Introduction

Bacteria inducing biocalcification

The most-commonly employed bacteria for biocalcification are of the Sporosarcina pasteurii species and are isolated from the soil. The bacterium is characterised by its ureolytic activity, which generates carbon dioxide and ammonia as a by-product (Castro-Alonso et al., Reference Castro-Alonso, Montañez-Hernandez, Sanchez-Muñoz, Macias Franco, Narayanasamy and Balagurusamy2019). This release of carbon dioxide can react with calcium ions in the soil matrix to form calcium carbonate crystals (Castro-Alonso et al., Reference Castro-Alonso, Montañez-Hernandez, Sanchez-Muñoz, Macias Franco, Narayanasamy and Balagurusamy2019). In the laboratory, the reaction initiated by S. pasteurii leads to the formation of calcite minerals. The physical properties of calcite, particularly its rigidity, have proved attractive for exploitation in commercial environmental engineering (Rahman et al., Reference Rahman, Hora, Ahenkorah, Beecham, Karim and Iqbal2020). However, in the environments where S. pasteurii likely resides within the soil matrix, it is unlikely to experience the high concentrations of calcium that are used in research and commercial contexts to induce calcite precipitation (Baker et al., Reference Baker, Flemons, Andersen, Coleborn and Treble2016; Xiao et al., Reference Xiao, Xiao and Adnan2021).

Optimal calcification protocols often involve a calcifying solution with a concentration of calcium chloride at or exceeding 0.25 M (Hirsch et al., Reference Hirsch, Lucherini, Zhao, Saracho and Amstad2023; Ouyang et al., Reference Ouyang, Liu, Sun, Xu, Wang and Ma2022). Very few environments on Earth experience calcium salt concentrations in this range, and in these kinds of extreme environments, S. pasteurii is not an active community member, and thus is likely to experience important levels of stress when it is involved in anthropogenic microbially induced calcite precipitation (MICP) processes (Marion et al., Reference Marion, Fritsen, Eicken and Payne2003). To the best of our knowledge, all biocalcification procedures used in both research and commercial settings involve the entombment of living S. pasteurii cells in a dense matrix of calcite minerals, likely leading to starvation and cell death (Burdalski and Gomez, Reference Burdalski and Gomez2020; Jarwar et al., Reference Jarwar, Dumontet, Pasquale and Chen2022). In this way, MICP materials can be characterised as grown materials (Camere and Karana, Reference Camere and Karana2018, Dade-Robertson, Reference Dade-Robertson2022), considered as living during their fabrication stage but perceived in their use state as inert.

Biocalcification in engineering and design

This type of biomineralisation, whereby the metabolic activity of some bacteria induces the production of calcium carbonate crystals, is the one commonly exploited by humans for design and engineering purposes. Within the context of soil stabilisation, the use of this process has progressed up to the commercial phase (Soletanche Bachy, n.d.) and is likely to increase in the coming decades as the quality and therefore the integrity of soils have been decreasing and will undoubtedly continue (Jie et al., Reference Jie, Jing-zhang, Man-zhi and Zi-tong2002; Baumhardt et al., Reference Baumhardt, Stewart and Sainju2015; Tully et al., Reference Tully, Sullivan, Weil and Sanchez2015).

MICP has also been explored in a lesser extent within the field of design and architecture, with interventions primarily focused on the probing of biocalcified sand materials (Arnardottir et al., Reference Arnardottir, Dade-Robertson, Mitrani, Zhang, Christgen, Slocum B, Ago V and Marcus2021; Myers, Reference Myers2012). Sand as the substrate for biocalcification is problematic due to the resource-intensive processes required to obtain quartz-based sand. Yet, designers and researchers have further expanded the material possibilities by employing MICP beyond the creation of bulk bio-concrete materials, such as substrates sourced from waste stream (Streich, Reference Streichn.d.), polymer lattice (Xin et al., Reference Xin, Su, Feng, Yan, Yu, Feng, Lee, Sun and Wang2021) or the stiffening of textile geometries (Beyer et al., Reference Beyer, Suárez and Palz2019; Mosse et al., 2024). To our knowledge, paper has only been used so far in biocalcification processes as an additive facilitating the calcification of quartz sands (Chen et al., Reference Chen, Gowthaman, Nakashima, Komatsu and Kawasaki2021).

Design-led approach to paper foam calcification

Building on a prior study, we examine here the relevance of an immersion strategy for the biocalcification of Papier Plume, a foam based on upcycled paper waste, for architectural and design circular contexts (Mosse and Bassereau, 2022). This immersion strategy is part of an overall design-led approach to research developed in the ImpressioVivo project (Cross, Reference Cross1982; Gray, Reference Gray and Strandman P1996; Joost, et al., Reference Joost, Bredies, Christensen, Conradi and Unteidig2016). Sitting at the intersection of architecture, design and microbiology, material evidence produced in this project are embedded in creative explorations and experimentations focused on issues of form, know-how and materiality, from the speculative to the applied (Mosse, 2021). The material evidence presented here results more specifically from exploratory material and design probes. Design probes are design-led investigations allowing speculative inquiry, theorisation and development of design concepts and the setting out of design criteria often materialised as scenario-buildings, speculative visualisations or conceptual mock-ups (Ramsgaard Thomsen and Tamke, Reference Ramsgaard Thomsen and Tamke2009; Mossé, Reference Mossé2018). Material probes are experiments focused on crafting processes and material behaviours. Their role is to facilitate defining, challenging or refining design probes in the light of the designers’ experiential knowledge of materials and form-finding process. They are for instance materialised in the form of material samples, physical prototypes. Our previous publication demonstrated the mixed outcomes of biocalcifying Papier Plume using two methods of introducing biocalcifying bacteria into Papier Plume: spraying the dry foam and inoculation directly into the paper foam itself (Mosse and Bassereau, 2022). Subsequent research explored the potential of a third inoculation method: immersing the paper foam in a liquid broth containing biocalcifying bacteria, followed by immersion in a bath containing a calcifying solution. Here, we describe an adaptation of the biosafety level 1 protocol used in Mosse et al. (2024) and the resulting material properties associated with the biocalcified paper foam together with a return-to-the-earth loop scenario.

Methods

Paper sourcing and processing

Paper is sourced locally from waste generated at Ecole Nationale Supérieure des Arts Décoratifs. Discarded black and white printed copies ranging from 80 to 120 g are sorted, before being grinded with a Retsch laboratory mill at a speed off 700 t/min. The obtained homogenate is subsequently sieved to collect particles of a granulometry inferior to 1 mm (Mosse and Bassereau, 2022).

Manufacturing of Papier Plume paper foam

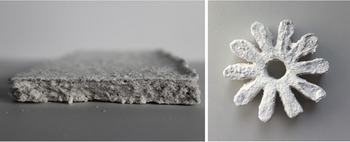

Papier Plume is a foam material resulting from the combination of this paper waste homogenate with the Genfil ® herbal resin-based foaming agent, starch glue and water through a whisking process (Mosse and Bassereau, 2022). The manufacturing of the foam is documented in the free access video entitled Today’s waste, foam and materials of tomorrow as well as subsequent form-finding process such laser-cutting, casting and fabric formwork (Combal-Weiss and Thibault-Picazo, 2021; Mosse and Bassereau, 2022). Samples used in the current study were processed using recipe 1 described in the aforementioned paper, which contains 16.7% of paper homogenate, 4.7% of Genfil ®, 2.4% of starch glue and 76.2% of water. The foam was subsequently casted (Figure 1) but also 3D printed on a mechanical extrusion-based system from ReflexLab (Figure 2).

Figure 1. Process diagram for Papier Plume foam crafting (top) and its biocalcification through an immersion strategy.

Figure 2. One-step calcified paper foam with a distinctive crystallised surface on the top, characteristic of this biocalcification process (left) 3D printed paper foam structure of 24 mm height after a 3-steps biocalcification. Both samples are obtained following the immersion technique highlighted in Figure 1.

Plate samples for flame retardancy probes were casted in a rectangular batylineFootnote 1 -based mould. Samples for tensile probes were processed in laser-cut Plexiglas dumbbell moulds. Compression samples were first casted in the same moulds as the flame retardancy samples before being carved into cylindrical shapes after biocalcification with a metal hole saw drill bit of 300 mm diameter.

Left to dry at room temperature air for 48 h, all casted samples are then placed in a dehumidifying environment kept at 40°C for another 48 h before being unmoulded. We implemented this two-step process after observing that immediately subjecting the crafted paper foam to accelerated dehydration caused the foam structure to collapse. 3D printed foam was subject to the same two-step drying process.

Biocalcification

The method lies in the double immersion of a dried sample of Papier Plume at room temperature (Figure 1). The foam sample is first immersed in a bacterial solution (BS) composed of Sporosarcina Pasteurii powder rehydrated in water for about an hour to ensure that the bacterial colonies fully penetrate the sample. Placed onto a supporting grid into a box-like bioreactor to avoid deformation, the paper foam sample is then carefully removed from the BS, before being soaked in a calcifying solution (CS) made of calcium, urea and water. After 24 h of immersion, the sample is removed from the CS. This process is repeated two subsequent times to obtain a full homogenous calcification throughout the whole sample while partially calcified samples only undergo one cycle of immersion into the BS and CS. Samples are then left to dry at room temperature for 48 h before being placed in a dehumidifier at 60°C for another 48 h.

The first paper foam material probed with this method was prepared in a large-scale bioreactor supplied with BS and CS by a peristaltic pump during the collaborative “Biolcalcified textile architecture” workshop (Figure 3) (Mosse et al., 2024). All other samples are biocalcified in the smaller-scale bioreactor described above. During the process, a risk of deformation of the samples exists as the foam comes back to a wet and therefore malleable state when immersed into the BS and CS. Yet, if precautions to avoid mechanical deformations are taken during immersion and drying, the initial shape can overall be maintained.

Figure 3. Papier Plume: a paper waste foam after (left) and before (right) a three-step biocalcification process, 2022.

In addition to the original Papier Plume foam, two types of samples are therefore prepared for characterisation tests, following this biocalcification protocol based on immersion: partially calcified paper foam samples that underwent a single cycle of biocalcification; fully calcified paper foam samples that underwent three calcification cycles.

Experiments to reduce consumables use

We also attempted to optimise our protocol to reduce consumables use with both plate and 3DP paper foam materials. The BS was produced according to manufacturer’s instructions and stored in a closed container in an incubator at 37°C for 1 h to activate the bacteria. Paper foam samples were then incubated in a BS bath for 15 min, allowing time for bacteria to enter the pores within the paper foam. Inoculated paper foam was then removed from the BS. The BS was stored at 8°C in a sealed container away from sunlight and used in subsequent BS inoculation steps rather than reproducing a fresh BS. To further reduce the use of consumables, CS produced for the first calcification step was reused for subsequent CS incubation steps. We also carried out experiments with lower CS concentrations compared to the manufacturer’s recommendations. We tested biocalcification with CS that was half the concentration compared to manufacturer’s recommendations as well as a minimal concentration containing 0.25 M equimolar solution of calcium and urea in accordance to research which suggests that a calcium concentration of 0.25 M is sufficient to achieve > 90% weight percentage of calcite at the endpoint of MICP processes using hydrogels as the substrate (Hirsch et al., Reference Hirsch, Lucherini, Zhao, Saracho and Amstad2023).

Scanning electron microscope (SEM) images

SEM images were obtained on a Thermo Scientific Quattro ESEM system. Particles from Papier Plume and biocalcified materials were extracted from the core of the samples, immobilised on sample stubs with carbon tape, then sputter-coated with a thin layer of gold and subsequently imaged and exported as a.jpg format.

Mechanical strength testing

Tensile strength was tested on an Instron 3343 single column testing system. Samples used are based on casting Papier Plume in a standard dumbbell shape with length of 115 mm, shaft width of 6 mm, and sample thickness of 10 mm. As the biocalcified samples underwent the biocalcification protocol in the section above, they had some variability in shape due to the non-uniform calcite crystal formation; they are not identical in length, shaft width, and thickness. Tests for both the uncalcified and the biocalcified paper foam were performed in triplicate using a traction speed of 5 mm/mn and a force of 1 kN.

Compression strength was tested on the same instrument, where samples were compressed in between two plates. We used cylindrical samples of about 27 mm diameter and a height comprised between 12 and 19 mm, generated by coring blocks of calcified/uncalcified Papier Plume. We attempted to produce cylinders used for testing gypsum-based products(Adamopoulos et al., Reference Adamopoulos, Foti, Voulgaridis and Passialis2015), but it was not possible to produce sufficiently straight and uniform cylinders matching these higher dimensions due to deformations of the foam during the biocalcification process. Due to the non-uniform calcite crystal formation, samples slightly vary in terms of diameter and height. Tests for both Papier Plume and the biocalcified paper foams were performed in triplicate using a compression speed of 5 mm/mn and a force of 800 N.

Flame retardancy testing

To evaluate the flame retardancy of the paper foam and biocalcified paper, we designed a testing setup similar to that used for the Single-Flame Source Test (ISO 11925). In our setup, a flame with an approximate temperature of 1300°C was held at 90° and ignited so that the edge of the flame was 40 mm from the edge of the sample. The sample was held in a stable position on a metal stand at an angle of 45°. The flame was applied to the sample for 1 min and the spreading of the flame was observed for a further 5 min after the flame was extinguished. The experiment was digitally recorded as stop-motion.jpg images with a Canon camera and as .mp4 formatted videos with a GoPro camera.

Hydrophobicity testing

To evaluate whether the biocalcified paper foam lies on the hydrophobic/hydrophilic spectrum, we dropped water coloured with blue food colouring drop by drop using a 100 uL pipette held 10 mm above the surface of the material and at an angle of 90°. If droplets remained on the surface of the material, then their angle was observed. If droplets immediately entered the material, the diameter of the wetted area following the deposition of 5 droplets from the 100 uL pipette was measured. This hydrophobicity test was digitally recorded similarly to the previous experiment.

Immersion testing

A sample of 100 × 80 × 15 mm is cut into both Papier Plume and the two qualities of biocalcified foam for normalisation with a stationary bandsaw. Each sample is then placed in distilled water for 24 h and subsequently dried in an incubator containing desiccating silica gel packs for 6 h at 40°C to observe any potential deformation associated with wet/dry cycles. To evaluate sample deformation, in addition to measurement, a picture of the sample is taken prior to, at the beginning and end of immersion as well as 24 h after drying.

Return-to-the earth loop scenario

To synthetise hypotheses resulting from collective brainstorming sessions and speculative explorations of biocircular dynamics for our biocalcified paper foam, a loop lifecycle scenario was developed as a digital visualisation generated with adobe illustrator.

Results

Outcomes of biocalcification process

The biocalcification process was successful for all samples created and was equally homogenous in partially and fully calcified samples. It had an impact on surface geometry resulting in a crystallised surface on the top of samples (Figure 2) but also on weight, multiplied by a factor of approximately 15 for the three-step calcification. Overall, samples that underwent a three-step biocalcification process can be described through sensory observation as acquiring a white, granular and more rigid texture clearly distinct from the original material (Figure 3). Our qualitative sensory assessment matched with SEM imaging, which showed some sporadic crystallisation in the semi-calcified sample and a well-defined and dense crystalline structure in the fully calcified sample (Figure 4).

Figure 4. 10 microns SEM images of Papier Plume (left) the one-step calcified paper foam (middle) and the 3-steps calcified paper foam (right). The latter shows a dense crystalline structure. Both calcified samples are obtained through the immersion technique described in Figure 1.

Experiments to reduce consumable uses

Preliminary sensory observation indicates that the reuse of CS over 3 cycles maintains a similar crystallised appearance and a slightly lower but consistent hardness than the material resulting from a single bath of fresh BS and the CS made according to the manufacturer’s instructions. The reuse of the BS over 3 cycles lead to a weaker calcification close to the one-step biocalcification process made according to the manufacturer’s instructions.

Flame retardancy

Papier Plume was highly flammable; it maintained its own flame after ignition. After the flame was removed, the sample continued to burn through the sample until the entire sample burned (Figure 5(a)). In contrast, the fully calcified sample did not maintain its own flame after the flame was removed and did not show any signs of afterglow or after flame; only a trace of combustion at the edge of the sample, associated with small amount of smoke emitted during burning. The total diameter of the burn area was approximately 3 cm on the edge and the visible burn area only expanded to a maximum of 2 cm depth on the top of the sample (Figure 5(e)). The one-step biolcacified paper foam shows intermediary results, where the sample produces no afterflame but an afterglow of 1 s, some smoke during another 30 additional seconds and a larger burnt area than the fully calcified sample (Figure 5(b) and (d)).

Figure 5. Papier Plume: (a) one-step calcified paper foam, (b) and three-step calcified paper foam, (c) at 1 mn of flame exposure (top) and 10 mn after (bottom). Observation of a one-step, (d) and three-step calcified foam samples, and (e) on grid graduated every 1 cm. After 10 mn, Papier Plume was completely consumed and could therefore not be moved for such observation.

Mechanical resistance

As Table 1 demonstrates, the calcification process increases the tensile and compression strength of the paper foam. The calcification process stiffens the material. There is considerable variability within samples that underwent identical degrees of calcification. None of the materials tested experienced rupture at a compressive strength of 800 N, but the extent of compression was high in uncalcified/semi-calcified samples, which showed a compression in the range of 43% to 96% of the original uncompressed volume. In comparison, the calcified samples demonstrated a lower compression rate, ranging between 34.5% and 48.5%.

Table 1. Mechanical strength associated with different levels of biocalcification of the Papier Plume foam. “Slope during Tension” is a proxy for the Young’s modulus, with a large slope indicating that the sample is characterised as rigid rather than flexible

Immersion test

With respect to water resistance, qualitative testing demonstrated that in contrast to the uncalcified paper foam, the calcified paper foam did not show perceptible signs of distortion to the naked eye following a 24 h immersion in a water bath. We observed no significant loss of crystals on the material surface. Photographic imaging however revealed extremely discrete deformation after drying the biocalcified sample following immersion (Figure 6(a)). In contrast to the biocalcified sample, the uncalcified sample did not maintain its shape and structure after immersion for 24 h; the foam appeared to distort.

Figure 6. (a) top and side view of respectively Papier Plume, one and three-step biocalcification samples after 24 h immersion and drying, showing a clear deformation of Papier Plume (b) 3-step biocalcified sample in immersion after 24 h.

Hydrophobicity testing

Uncalcified, semi-calcified, and fully biocalcified samples were hydrophilic. In all cases, water droplets did not remain on the surface but were immediately absorbed into the material. The size of the wetted area increased with increasing biocalcification, extent measuring 19 mm in the uncalcified sample, 21 mm in the semi-calcified sample, and 22.5 mm in the fully calcified sample (Figure 7). In terms of wetted area configuration, the shape was concentric in the uncalcified and the semi-calcified samples, irregular in the fully calcified paper foam, with a saturated centre of about 20 mm surrounded by a lighter zone. The depth of the wetted area varies according to samples, reaching 3 mm for the uncalcified sample, 10 mm for the semi-calcified sample and 1 mm for the fully calcified sample.

Figure 7. Results of hydrophobicity test respectively on Papier Plume (left), one-step calcified paper foam (middle), and three-step calcified paper foam (right).

Return-to-the earth loop scenario

Paper is an emblematic waste deposit of post-industrial societies, which represent 75% of waste produced in offices of which only 20% is recycled (Bareau, Reference Bareau2020). It is also an abundantly and recurrently used and discarded material within schools of arts and design, which has led us to develop a circular scenario for locally produced biocalcified paper foam (Figure 8). It is first imagined in the context of Ecole des Arts Décoratifs, where this research is undertaken, to increase tightness of feedback – one of the key principles of resilient thinking – in the fabrication chain, but its adaptation to similar contexts is also considered (Hopkins, Reference Hopkins2008). A first loop relates to the transformation of paper waste into paper foam-based artefacts following the Papier Plume manufacturing method described; artefacts which due to the sole use of bio-sourced and renewable resources can be crushed after use and reprocessed as foam for the design of new artefacts. We expect the process to be repeatable at least 7 times as it is already the case for paper upcycling (Bareau, Reference Bareau2020). According to the context of use, artefacts can subsequently be biocalcified to improve their performance and durability. The calcification process is conceived as a second loop of upcycling where the calcified foam is, after use, disposed into the soil so that S. pasteurii can return to the Earth, regenerate, and eventually be isolated again for a new cycle of paper foam calcification. We speculate that subjecting the calcified paper foam to a heating step at 70°C after its use can increase the number of calcifying bacteria in a sporulated state. Bacteria returned to the earth in a sporulated state will likely have a better chance of surviving the “return to Earth” step.

Figure 8. Circular lifecycle scenario for a biocalcified paper foam, from paper waste collection to return-to-earth.

Discussion

Relevance of a MICP immersion strategy for the biocalcification of Papier Plume

We previously explored two strategies for inoculating S. pasteurii into the Papier Plume substrate with mixed results lying in a random irregular calcification at the surface of the material, whose sensory observation did not attest of a distinct texture and hardness (Mosse and Bassereau, 2022). The immersion strategy presented here allows for a homogenous calcification throughout the whole structure of the sample, drastically affecting texture, colour, weight as much as the mechanical strength or flammability of the foam. As such, it is the most effective method we have explored to date to biocalcify Papier Plume. These results also point at the relevance of fibre-based foam bulk materials for MICP processes and further illustrate that more substrates should be explored beyond the frequently used quartz sands.

Biocalcified paper foam for architecture and design

Biocalcified paper foam materials have a significant potential and value within the fields of architecture and design. Considering the material properties evidenced in this article, we envision that it may be applied for sound and thermal insulation, wallcovering, lightweight furniture, partition, or other interior and decorative applications. While the biocalcified paper foam has lower mechanical strength compared to biocalcified hydrogels (Hirsch et al., Reference Hirsch, Lucherini, Zhao, Saracho and Amstad2023), it can withstand up to 20 newtons of force, meaning that it could be applied in situations where the material is not required to support weight. The flammability testing demonstrates that biocalcification is a process that enhances flame retardancy without the use of chemicals that are harmful to human health, an important consideration when considering the application of a material in architecture or interior design. We argue that calcification based on Papier Plume is more readily scalable compared to hydrogel-based MICP because its formulation is less temperature-sensitive, allowing biocalcified paper foam materials to progress more rapidly beyond the research phase and have a more significant impact on design and architecture. The porous and hydrophilic nature of Papier Plume mean that diffusion can occur freely, allowing for the potential creation of large biocalcified materials and forms. Additional optimisation of the biocalcification protocol should be explored in future research to be able to fully calcified foam objects with a thickness superior to 25 mm. The observed hydrophobicity of the biocalcified material was unexpected due to the hydrophobic properties of pure calcite crystals, but it may be explained by the fact that the calcite crystals in the biocalcified paper foam are biogenic calcite formations. The presence of organics (e.g. hydrocarbons) in the calcite matrix leads to significant changes in surface properties even if the calcite sample contains more than 99% calcite (Okhrimenko et al., Reference Okhrimenko, Dalby, Skovbjerg, Bovet, Christensen and Stipp2014). The hydrophilic nature of the material presented in this publication may render it unfeasible to use it in outdoor contexts. Yet, we have highlighted that Papier Plume can be given form through a variety of techniques from casting to 3D printing, giving designers and architects a wide array of potential forms, aesthetics and uses.

Circularity and sustainability of the material and process

The main ingredient of Papier Plume is paper waste, and the remaining ingredients are either exclusively bio-based and biodegradable ingredients. In this way, it is likely that the environmental impact of the material production is relatively small compared to synthetic foams. The calcification process requires little energy input, as the biocalcification process is performed at room temperature. The carbon footprint of the material production suggested in this publication could be further reduced by reclaiming the water used in the calcification and bacterial baths as the nutrients contained herein could serve as nutrients for other organisms. The calcifying bacteria used in this process produce ammonia, which could be further processed by ammonia oxidising bacteria (AOB) to produce nitrogen compounds that can be used in applications such as fertilisers. While previous research highlighted that discarded Papier Plume can be reused to create a new generation of paper foam (Bassereau et al., 2019), we have yet to test whether there is a way to re-circularise the calcified paper foam to create new biocalcified paper foam. To the best of our knowledge, the circularisation of biocalcified end-products of the MICP processes, regardless of the bulk material used (e.g. sand, paper, hydrogel, etc.) has yet to be explored but warrants further research. Until such time that this the circularisation of MICP products is achieved, we propose the “return-to earth” loop scenario (Figure 4), which involves a pre-treatment step described in the results section. In this perspective, future research should investigate the proportion of live:dead:sporulated calcifying bacteria after the final drying step of the material creation process as well as following the heat-activated sporulation step to determine whether this step leads to an increased number of viable calcifying bacteria in the soil matrix adjacent to where the biocalcified paper foam was deposited. Yet we assume that if the production of the material remains at a small scale and is locally produced, it can responsibly be disposed of in this manner. This strategy however should not be reconsidered for large volumes of biocalcified products due to a potential negative impact on native soil ecosystems.

Towards a bacterial perspective of biocalcification?

In the field of biodesign, some designers and architects engage with co-creation practices that attempt to flatten the human-nonhuman ontology, demanding a critical reflection on how the processes we employ as designers and architects have on our co-creators (Karana et al., 2023). In these biocalcification experiments, we considered the future of the bacteria beyond the creation process of the MICP-generated biocalcified paper foam. We attempted to strike the balance between our material design goals and a respect for the autonomy and agency of S. pasteurii. For this reason, we propose the final drying step illustrated in Figure 8 and described in the methods to induce S. pasteurii sporulation, allowing the bacteria to continue its existence when the biocalcified paper foam is returned to the Earth. However, we did not conduct any tests to determine the level of sporulation before and after this drying step, nor did we test whether S. pasteurii is able to re-activate after it is returned to the soil, its native environment. This should be further investigated. Nonetheless, we argue that considering the future of the co-creators that are engaging in biodesign processes is a critical consideration that is in line with less anthropocentric approaches such as the “honourable harvest” indigenous practices. These practices argue that sustaining the living beings who sustain humans in turn supports the resilience of the Earth (Wall Kimmerer, Reference Wall Kimmerer2021).

Conclusions

Biocalcification is a microbially induced process leading to the rigidification of various substances through the formation of calcite precipitation. In the field of design, it has mostly been applied to sand and occasionally textiles substrates. The results presented in this paper demonstrate that Papier Plume is a viable alternative substrate for creating homogeneous MICP materials. We evidenced that both casted and 3D-printed Papier Plume materials allow to produce homogenous biocalcified materials. The biocalcification of the paper foam improves its mechanical strength and drastically reduces the material’s flammability. These improved material properties resulting from the biocalcification process make it of notable relevance within architectural and design contexts. Our biodesigned composite material is composed of material harvested from post-industrial waste and rigidified through bacterial growth processes. Underpinned by circular and sustainable concerns, its design-led process reflects on a dual care for the lifecycle of the composite and the bacterial colony inducing its calcification, through a return-to-the-earth scenario encouraging sporulation. This publication acknowledges the fundamental role of Sporosarcina pasteurii bacteria in the crafting of the biocalcified foam. It also seeks to understand the implications of this process beyond anthropocentric perspectives and contributes to an emerging and growing body of interspecies approaches to architecture and design integrating interdependencies with the bacterial world. All in all, it provides insights on how and why interiors could be partly grown thanks to bacteria.

Data availability statement

The data that support the findings of this study are available from the corresponding author, [A.M.], upon reasonable request. They will be made available in a free and open-source repository by the end of the project.

Acknowledgements

Most experiments were undertaken in the design workshops of Ecole des Arts Décoratifs. The paper homogenate was grinded at Valesens in Tours with the tremendous support of Prof. Jean-François Bassereau. We also thank Dr. Bastian Beyer and Daniel Suárez Zamora for the large-scale bioreactor design and fabrication as part of the Biocalcified Textile architecture workshop, Prof. Benoît Roman and José Bico for access to Instron equipment at ESPCI. SEM images were processed at the Technological Platform of Institut Pierre Gilles de Gennes.

Author contributions

A.M., V.R. conceived and designed the experiments; Q.P., V.R., A.M and D.S.Z. performed and documented the experiments; A.M. processed the SEM images. A.M. and V.R. wrote the paper and primarily designed the figures, A.M. secured the funding supporting this research.

Financial support

This publication is integrally supported by Agence Nationale pour la Recherche (ANR) under project ANR-21-CE43-0023-01 entitled ImpressioVivo. Prior to that, the Papier Plume technology has initially benefited from the PSL University IRIS grant (2016) leading to patent FR1800097. In the perspective of its free access, the authors or the beneficiary owner applies an open access CCBY to any article accepted for publication resulting from this submission.

Competing interests

Bacteria used for initial biocalcification tests were kindly provided by Soletanche Bachy. A non-disclosure agreement with the company prevents us from disclosing the original composition of BS and CS solutions. The authors declare that they have no further competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethics statement

Biocalcification is processed with non-pathogenic biosafety level 1 bacteria. Ethical approval and consent are therefore not relevant to this article type in the institutional context where this research is carried out.

Comments

No accompanying comment.