Winemaking and the Phoenicians: an introduction

The socio-economic and ritual value of wine in antiquity has been repeatedly emphasised, often in relation to feasting activities or the ceramic containers supposedly used for its transport (e.g. McGovern Reference McGovern2003; Dietler Reference Dietler2006: 233–34). The Iron Age (c. first millennium BC) stands out as a period during which wine-production and -consumption practices spread across many regions of the Mediterranean, as indicated by the diversity in transport amphorae and by drinking sets documented in pottery and metallic assemblages (e.g. Botto Reference Botto, Pérez and Pérez2013: 111–19; Knapp & Demesticha Reference Knapp and Demesticha2017). The adaptation of foreign pottery shapes to facilitate the consumption of wine (e.g. bowls), and/or the incorporation of these vessels into local drinking sets in various Mediterranean regions (e.g. Botto Reference Botto, Pérez and Pérez2013: 111–13; Docter Reference Docter, Graells i Fabregat, Krueger, Sardà and Sciortino2014), further signifies the role of wine via feasting activities in cross-cultural encounters.

Discussions surrounding the spread of wine consumption commonly assign a primary role to the Phoenicians—the Iron Age inhabitants of coastal Central Levant (Sader Reference Sader2019: xii–xiv), who also founded new settlements in many Central and Western Mediterranean areas after the late ninth century BC. Scholars commonly associate Phoenician cross-Mediterranean trading, mobility and settlement with the spread of Near Eastern traditions of wine consumption and the introduction of the grapevine to Europe and north-western Africa (e.g. Botto Reference Botto, Pérez and Pérez2013).

Despite numerous hypotheses implying that the Phoenicians were key agents in the proliferation of wine, it is notable that evidence of winemaking in Phoenicia itself was, until recently, scarce. This scenario has changed as a result of recent excavations at the coastal site of Tell el-Burak (Figure 1), 9km south of Sidon in Lebanon, which have provided extensive new data suggesting the existence of local, Iron Age wine production (Kamlah et al. Reference Kamlah, Sader and Schmitt2016, in press).

Figure 1. Plan of the settlement at Tell el-Burak, showing the excavated areas: green) Middle Bronze Age palace; blue) Late Bronze Age structures; red) Iron Age buildings, including the three plastered structures. The results of a magnetometry survey undertaken in 2002 are also shown (courtesy of the Tell el-Burak Archaeological Project).

The dataset from Tell el-Burak includes an archaeobotanical assemblage (Orendi & Deckers Reference Orendi and Deckers2018) dominated by Vitis vinifera (common grape vine) seeds (41.7 per cent), along with an exceptional number of transport amphorae (Orendi & Deckers Reference Orendi and Deckers2018; Schmitt et al. Reference Schmitt, Badreshany, Tachatou and Sader2019). Most importantly, three plastered structures have been uncovered. The typology of one of the structures strongly suggests that it was associated with wine production. The wine press of Tell el-Burak is the first example of this type of installation identified in the region of ancient Phoenicia and, given its dimensions and remarkable state of preservation, is among the finest examples of a wine press in the ancient Mediterranean.

Along with a reassessment of the archaeological evidence from plastered wine installations in the Levant, this article presents the results of archaeometric analyses carried out on the Tell el-Burak wine press. Additionally, the two other plastered structures (of still uncertain function) are also considered here, in order to provide useful comparative data and to gain a clearer understanding of the selection and processing of raw materials for plaster production and its technological and archaeological implications. Although the study of plaster—particularly lime-based plaster—is well represented in the recent literature (Karkanas Reference Karkanas2007; Regev et al. Reference Regev, Zukerman, Hitchcock, Maeir, Weiner and Boaretto2010; Turco et al. Reference Turco, Davit, Chelazzi, Borghi, Bombardieri and Operti2016), almost no archaeometric studies have addressed the characterisation of plaster from Levantine wine presses. This research therefore serves as a reference point for future investigations of similar installations throughout the Mediterranean. Most importantly, the results of this study provide insights into technological innovation and advancements in plaster manufacturing that support the interpretation of Tell el-Burak as a highly specialised centre for the production, processing and storage of agricultural commodities (Schmitt et al. Reference Schmitt, Badreshany, Tachatou and Sader2019: 81).

Tell el-Burak and its plastered installations

Since 2001, the Tell el-Burak Archaeological Project has uncovered the remains of a small Phoenician settlement (Figure 1) dating from the last quarter of the eighth to the middle of the fourth century BC (Kamlah et al. Reference Kamlah, Sader and Schmitt2016, Reference Kamlah, Sader and Schmittin press). The important Phoenician city of Sidon appears to have been responsible for the foundation of this site (Orendi & Deckers Reference Orendi and Deckers2018: 719), and probably influenced its predominant agricultural role. On its south-western and south-eastern sides, the settlement was bordered by a 2.50m-thick terrace wall (Figure 1). To the south of this wall, excavations have unearthed the well-preserved remains of a wine press, constructed on the slope of the tell in area 4 (Figures 1–3).

Figure 2. Reconstruction of the wine press at Tell el-Burak, looking from the south-east (courtesy of the Tell el-Burak Archaeological Project; drawing by O. Bruderer).

Figure 3. The wine press at Tell el-Burak from the south-west (courtesy of the Tell el-Burak Archaeological Project).

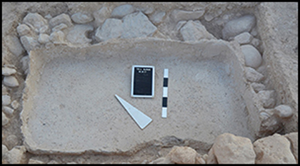

Excavations in area 3 have yielded the remains of four house structures. House 3 comprised two storerooms (rooms 3.1–3.2) and a courtyard (room 3.3). The remains of a basin-like plastered installation were uncovered from beneath the floor of this courtyard (Figure 4). A different type of plastered installation was discovered in room 4.1 of house 4 (Figure 5). During an early phase, this room was coated with plaster, with a plastered channel in the wall between rooms 4.1 and 4.2 serving as drainage. The exact chronological correlation of the three plastered installations, however, is yet to be established. Currently, it is thought—based on preliminary analysis of associated ceramics—that all three installations were probably constructed during the seventh century BC or, in the case of the wine press, during the late eighth century BC. The installations in rooms 4.1 and 3.3 went out of use at the end of the seventh or the beginning of the sixth century BC, while the wine press in area 4 would have continued in use into the sixth century BC.

Figure 4. Plastered basin in room 3 of house 3 at Tell el-Burak, from the south-west (courtesy of the Tell el-Burak Archaeological Project).

Figure 5. Structures at Tell el-Burak, area 3: a) plastered floor in room 1 of house 4, from the south-east; b) plastered floor in room 1 of house 4, from the north-west (courtesy of the Tell el-Burak Archaeological Project).

From the Levant to the Western Mediterranean: wine installations and plaster

In the Bronze and Iron Age Levant (c. third to first millennia BC), most wine presses were hewn into bedrock, while some were constructed of stone blocks. They were usually located outside or on the outskirts of settlements, probably close to associated vineyards. Wine presses comprised at least three elements:

1) A treading floor/basin, where grapes were first trodden.

2) A connecting channel, through which the must flowed.

3) A sunken vat, where the must was collected and (possibly) left for the initial fermentation process.

Numerous installations of this kind—although exhibiting varied building techniques, shapes, size and number of components—are documented in the Levant and across the Mediterranean from the fifth millennium BC (or even earlier) to the first centuries AD (e.g. Frankel Reference Frankel1999: 51–60; Brun Reference Brun2004: 42–43, 54–69; Avrutis Reference Avrutis2015: 55–82). The date of wine presses cannot always be precisely established (Ahlström Reference Ahlström1978: 45–46), particularly when hewn into the bedrock. Additional challenges arise when attempting to discern whether a press was used for wine, as opposed to oil production. In the Levant, the earliest examples of such wine presses are currently attested at Megiddo in stratum XX (Loud Reference Loud1948: 60, fig. 132: 4–5), which dates tentatively to the Pottery Neolithic, Chalcolithic or Early Bronze Age IA (c. 6000–3500 BC; see Ussishkin Reference Ussishkin2015: tab. 1), and at Ard el-Samra, where a basin is dated to the Chalcolithic period (c. 4700–3700 BC; Getzov Reference Getzov2011: fig. 5).

The wine press at Tell el-Burak consists of a rectangular treading basin (approximately 3.20 × 3.50m), a surrounding wall of ashlar blocks and flat stone-slab foundation and a semi-circular vat (approximately 2.50 × 1.95m). Among the wine presses built from stone and plaster and located within or close to settlements, Aphek and Ashkelon (Frankel et al. Reference Frankel, Gadot, Bachi, Gadot and Yadin2009; Stager et al. Reference Stager, Master, Schloen, Stager, Master and Schloen2011) currently provide the best parallels for the press at Tell el-Burak. The two Late Bronze Age wine presses (c. fourteenth to thirteenth centuries BC) at Aphek were also positioned on the slope of the tell, taking advantage of the difference in elevation to allow the must to flow through the installations. Although of smaller size than at Tell el-Burak, they were built above a foundation of stones and feature treading floors that were originally surrounded by a wall. The four wine installations in building 776 at Ashkelon (c. seventh century BC) represent not only closer chronological parallels to Tell el-Burak, but also share similarities in building technique, with foundations made of sandstone ashlar blocks laid in header-stretcher style and superimposed layers of cobblestones.

In the Levant, traces of plaster are recorded on various elements that constitute wine presses (Table 1). They are, however, rarely described, and then solely based on their macroscopic characteristics (Table 2). Although two incomplete plaster surfaces have been analysed at Tell es-Safi/ancient Gath (area A, square 223/80C; stratum A5: c. late eleventh to early tenth centuries BC) in the Southern Levant, they showed no clear relationship with adjacent walls, and, accordingly, their original function cannot be determined (Regev et al. Reference Regev, Zukerman, Hitchcock, Maeir, Weiner and Boaretto2010). The only known exception appears to come from a region much farther to the west. In western-central Sardinia, a permanent installation for producing wine (c. end of the fifth to mid second centuries BC) was discovered on a Punic farm at Truncu ’e Molas (van Dommelen et al. Reference van Dommelen, Bellard, Jordà, Milanese, Ruggeri, Vismara and Zucca2010: 1193–94, fig. 3). Here, only two rectangular vats (each approximately 0.90 × 1.40m) of the two-tiered wine press survived. Although constructed using different building techniques, they were placed side by side and lined with several layers of plaster. Residue analysis of the plaster has identified nine biomarkers of wine, strongly suggesting the presence of an aged wine (Duffy Reference Duffy2015: 138–65); the results of the petrographic study remain unpublished (van Dommelen & Gómez Bellard Reference van Dommelen and Bellard2012: 262, note 28).

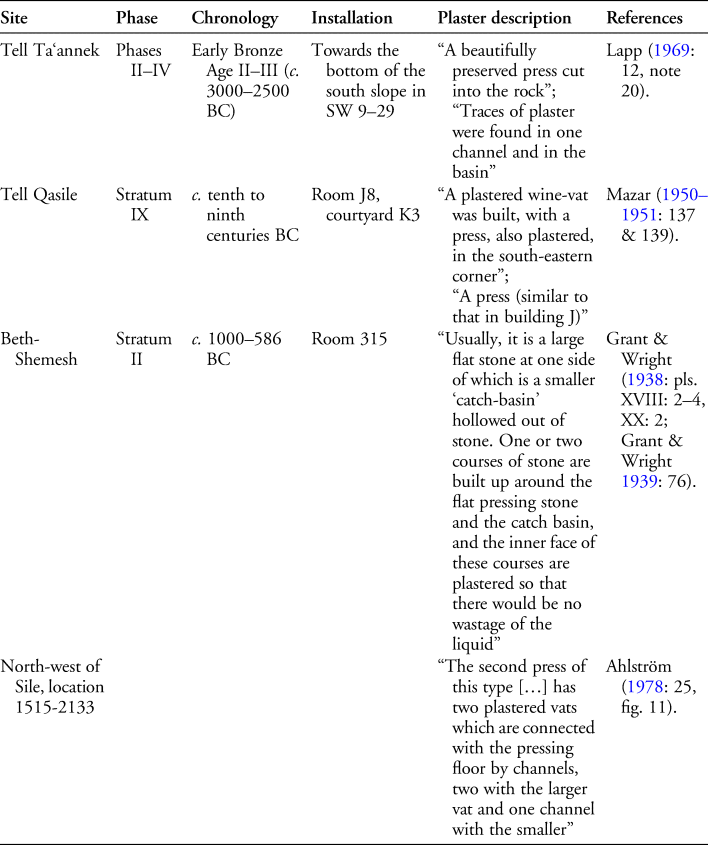

Table 1. A list of selected wine presses where the presence of plaster is mentioned.

Table 2. A list of selected wine presses where information on their plaster surfaces is available.

Archaeometric investigation of plastered installations at Tell el-Burak

Eighteen samples from the Tell el-Burak materials were selected for macroscopic and archaeometric analyses (see Table S1 in the online supplementary material (OSM)). The latter includes ceramic petrography (Quinn Reference Quinn2013) and non-destructive and local, highly resolved X-ray microdiffraction (μ-XRD2) on uncovered thin sections (Berthold & Mentzer Reference Berthold, Mentzer, Nicosia and Stoops2017). To run XRD analysis, a BRUKER D8 Discover X-ray microdiffractometer with a Co-X-ray tube running at 30kV/30mA was used. This was equipped with a primary monochromator, a monocapillary optic with 300μm beam diameter and a VÅNTEC-500 detector covering approximately 40° in °2Theta and Chi. Samples were not rotated, and measurement time was four minutes. Two of the samples (SA1–2) come from the eastern side of the plastered floor in room 4.1 of house 4, and three (SA3–5) from the basin in room 3.3 of house 3. Most of the samples, however, were taken from two components of the wine press (Figure 6): the treading basin (SA6–7 and SA11–15) and the collecting vat (SA8–10 and SA16–18). Additionally, it was possible to analyse a fragment of the stone structure covered by plaster (SA10), which clearly shows the interface between these two elements.

Figure 6. Plan of the wine press at Tell el-Burak, showing the position of the plaster samples.

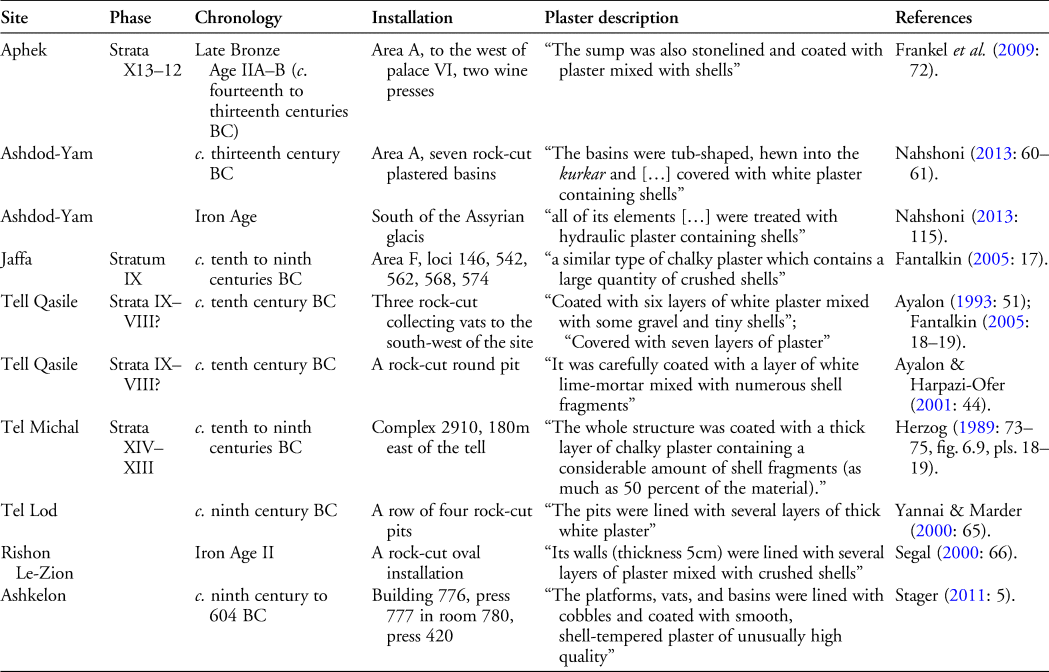

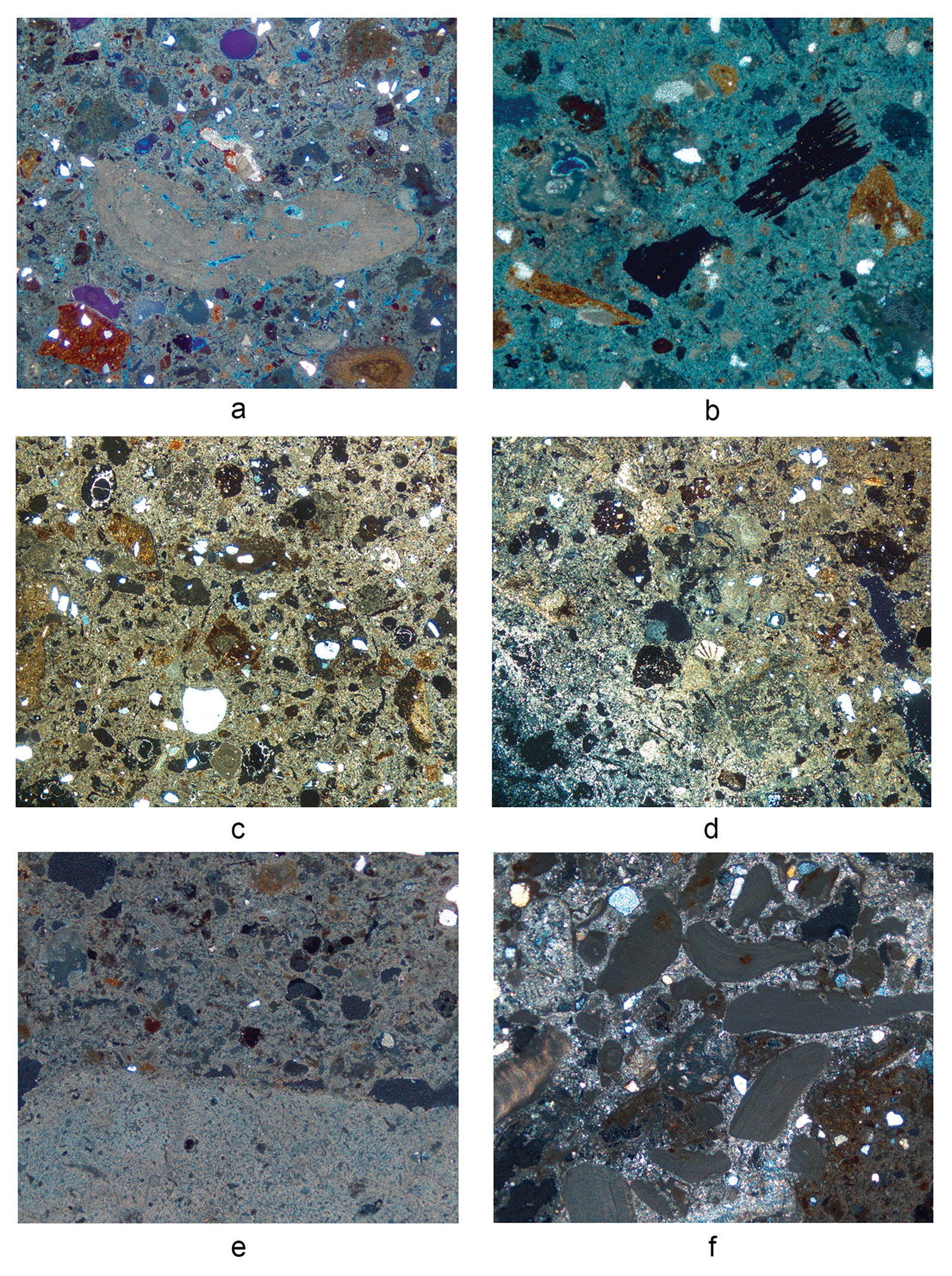

Macroscopic analysis indicates that the binder—the fine matrix that characterises plasters—is homogeneously pinkish white (Munsell 7.5YR 8/2), and that the colour of aggregates—the coarse particles/inclusions set within the binder/matrix—ranges from reddish yellow (Munsell 7.5YR 7/6) to pinkish grey (Munsell 7.5YR 7/2) and grey (Munsell 7.5YR 6/1). Macroscopic analysis alone, however, does not permit the clear identification of the nature of the aggregates in the plaster from Tell el-Burak, although it does suggest the possible use of grog (fragments of crushed ceramics; Whitbread Reference Whitbread1986). This is confirmed by petrographic analysis, which also enabled us to determine the mineralogical nature of the various components (aggregates and binder) in the selected samples (Table S2 in the OSM). Aside from the grog fragments, the aggregates with low optical activity include high-relief cryptocrystalline calcite with moderate, low-order birefringence (probably re-carbonated lime lumps) and quartz (Figures 7–8).

Figure 7. Thin-section micrographs of plaster samples from Tell el-Burak: a) SA7; b) SA5; c–d) SA2; e–f) SA3 (field of view is 4mm for all images; courtesy of the Tell el-Burak Archaeological Project).

Figure 8. Thin-section micrographs of plaster samples from Tell el-Burak: a–b) SA16; c) SA8; d) SA3; e) SA4; f) SA10. To enhance the colour of the pores, SA16 was prepared mixing the epoxy resin, which is used to consolidate the samples, with a blue dye (field of view is 4mm for all images; courtesy of the Tell el-Burak Archaeological Project).

Fragments of grog are orange to grey and contain quartz, shells, microfossils, opaque minerals and chert. A few inclusions of chert, clay pellets, opaque minerals and thermally altered shells and microfossils were also observed amongst the aggregates. The microfossils include coral fragments, small benthic foraminifera and, rarely, large benthic foraminifera. In addition, plagioclases and fragments of sedimentary rocks occur rarely. Lastly, fragments of charcoal and charred organic materials were observed. The binder is micrite-like and exhibits a uniform light-yellow colour. Sample SA4 includes an additional layer without aggregates. This layer is marked by a very fine, micrite-like texture that seems to match the binder observed in another layer of the same sample. The stone fragment (SA10) is a shelly limestone with shell and microfossil inclusions of the same type as those observed in the plaster samples.

The μ-XRD2 analysis of the binder (Figure 9) indicates the presence of fine crystalline calcite, without a significant amount of other crystalline phases (Turco et al. Reference Turco, Davit, Chelazzi, Borghi, Bombardieri and Operti2016: 291). Only quartz has been detected in some measurements, but it is probably part of the finest fraction of the aggregates, rather than of the binder.

Figure 9. X-ray microdiffraction (μ-XRD2) measurements of the binder in Tell el-Burak samples SA1, SA4 (two measurements), SA10, SA14 and SA16. In the corresponding diffractograms, the theoretical peak positions and intensities of calcite and quartz from the pdf database are shown (courtesy of the Tell el-Burak Archaeological Project).

Technology of plaster production at Tell el-Burak

The results of μ-XRD2 investigation, in combination with the petrographic analysis, suggest that the samples are lime plaster produced from the calcination of limestone. The μ-XRD2, however, did not reveal Portlandite (Ca(OH)2) or the unhydrated phases that often form in lime during the calcination process (Cultrone et al. Reference Cultrone, Sebastián and Huertas2005). Nevertheless, these mineral phases—through drying and ageing processes—re-carbonated to calcite by absorbing atmospheric carbon dioxide. The reformed fine crystalline calcite (CaCO3) is indistinguishable from the calcite of the original limestone (Turco et al. Reference Turco, Davit, Chelazzi, Borghi, Bombardieri and Operti2016). In contrast, the presence of calcite lumps (Figure 8a) and reacted, fine crystalline calcite groundmass, observed in thin section of sample SA16, support the interpretation of a lime-based plaster (Karkanas Reference Karkanas2007: 794). It is notable that a possible structure for the calcination process—in the form of a fire pit containing crushed limestone within ash layers—has been discovered near the wine press (Orendi & Deckers Reference Orendi and Deckers2018: 722, fig. 3).

Lime-based mortars were probably produced at Tell el-Burak using the local, naturally abundant limestone that was also used in the construction of the wine press. This notion is further supported by the presence of the same range of microfossils in the plaster samples and in the analysed fragment of limestone from the wine press. Such microfossils occur regularly in Eocene and Miocene chalks (Figure 10) found in the area spanning from the north of Sidon to the south of Tyre (BouDagher-Fadel & Noujaim Clark Reference BouDagher-Fadel and Clark2006: 83–85; Schmitt et al. Reference Schmitt, Badreshany, Tachatou and Sader2019). Furthermore, the same range of microfossils has been recorded in sand samples from Sidon (Ownby & Griffiths Reference Ownby and Griffiths2009). A similar type of sand could have been available in Tell el-Burak and used as an additional source of aggregates.

Figure 10. General geological map of Lebanon (courtesy of K. Badreshany, after Dubertret Reference Dubertret1955).

Finally, microscopic analysis demonstrates that grog is the main aggregate used in the production of plaster at Tell el-Burak. Although these ceramic fragments are too small for systematic petrographic study, their composition suggests a parallel with the fabrics (especially fabric 1A) that characterise the amphorae found at Tell el-Burak (Schmitt et al. Reference Schmitt, Badreshany, Tachatou and Sader2019: 69–70). These vessels could therefore be the possible source of tempering material added into the lime. Notably, grog tempering was not employed by the long-established community of potters at Sarepta (4km from and contemporaneous with Tell el-Burak), where some of these amphorae were probably produced (Schmitt et al. Reference Schmitt, Badreshany, Tachatou and Sader2019: 82). Without denying that the use of grog could have had symbolic value (Chapman Reference Chapman2000: 54), it seems more likely that, at Tell el-Burak, this practice was functional. The addition of grog enhanced the mechanical properties of the lime plaster by increasing its stiffness and reducing shrinkage-related cracking around the aggregates (Tesárek et al. Reference Tesárek, Nežerka, Padevět, Antoš and Plachý2014: 293; Turco et al. Reference Turco, Davit, Chelazzi, Borghi, Bombardieri and Operti2016: 294). Grog-tempering therefore represents a technological choice linked to the production of a high-quality, hydraulic lime plaster. A more detailed archaeometric investigation is ongoing to confirm whether grog was indeed added for this reason at Tell el-Burak. Hydraulic lime plaster hardens under water and is normally produced by mixing lime with pozzolanic materials rich in silica (SiO2) and alumina (Al2O3), such as burnt ceramic materials (Matias et al. Reference Matias, Faria and Torres2014). This mixture enhances the binder-aggregate cohesion, resulting in a water-resistant plaster with superior mechanical performance, in comparison to pure air-lime plasters (Matias et al. Reference Matias, Faria and Torres2014: 130–31).

Plaster traditions in the Levant

Large-scale agricultural production at Tell el-Burak has been hypothesised based on the quantity of amphorae and the presence of Vitis vinifera seeds (Kamlah Reference Kamlah2016; Orendi & Deckers Reference Orendi and Deckers2018; Schmitt et al. Reference Schmitt, Badreshany, Tachatou and Sader2019: 84). This notion is further supported by the size and volume of the wine press and by putative evidence for a second press at the site revealed by recent geophysical survey (Kamlah et al. Reference Kamlah, Sader and Schmittin press). The agricultural specialisation at Tell el-Burak appears to have been an important part of a broader, centralised economic system (Schmitt et al. Reference Schmitt, Badreshany, Tachatou and Sader2019: 86–87), within which individual sites may have engaged in specific agricultural and industrial activities (e.g. pottery production at Sarepta). This system probably took advantage of the regional stability during the period of Assyrian control (c. mid eighth to late seventh centuries BC; Fales Reference Fales2017: 272), which lasted until the end of the Persian period (c. 539–332 BC).

The archaeometric analyses presented in this article reveal the existence of a consistent technological tradition of Iron Age plaster production associated with all three installations at Tell el-Burak. This tradition is characterised by the use of lime-based plaster in which grog is added as the principal aggregate. Although petrographic analyses of plaster from sites in the Southern Levant are lacking, their macroscopic descriptions (Table 2) suggest the ubiquitous use of shell as an aggregate, thereby implying the existence of a different technological plaster tradition at Tell el-Burak. It is notable that grog was very rarely used as a tempering agent in pottery production in pre-classical Lebanon (Badreshany & Philip Reference Badreshany and Philip2020), and it is found in the amphorae at Tell el-Burak (Schmitt et al. Reference Schmitt, Badreshany, Tachatou and Sader2019). This strengthens the hypothesis that the addition of grog to plaster was a well-defined technological choice not influenced by environmental constraints, especially given the local presence of microfossil- and shell-rich sand that could itself have been an ideal source for aggregates.

The tradition of mixing crushed ceramic (or tiles) with lime to produce hydraulic plasters has obscure origins (Regev et al. Reference Regev, Zukerman, Hitchcock, Maeir, Weiner and Boaretto2010) and is rarely attested prior to the third century BC. Although this technique is often defined as opus signinum in the literature (e.g. Gros Reference Gros and Ciotta2003; Vassal Reference Vassal2006), the use of the term in ancient sources (e.g. Vitruvius De Architectura 8.6.14; Granger Reference Granger1934) does not necessarily imply the presence of ceramic sherds within plaster. Accordingly, its definition as cocciopesto is preferred (Braconi Reference Braconi and Angelelli2009). In the scientific literature (e.g. Furlan & Bissegger Reference Furlan and Bissegger1975: 167; Matias et al. Reference Matias, Faria and Torres2014: 126), the Phoenicians are often reported to have promoted the use of these types of plasters and mortars. Precise textual and archaeological sources to support this claim, however, are never adequately offered. Although the exact chronology of the plastered installations at Tell el-Burak remains uncertain, they were probably built during the seventh century BC. The wine press may have already been in use during the first occupation of the settlement (phase E: c. 725–650 BC). If this were the case, it would indicate that the addition of grog into lime plaster was employed at Tell el-Burak since the earliest phase of the settlement, and could be considered the first evidence of such a practice in the Phoenician homeland. Nevertheless, the settlers of Tell el-Burak probably adopted this tradition from elsewhere, with the most likely candidates being the pre-existing settlements in this region, such as Sarepta and Sidon (the latter considered to have re-founded Tell el-Burak; Orendi & Deckers Reference Orendi and Deckers2018: 719).

Although the results of the archaeometric analysis do not confirm whether ceramic sherds were added into the lime plaster at Tell el-Burak in order to enhance its hydraulicity, the mixing of grog into lime plaster certainly improved its mechanical properties. This implies a technological awareness that demonstrates advancement in the construction of agricultural structures, paralleling a high degree of specialisation in the production of agricultural commodities at Tell el-Burak. Additional research that includes archaeometric analyses will allow us to investigate further the origins and dissemination of this technology, and its archaeological implications. Furthermore, to refine our interpretations, it is necessary to determine whether all three plastered structures considered in this study were indeed connected to wine production. This may be resolved by an ongoing organic residue analysis project at the University of Tübingen.

The current work represents a significant contribution to the study of plaster production at Tell el-Burak, and its role in the broader Iron Age Mediterranean context. The results give insights into Phoenician building traditions employed in winemaking-related structures in the Levant. They also provide evidence of the long-claimed role of the Phoenicians in the development and use of cocciopesto, which further developed in the Western Mediterranean during the Punic and Roman periods (c. mid sixth century BC to fifth century AD). The important socio-economic role that wine played in Phoenician societies seems to have favoured the development of innovative solutions in the building technology of installations for the production of wine.

Acknowledgements

This work was generously supported by the SFB 1070 ResourceCultures (project A05) of the Eberhard Karls University of Tübingen. We would like to express our gratitude to the Excellence Initiative of the University of Tübingen, the Ministry for Science, Research and Art of Baden-Württemberg and the Helmut Fischer GmbH Institut für Elektronik und Messtechnik for their support. We would like to thank: Aaron W. Schmitt (Johannes Gutenberg-Universität Mainz), co-director of the Tell el-Burak Archaeological Project, for his useful feedback; Cynthianne Spiteri (University of Tübingen) for her collaboration and plaster sampling; Philipp Munz (University of Tübingen) for sharing his expertise on microfossils; and Arvin Raj Mathur, who prepared the thin sections of the plaster samples. Finally, we would like to thank the anonymous reviewers for their constructive comments.

Adriano Orsingher: conceptualisation, methodology, formal analysis (petrography, XRD), investigation (archaeology, ancient technology), writing (original draft preparation) and project administration. Silvia Amicone: conceptualisation, methodology, formal analysis (petrography, XRD), investigation (ancient technology), writing (original draft preparation) and supervision (petrography, XRD). Jens Kamlah and Hélène Sader: investigation (excavation), resources, writing (review and editing) and funding acquisition. Christoph Berthold: resources, methodology, writing (review and editing), supervision (XRD) and funding acquisition.

Supplementary material

To view supplementary material for this article, please visit https://doi.org/10.15184/aqy.2020.4