1. Introduction

The transport of micrometre-sized particles within confined geometries is an active subject of practical and scientific research, as it is found in everyday life and draws increasing interest in industrial applications. This phenomenon encompasses various fields, including the flow of blood in microvessels within our bodies (Poddar, Mondal & Madden Reference Poddar, Mondal and Madden2021), particle separation through microfiltration (Vernhet, Cartalade & Moutounet Reference Vernhet, Cartalade and Moutounet2003; Rayess et al. Reference Rayess, Albasi, Bacchin, Taillandier, Raynal and Mietton-Peuchot2011), applications in lab-on-a-chip devices (Agastin, King & Jones Reference Agastin, King and Jones2009; Samiei, Tabrizian & Hoorfar Reference Samiei, Tabrizian and Hoorfar2016) and material transport in microfluidics (Sharp & Adrian Reference Sharp and Adrian2005; Mirani, Fazlali & Rahimi Reference Mirani, Fazlali and Rahimi2021; Kim et al. Reference Kim, Jung, Lee, Jin and Ahn2023a,Reference Kim, Kim, Park, Jeon and Chob). Particle dynamics within microscopic channels, observed across diverse disciplines, shares several common characteristics. First, due to the small characteristic length scales found in a microchannel, particle dynamics occurs in the very-low-Reynolds-number regime, approaching zero. Therefore, to observe noticeable macroscopic structural changes occurring in the microchannel, analysis over a long-time scale is inevitably required. Second, stochastic fluctuations induced by Brownian motion or external excitations like background noise can also influence the dynamics of micro or sub-micro sized particles, which complicates the analysis (Zuriguel et al. Reference Zuriguel2014; Sendekie & Bacchin Reference Sendekie and Bacchin2016). Lastly, low Reynolds numbers in confined flow channels correspond to the regime where various factors influencing particle dynamics, including the background velocity of the fluid, hydrodynamic interactions between particles and inter-particle interactions, occur with comparable magnitudes. Thus, the complex interplay among these factors that influences particle dynamics has largely limited its comprehensive physical understanding, despite the importance of particle transport within confined microchannels. In these circumstances, numerical simulations that allow for the convenient and independent control of individual factors and enable easy comparisons with experimental results across various length scales can serve as valuable tools for studying particle dynamics in a flow channel.

Various simulation methods have been employed to comprehend the intricate interactions between particles and fluids within confined flow channels. These methods can be categorized based on the manner of describing both fluids and particles: Euler–Euler, Euler–Lagrangian and fully Lagrangian models. We outline the features of existing methodologies within each category, particularly when they are applied to simulate particle flow within microchannels.

As the first category, the Euler–Euler model treats the fluid and particles as an interpenetrating continuum and solves the momentum balance equations for both phases (Filtvedt el al. Reference Filtvedt, Holt, Ramachandran and Melaaen2012). In this approach, rather than seeking a detailed solution to the Navier–Stokes equation, a reduced description based on spatially or ensemble-averaged mathematical models is pursued, retaining the fundamental physical processes that determine the behaviour of the system (Prosperetti & Tryggvason Reference Prosperetti and Tryggvason2009). In the discretized computational domain, a key characteristic of the Eulerian framework is that the model equation is solved including the volume occupied by the particles. Specific body forces are set to make the so-called fictitious fluid inside each particle respond as if it is in rigid-body motion (Maxey Reference Maxey2017). One of the representative methods used in this category is the lattice Boltzmann method, where the simulation involves modelling fluid density on a discretized lattice using streaming and collision processes (Chen & Doolen Reference Chen and Doolen1998; Tong et al. Reference Tong, Li, He and Li2015; Johannsmann et al. Reference Johannsmann, Petri, Leppin, Langhoff and Ibrahim2023). Due to its adaptive nature and local dynamics, the lattice Boltzmann method can accommodate complex particle shapes and intricate confinement boundaries. Furthermore, the lattice Boltzmann method naturally introduces Brownian forces by incorporating random forces into fluid particles directly. However, despite being a linear simulation with respect to the number of colloidal particles, it exhibits a super-linear computational complexity in overdamped systems (Fiore et al. Reference Fiore, Usabiaga, Donev and Swan2017). As pointed out by Fiore & Swan (Reference Fiore and Swan2019), this is due to the characteristic behaviour of the Stokes flow in overdamped systems, so a sufficiently short simulation time scale must be set to allow vorticity to diffuse out of the system volume. Also, the need to resolve inertial degrees of freedom in the solvent results in a loss of efficiency when dealing with overdamped systems.

In the case of Euler–Lagrangian modelling, the fluid phase is described in a conventional averaged Eulerian grid, while groups of particles are tracked in a Lagrangian manner, adapted to Eulerian grids (Prosperetti & Tryggvason Reference Prosperetti and Tryggvason2009). Since each phase can employ an independent model equation, specific methods differ according to how forces are determined and how force localization on the particle is achieved. The force-coupling method is one example in which the particles, modelled by forcing terms spatially spread out in Gaussian envelopes, are added to the momentum equations of the fluid (Maxey & Patel Reference Maxey and Patel2001). Once the resolution is fine enough to resolve the Gaussian force envelope, the force-coupling method can accurately reproduce flow perturbations and is extensively used to study confined particulate flows (Agbangla, Bacchin & Climent Reference Agbangla, Bacchin and Climent2014a; Agbangla, Climent & Bacchin Reference Agbangla, Climent and Bacchin2014b). The force-coupling method offers an advantage in its ease of adaptation to complex channel boundaries, eliminating the necessity to compute an expensive Green's function for each iteration. However, a drawback exists when resolving particles in the near-contact range under lubrication interaction, where additional assumptions, such as introducing lubrication force and torque, are required to account for viscous lubrication (Maxey Reference Maxey2017). Additionally, the coupling of lubrication correction with Brownian fluctuation remains unclear, despite recent research findings (Yeo & Maxey Reference Yeo and Maxey2010). Another example within the Euler–Lagrangian model, widely used in the study of flow channels, is the discrete element method (DEM) coupled with a computational fluid dynamics (CFD) solver (Zhu et al. Reference Zhu, Zhou, Yang and Yu2007; Yang et al. Reference Yang, Cheng, Wang and Ahmad2019). The CFD solver discretizes domains using finite-volume or finite-element approximations, and nonlinear flow equations are solved iteratively (Wang et al. Reference Wang, Zhang, Furtney and Damjanac2022). The DEM provides dynamic information, including trajectories and transient forces acting on individual particles. This method has demonstrated its versatility in accommodating various shapes of simulated objects, including granular materials and bonded assemblies (Ai et al. Reference Ai, Chen, Rotter and Ooi2011; Ma & Huang Reference Ma and Huang2018). However, there are also limitations, such as the intrinsic reliance on approximations for determining the magnitude of the drag force applied to each individual suspended object. Additionally, to obtain a high resolution of accurate fluid flow, fluid mesh sizes much smaller than the diameters of particles are required, which can become a significant computational burden as the number of particles increases (Yang et al. Reference Yang, Cheng, Wang and Ahmad2019).

In the Stokes flow regime, fluid inertia becomes negligible, resulting in linear equations of motion. Therefore, fully Lagrangian approaches that describe particle dynamics, especially in microchannels, generate fluid disturbances about given boundaries by superimposing a fundamental solution to a point force. When incorporating boundary conditions through surface integrals, an infinite number of multipole terms is required to provide a spectrally accurate representation (Brady & Bossis Reference Brady and Bossis1988; Maxey Reference Maxey2017). As this is a formidable task, truncated multipole expansions are typically employed based on the desired level of accuracy. The commonly used method in this category is the Stokesian dynamics (SD) method, which uses Stokeslet, rotlet and stresslet terms along with associated degenerate multipoles. Lubrication corrections for viscous forces and torques, when particles are in close contact, are included in a pairwise manner to construct the resistance matrix. The Lagrangian approach offers the advantage of independently controlling the influence of particle–particle interactions and particle–surface interactions, facilitating a direct mapping of physical properties such as viscosity and temperature of the medium. However, obtaining the fundamental solution of fluid for arbitrary geometries is challenging, making it difficult to handle complex-shaped particles and confinement. Additionally, considering higher-order terms of far-field flow induced by particles necessitates the effect of matrix inversion, which can lead to expensive computational expenses.

Upon reexamining the characteristics of particulate transport in microchannels at a low-Reynolds-number region, microstructures develop over an extended time scale, and hydrodynamic forces, along with inter-particle interactions, exert comparable influences on the particles. Therefore, when evaluating the advantages of the simulation methodologies discussed earlier, formulating equations of motion for individual particles and tracking their micro-scale changes appears to be an appropriate choice. Euler–Lagrangian modelling is an approach widely used in the field of particle transport because it allows obtaining the velocity of the fluid at all points in the system domain, and the dynamics of closely located particles can be improved by using appropriate mesh refinement and sufficiently small time steps. However, this property can also become a drawback when the particle volume fraction is high or when particle interactions are predominantly attractive, as computational costs increase significantly due to the need for mesh refinements. Alternative methods exist, such as using a non-deforming mesh along the boundaries, as demonstrated by the immersed boundary method (Peskin Reference Peskin2002; Griffith & Patankar Reference Griffith and Patankar2020) or Brownian dynamics coupled with the finite-element method (Myung et al. Reference Myung, Song, Ahn and Lee2011; Jung et al. Reference Jung, Jeong, Park and Ahn2021). In these cases, solving the momentum balance for the fluid throughout the entire computational domain is still necessary, or many-body inter-particle hydrodynamic interactions are not taken into consideration, even in sparse particulate suspensions. This implies that even systems with a small number of particles do not benefit from cost savings. However, in the fully Lagrangian description, as the equations of motion are only solved at the centre of particles, a relatively low computational cost is required when the number of particles is low, which is proportional to the number of particles, to describe particle dynamics within the channel. However, while the fully Lagrangian description evaluates velocity disturbances by superimposing fundamental Green's solutions of the fluid equation, this Green's function becomes increasingly complex even with minor modifications to the boundaries. In some cases, no explicit solution may be available. Therefore, simulating particle transport in a confined flow channel using a fully Lagrangian description has been considered an inappropriate choice. Alternatively, methods incorporating only non-hydrodynamic interactions, such as Brownian dynamics, have frequently been used to study the interaction between channel walls and particles (Oberholzer et al. Reference Oberholzer, Stankovich, Carnie, Chan and Lenhoff1997; Chang, Chen & Lee Reference Chang, Chen and Lee2003; Brewer, Tsapatsis & Kumar Reference Brewer, Tsapatsis and Kumar2010).

In this study, we propose a novel simulation method to address the challenges associated with mesh refinement in the Eulerian framework and the complexity of boundary treatment in the Lagrangian framework, which is particularly applicable in microchannels with low Reynolds numbers. This new method combines a computational fluid dynamics solver with the Stokesian dynamics method, creating a multiscale simulation scheme. The advantages of our simulation methodology for exploring particle dynamics within microscopic channels can be summarized as follows. Through the Lagrangian framework, it is possible to simulate particle dynamics that is proportional to the number of particles, even for complex geometries. Additionally, simulations of particle interactions with high accuracy are achievable, especially when a large number of particles is present, by considering exact lubrication interactions between particles. Furthermore, because hydrodynamic forces and stresses acting on colloid particles or walls are explicitly obtained during the simulation process, it allows for an intuitive explanation of agglomerate deformation or resuspension dynamics at the individual particle scale, even in systems where the particles form structures and interact vigorously with walls. Therefore, our approach can serve as a comprehensive way of investigating particle dynamics in confined flow channels, from the entry of particles into the channel to the occurrence of channel clogging, even in environments with high areal fractions, without the need for introducing additional structural kinetic models or parameters.

The developed simulation method has been demonstrated to simulate the transport of attractive colloid suspensions within a microscopic channel, which is susceptible to causing particle fouling. Fouling initiates with the deposition of individual particles on an initially clean surface, and the continuous accumulation of particles can eventually lead to a complete blockage of the fluid cross-section (Henry, Minier & Lefevre Reference Henry, Minier and Lefevre2012). Consequently, the dynamics of cluster breakup and resuspension processes until clogging occurs become highly complex. While many existing simulation methods have been limited to observing only specific aspects of particle fouling, the proposed simulation method effectively captures particle and structural dynamics from the initial introduction of particles to the point of complete channel blocking.

This paper is structured as follows. In § 2, the equation of motion describing overdamped colloid particle dynamics inside a channel is derived by combining a fluid dynamics solver and the SD method. In the same section, a constrained SD formulation aimed at minimizing computational costs when including wall geometry within the SD framework is suggested and examined in comparison to existing methodologies using SD. In § 3.1, the established methodology is validated by comparing friction coefficients, rheological properties and diffusion coefficients to previous exact or numerical studies to assess how accurately it captures the dynamics of particles within the channel. Additionally, the efficiency of the constrained formulation is assessed based on the measured wall time of the simulation time step relative to the number of interior and wall particles. Furthermore, in § 3.2, the developed methodologies are applied to the contraction and T-shaped cross-flow channel, and comparisons are made with experimental results under the same flow conditions and inter-particle potential.

2. Simulation methods

In this section, a Lagrangian formulation is derived that describes the motion of individual particles when a colloid suspension is transported in a confined flow channel. The fundamental principle is to treat the boundary effect as a force field by expanding the force density at the solid boundary using a multipole expansion. This principle is based on the fact that the background velocity is perturbed by the force density on the particle surface. Consequently, velocity and force moments are evaluated at the centre of the particle, without the need to calculate velocity changes at all points within the open channel. This implies that there is no need to refine the mesh, including the case when new particles are introduced at the channel inlet.

The flowchart of the overall simulation scheme is presented in figure 1. In the first step, the fluid dynamics solver computes the Stokes equation and obtains the velocity moments of the fluid within the confined channel, in the absence of suspended particles. These velocity fields serve as ambient velocities for the subsequent introduction of a particulate suspension into the confined channel. Using the positions of the inlet particles, a mobility matrix is constructed, which is then used to calculate the velocity moments at the centre of the particles located in the ambient velocity field. Based on these particle velocities, the positions of the particles for the next time step are updated. This process is repeated iteratively, with each cycle involving the construction of a new mobility matrix from the altered particle positions and the calculation of particle velocities. In the Stokes flow regime, the mobility formulation is derived based on the linearity of the forces acting on particle velocities and is uniquely determined from the properties of the fundamental solution in this regime (Dhont Reference Dhont1996). This means that the mobility relation represents the unique response of particles in the suspended flow field, and each simulation step is essentially independent. As a result, the background velocity is computed only once at the beginning of the simulation when no particles are present, and each step calculates velocity disturbances from it. However, addressing the complexity of dealing with boundary conditions resulting from the channel geometry is achieved by introducing imaginary particles on the wall. This approach allows for the use of the same Green's function for both imaginary wall particles and interior particles within the channel. The concept of introducing imaginary wall particles to tackle transport problems in confined suspensions has been explored previously through the suspension balance model by Nott & Brady (Reference Nott and Brady1994). However, it is also recognized that the introduction of wall particles essentially constitutes the bumpy walls which entail a certain sacrifice in terms of accuracy (Singh & Nott Reference Singh and Nott2000). In this study, an extension to arbitrary confined geometries is pursued through the integration of the finite-element method (FEM) with the SD framework, with due consideration given to additional higher-order terms pertaining to the far-field interaction between interior and wall particles.

Figure 1. Flowchart of the proposed multiscale simulation method, including the mathematical symbols used in this study. The blue box represents the process conducted by the fluid dynamics solver, which uses the finite-element method, while the black box represents the process conducted by the Stokesian dynamics method.

In this section, we detail the simulation methodology presented in figure 1 by explaining how to obtain ambient velocity moments and establish the equation of motion for suspended particles. Since ambient velocity moments are specific to the target geometry, we describe the FEM part alongside the definition of the target geometry for conducting case studies. For the equation of motion for particles, we briefly discuss the principles of conventional Stokesian dynamics simulation in § 2.1.1, which cast inter-particle hydrodynamic interactions into matrix-vector form. Subsequently, in § 2.1.2, a constrained Stokesian formulation is derived considering wall particles subject to velocity constraints. Next, in § 2.1.3, we introduce a way of applying the suggested approach to further accelerate computation speeds, leveraging the characteristics of the constrained formulation. Finally, § 2.2 provides a geometric description of the microchannels on which case studies will be conducted for the transport of attractive colloidal suspensions.

2.1. Equation of motion for particles

2.1.1. Matrix-vector formulation of hydrodynamic interactions

In the Stokes flow regime, the equations of motion for particles are described by the Langevin equation, which represents the balance of forces affecting particle motion. The Stokesian dynamics is one approach that accounts for multibody hydrodynamic interactions through the effect of matrix inversion pioneered by Brady & Bossis (Reference Brady and Bossis1988). The changes in force density within a suspension inevitably lead to fluctuations at all points, and this, in turn, affects the changes in force density. This infinite sum of reflections is analogous to the inversion of the mobility matrix, which contains the information on force density (Durlofsky, Brady & Bossis Reference Durlofsky, Brady and Bossis1987). Therefore, in this section, we start from the Langevin equation and briefly describe the conventional methods for formulating multibody hydrodynamic interactions in particle suspensions using matrix-based approaches.

The number of N colloid particles suspended in the fluid that have viscosity ![]() $\mu $ and density

$\mu $ and density ![]() $\rho$ satisfies the following force and torque balance (Brady Reference Brady1993):

$\rho$ satisfies the following force and torque balance (Brady Reference Brady1993):

In the above equations, the left-hand sides can be ignored in the overdamped condition where the mass and relaxation time of the particles are sufficiently small. Here, ![]() ${\boldsymbol{m}}$ and

${\boldsymbol{m}}$ and ![]() ${{\boldsymbol{I}}_m}$ denote mass and moment of inertia, respectively, while

${{\boldsymbol{I}}_m}$ denote mass and moment of inertia, respectively, while ![]() ${\boldsymbol{U}}$ and

${\boldsymbol{U}}$ and ![]() ${\boldsymbol{\varOmega} }$ denote the translational and rotational velocity of the particle, respectively. Therefore, the forces and torques that make balances are hydrodynamic contributions denoted by superscript H, deterministic non-hydrodynamic force or torque with superscript

${\boldsymbol{\varOmega} }$ denote the translational and rotational velocity of the particle, respectively. Therefore, the forces and torques that make balances are hydrodynamic contributions denoted by superscript H, deterministic non-hydrodynamic force or torque with superscript ![]() $P$ and stochastic force or torque with B. Hydrodynamic force acts upon the particle due to the relative motion of the fluid with respect to the particle, and deterministic non-hydrodynamic force acts between a pair of particles based on the inter-particle potential. However, stochastic force and torque describe the thermal motion of particles through Brownian random walk and are uncorrelated with time.

$P$ and stochastic force or torque with B. Hydrodynamic force acts upon the particle due to the relative motion of the fluid with respect to the particle, and deterministic non-hydrodynamic force acts between a pair of particles based on the inter-particle potential. However, stochastic force and torque describe the thermal motion of particles through Brownian random walk and are uncorrelated with time.

To obtain the hydrodynamic contributions acting on a particle, a correlation between the velocity moments and force moments needs to be established. In the Stokes flow regime, characterized by the negligible fluid inertia, a linear relationship exists between an infinitude of higher-order velocity derivatives and hydrodynamic traction moments. Mediating this relationship is the Green's function ![]() ${\boldsymbol{J}}$, a fundamental solution of the Stokes equation. The point force

${\boldsymbol{J}}$, a fundamental solution of the Stokes equation. The point force ![]() ${\boldsymbol{f}}(\kern 1.5pt {\boldsymbol{y}})$, located on the surface element

${\boldsymbol{f}}(\kern 1.5pt {\boldsymbol{y}})$, located on the surface element ![]() $\textrm{d}{S_{\boldsymbol{y}}}$ of the particle suspended in the fluid where

$\textrm{d}{S_{\boldsymbol{y}}}$ of the particle suspended in the fluid where ![]() ${\boldsymbol{y}}$ is a position vector, is integrated to determine the fluid velocity

${\boldsymbol{y}}$ is a position vector, is integrated to determine the fluid velocity ![]() ${\boldsymbol{u}}({\boldsymbol{x}})$ at point

${\boldsymbol{u}}({\boldsymbol{x}})$ at point ![]() ${\boldsymbol{x}}$:

${\boldsymbol{x}}$:

\begin{equation}{\boldsymbol{u}}({\boldsymbol{x}}) = {{\boldsymbol{u}}^\infty }({\boldsymbol{x}}) - \frac{1}{{8{\rm \pi} \mu }}\sum\limits_{\alpha = 1}^N {\int_{{S^\alpha }} {[{\boldsymbol{J}}({\boldsymbol{x}} - {\boldsymbol{y}})\boldsymbol{\cdot }{\boldsymbol{f}}({\,\boldsymbol{y}})]\,\textrm{d}{S_{\boldsymbol{y}}}} } .\end{equation}

\begin{equation}{\boldsymbol{u}}({\boldsymbol{x}}) = {{\boldsymbol{u}}^\infty }({\boldsymbol{x}}) - \frac{1}{{8{\rm \pi} \mu }}\sum\limits_{\alpha = 1}^N {\int_{{S^\alpha }} {[{\boldsymbol{J}}({\boldsymbol{x}} - {\boldsymbol{y}})\boldsymbol{\cdot }{\boldsymbol{f}}({\,\boldsymbol{y}})]\,\textrm{d}{S_{\boldsymbol{y}}}} } .\end{equation} The multipole expansion of the Green's function about the centre ![]() ${{\boldsymbol{x}}^\alpha }$ of each particle yields

${{\boldsymbol{x}}^\alpha }$ of each particle yields

The above expansion is substituted into (2.3), and after simplification through some replacements, it yields

\begin{align}{u_i}({\boldsymbol{x}}) = u_i^\infty ({\boldsymbol{x}}) - \frac{1}{{8{\rm \pi} \mu }}\sum\limits_{\alpha = 1}^N {[{J_{ij}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })F_j^H + {R_{ij}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })T_j^H - {K_{ijk}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })S_{jk}^H + \cdots ].}\end{align}

\begin{align}{u_i}({\boldsymbol{x}}) = u_i^\infty ({\boldsymbol{x}}) - \frac{1}{{8{\rm \pi} \mu }}\sum\limits_{\alpha = 1}^N {[{J_{ij}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })F_j^H + {R_{ij}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })T_j^H - {K_{ijk}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })S_{jk}^H + \cdots ].}\end{align} The replaced terms are equal to (2.6)–(2.10), while ![]() $\varepsilon$ is the Levi-Civita symbol in three dimensions. Here,

$\varepsilon$ is the Levi-Civita symbol in three dimensions. Here, ![]() ${{\boldsymbol{F}}^H}$ and

${{\boldsymbol{F}}^H}$ and ![]() ${{\boldsymbol{T}}^H}$ are the total force and torque on the particle exerted by the fluid. The propagator for the torque

${{\boldsymbol{T}}^H}$ are the total force and torque on the particle exerted by the fluid. The propagator for the torque ![]() ${\boldsymbol{R}}$ is called the rotlet and

${\boldsymbol{R}}$ is called the rotlet and ![]() ${{\boldsymbol{S}}^H}$ is the stresslet on the fluid exerted by the particle. In (2.5), each moment of the force density induces a velocity disturbance of the fluid through propagators. For these moments,

${{\boldsymbol{S}}^H}$ is the stresslet on the fluid exerted by the particle. In (2.5), each moment of the force density induces a velocity disturbance of the fluid through propagators. For these moments, ![]() ${{\boldsymbol{F}}^H}$ corresponds to the monopole or zeroth moment, the asymmetric part of the dipole or first moment becomes

${{\boldsymbol{F}}^H}$ corresponds to the monopole or zeroth moment, the asymmetric part of the dipole or first moment becomes ![]() ${{\boldsymbol{T}}^H}$, while the symmetric part becomes

${{\boldsymbol{T}}^H}$, while the symmetric part becomes ![]() ${{\boldsymbol{S}}^H}$. In this study, terms beyond the first moment are truncated in subsequent expansions, except for two higher multipole contributions arising from the finite size of particles. There are two main reasons for this truncation. The first reason is for computational efficiency. The second reason is that while the force moments and velocity moments are linearly related by the proportionality tensor with the same degree of correlation, in this study, background velocity moments are obtained up to the first moment through a fluid dynamics solver, thus coupling up to this degree of accuracy is considered. Therefore, higher force moments lose their significance as they would not introduce additional coupling effects beyond the first moment.

${{\boldsymbol{S}}^H}$. In this study, terms beyond the first moment are truncated in subsequent expansions, except for two higher multipole contributions arising from the finite size of particles. There are two main reasons for this truncation. The first reason is for computational efficiency. The second reason is that while the force moments and velocity moments are linearly related by the proportionality tensor with the same degree of correlation, in this study, background velocity moments are obtained up to the first moment through a fluid dynamics solver, thus coupling up to this degree of accuracy is considered. Therefore, higher force moments lose their significance as they would not introduce additional coupling effects beyond the first moment.

Assuming the spherical particles with radius a, each particle generates fluid disturbances due to its finite size in the fluid. The higher terms of the force moments that are added correspond to the quadrupole contribution ![]() $(1/6){a^2}{\nabla ^2}{J_{ij}}$ and octuplet contribution

$(1/6){a^2}{\nabla ^2}{J_{ij}}$ and octuplet contribution ![]() $(1/10){a^2}{\nabla ^2}{K_{ijk}}$ from straining motion (Durlofsky et al. Reference Durlofsky, Brady and Bossis1987).

$(1/10){a^2}{\nabla ^2}{K_{ijk}}$ from straining motion (Durlofsky et al. Reference Durlofsky, Brady and Bossis1987).

\begin{align}{u_i}({\boldsymbol{x}}) = u_i^\infty ({\boldsymbol{x}}) - \frac{1}{{8{\rm \pi} \mu }}\sum\limits_{\alpha = 1}^N {\left[ \begin{array}{@{}l@{}} \left( {1 + \dfrac{1}{6}{a^2}{\nabla^2}} \right){J_{ij}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })F_j^H + {R_{ij}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })T_j^H\\ \quad - \left( {1 + \dfrac{1}{{10}}{a^2}{\nabla^2}} \right){K_{ijk}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })S_{jk}^H \end{array} \right]} .\end{align}

\begin{align}{u_i}({\boldsymbol{x}}) = u_i^\infty ({\boldsymbol{x}}) - \frac{1}{{8{\rm \pi} \mu }}\sum\limits_{\alpha = 1}^N {\left[ \begin{array}{@{}l@{}} \left( {1 + \dfrac{1}{6}{a^2}{\nabla^2}} \right){J_{ij}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })F_j^H + {R_{ij}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })T_j^H\\ \quad - \left( {1 + \dfrac{1}{{10}}{a^2}{\nabla^2}} \right){K_{ijk}}({\boldsymbol{x}} - {{\boldsymbol{x}}^\alpha })S_{jk}^H \end{array} \right]} .\end{align} Due to the flow disturbance in the summation of (2.11) without contribution from the particle ![]() $\alpha$, denoted by

$\alpha$, denoted by ![]() ${\boldsymbol{u}^{\prime}}({{\boldsymbol{x}}^\alpha })$, the particle velocities at the centre of the particle

${\boldsymbol{u}^{\prime}}({{\boldsymbol{x}}^\alpha })$, the particle velocities at the centre of the particle ![]() ${{\boldsymbol{x}}^\alpha }$ are given by Faxen's formulae (2.12)–(2.14). In these equations,

${{\boldsymbol{x}}^\alpha }$ are given by Faxen's formulae (2.12)–(2.14). In these equations, ![]() ${{\boldsymbol{U}}^\alpha }$ and

${{\boldsymbol{U}}^\alpha }$ and ![]() ${{\boldsymbol{\varOmega} }^\alpha }$ refer to the translational and rotational velocities of the particle

${{\boldsymbol{\varOmega} }^\alpha }$ refer to the translational and rotational velocities of the particle ![]() $\alpha$, respectively.

$\alpha$, respectively.

\begin{gather}- E_{ij}^\infty = \frac{1}{2}\left[ { - \frac{{S_{ij}^{H,\alpha }}}{{(10/3){\rm \pi} \mu a_\alpha^3}} + \left( {1 + \frac{{a_\alpha^2}}{{10}}{\nabla^2}} \right)({\nabla_j}{u^{\prime}_i}({{\boldsymbol{x}}^\alpha }) + {\nabla_i}{u^{\prime}_j}({{\boldsymbol{x}}^\alpha }))} \right].\end{gather}

\begin{gather}- E_{ij}^\infty = \frac{1}{2}\left[ { - \frac{{S_{ij}^{H,\alpha }}}{{(10/3){\rm \pi} \mu a_\alpha^3}} + \left( {1 + \frac{{a_\alpha^2}}{{10}}{\nabla^2}} \right)({\nabla_j}{u^{\prime}_i}({{\boldsymbol{x}}^\alpha }) + {\nabla_i}{u^{\prime}_j}({{\boldsymbol{x}}^\alpha }))} \right].\end{gather} Using Faxen's equations, the velocity moments that include particle translational (![]() ${\boldsymbol{U}} - {{\boldsymbol{u}}^\infty }$) and angular velocity against the background flow (

${\boldsymbol{U}} - {{\boldsymbol{u}}^\infty }$) and angular velocity against the background flow (![]() ${\boldsymbol{\varOmega} } - {{\boldsymbol{\varOmega} }^\infty }$), as well as the rate of strain of the background flow

${\boldsymbol{\varOmega} } - {{\boldsymbol{\varOmega} }^\infty }$), as well as the rate of strain of the background flow ![]() $- {{\boldsymbol{E}}^\infty }$, are represented by the linear combination of force moments

$- {{\boldsymbol{E}}^\infty }$, are represented by the linear combination of force moments ![]() ${{\boldsymbol{F}}^H}$,

${{\boldsymbol{F}}^H}$, ![]() ${{\boldsymbol{T}}^H}$ and

${{\boldsymbol{T}}^H}$ and ![]() ${{\boldsymbol{S}}^H}$. By representing the corresponding proportionalities in a matrix-tensor formulation, the far-field mobility matrix

${{\boldsymbol{S}}^H}$. By representing the corresponding proportionalities in a matrix-tensor formulation, the far-field mobility matrix ![]() ${{\mathcal{M}}^\infty }$ is constructed. However, to account for lubrication interactions, all terms of the multipole expansion are necessary. Therefore, for particles within the lubrication cutoff radius, the exact resistivity is reflected in a pairwise additive manner. In this process, the far-field corrective term is excluded to prevent double-counting of far-field interactions, resulting in the contribution of the near-field resistance matrix

${{\mathcal{M}}^\infty }$ is constructed. However, to account for lubrication interactions, all terms of the multipole expansion are necessary. Therefore, for particles within the lubrication cutoff radius, the exact resistivity is reflected in a pairwise additive manner. In this process, the far-field corrective term is excluded to prevent double-counting of far-field interactions, resulting in the contribution of the near-field resistance matrix ![]() ${{\mathcal{R}}_{nf}}$ (Jeffrey & Onishi Reference Jeffrey and Onishi1984; Jeffrey Reference Jeffrey1992). The near-field and far-field resistivity are combined to give the grand resistance matrix

${{\mathcal{R}}_{nf}}$ (Jeffrey & Onishi Reference Jeffrey and Onishi1984; Jeffrey Reference Jeffrey1992). The near-field and far-field resistivity are combined to give the grand resistance matrix ![]() ${\mathcal{R}} = {({\mathcal{M}^\infty })^{ - 1}} + {{\mathcal{R}}_{nf}}$.

${\mathcal{R}} = {({\mathcal{M}^\infty })^{ - 1}} + {{\mathcal{R}}_{nf}}$.

\begin{equation}\left( {\begin{array}{@{}c@{}} {{{\boldsymbol{F}}^H}}\\ {{{\boldsymbol{T}}^H}}\\ {{{\boldsymbol{S}}^H}} \end{array}} \right) ={-} {\mathcal{R}}\boldsymbol{\cdot }\left( {\begin{array}{@{}c@{}} {{\boldsymbol{U}} - {{\boldsymbol{u}}^\infty }}\\ {{\boldsymbol{\varOmega} } - {{\boldsymbol{\varOmega} }^\infty }}\\ { - {{\boldsymbol{E}}^\infty }} \end{array}} \right).\end{equation}

\begin{equation}\left( {\begin{array}{@{}c@{}} {{{\boldsymbol{F}}^H}}\\ {{{\boldsymbol{T}}^H}}\\ {{{\boldsymbol{S}}^H}} \end{array}} \right) ={-} {\mathcal{R}}\boldsymbol{\cdot }\left( {\begin{array}{@{}c@{}} {{\boldsymbol{U}} - {{\boldsymbol{u}}^\infty }}\\ {{\boldsymbol{\varOmega} } - {{\boldsymbol{\varOmega} }^\infty }}\\ { - {{\boldsymbol{E}}^\infty }} \end{array}} \right).\end{equation} The inverse problem is to obtain velocity moments from force moments, and the proportionality tensor ![]() ${\mathcal{M}}$ in this relation is called the grand mobility matrix, which has a relation

${\mathcal{M}}$ in this relation is called the grand mobility matrix, which has a relation ![]() ${\mathcal{M}}= {{\mathcal{R}}^{ - 1}}$ with the grand resistance matrix. Each component of the grand resistance matrix is important for subsequent developments and is given as shown in (2.16). Another characteristic of the proportionality tensor is their symmetry and positive definiteness, which arise from the dissipative nature of the system (Kim & Karrila Reference Kim and Karrila2005).

${\mathcal{M}}= {{\mathcal{R}}^{ - 1}}$ with the grand resistance matrix. Each component of the grand resistance matrix is important for subsequent developments and is given as shown in (2.16). Another characteristic of the proportionality tensor is their symmetry and positive definiteness, which arise from the dissipative nature of the system (Kim & Karrila Reference Kim and Karrila2005).

\begin{equation}{\mathcal{R}} = \left( {\begin{array}{@{}ccc@{}} {{{\boldsymbol{R}}_{FU}}}&{{{\boldsymbol{R}}_{F\varOmega }}}&{{{\boldsymbol{R}}_{FE}}}\\ {{{\boldsymbol{R}}_{TU}}}&{{{\boldsymbol{R}}_{T\varOmega }}}&{{{\boldsymbol{R}}_{TE}}}\\ {{{\boldsymbol{R}}_{SU}}}&{{{\boldsymbol{R}}_{S\varOmega }}}&{{{\boldsymbol{R}}_{SE}}} \end{array}} \right).\end{equation}

\begin{equation}{\mathcal{R}} = \left( {\begin{array}{@{}ccc@{}} {{{\boldsymbol{R}}_{FU}}}&{{{\boldsymbol{R}}_{F\varOmega }}}&{{{\boldsymbol{R}}_{FE}}}\\ {{{\boldsymbol{R}}_{TU}}}&{{{\boldsymbol{R}}_{T\varOmega }}}&{{{\boldsymbol{R}}_{TE}}}\\ {{{\boldsymbol{R}}_{SU}}}&{{{\boldsymbol{R}}_{S\varOmega }}}&{{{\boldsymbol{R}}_{SE}}} \end{array}} \right).\end{equation} Returning to (2.1) and (2.2), the non-hydrodynamic inter-particle force ![]() ${{\boldsymbol{F}}^P}$ is pairwise additive and is obtained by taking a derivative of the analytic form of the potential based on the inter-particle distance. Though various analytical potentials can be employed to study fouling dynamics, in our case study in § 3.2, we use a Morse potential due to its finite-sized derivative, including the potential well. In the definition in (2.17),

${{\boldsymbol{F}}^P}$ is pairwise additive and is obtained by taking a derivative of the analytic form of the potential based on the inter-particle distance. Though various analytical potentials can be employed to study fouling dynamics, in our case study in § 3.2, we use a Morse potential due to its finite-sized derivative, including the potential well. In the definition in (2.17), ![]() ${r_{d,}}_{ij}$ is the inter-particle distance between particles i and j, equal to

${r_{d,}}_{ij}$ is the inter-particle distance between particles i and j, equal to ![]() $|{{{\boldsymbol{x}}_i} - {{\boldsymbol{x}}_j}} |$, while

$|{{{\boldsymbol{x}}_i} - {{\boldsymbol{x}}_j}} |$, while ![]() ${a_i}$ and

${a_i}$ and ![]() ${a_j}$ are the radius of particles i and j, respectively. However, the attraction range parameter

${a_j}$ are the radius of particles i and j, respectively. However, the attraction range parameter ![]() $\kappa$ controls the magnitude of attraction and is suggested in accordance with the specific case study. The potential well depth

$\kappa$ controls the magnitude of attraction and is suggested in accordance with the specific case study. The potential well depth ![]() ${V_0}$ is represented as

${V_0}$ is represented as ![]() $6{\rm \pi} \mu u_{avg}^\infty {a^2}/{V_0}$, signifying the dimensionless ratio of the characteristic hydrodynamic force

$6{\rm \pi} \mu u_{avg}^\infty {a^2}/{V_0}$, signifying the dimensionless ratio of the characteristic hydrodynamic force ![]() $6{\rm \pi} \mu u_{avg}^\infty a$ to the attractive force

$6{\rm \pi} \mu u_{avg}^\infty a$ to the attractive force ![]() ${V_0}/a$ in the specific simulation system. In this ratio,

${V_0}/a$ in the specific simulation system. In this ratio, ![]() $u_{avg}^\infty$ is the surface average of the background fluid velocity at the inlet surface.

$u_{avg}^\infty$ is the surface average of the background fluid velocity at the inlet surface.

\begin{gather}F_{ij}^P ={-} \frac{{\partial {\varphi _{Morse}}({r_{d,}}_{ij})}}{{\partial {r_{d,}}_{ij}}}.\end{gather}

\begin{gather}F_{ij}^P ={-} \frac{{\partial {\varphi _{Morse}}({r_{d,}}_{ij})}}{{\partial {r_{d,}}_{ij}}}.\end{gather}

Despite the singular lubrication forces, a small amount of particle overlap may occur due to the finite time step of the simulation (Ekiel-Jezewska, Tomasz & Szymczak Reference Ekiel-Jezewska, Tomasz and Szymczak2008). The same Morse potential is also used to prevent unphysical overlap at ![]() ${r_{d,ij}} < {a_i} + {a_j}$.

${r_{d,ij}} < {a_i} + {a_j}$.

Finally, the Brownian random force and torque terms ![]() ${{\boldsymbol{F}}^B}$ and

${{\boldsymbol{F}}^B}$ and ![]() ${{\boldsymbol{T}}^B}$ originate from the thermal fluctuation of the fluid and are given by the following equations, with angle brackets representing an ensemble average over the entire suspension:

${{\boldsymbol{T}}^B}$ originate from the thermal fluctuation of the fluid and are given by the following equations, with angle brackets representing an ensemble average over the entire suspension:

In this section, each term that constitutes the force balance in the Langevin equation has been introduced. However, there are additional considerations when describing particle dynamics inside a confined channel. For example, as wall particles are immobile, a constraint must be imposed to fix the hydrodynamic velocity moments to zero. Similarly, since there are no thermal fluctuations for the wall particles, (2.19)–(2.21) should also be appropriately modified to account for the Brownian motion of interior particles only while preserving multi-body hydrodynamic interactions. The derivation of the modified formulation, including these constraints, is carried out in the next section.

2.1.2. Stokesian dynamics with velocity constraint

In the framework of Stokesian-based methods, various attempts have been made to incorporate a channel's confined geometries in describing particle-laden flow. One of them is constructing a new Green's function in the presence of wall geometry using Blake's solution to obtain images of Stokeslets based on the distance H from the wall (Blake Reference Blake1971; Bossis, Meunier & Sherwood Reference Bossis, Meunier and Sherwood1991; Swan & Brady Reference Swan and Brady2007). This additional Green's function induced from wall geometry ![]() ${{\boldsymbol{J}}_{wall}}({\boldsymbol{x}},{\boldsymbol{y}};H)$ is superposed onto the fundamental function for particles in (2.22) to form the total Green's function

${{\boldsymbol{J}}_{wall}}({\boldsymbol{x}},{\boldsymbol{y}};H)$ is superposed onto the fundamental function for particles in (2.22) to form the total Green's function ![]() ${\boldsymbol{J}}({\boldsymbol{x}},{\boldsymbol{y}};H) = {{\boldsymbol{J}}_{non\text{-}peri}}({\boldsymbol{x}},{\boldsymbol{y}}) + {{\boldsymbol{J}}_{wall}}({\boldsymbol{x}},{\boldsymbol{y}};H)$.

${\boldsymbol{J}}({\boldsymbol{x}},{\boldsymbol{y}};H) = {{\boldsymbol{J}}_{non\text{-}peri}}({\boldsymbol{x}},{\boldsymbol{y}}) + {{\boldsymbol{J}}_{wall}}({\boldsymbol{x}},{\boldsymbol{y}};H)$.

The above function is also called the Oseen tensor (Oseen Reference Oseen1927), while ![]() ${\boldsymbol{I}}$ denotes the identity tensor,

${\boldsymbol{I}}$ denotes the identity tensor, ![]() ${\boldsymbol{r}} = {\boldsymbol{x}} - {\boldsymbol{y}}$ and

${\boldsymbol{r}} = {\boldsymbol{x}} - {\boldsymbol{y}}$ and ![]() ${r^2} = {\boldsymbol{r}}\boldsymbol{\cdot }{\boldsymbol{r}}$. For the fluid velocity at

${r^2} = {\boldsymbol{r}}\boldsymbol{\cdot }{\boldsymbol{r}}$. For the fluid velocity at ![]() ${\boldsymbol{x}}$ induced by the periodic images at

${\boldsymbol{x}}$ induced by the periodic images at ![]() ${\boldsymbol{y}}$, the Green's function derived by Hasimoto (Reference Hasimoto1959) is used while

${\boldsymbol{y}}$, the Green's function derived by Hasimoto (Reference Hasimoto1959) is used while ![]() ${\boldsymbol{k}}$ represents lattice vector on a reciprocal space:

${\boldsymbol{k}}$ represents lattice vector on a reciprocal space:

\begin{equation}{{\boldsymbol{J}}_{peri}}({\boldsymbol{x}},{\boldsymbol{y}}) = \frac{1}{{\mu V}}\sum\limits_{{\boldsymbol{k}} {\ne} 0} {{\textrm{e}^{\textrm{i}{\boldsymbol{k}}\,\boldsymbol{\cdot}\,({\boldsymbol{x}} - {\boldsymbol{y}})}}\frac{1}{{{k^2}}}({\boldsymbol{I}} - {\hat{\boldsymbol{k}}\hat{\boldsymbol{k}}})} .\end{equation}

\begin{equation}{{\boldsymbol{J}}_{peri}}({\boldsymbol{x}},{\boldsymbol{y}}) = \frac{1}{{\mu V}}\sum\limits_{{\boldsymbol{k}} {\ne} 0} {{\textrm{e}^{\textrm{i}{\boldsymbol{k}}\,\boldsymbol{\cdot}\,({\boldsymbol{x}} - {\boldsymbol{y}})}}\frac{1}{{{k^2}}}({\boldsymbol{I}} - {\hat{\boldsymbol{k}}\hat{\boldsymbol{k}}})} .\end{equation}When this total Green's function is integrated through a surface boundary integral that takes wall geometry into account, it allows for the evaluation of fluid disturbances at arbitrary points (Ladyzhenskaya Reference Ladyzhenskaya1963). For the extension in the case of multiple wall geometries, the same method of continuously superposing Green's functions has been used for studying the dynamics and rheology of particles placed between the parallel and perpendicular walls (Swan & Brady Reference Swan and Brady2003, Reference Swan and Brady2011; Staben, Zinchenko & Davis Reference Staben, Zinchenko and Davis2003). While it has the advantage of accurately reflecting the boundary effects where point forces are located, it also has certain limitations. The rapid increase in complexity with each superposed boundary makes it challenging to derive an explicit form of the Green function; an explicit form of the Green function does not already exist in the case of the flow between parallel slits according to Swan & Brady (Reference Swan and Brady2011). Expandability to accommodate changed boundary conditions is also limited, as the strategies to integrate force densities on each surface boundary have to be changed.

In this study, to circumvent these difficulties, the confined channel wall is simulated using a particle-wall scheme, as shown in figure 2. The primary advantage of this scheme is that it allows for the utilization of the same form of Green's function for both interior particles and wall particles, eliminating the need for calculating complex Green's functions. The placement of imaginary particles on the wall has been previously employed in a suspension balance model (Singh & Nott Reference Singh and Nott2000; Nott, Guazzelli & Pouliquen Reference Nott, Guazzelli and Pouliquen2011). In our study, we have developed an extension to arbitrary channel geometries by coupling a fluid dynamic solver to obtain background velocity moments while satisfying the microscopic force balances on the suspended particles and deriving macroscopic properties from the overall force balance on the channel. This approach develops into an efficient method for solving the interior dynamics of particles, leveraging the constraint properties on wall particles. Furthermore, by analysing the hydrodynamic force moments applied to the wall particles, it becomes possible to calculate the stress applied to a specific location on the channel wall, a capability challenging to achieve when using Oseen's superposition approach.

Figure 2. Schematic pictures of boundary treatment methods using wall particles. In panel (a), the excluded volume scheme is displayed, where the wall particles are entirely excluded from the fluid domain where fluid and particle velocity are evaluated. In panel (b), the included volume scheme is displayed, where the wall particles are arranged in a way that removes the excluded volume.

However, the accompanying limitations of the particle-wall scheme are examined. Since it models the boundary using wall particles, and point forces are located on the surfaces of spherical particles, it practically simulates a rough or bumpy wall. Moreover, as it considers particles as a patch on the wall approximating the wall resistivity, the computational cost increases rapidly as the system size becomes larger, in proportion to the cube of the total number of particles used. To mitigate this cubic dependence on the total number of particles, the effects from the wall particles are separated and treated as predetermined hydrodynamic force moments acting on the interior particles, originating from the properties of the prescribed velocity of wall particles. This treatment allows an efficient description of particle dynamics inside the channel, especially at the beginning of the simulation. However, as the volume fraction inside the channel increases in the late stage of the simulation, hydrodynamics within the channel becomes dominated by particle–particle interactions, and the influence of the wall on particle motion becomes less significant (Swan & Brady Reference Swan and Brady2011). The deviatoric effects of the particle-wall scheme on the transport properties and scaling performance of the constrained SD by the system size are discussed in § 3.1.

There are two ways of arranging particles to replace the wall boundary, which are the excluded volume scheme in figure 2(a), where the particles completely retreat from the target boundary, and the included volume scheme in figure 2(b), where the particles intrude over the target boundary. The excluded volume scheme has the advantage that macroscopic properties converge to those of pure fluid when there are no interior particles. However, the included scheme focuses on filling the place of the wall to the greatest extent. If the background flow is uniform, or in simulations where both force-rotational velocity and force-strain rate coupling do not exist (Nott & Brady Reference Nott and Brady1994), there is no practical difference between the two methods as they do not differ in the hydrodynamic forces experienced by interior and wall particles. However, in this study, the background velocity within the channel is calculated through the fluid dynamics solver, allowing for the application of any form of background flow field within the Stokes flow region. Due to its generality, force moments up to the dipole term, which corresponds to the same degree of accuracy as velocity moments, are considered. This increases the accuracy of the mobility relation governing HI. Thus, as depicted in figure 2(b), if particle centres are located on the target boundary, additional stresses are exerted on the channel wall even when there are no suspended particles due to the velocity gradient at the centre of wall particles. Therefore, in this study, we will proceed with the development according to the excluded volume scheme in figure 2(a) to avoid this situation.

If we expand the hydrodynamic forces on interior particles I and wall particles W through the resistance formulation in (2.15), each force can respectively be expressed as follows:

\begin{align}{{\boldsymbol{F}}^I} &={-}

{\boldsymbol{R}}_{FU}^{II}\boldsymbol{\cdot

}({{\boldsymbol{u}}^I} - {{\boldsymbol{U}}^\infty }) +

{\boldsymbol{R}}_{FU}^{IW}\boldsymbol{\cdot

}{{\boldsymbol{U}}^\infty } - {\boldsymbol{R}}_{F\varOmega

}^{II}\boldsymbol{\cdot }({{\boldsymbol{\omega} }^I} -

{{\boldsymbol{\varOmega} }^\infty })\nonumber\\ &\quad +

{\boldsymbol{R}}_{F\varOmega }^{IW}\boldsymbol{\cdot

}{{\boldsymbol{\varOmega} }^\infty } +

{\boldsymbol{R}}_{FE}^{II}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty } +

{\boldsymbol{R}}_{FE}^{IW}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty

},\end{align}

\begin{align}{{\boldsymbol{F}}^I} &={-}

{\boldsymbol{R}}_{FU}^{II}\boldsymbol{\cdot

}({{\boldsymbol{u}}^I} - {{\boldsymbol{U}}^\infty }) +

{\boldsymbol{R}}_{FU}^{IW}\boldsymbol{\cdot

}{{\boldsymbol{U}}^\infty } - {\boldsymbol{R}}_{F\varOmega

}^{II}\boldsymbol{\cdot }({{\boldsymbol{\omega} }^I} -

{{\boldsymbol{\varOmega} }^\infty })\nonumber\\ &\quad +

{\boldsymbol{R}}_{F\varOmega }^{IW}\boldsymbol{\cdot

}{{\boldsymbol{\varOmega} }^\infty } +

{\boldsymbol{R}}_{FE}^{II}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty } +

{\boldsymbol{R}}_{FE}^{IW}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty

},\end{align} \begin{align}{{\boldsymbol{F}}^W} &=

{\boldsymbol{R}}_{FU}^{WW}\boldsymbol{\cdot

}{{\boldsymbol{U}}^\infty } -

{\boldsymbol{R}}_{FU}^{WI}\boldsymbol{\cdot

}({{\boldsymbol{u}}^I} - {{\boldsymbol{U}}^\infty })\nonumber\\ &\quad +

{\boldsymbol{R}}_{FU}^{WW}\boldsymbol{\cdot

}{{\boldsymbol{\varOmega} }^\infty } -

{\boldsymbol{R}}_{F\varOmega }^{WI}\boldsymbol{\cdot

}({{\boldsymbol{\omega} }^I} - {{\boldsymbol{\varOmega}

}^\infty }) + {\boldsymbol{R}}_{FE}^{WW}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty } +

{\boldsymbol{R}}_{FE}^{WI}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty

}.\end{align}

\begin{align}{{\boldsymbol{F}}^W} &=

{\boldsymbol{R}}_{FU}^{WW}\boldsymbol{\cdot

}{{\boldsymbol{U}}^\infty } -

{\boldsymbol{R}}_{FU}^{WI}\boldsymbol{\cdot

}({{\boldsymbol{u}}^I} - {{\boldsymbol{U}}^\infty })\nonumber\\ &\quad +

{\boldsymbol{R}}_{FU}^{WW}\boldsymbol{\cdot

}{{\boldsymbol{\varOmega} }^\infty } -

{\boldsymbol{R}}_{F\varOmega }^{WI}\boldsymbol{\cdot

}({{\boldsymbol{\omega} }^I} - {{\boldsymbol{\varOmega}

}^\infty }) + {\boldsymbol{R}}_{FE}^{WW}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty } +

{\boldsymbol{R}}_{FE}^{WI}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty

}.\end{align} Here, ![]() ${{\boldsymbol{F}}^I}$ and

${{\boldsymbol{F}}^I}$ and ![]() ${{\boldsymbol{F}}^W}$ denote the hydrodynamic forces on the interior and wall particles exerted by the fluid, respectively. In subsequent developments, the additional superscript H will be omitted for the sake of simplicity since the grand resistance formulation itself is based on the common understanding that it represents relationships involving hydrodynamic force moments. Regarding the meaning of the proportionalities,

${{\boldsymbol{F}}^W}$ denote the hydrodynamic forces on the interior and wall particles exerted by the fluid, respectively. In subsequent developments, the additional superscript H will be omitted for the sake of simplicity since the grand resistance formulation itself is based on the common understanding that it represents relationships involving hydrodynamic force moments. Regarding the meaning of the proportionalities, ![]() ${\boldsymbol{R}}_{FU}^{II}$ corresponds to the resistance matrix, indicating the coupling between the force and translational velocity among the interior particles, while

${\boldsymbol{R}}_{FU}^{II}$ corresponds to the resistance matrix, indicating the coupling between the force and translational velocity among the interior particles, while ![]() ${\boldsymbol{R}}_{FE}^{IW}$ represents the coupling between the force and strain rate among the interior and wall particles. The remaining components of the resistance matrix follow the same fashion of coupling notation. Here,

${\boldsymbol{R}}_{FE}^{IW}$ represents the coupling between the force and strain rate among the interior and wall particles. The remaining components of the resistance matrix follow the same fashion of coupling notation. Here, ![]() ${{\boldsymbol{u}}^I}$ and

${{\boldsymbol{u}}^I}$ and ![]() ${{\boldsymbol{u}}^W}$ denote the translational velocities of interior and wall particles, respectively, while

${{\boldsymbol{u}}^W}$ denote the translational velocities of interior and wall particles, respectively, while ![]() ${{\boldsymbol{\omega} }^I}$ and

${{\boldsymbol{\omega} }^I}$ and ![]() ${{\boldsymbol{\omega} }^W}$ represent the rotational velocities of interior and wall particles. Wall particles are assumed to be immobile, and velocity constraints are applied as

${{\boldsymbol{\omega} }^W}$ represent the rotational velocities of interior and wall particles. Wall particles are assumed to be immobile, and velocity constraints are applied as ![]() ${{\boldsymbol{u}}^W} = {{\boldsymbol{\omega} }^W} = {\textbf{0}}$. Subsequently, as the resistance tensor is independent of the particles’ momentum and is pre-determined based on the configuration of the particles and the topology of the wall, the deterministic part of the hydrodynamic forcing term under the background velocity is substituted, as shown in (2.26) and (2.27), and the velocity moments of interior particles are reformulated, as in (2.28):

${{\boldsymbol{u}}^W} = {{\boldsymbol{\omega} }^W} = {\textbf{0}}$. Subsequently, as the resistance tensor is independent of the particles’ momentum and is pre-determined based on the configuration of the particles and the topology of the wall, the deterministic part of the hydrodynamic forcing term under the background velocity is substituted, as shown in (2.26) and (2.27), and the velocity moments of interior particles are reformulated, as in (2.28):

\begin{gather}\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{F}}^P} +

{{\boldsymbol{F}}^B} + {\boldsymbol{A}}}\\

{{{\boldsymbol{T}}^B} + {\boldsymbol{B}}} \end{array}}

\right] = \left[ {\begin{array}{@{}cc@{}}

{{\boldsymbol{R}}_{FU}^{II}}& {{\boldsymbol{R}}_{F\varOmega

}^{II}}\\

{{\boldsymbol{R}}_{TU}^{II}}& {{\boldsymbol{R}}_{T\varOmega

}^{II}} \end{array}} \right]\boldsymbol{\cdot }\left[

{\begin{array}{@{}c@{}} {{{\boldsymbol{u}}^I}}\\

{{{\boldsymbol{\omega} }^I}} \end{array}}

\right],\end{gather}

\begin{gather}\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{F}}^P} +

{{\boldsymbol{F}}^B} + {\boldsymbol{A}}}\\

{{{\boldsymbol{T}}^B} + {\boldsymbol{B}}} \end{array}}

\right] = \left[ {\begin{array}{@{}cc@{}}

{{\boldsymbol{R}}_{FU}^{II}}& {{\boldsymbol{R}}_{F\varOmega

}^{II}}\\

{{\boldsymbol{R}}_{TU}^{II}}& {{\boldsymbol{R}}_{T\varOmega

}^{II}} \end{array}} \right]\boldsymbol{\cdot }\left[

{\begin{array}{@{}c@{}} {{{\boldsymbol{u}}^I}}\\

{{{\boldsymbol{\omega} }^I}} \end{array}}

\right],\end{gather} \begin{gather}\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{u}}^I}}\\

{{{\boldsymbol{\omega} }^I}} \end{array}} \right] = \left[

{\begin{array}{@{}cc@{}} {{{({\boldsymbol{R}}_{FU}^{II})}^{

- 1}}}&{{{({\boldsymbol{R}}_{F\varOmega }^{II})}^{ - 1}}}\\

{{{({\boldsymbol{R}}_{TU}^{II})}^{ -

1}}}&{{{({\boldsymbol{R}}_{T\varOmega }^{II})}^{ - 1}}}

\end{array}} \right]\boldsymbol{\cdot }\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{F}}^P} +

{{\boldsymbol{F}}^B} + {\boldsymbol{A}}}\\

{{{\boldsymbol{T}}^B} + {\boldsymbol{B}}} \end{array}}

\right].\end{gather}

\begin{gather}\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{u}}^I}}\\

{{{\boldsymbol{\omega} }^I}} \end{array}} \right] = \left[

{\begin{array}{@{}cc@{}} {{{({\boldsymbol{R}}_{FU}^{II})}^{

- 1}}}&{{{({\boldsymbol{R}}_{F\varOmega }^{II})}^{ - 1}}}\\

{{{({\boldsymbol{R}}_{TU}^{II})}^{ -

1}}}&{{{({\boldsymbol{R}}_{T\varOmega }^{II})}^{ - 1}}}

\end{array}} \right]\boldsymbol{\cdot }\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{F}}^P} +

{{\boldsymbol{F}}^B} + {\boldsymbol{A}}}\\

{{{\boldsymbol{T}}^B} + {\boldsymbol{B}}} \end{array}}

\right].\end{gather} In writing (2.28), the governing equation in (2.1) substitutes the hydrodynamic force on the interior particles. Here, with regards to ![]() ${({\boldsymbol{R}}_{FU}^{II})^{ - 1}}$, it should be noted that it is not a result of direct inversion of the force-velocity coupling part of the resistance tensor, but rather the submatrix obtained after inverting the entire resistance matrix between interior particles in (2.28). The contribution from the inter-particle non-hydrodynamic interactions

${({\boldsymbol{R}}_{FU}^{II})^{ - 1}}$, it should be noted that it is not a result of direct inversion of the force-velocity coupling part of the resistance tensor, but rather the submatrix obtained after inverting the entire resistance matrix between interior particles in (2.28). The contribution from the inter-particle non-hydrodynamic interactions ![]() ${{\boldsymbol{F}}^P}$ is calculated in the pairwise additive fashion as in conventional SD, while the Brownian force and torque terms, represented as

${{\boldsymbol{F}}^P}$ is calculated in the pairwise additive fashion as in conventional SD, while the Brownian force and torque terms, represented as ![]() ${{\boldsymbol{F}}^B}$ and

${{\boldsymbol{F}}^B}$ and ![]() ${{\boldsymbol{T}}^B}$, can be simplified as follows:

${{\boldsymbol{T}}^B}$, can be simplified as follows:

While the Brownian random force has been explicitly added in (2.29), it alone does not fully account for the effects of thermal motion. In concentrated colloid systems, diffusivity varies depending on the configuration, and particle diffusion can be enhanced by random walks in structures with high diffusivity (Ermak & McCammon Reference Ermak and Mccammon1978). Therefore, a mean drift term with equal strength is added to counteract the erroneous particle depletion resulting from configurations that have high diffusivity (Brady & Bossis Reference Brady and Bossis1988).

\begin{align}\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{x}}^I}({t_{n +

1}})}\\ {{{\boldsymbol{\theta} }^I}({t_{n + 1}})}

\end{array}} \right] &= \left[ {\begin{array}{*{20}{@{}c@{}}}

{{{\boldsymbol{x}}^I}({t_n})}\\ {{{\boldsymbol{\theta}

}^I}({t_n})} \end{array}} \right] + ({t_{n + 1}} -

{t_n})\nonumber\\ &\quad \times \left( \begin{array}{l} \left[

{\begin{array}{@{}cc@{}} {{{({\boldsymbol{R}}_{FU}^{II})}^{

- 1}}}&{{{({\boldsymbol{R}}_{F\varOmega }^{II})}^{ - 1}}}\\

{({\boldsymbol{R}}_{TU}^{II})^{ -

1}}&{{{({\boldsymbol{R}}_{T\varOmega }^{II})}^{ - 1}}}

\end{array}} \right]\boldsymbol{\cdot }\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{F}}^P} +

{{\boldsymbol{F}}^B} + {\boldsymbol{A}}}\\

{{{\boldsymbol{T}}^B} + {\boldsymbol{B}}} \end{array}}

\right]\\ + \left[ {\begin{array}{*{20}{@{}c@{}}}

{\boldsymbol{\nabla }\boldsymbol{\cdot

}{{({\boldsymbol{R}}_{FU}^{II})}^{ - 1/2}}}\\

{\boldsymbol{\nabla }\boldsymbol{\cdot

}{{({\boldsymbol{R}}_{T\varOmega }^{II})}^{ - 1/2}}}

\end{array}} \right] \end{array}

\right).\end{align}

\begin{align}\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{x}}^I}({t_{n +

1}})}\\ {{{\boldsymbol{\theta} }^I}({t_{n + 1}})}

\end{array}} \right] &= \left[ {\begin{array}{*{20}{@{}c@{}}}

{{{\boldsymbol{x}}^I}({t_n})}\\ {{{\boldsymbol{\theta}

}^I}({t_n})} \end{array}} \right] + ({t_{n + 1}} -

{t_n})\nonumber\\ &\quad \times \left( \begin{array}{l} \left[

{\begin{array}{@{}cc@{}} {{{({\boldsymbol{R}}_{FU}^{II})}^{

- 1}}}&{{{({\boldsymbol{R}}_{F\varOmega }^{II})}^{ - 1}}}\\

{({\boldsymbol{R}}_{TU}^{II})^{ -

1}}&{{{({\boldsymbol{R}}_{T\varOmega }^{II})}^{ - 1}}}

\end{array}} \right]\boldsymbol{\cdot }\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{F}}^P} +

{{\boldsymbol{F}}^B} + {\boldsymbol{A}}}\\

{{{\boldsymbol{T}}^B} + {\boldsymbol{B}}} \end{array}}

\right]\\ + \left[ {\begin{array}{*{20}{@{}c@{}}}

{\boldsymbol{\nabla }\boldsymbol{\cdot

}{{({\boldsymbol{R}}_{FU}^{II})}^{ - 1/2}}}\\

{\boldsymbol{\nabla }\boldsymbol{\cdot

}{{({\boldsymbol{R}}_{T\varOmega }^{II})}^{ - 1/2}}}

\end{array}} \right] \end{array}

\right).\end{align}Various algorithms have been proposed to account for the mean drift term simultaneously during time-stepping (Grassia, Hinch & Nitsche Reference Grassia, Hinch and Nitsche1995; Delong et al. Reference Delong, Usabiaga, Buscalioni, Griffith and Donev2014). Among these methods, the mid-point algorithm of Fixman (Reference Fixman1986) has been widely adopted and can be readily implemented within the current formalism. Employing this method, the evolution equations for the particle trajectories become

\begin{align}{\left. {\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{x}}^I}}\\

{{{\boldsymbol{\theta} }^I}} \end{array}} \right]}

\right|_{{t_{n + 1/2}}}} &= {\left. {\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{x}}^I}}\\

{{{\boldsymbol{\theta} }^I}} \end{array}} \right]}

\right|_{{t_n}}} + \frac{{({t_{n + 1}} - {t_n})}}{2}{\left.

{\left[ {\begin{array}{@{}cc@{}}

{{{({\boldsymbol{R}}_{FU}^{II})}^{ -

1}}}&\ {{{({\boldsymbol{R}}_{F\varOmega }^{II})}^{ - 1}}}\\

{{{({\boldsymbol{R}}_{TU}^{II})}^{ -

1}}}&\ {{{({\boldsymbol{R}}_{T\varOmega }^{II})}^{ - 1}}}

\end{array}} \right]} \right|_{{t_n}}}\nonumber\\ &\quad \boldsymbol{\cdot

}\left[ {\begin{array}{*{20}{@{}c@{}}} {{{ {({{\boldsymbol{F}}^P}

+ {\boldsymbol{A}})} |}_{{t_n}}} + {{

{{{\boldsymbol{F}}^B}} |}_{{t_n}}}}\\ {{{ {\boldsymbol{B}}

|}_{{t_n}}} + {{ {{{\boldsymbol{T}}^B}} |}_{{t_n}}}}

\end{array}}

\right],\end{align}

\begin{align}{\left. {\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{x}}^I}}\\

{{{\boldsymbol{\theta} }^I}} \end{array}} \right]}

\right|_{{t_{n + 1/2}}}} &= {\left. {\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{x}}^I}}\\

{{{\boldsymbol{\theta} }^I}} \end{array}} \right]}

\right|_{{t_n}}} + \frac{{({t_{n + 1}} - {t_n})}}{2}{\left.

{\left[ {\begin{array}{@{}cc@{}}

{{{({\boldsymbol{R}}_{FU}^{II})}^{ -

1}}}&\ {{{({\boldsymbol{R}}_{F\varOmega }^{II})}^{ - 1}}}\\

{{{({\boldsymbol{R}}_{TU}^{II})}^{ -

1}}}&\ {{{({\boldsymbol{R}}_{T\varOmega }^{II})}^{ - 1}}}

\end{array}} \right]} \right|_{{t_n}}}\nonumber\\ &\quad \boldsymbol{\cdot

}\left[ {\begin{array}{*{20}{@{}c@{}}} {{{ {({{\boldsymbol{F}}^P}

+ {\boldsymbol{A}})} |}_{{t_n}}} + {{

{{{\boldsymbol{F}}^B}} |}_{{t_n}}}}\\ {{{ {\boldsymbol{B}}

|}_{{t_n}}} + {{ {{{\boldsymbol{T}}^B}} |}_{{t_n}}}}

\end{array}}

\right],\end{align} \begin{align}{\left. {\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{x}}^I}}\\

{{{\boldsymbol{\theta} }^I}} \end{array}} \right]}

\right|_{{t_{n + 1}}}} &= {\left. {\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{x}}^I}}\\

{{{\boldsymbol{\theta} }^I}} \end{array}} \right]}

\right|_{{t_n}}} + ({t_{n + 1}} - {t_n}){\left. {\left[

{\begin{array}{@{}cc@{}} {{{({\boldsymbol{R}}_{FU}^{II})}^{

- 1}}}&\ {{{({\boldsymbol{R}}_{F\varOmega }^{II})}^{ - 1}}}\\

{{{({\boldsymbol{R}}_{TU}^{II})}^{ -

1}}}&\ {{{({\boldsymbol{R}}_{T\varOmega }^{II})}^{ - 1}}}

\end{array}} \right]} \right|_{{t_{n + 1/2}}}}\nonumber\\ &\quad \cdot \left[

{\begin{array}{*{20}{@{}c@{}}} {{{ {({{\boldsymbol{F}}^P} +

{\boldsymbol{A}})} |}_{{t_{n + 1/2}}}} + {{

{{{\boldsymbol{F}}^B}} |}_{{t_n}}}}\\ {{{ {\boldsymbol{B}}

|}_{{t_{n + 1/2}}}} + {{ {{{\boldsymbol{T}}^B}}

|}_{{t_n}}}} \end{array}}

\right].\end{align}

\begin{align}{\left. {\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{x}}^I}}\\

{{{\boldsymbol{\theta} }^I}} \end{array}} \right]}

\right|_{{t_{n + 1}}}} &= {\left. {\left[

{\begin{array}{*{20}{@{}c@{}}} {{{\boldsymbol{x}}^I}}\\

{{{\boldsymbol{\theta} }^I}} \end{array}} \right]}

\right|_{{t_n}}} + ({t_{n + 1}} - {t_n}){\left. {\left[

{\begin{array}{@{}cc@{}} {{{({\boldsymbol{R}}_{FU}^{II})}^{

- 1}}}&\ {{{({\boldsymbol{R}}_{F\varOmega }^{II})}^{ - 1}}}\\

{{{({\boldsymbol{R}}_{TU}^{II})}^{ -

1}}}&\ {{{({\boldsymbol{R}}_{T\varOmega }^{II})}^{ - 1}}}

\end{array}} \right]} \right|_{{t_{n + 1/2}}}}\nonumber\\ &\quad \cdot \left[

{\begin{array}{*{20}{@{}c@{}}} {{{ {({{\boldsymbol{F}}^P} +

{\boldsymbol{A}})} |}_{{t_{n + 1/2}}}} + {{

{{{\boldsymbol{F}}^B}} |}_{{t_n}}}}\\ {{{ {\boldsymbol{B}}

|}_{{t_{n + 1/2}}}} + {{ {{{\boldsymbol{T}}^B}}

|}_{{t_n}}}} \end{array}}

\right].\end{align} First, by using (2.34), particle displacement at ![]() ${t_{n + 1/2}}$ is computed, and subsequently, employing the updated resistance matrix, particle displacement at

${t_{n + 1/2}}$ is computed, and subsequently, employing the updated resistance matrix, particle displacement at ![]() ${t_{n + 1}}$ is determined according to (2.35). This step corresponds to the final phase of the algorithm, as illustrated in figure 1, which entails determining the new particle positions through time marching.

${t_{n + 1}}$ is determined according to (2.35). This step corresponds to the final phase of the algorithm, as illustrated in figure 1, which entails determining the new particle positions through time marching.

When drawing an analogy between the present approach and conventional SD, the grand resistance matrix presented in (2.15) is replaced with the resistance matrix between interior particles in (2.28). Furthermore, the Brownian motions described by (2.19)–(2.21) are replaced by those designed for interior particles in (2.30)–(2.32). Consequently, in constrained SD, the procedure for calculating the square root or inverse of the grand resistance matrix in conventional SD is replaced with the process of determining the square root or inverse of the resistance matrix, which accounts for the interactions among the interior particles. In essence, as the system size increases, primarily due to the greater number of wall particles, the computational overhead associated with direct matrix inversion is confined to that from interior particles. This structural advantage ensures that the number of independent equations is directly proportional to the number of interior particles, effectively minimizing the computational cost stemming from the number of wall particles.

However, the influence of wall particles on computational cost is not entirely negligible throughout the entire algorithm. This is because when obtaining the grand resistance matrix in (2.16), it is necessary to invert the far-field mobility matrix containing information about all the particles to account for long-ranged hydrodynamics induced by wall particles. As a result of this process, the dynamics of particles in accordance with ambient flow and thermal fluctuation reflect the effects from the channel walls. However, since hydrodynamic effects from far-field interactions change slowly over time, this process is performed only once per single diffusional time of a particle ![]() $6{\rm \pi} \mu {a^3}/{k_B}T$ (Nott & Brady Reference Nott and Brady1994), where

$6{\rm \pi} \mu {a^3}/{k_B}T$ (Nott & Brady Reference Nott and Brady1994), where ![]() ${k_B}$ is the Boltzmann constant and T is the system temperature. In our study, the time step used for simulations is 10−4 times a single diffusional time, so the inversion of the grand mobility matrix is performed once every 104 steps, significantly reducing its computational proportion in the simulation.

${k_B}$ is the Boltzmann constant and T is the system temperature. In our study, the time step used for simulations is 10−4 times a single diffusional time, so the inversion of the grand mobility matrix is performed once every 104 steps, significantly reducing its computational proportion in the simulation.

However, as (2.29) takes a fully generalized form independent of the number of wall particles, this formulation can also be applied in conventional SD where wall particles are not present. Interestingly, Wang & Swan (Reference Wang and Swan2019) employed a similar form of the governing equation to investigate the heterogeneity effect of patched beads on colloid gelation. In this study, each of the sphere particles comprising the beads is compelled into rigid body motion through the action of constraint force. Although developed for different systems, this constraint-containing Stokesian dynamics formulation shares the structural advantages presented in (2.29) and could find applications in various systems.

Not only essential aspects of particle motion, but also the rheological properties of interior particles and the hydrodynamic stress ![]() ${{\boldsymbol{S}}^H}$ exerted on the channel wall can be efficiently calculated. First, obtaining the hydrodynamic force

${{\boldsymbol{S}}^H}$ exerted on the channel wall can be efficiently calculated. First, obtaining the hydrodynamic force ![]() ${{\boldsymbol{F}}^W}$ on the channel wall is straightforward, achieved by performing the matrix-vector multiplication in (2.25) using the velocity vector of interior particles obtained during the time marching. Similarly, the hydrodynamic stress experienced by the wall and interior particles is determined using the velocity vector of internal particles and (2.15). More specifically, the particle-phase stress is divided into non-hydrodynamic and hydrodynamic contributions, as illustrated in (2.36) (Batchelor Reference Batchelor1970, Reference Batchelor1977). The first two terms, ideal osmotic pressure and inter-particle elastic stress, constitute the non-hydrodynamic stress, while the third term, representing the hydrodynamic component, is elaborated upon in (2.37) for interior particles (

${{\boldsymbol{F}}^W}$ on the channel wall is straightforward, achieved by performing the matrix-vector multiplication in (2.25) using the velocity vector of interior particles obtained during the time marching. Similarly, the hydrodynamic stress experienced by the wall and interior particles is determined using the velocity vector of internal particles and (2.15). More specifically, the particle-phase stress is divided into non-hydrodynamic and hydrodynamic contributions, as illustrated in (2.36) (Batchelor Reference Batchelor1970, Reference Batchelor1977). The first two terms, ideal osmotic pressure and inter-particle elastic stress, constitute the non-hydrodynamic stress, while the third term, representing the hydrodynamic component, is elaborated upon in (2.37) for interior particles (![]() ${\langle {\boldsymbol{\Sigma} }\rangle ^H} = {\langle {\boldsymbol{S}}\rangle ^I}$), and (2.38) for the wall stress simulated by wall particles (

${\langle {\boldsymbol{\Sigma} }\rangle ^H} = {\langle {\boldsymbol{S}}\rangle ^I}$), and (2.38) for the wall stress simulated by wall particles (![]() ${\langle {\boldsymbol{\Sigma} }\rangle ^H} = {\langle {\boldsymbol{S}}\rangle ^W}$).

${\langle {\boldsymbol{\Sigma} }\rangle ^H} = {\langle {\boldsymbol{S}}\rangle ^W}$).

\begin{gather}{{\boldsymbol{S}}^I} ={-}

{\boldsymbol{R}}_{SU}^{II}\boldsymbol{\cdot

}({{\boldsymbol{u}}^I} - {{\boldsymbol{U}}^\infty }) +

{\boldsymbol{R}}_{SU}^{IW}\boldsymbol{\cdot

}{{\boldsymbol{U}}^\infty } - {\boldsymbol{R}}_{S\varOmega

}^{II}\boldsymbol{\cdot }({{\boldsymbol{\omega} }^I} -

{{\boldsymbol{\varOmega} }^\infty })\nonumber\\ \quad +\,{\boldsymbol{R}}_{S\varOmega }^{IW}\boldsymbol{\cdot

}{{\boldsymbol{\varOmega} }^\infty } +

{\boldsymbol{R}}_{SE}^{II}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty } +

{\boldsymbol{R}}_{SE}^{IW}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty

},\end{gather}

\begin{gather}{{\boldsymbol{S}}^I} ={-}

{\boldsymbol{R}}_{SU}^{II}\boldsymbol{\cdot

}({{\boldsymbol{u}}^I} - {{\boldsymbol{U}}^\infty }) +

{\boldsymbol{R}}_{SU}^{IW}\boldsymbol{\cdot

}{{\boldsymbol{U}}^\infty } - {\boldsymbol{R}}_{S\varOmega

}^{II}\boldsymbol{\cdot }({{\boldsymbol{\omega} }^I} -

{{\boldsymbol{\varOmega} }^\infty })\nonumber\\ \quad +\,{\boldsymbol{R}}_{S\varOmega }^{IW}\boldsymbol{\cdot

}{{\boldsymbol{\varOmega} }^\infty } +

{\boldsymbol{R}}_{SE}^{II}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty } +

{\boldsymbol{R}}_{SE}^{IW}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty

},\end{gather} \begin{align}{{\boldsymbol{S}}^W} &=

{\boldsymbol{R}}_{SU}^{WW}\boldsymbol{\cdot

}{{\boldsymbol{U}}^\infty } -

{\boldsymbol{R}}_{SU}^{WI}\boldsymbol{\cdot

}({{\boldsymbol{u}}^I} - {{\boldsymbol{U}}^\infty }) +

{\boldsymbol{R}}_{S\varOmega }^{WW}\boldsymbol{\cdot

}{{\boldsymbol{\varOmega} }^\infty } -

{\boldsymbol{R}}_{S\varOmega }^{WI}\boldsymbol{\cdot

}({{\boldsymbol{\omega} }^I} - {{\boldsymbol{\varOmega}

}^\infty })\nonumber\\ &\quad + {\boldsymbol{R}}_{SE}^{WI}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty } +

{\boldsymbol{R}}_{SE}^{WW}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty

}.\end{align}

\begin{align}{{\boldsymbol{S}}^W} &=

{\boldsymbol{R}}_{SU}^{WW}\boldsymbol{\cdot

}{{\boldsymbol{U}}^\infty } -

{\boldsymbol{R}}_{SU}^{WI}\boldsymbol{\cdot

}({{\boldsymbol{u}}^I} - {{\boldsymbol{U}}^\infty }) +

{\boldsymbol{R}}_{S\varOmega }^{WW}\boldsymbol{\cdot

}{{\boldsymbol{\varOmega} }^\infty } -

{\boldsymbol{R}}_{S\varOmega }^{WI}\boldsymbol{\cdot

}({{\boldsymbol{\omega} }^I} - {{\boldsymbol{\varOmega}

}^\infty })\nonumber\\ &\quad + {\boldsymbol{R}}_{SE}^{WI}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty } +

{\boldsymbol{R}}_{SE}^{WW}\boldsymbol{\cdot

}{{\boldsymbol{E}}^\infty

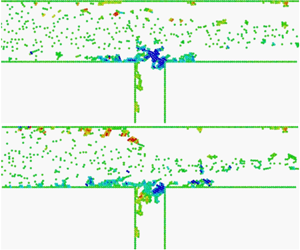

}.\end{align}The hydrodynamic part of the stress is further divided into the stress from the background velocity field, the Brownian stress and the dissipative part of the inter-particle stress. If relative motion between particles is induced by inter-particle forces and they are hydrodynamically coupled, this motion induces stresslets (Chu & Zia Reference Chu and Zia2016). The individual contributions constituting the hydrodynamic part can be calculated by determining the slip velocity under the influence of the corresponding force using (2.29), followed by performing matrix-vector multiplications as described in (2.37) and (2.38).