crystals is identical to that with an ordinary ice sample, except that about 30 cm3 S.T.P. of either CO2-free nitrogen or a CO2 standard gas mixture are added into the ice sample container before milling is started. The results of the analyses of the collected gas samples are shown in Table I. They indicate that contamination by CO2 is of the order of magnitude of 1 p.p.m., as long as the extraction time is kept short. Only for the sample with an extrction time more than ten times normal was a much higher CO2 concentration measured.

Table I. Results of Tests with Bubble-Free Single Ice Crystals. The Standard Gas Added is also Used to Calibrate the Gas-Chromatograph

A second series of tests was made with samples from an ice core drilled by PICO in 1982 at the South Pole Reference Kuivinen(Kuivinen, 1983) (Table II). The samples are from a depth below the surface of between 160 m and 220 m corresponding to an age of the enclosed air of about 400 to 1000 years. Several parameters were varied during the extraction procedure to investigate if these parameters have any influence on the composition of the extracted gas. There seems to be no difference whether we crush the ice to fine or coarse chips, or whether we start with an ice sample in one piece or with one cut into several discs, thus increasing the surface. Values of the CO2 concentration which are too low, compared to the mean value, are observed if the condensation time is kept below 10 min (samples no. 30 and no. 35, Table II).

Table II. South Pole Station Ice Core. CO2 Concentration in Air Bubbles

If samples no. 30 and no. 35 are excluded, the mean value of the CO2 concentration is 283.3 ± 0.8 p.p.m. This value is about 20 p.p.m. higher than the mean value measured on samples of 1 g from this ice core using an infrared laser-absorption spectrometer in combination with a small crusher described by Reference Zumbrunn, Zumbrunn, Neftel and OeschgerZumbrunn and others (1982).Footnote *

The difference is due to differences in the extraction and not in the gas analysis methods, but the detailed reasons for it are not yet known, and it is not clear which of the values is correct. The results in Table II show, however, that the new extraction method leads to results which are reproducible and show a very low scatter.

Acknowledgements

The dry extraction system was developed in the course of a research program directed by H. Oeschger and supported by the Swiss National Science Foundation. We would like to thank A. Neftel, M. Möll, and J. Schwander for valuable discussions, and H. Frick, F. Hosner, M. Läuffer, S. Studer, M. Stucki, and H. Riesen for the manufacture of the system.