Introduction

Fashion and textiles are amongst the most polluting and waste-generating industries in our current landscape. In order to ease their environmental footprint, a holistic shift in industry towards circular models becomes necessary (Fletcher and Tham, Reference Fletcher and Tham2019). By 2050, the globe is projected to house 9.7 billion inhabitants who will need to be clothed and fed (UN, 2022:3). Such a vertiginous expanse in population poses critical issues for textile production to keep up with consumer demand while running on finite natural resources (Fletcher and Tham, Reference Fletcher and Tham2019; Collet, Reference Collet2015). Production and consumption patterns are central to this industrial shift, with the adoption of regenerative design and circular material futures at its epicentre (Collet, Reference Collet2020).

Ecological concerns are central to biodesign, whose perspective goes beyond understanding materials by the substance that constitutes them alone. Considering the whole life cycle of any material, from pre-production to end-of-life stages, is crucial (D’Itria and Colombi, Reference D’Itria and Colombi2022) to working with living materials, and merits meticulous attention as designing and making result in lingering effects beyond the consumption of natural resources, such as the destruction of habitats for a plethora of living beings (Collet, Reference Collet2020).

Cellulose is a polymer abundant in nature (Lee et al., Reference Lee, Preez and Jones2007). Commonly derived from plants, its extraction through mechanical or chemical methods and lifecycle have “considerable environmental repercussions like high carbon emissions, eutrophication or soil impoverishment” (Cohen et al., Reference Cohen, Sicher, Merino and Yavuz2021). Bacterial cellulose (BC) offers the advantage of higher purity, improved properties and a reduced necessity for extraction processes (Cohen et al., Reference Cohen, Sicher, Merino and Yavuz2021; Morrow et al., Reference Morrow, Ribul, Eastmond, Lanot and Baurley2023), demonstrating potential contributions to the adoption of circular systems in fashion and textile manufacturing.

Camere and Karana (Reference Camere and Karana2017) present a thorough examination of fabrication achieved alongside non-human living organisms by reviewing multiple explorations intersecting biology and design. “Despite the large interest shown, this emerging material practice is still scarcely understood” (Camere and Karana, Reference Camere and Karana2017), and prototypes are often contextualised in speculative practice. “Biodesign refers specifically to the incorporation of living organisms as essential components, enhancing the function of the finished work” (Myers and Antonelli, Reference Myers and Antonelli2018). Fashion and textiles are demanding regarding performance, but thrive through imagination and creativity (Lee et al., Reference Lee, Preez and Jones2007). Ribul et al. (Reference Ribul, Goldsworthy and Collet2021) exemplify how the inclusion of non-human living organisms compounded with interaction between designers and scientists can produce innovation in circular outcomes, a collaborative approach to design crucial to realise regenerative production methods (Collet, Reference Collet2015; Myers and Antonelli, Reference Myers and Antonelli2018) that can be sustained in the future (Lee et al., Reference Lee, Preez and Jones2007).

Material properties

Form variation during BC growth and after drying is key in the material outcome as shown in the creation of BC filament textiles (Morrow et al., Reference Morrow, Ribul, Eastmond, Lanot and Baurley2023) and 2.5-dimensional fashion pattern cutting (Kawasaki and Mizuno, Reference Kawasaki and Mizuno2017). Both projects cite the shrinking quality of BC as key to achieving and retaining the desired form for their projects. This shrinking quality is akin to heat-setting, in which heat is applied to a lasted shoe going from a humid to dry environment, and results in leather relaxation (Hanson, Reference Hanson1980). Other materials display form-retaining abilities through similar methods, whose interaction with BC can be utilised as design element (De Lara, Reference De Lara2023b) at varying scales.

In order to increase the performance properties of BC, underlying yarn structures have successfully produced composite textile materials and objects. HBBE’s BioKnit prototype (Scott et al., Reference Scott, Kaiser, Ozkan, Hoenerloh, Agraviador, Elsacker and Bridgens2022) makes use of three-dimensional knitting using a Shima knitting machine to build architectural structures combining knitted scaffolds with mycelium and BC in architectural contexts. Using woven techniques, Keane’s (Melton, Reference Melton2022) This is Grown sneaker used woven basal structures to grow BC in the shape of patterns, which were lasted and made into a sneaker. This method improved the textile’s performance with minimal waste; however, optimisation strategies are still underway towards commercial competitiveness.

This project aims to create a series of knit-cellulose biocomposite textiles that enhance the properties of BC and expand its designable characteristics using low-tech methods within the scope of footwear as a subset of fashion as design discipline.

Textile design is approached with intention of being applied later on to footwear design from a material-driven exploration focusing on BC’s ability of self-assembly (Cohen et al., Reference Cohen, Sicher, Merino and Yavuz2021). Within the scope of footwear, the ubiquity of leather stems from its outstanding properties, however, its association to animal slaughtering and high pollution questions its sustainability as a raw material. Leather alternatives, such as polyurethane or synthetic textiles, equally pose a level of risk, especially surrounding disposal and biodegradability (Rathinamoorthy and Kiruba, Reference Rathinamoorthy and Kiruba2020), whereas the sustainable advantage of biomaterials and BC’s excellent properties targeting leather applications (Phan et al., Reference Phan, Vu and Bui2023) make BC ideal for the realm of footwear. Although different, the properties of BC (Girard, Chaussé, Vermette, Reference Girard, Chaussé and Vermette2024; Phan et al., Reference Phan, Vu and Bui2023) are comparably unique to leather, particularly regarding its textural singularity and full-bodied drape. Footwear displays reduced degree of motion compared to garments, but enhanced nuance within the possible range of motion. Introducing BC to footwear design opens possibilities to design with BC as textile material and better showcase the result of these investigations in an artistic manner that may be more easily disseminated than scientific findings through visual narratives.

As “BC still faces obstacles in […] functionalization” (Phan et al., Reference Phan, Vu and Bui2023) its composite application may be more effective than its mono-material state in creating textile materials. Specifically, the possibility of reassembly of the cellulose fibres around a knitted scaffold following breakdown is targeted, as well as achieving voluminous forms necessary to footwear making through the utilisation of shrinkage of the cellulose during drying, as this process resembles the application of heat-setting to leather (Bayes, Reference Bayes and Bingham2016).

Method

This material-driven exploration intends to inform future footwear design propositions using techniques and materials obtained throughout this research. A successful outcome evaluates the possibility of BC’s knit coverage paying attention to artistic expression following fibre reassembly, as well as the potential to produce and retain a degree of volume in order to be later applied onto a footwear last.

This practice-based research stems from a previous sample where a culture of agitated BC was grown on a sample of knitted Pemotex (Fig. 1); this sample retained flexibility with minimal signs of breakage for over twelve months using only beeswax once every three months as maintenance. Due to the scale possible for agitated cultures, required expertise and resources available, design methods and set-up were overhauled to accommodate static cultures and minimal laboratory environments.

Figure 1. Agitated culture of Bacterial Cellulose pellicle grown on Pemotex knit textile sample.

Set-up

Bacterial cellulose culture fermentation

A static culture of BC was grown using the ingredient ratio below to make the starter liquid;

-

1 L Water

-

3 Black tea bags

-

100 g Raw sugar

-

100 ml Apple cider vinegar

-

200 ml Starter liquid from existing kombucha culture

This culture was incubated for fourteen days in Kyoto Design Lab within a container sealed and placed outdoors, at temperatures ranging between 25°C and 35°C.

Knit structures

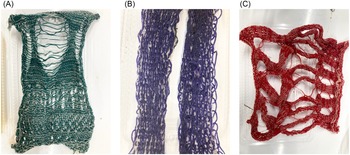

Several samples were used to achieve a range of stitch and knit types; three knits taken from second-hand sourced garments provided three samples each, three crocheted samples, one sample combining hand knitting with hand-machine (Brother KH965) knitting and four samples knitted entirely in the Brother KH965 machine. Second-hand sourced fabrics were cotton-acrylic blends: small swatches were cut and hand-sewn at the edges with cotton thread to prevent fraying. Crocheted and hand-knitted techniques used recycled cotton and polyester blend yarns. Samples knitted in the Brother KH965 machine used 100% cotton and bamboo yarns. Hand and hand-machine samples were knitted directly into their final shape. All samples were autoclaved at 121ºC for 25 minutes (Figs. 2 to 7).

Figure 2. Selection of knit samples before integration with BC exploring (from left to right); A) stitch and gap size using Brother KH965, B) knitted loops as anchors for BC regrowth using Brother KH965 combined with hand-knitting techniques, C) volume knitted using partial knit in Brother KH965.

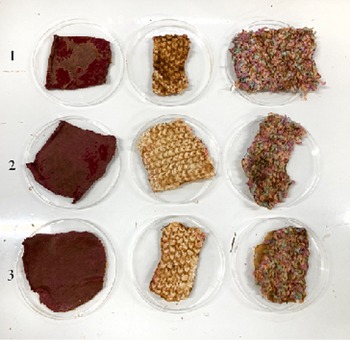

Figure 3. Comparison of second-hand knit samples after drying the resheeted BC. Row 1: Moisture added; row 2: Moisture unchanged; row 3: Moisture partially removed.

Figure 4. Knitted samples after drying the resheeted BC. Samples 1 and 2 are crocheted in circular stitches and have the most solid attachment. Sample 3 is crocheted in regular double crochet stitch and shows a thorough integration, although not as sturdy as #1 and #2. Samples 4 and 5 used thicker yarns as anchors for the BC to form, but this process flattened the volume of the e-wrapped bulky yarn barely sheeting through the loops. Samples 5 and 6 show successful volume formation, particularly where stitch gaps are larger, as well as harmony in movement when BC and knit are combined.

Figure 5. Table detailing conclusions from sample results.

Figure 6. Visual comparison of granny square knitted with bulky and lightweight yarns, placed under regular daylight (left) and a source of hard light (right).

Figure 7. Visual comparison with previous samples (figure 4.6) knitted in Brother KH965 hand knitting machine using various techniques, and placed against a direct light source. Presence of transparency alters how the textile is perceived, enhancing the pool of designable qualities.

Integration and fibre reassembly

BC was incubated until it formed a pellicle of 2 cm in thickness, which was harvested, washed and blended into a homogeneous dope using a domestic food processor. As the processing was done in small batches, the addition of starter liquid and water was done based on the weight of each added piece to facilitate blending. Added starter liquid and distilled water equalled 10% of BC weight. The addition of starter liquid and water addresses the necessity of an oxygen-rich environment with an accessible nutrient source (Morrow et al., Reference Morrow, Ribul, Eastmond, Lanot and Baurley2023). The resulting paste was manually kneaded into each sterilised sample and smoothed out ensuring an even coating of cellulose.

The second-hand-sourced samples were placed in sterilised containers in three iterations; a) adding 20 ml of boiled and cooled water into the container, b) allowing present moisture to remain unchanged, and c) removing as much moisture present in the paste by letting it rest for one hour and absorbing the liquid that had seeped from the paste using an absorbent pad.

Remaining BC paste was further diluted with 100 ml of water and 50 ml of starter liquid and divided into sterilised containers, where the crocheted and hand-machine knitted samples were placed in. The addition of BC paste was done to increase the strength of the bacterial culture against possible outside contaminants.

The samples were incubated inside D-Lab’s Biomaterial Factory for four days at temperatures between 25°C and 30°C. As previous attempts at producing BC-based composite textiles (Mizuno et al., Reference Mizuno, Kamiya, Katsuta, Oshima, Nozaki and Amano2011) highlighted the necessity of reversing fabric samples in static BC cultures to allow for oxygen access, this project reversed the hand-machine knitted and crocheted samples at this point. All samples were incubated for four more days.

The textile samples were lifted from their containers, washed with regular tap water and air-dried inside D-Lab’s Biomaterial Factory at room temperature on a flat, non-porous plastic surface.

Results

This project set out to test whether BC could achieve a sheeted form following fibre breakdown, attempting to reformulate a sample which retained pliability and resistance using less specialised equipment and environments. This low-tech set-up was chosen to posit ways to disseminate research around BC to designers with artistic or otherwise non-scientific backgrounds that would bar them from laboratory environments. All samples showed successful sheeting of BC stemming from the blended BC dope around the knit, although to differing degrees of coverage.

Second-hand-sourced knits featured different yarns whose pre-existing attributes, such as dyestuffs, were unknown. Varying the amount of liquid in the container affected how cellulose formed on the knit. The samples with added liquid showed the most even BC arrangement, however, the BC formed a pellicle over the liquid rather than mingling with the knit. The samples where moisture was extracted showed BC formation on the knit without pellicle forming beyond the stitches, as well as a more solid coverage than those samples where water was added and not removed.

Crocheted and hand-machine knitted samples showed thicker BC formation in the stitches than second-hand knits, and more even distribution in larger gaps between stitches. BC also formed in areas where voluminous forms had been knitted, demonstrating that the pellicle can reassemble with volume, rather than as a flat sheet only.

Discussion

BC commonly grows in non-woven sheet-like material form, and has generally been used as such in fashion and textile contexts. Increasing collaborative projects between designers and scientists demonstrate the potential to develop BC functionally and aesthetically as a material that could alleviate the footprint of textile and fashion production, offsetting these fields closer to regenerative practices (Collet, Reference Collet2015).

Combined scientific and designerly approaches are necessary to innovate throughout fashion and textile industries (Williams and Collet, Reference Williams and Collet2020; Ribul et al. Reference Ribul, Goldsworthy and Collet2021; Morrow et al., Reference Morrow, Ribul, Eastmond, Lanot and Baurley2023) in order to effectively address their ecological impact (Fletcher and Tham, Reference Fletcher and Tham2019). Low-tech fabrication approaches can broaden access to biodesign to designers without scientific backgrounds, allowing for interdisciplinary, collaborative research to approach circularity from practice-led perspectives. This type of co-designing with nature has generated much interest (Camere and Karana, Reference Camere and Karana2017), and is expected to continue growing as its own industrial field (Collet, Reference Collet2015; Ginsberg et al., Reference Ginsberg, Calvert, Schyfter, Elfick and Endy2014). Collaborative practices can increase iterations and interest generated from these materials, opening ways to bring bio-based design closer to generalised audiences and maximising their benefits as everyday objects.

As demonstrated by the second-hand-sourced knits, placement of oxygen and nutrient source produce variation in results, specifically, in directing where BC fibres will form. Considering the most successful samples had existing moisture removed, there is an identifiable gap in utilising the knit to alter the pattern in which BC forms. This could become a designable feature with functional attributes by applying the BC dope in patterns, or even to guide the bacteria to grow in desired places or shapes through knit design due to the knit’s shapeability potential from stitch to full textile (De Lara, Reference De2023a). Employing similar dual design elements in the creation of a single outcome offers opportunities for designers lacking scientific training to design using biological engineering principles (Ginsberg et al., Reference Ginsberg, Calvert, Schyfter, Elfick and Endy2014).

Visual appearance is primordial when encountering textile and fashion objects, and within this scope, colour is a crucial element. As this research focused on the potential of fibre reassembly, colouration was not tested. Yarns were selected for their availability and potential to produce desired stitch forms, and endured aesthetic changes when integrating with BC, such as colour and texture appearance. However, there is a research gap regarding colour application systems (Kawasaki and Mizuno, Reference Kawasaki and Mizuno2017). Possible design outcomes of colour tests applied to BC are augmented by its translucent properties, which is uncommon amongst natural fibres, as well as using natural substances both as colouring agents and nutrient sources.

Conclusion

Experimentation has shown not only BC’s self-assembling potential, but reassembling capacity, revealing the possibility of working BC in textile contexts through various growth stages. Integrating additional materials can supplement BC properties and is facilitated by the potential to utilise the growth process as guidance for material development. Depending on the intention of investigation, material and design methodologies require individual formulation to achieve success in objects or products created using these materials and practice-led design perspectives. In the case of future directions in footwear design, knitted stitch design seems the most viable option, with BC paste reformulation as the second most promising possibility to achieve a range of components and tactile qualities.

Data availability statement

Data supporting this study are included within the article and/or supporting materials.

Financial support

No funding was received for conducting this study.

Competing interests

The author declares none.

Comments

No accompanying comment.