1. Introduction

Cavitation is associated with the formation, growth, oscillation and collapse of vapour and gas filled bubbles due to rapid changes of the pressure in the surrounding liquid. In hydraulic systems, e.g. fuel injection or oil-hydraulics devices, cavitation may have serious complications as generation of sound, vibration and cavitation erosion. One peculiarity of hydraulic systems is the working fluid in terms of e.g. fuel or hydraulic oil, which may consist of several hundred components. Thermophysical properties thus depend, beyond local temperature and pressure, also on the local mixture composition. In recent three-dimensional computational fluid dynamics (3-D CFD) approaches of cavitating flow in hydraulic systems, single-component surrogate fluids have been utilized to model the real mixtures. For example, Schnerr et al. (Reference Schnerr, Schmidt, Sezal and Thalhamer2006) utilized water as a surrogate. Further studies, e.g. Giannadakis, Gavaises & Arcoumanis (Reference Giannadakis, Gavaises and Arcoumanis2008a), Giannadakis et al. (Reference Giannadakis, Papoulias, Theodorakakos and Gavaises2008b), Skoda et al. (Reference Skoda, Iben, Güntner and Schilling2012), Theodorakakos et al. (Reference Theodorakakos, Strotos, Mitroglou, Atkin and Gavaises2014), Koukouvinis et al. (Reference Koukouvinis, Gavaises, Li and Wang2016) and Oerley et al. (Reference Oerley, Trummler, Hickel, Mihatsch, Schmidt and Adams2015), to cite only a few, applied the properties of dodecane, decane, heptane or a diesel-like single-component surrogate fluid to model real diesel fuel. For hydraulic oil, also single-component surrogate fluids were utilized (Schrank, Murrenhoff & Stammen Reference Schrank, Murrenhoff and Stammen2013).

The liquid and vapour phases of single-component surrogate fluids are based on a homogeneous, i.e. spatially and temporally constant, mixture. As for pure substances, the properties of the surrogate fluid are dependent only on temperature and pressure. A prospective local change of properties due to local segregation of mixture components at phase interfaces in cavitating flow is inherently neglected. In fact, in the transmission light study by Dorofeeva, Thomas & Dunn (Reference Dorofeeva, Thomas and Dunn2009) and Dunn et al. (Reference Dunn, Thomas, Davis and Dorofeeva2010) on cavitating kerosene flow in a Venturi nozzle, a significant local fuel segregation was observed. A comparison to pure fluids in terms of water, decane and dodecane revealed significant differences of the cavitation void structures in kerosene. Kerosene is a classical real fuel mixture with a multitude of components, essentially consisting of alkanes and aromatics. The vapour saturation pressure of the separate components varies by three orders of magnitude (Dunn et al. Reference Dunn, Thomas, Davis and Dorofeeva2010), so the particular cavitation structures were traced back to a temporally staggered evaporation and re-condensation of the individual kerosene components (Dorofeeva et al. Reference Dorofeeva, Thomas and Dunn2009; Dunn et al. Reference Dunn, Thomas, Davis and Dorofeeva2010). However, due to inherent limitations of the optical measurement techniques, it remained unclear if the segregation of fuel components or the segregation of fuel and dissolved air by air desorption was the dominating observation, and it may be speculated that both effects arise simultaneously. This observation motivated us to launch this simulation study on local segregation of fuel components associated with bubble dynamics and cavitation.

In 3-D CFD methods, mass transfer cavitation models, as proposed e.g. by Schnerr & Sauer (Reference Schnerr and Sauer2001) and Zwart, Gerber & Belamri (Reference Zwart, Gerber and Belamri2014), are combined with the Navier–Stokes equations for the evaluation of phase transition from liquid to vaporous phase and vice versa. This model class is based on simplified fundamentals of bubble dynamics and mostly uses the simple Rayleigh equation (Plesset & Prosperetti Reference Plesset and Prosperetti1977) to evaluate the mass transfer rate. So far, available mass transfer cavitation models are based on single-component fluids only, to the best knowledge of the authors. Therefore, when fluid mixtures are considered by single-component surrogates, only bulk properties of the mixture enter the cavitation model and the governing equations. In fact, it can be concluded that the fuel segregation during cavitation, observed e.g. by Dorofeeva et al. (Reference Dorofeeva, Thomas and Dunn2009) and Dunn et al. (Reference Dunn, Thomas, Davis and Dorofeeva2010), cannot be reproduced with available mass transfer cavitation models, a fact that reveals inherent limitations of state-of-the-art 3-D CFD methods. Another interesting cavitation model approach is based on statistical associating fluid theory (SAFT) (Rokni et al. Reference Rokni, Gupta, Moore, McHugh, Bamgbade and Gavaises2019; Vidal et al. Reference Vidal, Rodriguez, Koukouvinis, Gavaises and McHugh2020; Kolovos et al. Reference Kolovos, Kyriazis, Koukouvinis, Vidal, Gavaises and McDavid2021) and allows for the description of local changes of phase composition and therefore of fuel mixture properties changes. However, this approach is based on thermodynamic equilibrium, and a local transport of the mixture components is inherently not accounted for. Thus an important step towards a multi-component mass transfer cavitation model demands a reconsideration of local transport processes around single bubbles for a description of a staggered phase transition of low- and high-volatile mixture components, which has not been considered until now and is therefore the subject of this study.

Beyond the segregation of fuel components, desorption of non-condensable gas may occur during dynamics of a single bubble and should be considered in the modelling approach, together with the fuel segregation. Thus far, available studies focused only on single-fluid/non-condensable gas systems, and most of them considered water and air. Approximations with the spatial transport of either vapour or non-condensable gas have been proposed by Nigmatulin & Khabeev (Reference Nigmatulin and Khabeev1975) for the former, or Nigmatulin & Khabeev (Reference Nigmatulin and Khabeev1974), Arefmanesh, Advani & Michaelides (Reference Arefmanesh, Advani and Michaelides1992), Naji Meidani & Hasan (Reference Naji Meidani and Hasan1997, Reference Naji Meidani and Hasan2004), Klein & Iben (Reference Klein and Iben2010) and Vachaparambil & Einarsrud (Reference Vachaparambil and Einarsrud2020) for the latter. Sochard, Wilhelm & Delmas (Reference Sochard, Wilhelm and Delmas1998) have also considered gas–vapour interdiffusion within the bubble as well as the liquid–vapour phase transition, i.e. evaporation and condensation across the interface, but gas diffusion across the interface was neglected. Kamath & Prosperetti (Reference Kamath and Prosperetti1989) considered interdiffusing non-condensable gases in the bubble interior. However, no phase transition over the interface and no vapour content in the bubble were considered. Matsumoto & Takemura (Reference Matsumoto and Takemura1994), Takemura & Matsumoto (Reference Takemura and Matsumoto1994) and Matsumoto & Yoshizawa (Reference Matsumoto and Yoshizawa2005) solved the Navier–Stokes equations with radial resolution of the concentration and temperature field within and outside of the bubble, while a Rayleigh–Plesset equation considering mass transfer (Fujikawa & Akamatsu Reference Fujikawa and Akamatsu1980) determined the time-dependent bubble wall position. Air diffusion and the interface condition for air were modelled by Fick's and Henry's laws, respectively. Phase transition was approximated as a thermal non-equilibrium process by the Hertz–Knudsen relation (Persad & Ward Reference Persad and Ward2016), while Bermudez-Graterol, Nickaeen & Skoda (Reference Bermudez-Graterol, Nickaeen and Skoda2021) could show that an equilibrium condition hardly changed the bubble dynamics even during the collapse phase. Jinbo et al. (Reference Jinbo, Kobayashi, Watanabe and Takahira2015) used an approach similar to that of Matsumoto & Takemura (Reference Matsumoto and Takemura1994) but resolved the bubble interface with a level-set and ghost fluid method. Yamamoto et al. (Reference Yamamoto, Kobayashi, Watanabe, Fujii, Kon and Takahira2019) figured out by a molecular dynamics method that a small amount of non-condensable gas strongly affects the temperature field inside the collapsing bubble. Zein, Hantke & Warnecke (Reference Zein, Hantke and Warnecke2013) performed 3-D simulations with mass and heat transfer together with the transport of vapour as well as air. Assuming homobaricity within the bubble – i.e. the bubble pressure is spatially homogeneous and dependent only on time – Nigmatulin, Khabeev & Nagiev (Reference Nigmatulin, Khabeev and Nagiev1981) and Kawashima & Kameda (Reference Kawashima and Kameda2008), and more recently Hao, Zhang & Prosperetti (Reference Hao, Zhang and Prosperetti2017) and Bermudez-Graterol et al. (Reference Bermudez-Graterol, Nickaeen and Skoda2021), evaluated the spatial velocity distribution within the bubble as well as the temporal evolution of the (spatially constant) bubble pressure by an analytical expression that was derived from the energy equation. In the surrounding liquid, the flow was irrotational and thus potential. A similar approach has been used by other authors (Prosperetti Reference Prosperetti1991; Soh & Karimi Reference Soh and Karimi1996; Delale & Pasinlioğlu Reference Delale and Pasinlioğlu2015; Ali & Ake Reference Ali and Ake2016). Hao et al. (Reference Hao, Zhang and Prosperetti2017) pointed out the effect of bubble content, in terms of both vapour and non-condensable gas, on bubble dynamics. These cited studies are based on pure water/non-condensable gas (mostly air) systems, and no other fluids than water and, least of all, fluid mixtures have been considered.

Studies on bubble dynamics with fluid mixtures and a systematic fluid variation are rare. Plesset (Reference Plesset1970) performed experiments on cavitation erosion in an ultrasound device with binary fluid mixtures of water with acetone, formamide, ethanol or glycerol, and concluded that mixture viscosity and air content affected the erosion rate. Huang & Mohamad (Reference Huang and Mohamad2009) performed single-bubble simulations to reproduce the binary mixture measurements of Plesset (Reference Plesset1970). Their model was based on the Rayleigh–Plesset equation for a single-component surrogate fluid, where linear mixture rules for obtaining the surrogate bulk properties were applied. Thus local fluid segregation was inherently neglected by Huang & Mohamad (Reference Huang and Mohamad2009). Regarding wall heat transfer simulations on pool boiling of binary mixtures (Wang, Xie & Tan Reference Wang, Xie and Tan1996a,Reference Wang, Xie and Tanb), the effect of segregation was taken into account via different concentrations of fluid components both within and outside the bubble. However, the spatial and temporal variation of the mixture composition was not considered. By solving the Navier–Stokes equations, Storey & Szeri (Reference Storey and Szeri1999, Reference Storey and Szeri2000) studied sonoluminescence by a segregation of helium and argon as well as argon and steam, and resolved the spatial and temporal distribution of the components within the bubble. During bubble collapse, an enhanced segregation and a concentration of water or helium, respectively, was observed towards the bubble centre. Beyond diffusion due to concentration gradients, thermal diffusion due to temperature gradients affected the in-bubble flow during a later stage of bubble collapse. In contrast, pressure diffusion due to pressure gradients had an appreciable effect only in a very short time interval, so its effect was considered inessential (Storey & Szeri Reference Storey and Szeri1999, Reference Storey and Szeri2000). A prospective segregation of fluid in the surrounding liquid was not investigated by Storey & Szeri (Reference Storey and Szeri1999, Reference Storey and Szeri2000).

Thus the local segregation of fluid mixture components during bubble dynamics has hardly been considered in previous studies. In fact, the studies by Storey & Szeri (Reference Storey and Szeri1999, Reference Storey and Szeri2000) on helium, argon and steam are the only ones of which we are aware, and even these are restricted to segregation of gaseous components within the bubble, while a segregation of liquid mixture components outside the bubble was not considered. A completely different situation occurs for droplet evaporation. Local segregation of liquid mixture components in fuel droplets has been investigated widely by multi-component evaporation models for gasoline (Gartung, Arndt & Seibel Reference Gartung, Arndt and Seibel2002), diesel (Lippert & Reitz Reference Lippert and Reitz1997), biodiesel fuels or ethanol–gasoline mixtures (Hallett & Beauchamp-Kiss Reference Hallett and Beauchamp-Kiss2010; Hallett & Legault Reference Hallett and Legault2011; Zhang & Kong Reference Zhang and Kong2012; Bader, Keller & Hasse Reference Bader, Keller and Hasse2013), to list only a few. Sazhin et al. (Reference Sazhin, Elwardany, Krutitskii, Deprédurand, Castanet, Lemoine, Sazhina and Heikal2011) provided an overview of multi-component models for fuel droplet evaporation. In more recent studies on binary mixtures, Li et al. (Reference Li, Lv, Diddens, Tan, Wijshoff, Versluis and Lohse2018, Reference Li, Diddens, Segers, Wijshoff, Versluis and Lohse2020) reported evaporation-triggered segregation in 1,2-hexanediol–water droplets, and Millán-Merino, Fernández-Tarrazo & Sánchez-Sanz (Reference Millán-Merino, Fernández-Tarrazo and Sánchez-Sanz2021) observed higher vaporization rates with increasing ambient humidity for ethanol–water droplets. The mixture segregation of the droplet is associated with strongly different and temporally staggered mass flow rates of the individual mixture components at the phase interface. The evaporation rate of high-volatile components is larger than that of low-volatile components, leading to a densification of the liquid fuel within the droplet. The opposite trend was observed during condensation. In the liquid phase within the droplet as well as in the surrounding vaporous phase, a temporal and spatial variation of the local fuel composition occurs that again affects the mixture state and transport properties, e.g. for cold environmental conditions (Lippert & Reitz Reference Lippert and Reitz1997) or flash boiling (Ra & Reitz Reference Ra and Reitz2003; Yang & Reitz Reference Yang and Reitz2009). We assume that such processes occur also during different stages of bubble dynamics, which has, however, not been studied yet. Therefore, the subject of the present study is the assessment of local segregation of fluid mixtures by single-bubble flow simulations. Thereby, we pay particular attention to the peculiarities of multi-component transport in comparison with a conventional single-component bulk fluid treatment (termed a pseudo-fluid in this study). We content ourselves with binary mixtures in this first study on this topic, and choose heptane (![]() $\mathrm {C7H16}$) and dodecane (

$\mathrm {C7H16}$) and dodecane (![]() $\mathrm {C12H26}$) as high- and low-volatile components, respectively, since these fluids are common components of real fuels. Since no single-bubble simulation model for fluid mixtures has been presented before, we present a complete governing equation set that comprises an extension of our preceding study on water–air systems (Bermudez-Graterol et al. Reference Bermudez-Graterol, Nickaeen and Skoda2021). No experimental data on mixture bubble dynamics are available, so we must content ourselves with a validation on bubble growth in water. However, the simulation results will provide an insight into the local heat, mass and phase transfer processes of mixture bubble dynamics, and hence may serve as a basis for a purposeful experimental set-up in future studies.

$\mathrm {C12H26}$) as high- and low-volatile components, respectively, since these fluids are common components of real fuels. Since no single-bubble simulation model for fluid mixtures has been presented before, we present a complete governing equation set that comprises an extension of our preceding study on water–air systems (Bermudez-Graterol et al. Reference Bermudez-Graterol, Nickaeen and Skoda2021). No experimental data on mixture bubble dynamics are available, so we must content ourselves with a validation on bubble growth in water. However, the simulation results will provide an insight into the local heat, mass and phase transfer processes of mixture bubble dynamics, and hence may serve as a basis for a purposeful experimental set-up in future studies.

The paper is organized as follows. In §§ 2 and 3, the mathematical model and its numerical solution method are presented. In § 4, results of two example bubble dynamics scenarios are presented: first, bubble oscillation after a rapid pressure drop is investigated in § 4.1; and second, continuous bubble growth in superheated liquid is studied in § 4.2. We finalize the paper with our conclusions and outlook in § 5.

2. Mathematical model formulation

2.1. Model outline and notations

The mathematical model of a single spherical bubble is based on our preceding study on water–air mixtures (Bermudez-Graterol et al. Reference Bermudez-Graterol, Nickaeen and Skoda2021). Homobaricity is assumed within (but not outside) the bubble, which is justified for ![]() $| \dot {R} | \ll a^{G}$ (Nigmatulin et al. Reference Nigmatulin, Khabeev and Nagiev1981), where

$| \dot {R} | \ll a^{G}$ (Nigmatulin et al. Reference Nigmatulin, Khabeev and Nagiev1981), where ![]() $a^{G}$ is the speed of sound. This condition is fulfilled for any test case in this study. Homobaricity allows the omission of the full Navier–Stokes equations. Instead of solving the Navier–Stokes equations, the velocity field and the pressure within the bubble are obtained by the energy equation. Outside the bubble, the velocity and pressure fields are obtained by noting that the flow is irrotational. The homobaricity assumption reduces considerably the computational effort and thereby opens the opportunity to embed a large number of single bubbles in a 3-D Euler–Lagrange framework in future studies, which will be picked up in the outlook at the end of this paper. Binary heptane/dodecane mixtures are investigated, referred to as fuel in what follows, together with air. Air is treated as a single-component pseudo-fluid, so the model comprises three species in total. Thus the bubble contains a mixture of vaporous heptane and dodecane as well as non-condensable gas, i.e. air, which are assumed to be thermally and calorically ideal. The bubble is surrounded with an infinite amount of a liquid heptane/dodecane mixture, in which air is dissolved. Both within (superscript

$a^{G}$ is the speed of sound. This condition is fulfilled for any test case in this study. Homobaricity allows the omission of the full Navier–Stokes equations. Instead of solving the Navier–Stokes equations, the velocity field and the pressure within the bubble are obtained by the energy equation. Outside the bubble, the velocity and pressure fields are obtained by noting that the flow is irrotational. The homobaricity assumption reduces considerably the computational effort and thereby opens the opportunity to embed a large number of single bubbles in a 3-D Euler–Lagrange framework in future studies, which will be picked up in the outlook at the end of this paper. Binary heptane/dodecane mixtures are investigated, referred to as fuel in what follows, together with air. Air is treated as a single-component pseudo-fluid, so the model comprises three species in total. Thus the bubble contains a mixture of vaporous heptane and dodecane as well as non-condensable gas, i.e. air, which are assumed to be thermally and calorically ideal. The bubble is surrounded with an infinite amount of a liquid heptane/dodecane mixture, in which air is dissolved. Both within (superscript ![]() $\gamma = {G}$) and outside (superscript

$\gamma = {G}$) and outside (superscript ![]() $\gamma = {L}$) the bubble, mixture values (subscript

$\gamma = {L}$) the bubble, mixture values (subscript ![]() ${m}$) are evaluated by a mass fraction weight

${m}$) are evaluated by a mass fraction weight ![]() $y_{\alpha }^{\gamma }=\rho _{\alpha }^{\gamma }/\rho _{m}^{\gamma }$, where

$y_{\alpha }^{\gamma }=\rho _{\alpha }^{\gamma }/\rho _{m}^{\gamma }$, where ![]() $\rho$ is the mass density, and index

$\rho$ is the mass density, and index ![]() $\alpha$ means either heptane (subscript

$\alpha$ means either heptane (subscript ![]() $\alpha = {Hep}$), dodecane (subscript

$\alpha = {Hep}$), dodecane (subscript ![]() $\alpha = {Dod}$) or air (subscript

$\alpha = {Dod}$) or air (subscript ![]() $\alpha = {Air}$). The species add to 1 when

$\alpha = {Air}$). The species add to 1 when ![]() $\alpha$ is summed over all

$\alpha$ is summed over all ![]() $N_{S} = 3$ species:

$N_{S} = 3$ species:

\begin{equation} \sum_{\alpha=1}^{N_{S}} y_{\alpha}^{\gamma} = y_{Hep}^{\gamma} + y_{Dod}^{\gamma} + y_{Air}^{\gamma} = 1. \end{equation}

\begin{equation} \sum_{\alpha=1}^{N_{S}} y_{\alpha}^{\gamma} = y_{Hep}^{\gamma} + y_{Dod}^{\gamma} + y_{Air}^{\gamma} = 1. \end{equation}In what follows, the mathematical model is outlined, while details are presented in Appendix A. The assumptions made are listed in § A.1.

2.2. Governing equations

The governing equations are solved in spherical coordinates. For both the gaseous bubble interior and its surrounding liquid, the mass conservation of mixture ![]() $m$ and its components

$m$ and its components ![]() $\alpha$ reads

$\alpha$ reads

where ![]() $u$ is the absolute velocity,

$u$ is the absolute velocity, ![]() $D$ is the diffusion coefficient,

$D$ is the diffusion coefficient, ![]() $\alpha = {Hep}$,

$\alpha = {Hep}$, ![]() ${Dod}$ or

${Dod}$ or ![]() ${Air}$, and

${Air}$, and ![]() $\gamma = {G}$ or

$\gamma = {G}$ or ![]() ${L}$.

${L}$.

2.2.1. Within bubble

Mixture pressure ![]() $p^{G}$ is assumed to fulfil Dalton's law,

$p^{G}$ is assumed to fulfil Dalton's law, ![]() $p^{G}= p^{G}_{Hep} + p^{G}_{Dod} +p^{G}_{Air}$. For a thermally ideal gas, it is evaluated by

$p^{G}= p^{G}_{Hep} + p^{G}_{Dod} +p^{G}_{Air}$. For a thermally ideal gas, it is evaluated by

where ![]() $\mathfrak {R}_{m}$ and

$\mathfrak {R}_{m}$ and ![]() $T^{G}$ correspond to the mixture gas constant and the temperature, respectively.

$T^{G}$ correspond to the mixture gas constant and the temperature, respectively.

Employing the homobaricity assumption ![]() $\partial p^{G}/\partial r = 0$, an integro-differential expression for the velocity profile is obtained from energy conservation:

$\partial p^{G}/\partial r = 0$, an integro-differential expression for the velocity profile is obtained from energy conservation:

with

\begin{align} G(r) &= \frac{\mathfrak{R}_{m}}{c_{p,{m}}^{G}} \left \{ \frac{1}{r^{2}}\,\frac{\partial}{\partial r} \left(r^{2} \rho_{m}^{G} T^{G} \sum_{\alpha=1}^{N_{S}} \mathfrak{R}_{\alpha}D_{\alpha}^{G}\,\frac{\partial y_{\alpha}^{G}}{\partial r} \right) + \frac{1}{r^{2}}\,\frac{\partial}{\partial r}\left(r^{2} \lambda_{m}^{G}\,\frac{\partial T^{G}}{\partial r} \right) \right.\nonumber\\ &\quad \left. {}+ \frac{T^{G} c_{v,{m}}^{G}}{\mathfrak{R}_{m}}\,\frac{1}{r^{2}} \sum_{\alpha=1}^{N_{S}} \mathfrak{R}_{\alpha}\,\frac{\partial}{\partial r} \left(r^{2} \rho_{m}^{G} D_{\alpha}^{G}\,\frac{\partial y_{\alpha}^{G}}{\partial r} \right ) + \rho_{m}^{G}\,\frac{\partial T^{G}}{\partial r} \sum_{\alpha=1}^{N_{S}} c_{v,{\alpha}}^{G} D_{\alpha}^{G}\,\frac{\partial y_{\alpha}^{G}}{\partial r} \right \}. \end{align}

\begin{align} G(r) &= \frac{\mathfrak{R}_{m}}{c_{p,{m}}^{G}} \left \{ \frac{1}{r^{2}}\,\frac{\partial}{\partial r} \left(r^{2} \rho_{m}^{G} T^{G} \sum_{\alpha=1}^{N_{S}} \mathfrak{R}_{\alpha}D_{\alpha}^{G}\,\frac{\partial y_{\alpha}^{G}}{\partial r} \right) + \frac{1}{r^{2}}\,\frac{\partial}{\partial r}\left(r^{2} \lambda_{m}^{G}\,\frac{\partial T^{G}}{\partial r} \right) \right.\nonumber\\ &\quad \left. {}+ \frac{T^{G} c_{v,{m}}^{G}}{\mathfrak{R}_{m}}\,\frac{1}{r^{2}} \sum_{\alpha=1}^{N_{S}} \mathfrak{R}_{\alpha}\,\frac{\partial}{\partial r} \left(r^{2} \rho_{m}^{G} D_{\alpha}^{G}\,\frac{\partial y_{\alpha}^{G}}{\partial r} \right ) + \rho_{m}^{G}\,\frac{\partial T^{G}}{\partial r} \sum_{\alpha=1}^{N_{S}} c_{v,{\alpha}}^{G} D_{\alpha}^{G}\,\frac{\partial y_{\alpha}^{G}}{\partial r} \right \}. \end{align} By evaluating (2.5) at the bubble wall ![]() $r=R$ and rearranging, an expression for the temporal pressure evolution within the bubble is obtained:

$r=R$ and rearranging, an expression for the temporal pressure evolution within the bubble is obtained:

\begin{equation} \frac{{\mathrm d}p^{G}}{{\mathrm d}t} = \frac{\displaystyle - R^2 p^{G} u_{{w}}^{G} + \int_0^R G(r)\,r^2 \, \mathrm{d}r}{\displaystyle \frac{R^3}{3} - \int_0^R \frac{\mathfrak{R}_{m}}{c_{p,{m}}^{G}}\,r^2 \, \mathrm{d}r }. \end{equation}

\begin{equation} \frac{{\mathrm d}p^{G}}{{\mathrm d}t} = \frac{\displaystyle - R^2 p^{G} u_{{w}}^{G} + \int_0^R G(r)\,r^2 \, \mathrm{d}r}{\displaystyle \frac{R^3}{3} - \int_0^R \frac{\mathfrak{R}_{m}}{c_{p,{m}}^{G}}\,r^2 \, \mathrm{d}r }. \end{equation} More details are provided in § A.2. An even more detailed derivation of the governing equations for the velocity field and the pressure has been provided in Nickaeen (Reference Nickaeen2020) for a water–air system. As a main advance provided in this study, we have extended the equations from water to discrete alkane mixtures, resulting in (2.5)–(2.7). The velocity ![]() $u_{{w}}^{G}$ at the gaseous side of the bubble wall is obtained by the conservation of mass flux

$u_{{w}}^{G}$ at the gaseous side of the bubble wall is obtained by the conservation of mass flux ![]() $\dot {m}''= \dot {m}_{Hep}'' + \dot {m}_{Dod}'' + \dot {m}_{Air}''$ through the bubble wall. The mass flux reads

$\dot {m}''= \dot {m}_{Hep}'' + \dot {m}_{Dod}'' + \dot {m}_{Air}''$ through the bubble wall. The mass flux reads ![]() $\dot {m}''= \rho _{{m,w}}^{G}(\dot {R} - u_{{w}}^{G})$ and is assumed positive when flowing into the bubble. Thus

$\dot {m}''= \rho _{{m,w}}^{G}(\dot {R} - u_{{w}}^{G})$ and is assumed positive when flowing into the bubble. Thus

Note that ![]() $\dot {m}''$ corresponds to the area-specific mass flux, and the actual mass flow

$\dot {m}''$ corresponds to the area-specific mass flux, and the actual mass flow ![]() $\dot {m}_{\alpha }$ is obtained by

$\dot {m}_{\alpha }$ is obtained by ![]() $\dot {m}_{\alpha } = A_{{B}} \, \dot {m}''_{\alpha }$ with the bubble area

$\dot {m}_{\alpha } = A_{{B}} \, \dot {m}''_{\alpha }$ with the bubble area ![]() $A_{{B}}=4{\rm \pi} R^2$. Assuming ideal gas, energy conservation reads

$A_{{B}}=4{\rm \pi} R^2$. Assuming ideal gas, energy conservation reads

\begin{align}

\rho_{m}^{G} c_{p,{m}}^{G}\,\frac{\partial T^{G}}{\partial

t} &={-}\rho_{m}^{G} c_{p,{m}}^{G} u^{G}\,\frac{\partial

T^{G}}{\partial r} +

\frac{1}{r^{2}}\,\frac{\partial}{\partial r}\left(r^{2}

\lambda_{m}^{G}\,\frac{\partial T^{G}}{\partial r}

\right)\nonumber\\ &\quad + \rho_{m}^{G}\,\frac{\partial

T^{G}}{\partial r} \sum_{\alpha=1}^{N_{S}}

c_{p,{\alpha}}^{G} D_{\alpha}^{G}\,\frac{\partial

y_{\alpha}^{G}}{\partial r}+\frac{{\mathrm

d}p^{G}}{{\mathrm d}t}.

\end{align}

\begin{align}

\rho_{m}^{G} c_{p,{m}}^{G}\,\frac{\partial T^{G}}{\partial

t} &={-}\rho_{m}^{G} c_{p,{m}}^{G} u^{G}\,\frac{\partial

T^{G}}{\partial r} +

\frac{1}{r^{2}}\,\frac{\partial}{\partial r}\left(r^{2}

\lambda_{m}^{G}\,\frac{\partial T^{G}}{\partial r}

\right)\nonumber\\ &\quad + \rho_{m}^{G}\,\frac{\partial

T^{G}}{\partial r} \sum_{\alpha=1}^{N_{S}}

c_{p,{\alpha}}^{G} D_{\alpha}^{G}\,\frac{\partial

y_{\alpha}^{G}}{\partial r}+\frac{{\mathrm

d}p^{G}}{{\mathrm d}t}.

\end{align} With (2.3) (![]() $\gamma = {G}$), (2.4), (2.5), (2.7) and (2.9), an equation set for the evaluation of the gas field variables

$\gamma = {G}$), (2.4), (2.5), (2.7) and (2.9), an equation set for the evaluation of the gas field variables ![]() $y_{\alpha }^{G}$,

$y_{\alpha }^{G}$, ![]() $\rho _{m}^{G}$,

$\rho _{m}^{G}$, ![]() $u^{G}$ and

$u^{G}$ and ![]() $T^{G}$, as well as the time-dependent pressure

$T^{G}$, as well as the time-dependent pressure ![]() $p^{G}$, is available.

$p^{G}$, is available.

2.2.2. Within liquid

Neglecting viscous effects, the energy equation reads

\begin{equation} \rho_{m}^{L} c_{m}^{L} \left( \frac{\partial T^{L}}{\partial t} + u^{L}\,\frac{\partial T^{L}}{\partial r} \right ) = \frac{1}{r^2}\, \frac{\partial}{\partial r}\left(r^2 \lambda_{m}^{L}\,\frac{\partial T^{L}}{\partial r} \right ) + \rho_{m}^{L} \sum_{\alpha=1}^{N_{S}} D_{\alpha}^{L}\,\frac{\partial y_{\alpha}^{L}}{\partial r}\,\frac{\partial h_{\alpha}^{L}}{\partial r}, \end{equation}

\begin{equation} \rho_{m}^{L} c_{m}^{L} \left( \frac{\partial T^{L}}{\partial t} + u^{L}\,\frac{\partial T^{L}}{\partial r} \right ) = \frac{1}{r^2}\, \frac{\partial}{\partial r}\left(r^2 \lambda_{m}^{L}\,\frac{\partial T^{L}}{\partial r} \right ) + \rho_{m}^{L} \sum_{\alpha=1}^{N_{S}} D_{\alpha}^{L}\,\frac{\partial y_{\alpha}^{L}}{\partial r}\,\frac{\partial h_{\alpha}^{L}}{\partial r}, \end{equation}

where ![]() $c_{m}^{L}$ is the specific heat of the liquid mixture. Liquid density

$c_{m}^{L}$ is the specific heat of the liquid mixture. Liquid density ![]() $\rho _{m}^{L}$ is variable due to a varying mixture composition in the surrounding liquid phase. However, since the densities of pure liquid heptane and dodecane deviate by less than 10 %, and liquid density variations due to variable mixing ratio are therefore small, we prefer the incompressible formulation of the energy equation in terms of (2.10) that does not include the work done by the pressure force, according to Bird, Stewart & Lightfoot (Reference Bird, Stewart and Lightfoot1960). Nevertheless, slight variations of

$\rho _{m}^{L}$ is variable due to a varying mixture composition in the surrounding liquid phase. However, since the densities of pure liquid heptane and dodecane deviate by less than 10 %, and liquid density variations due to variable mixing ratio are therefore small, we prefer the incompressible formulation of the energy equation in terms of (2.10) that does not include the work done by the pressure force, according to Bird, Stewart & Lightfoot (Reference Bird, Stewart and Lightfoot1960). Nevertheless, slight variations of ![]() $\rho _{m}^{L}$ are considered by a mixture equation of state that will be introduced in § A.4.1. This approximation is equivalent to the assumption that liquid compressibility effects due to flow dynamics are neglected in (2.10), and only a locally varying fuel composition accounts for liquid density variations. The second term on the right-hand side of (2.10) corresponds to the heat transport by each of the diffusing species. The spatial change of the enthalpy of the separate species

$\rho _{m}^{L}$ are considered by a mixture equation of state that will be introduced in § A.4.1. This approximation is equivalent to the assumption that liquid compressibility effects due to flow dynamics are neglected in (2.10), and only a locally varying fuel composition accounts for liquid density variations. The second term on the right-hand side of (2.10) corresponds to the heat transport by each of the diffusing species. The spatial change of the enthalpy of the separate species ![]() $h_{\alpha }^{L}$ is evaluated by

$h_{\alpha }^{L}$ is evaluated by

The liquid pressure ![]() $p^{L}$ distribution is evaluated by Bernoulli's equation, noting that we have a potential flow around the bubble. A detailed description of the evaluation of

$p^{L}$ distribution is evaluated by Bernoulli's equation, noting that we have a potential flow around the bubble. A detailed description of the evaluation of ![]() $p^{L}$ is provided in § 1 of the supplementary material.

$p^{L}$ is provided in § 1 of the supplementary material.

The integral momentum balance is considered by a modified form of the Rayleigh–Plesset equation (Fujikawa & Akamatsu Reference Fujikawa and Akamatsu1980) that takes into account the mass flux ![]() $\dot {m}''$ across the bubble wall:

$\dot {m}''$ across the bubble wall:

Equation (2.12) governs the bubble interface location in terms of the temporal progression of ![]() $R$, where

$R$, where ![]() $\dot {\square }$ denotes the time derivative, and

$\dot {\square }$ denotes the time derivative, and ![]() $\ddot {\square }$ denotes the second time derivative. In (2.12),

$\ddot {\square }$ denotes the second time derivative. In (2.12), ![]() $p_{\infty }^{L}$ can be understood as the driving variable of the bubble motion. Note that although we do not resolve spatially the momentum conservation equation, momentum balance is considered integrally by the solution of (2.12). This equation has been formulated by Fujikawa & Akamatsu (Reference Fujikawa and Akamatsu1980), taking into account liquid compressibility effects. We have adopted the incompressible form here. Assuming incompressibility has been verified in preliminary test simulations, for the test cases considered in § 4. By the terms including the mass flux

$p_{\infty }^{L}$ can be understood as the driving variable of the bubble motion. Note that although we do not resolve spatially the momentum conservation equation, momentum balance is considered integrally by the solution of (2.12). This equation has been formulated by Fujikawa & Akamatsu (Reference Fujikawa and Akamatsu1980), taking into account liquid compressibility effects. We have adopted the incompressible form here. Assuming incompressibility has been verified in preliminary test simulations, for the test cases considered in § 4. By the terms including the mass flux ![]() $\dot {m}''$ in (2.12), local heat and mass transport are coupled to bubble dynamics. The mass flux

$\dot {m}''$ in (2.12), local heat and mass transport are coupled to bubble dynamics. The mass flux ![]() $\dot {m}''$ is composed of its individual components

$\dot {m}''$ is composed of its individual components ![]() $\dot {m}''_{Hep}$,

$\dot {m}''_{Hep}$, ![]() $\dot {m}''_{Dod}$ and

$\dot {m}''_{Dod}$ and ![]() $\dot {m}''_{Air}$, which govern fuel segregation in the proximity of the bubble wall. It is interesting to note that for the test cases considered, the inclusion of

$\dot {m}''_{Air}$, which govern fuel segregation in the proximity of the bubble wall. It is interesting to note that for the test cases considered, the inclusion of ![]() $\dot {m}''$ and

$\dot {m}''$ and ![]() $\ddot {m}''$ in (2.12) virtually does not affect bubble dynamics, so it can be omitted in the Rayleigh–Plesset equation.

$\ddot {m}''$ in (2.12) virtually does not affect bubble dynamics, so it can be omitted in the Rayleigh–Plesset equation.

By the same reasoning on mass conservation as applied to the velocity at the gas side of the bubble wall in terms of (2.8), a relation for the liquid side velocity is obtained:

The velocity field in the liquid surrounding the bubble is approximated by the mass conservation, neglecting small variations of the liquid density:

Equation (2.14) corresponds to an incompressible and irrotational flow.

With (2.3) (![]() $\gamma = {L}$), (2.10), (2.12) and (2.14), an equation set for the evaluation of the liquid field variables

$\gamma = {L}$), (2.10), (2.12) and (2.14), an equation set for the evaluation of the liquid field variables ![]() $y_{\alpha }^{L}$,

$y_{\alpha }^{L}$, ![]() $T^{L}$ and

$T^{L}$ and ![]() $u^{L}$, as well as the time-dependent bubble radius

$u^{L}$, as well as the time-dependent bubble radius ![]() $R$, has been obtained.

$R$, has been obtained.

2.3. Boundary conditions

2.3.1. At the bubble centre and in the liquid far field

The bubble centre is assumed to be motionless, and all variables approach the centre with a vanishing gradient. Thus Neumann boundary conditions are formulated for the dependent variables:

At the outer liquid boundary of the computational domain, referred to as the liquid far field (index ![]() $\infty$),

$\infty$), ![]() $u^{L}$ is readily available by the kinematic condition (2.14) and does not demand any further boundary treatment. In the liquid far field,

$u^{L}$ is readily available by the kinematic condition (2.14) and does not demand any further boundary treatment. In the liquid far field, ![]() $y_{\alpha }^{L}$ and

$y_{\alpha }^{L}$ and ![]() $T^{L}$ remain at their initial values (which is explicated in § 2.4) and are formulated as Dirichlet conditions:

$T^{L}$ remain at their initial values (which is explicated in § 2.4) and are formulated as Dirichlet conditions:

In the Rayleigh–Plesset equation (2.12), ![]() $p_{\infty }^{L}$ is prescribed explicitly as a function of time.

$p_{\infty }^{L}$ is prescribed explicitly as a function of time.

2.3.2. At the bubble wall

For the evaluation of the pressure ![]() $p_{w}^{L}$ at the liquid side of the bubble wall in (2.12), the relation between bubble pressure

$p_{w}^{L}$ at the liquid side of the bubble wall in (2.12), the relation between bubble pressure ![]() $p^{G}$ and liquid pressure

$p^{G}$ and liquid pressure ![]() $p_{w}^{L}$ is given by

$p_{w}^{L}$ is given by

\begin{equation} p_{w}^{L}= p^{G} -\frac{2\sigma_{m}}{R} -\frac{(\dot{m}'')^2(\rho_{{m,w}}^{G} - \rho_{{m,w}}^{L} )}{\rho_{{m,w}}^{G} \rho_{{m,w}}^{L}}, \end{equation}

\begin{equation} p_{w}^{L}= p^{G} -\frac{2\sigma_{m}}{R} -\frac{(\dot{m}'')^2(\rho_{{m,w}}^{G} - \rho_{{m,w}}^{L} )}{\rho_{{m,w}}^{G} \rho_{{m,w}}^{L}}, \end{equation}

where ![]() $\sigma _{m}$ is the surface tension of the mixture. Equation (2.17) does not include the effect of viscosity since we found that it has virtually no effect for the test cases considered. According to Fujikawa & Akamatsu (Reference Fujikawa and Akamatsu1980), the last term on the right-hand side of (2.17) can be neglected, which we have also verified in preliminary tests.

$\sigma _{m}$ is the surface tension of the mixture. Equation (2.17) does not include the effect of viscosity since we found that it has virtually no effect for the test cases considered. According to Fujikawa & Akamatsu (Reference Fujikawa and Akamatsu1980), the last term on the right-hand side of (2.17) can be neglected, which we have also verified in preliminary tests.

Thermal and phase equilibrium is assumed and enables a straightforward formulation of mixture boundary conditions at the bubble wall. Thermal equilibrium means that the temperatures at both sides of the bubble wall are equal:

Phase equilibrium means that the liquid and vapour phases have the same chemical potential. At low pressures, assuming that the vapour behaves like an ideal gas, the following relation is often used to describe the vapour–liquid equilibrium (Koretsky Reference Koretsky2012):

with mole fractions ![]() $x_{\alpha,{w}}^{L}$ and

$x_{\alpha,{w}}^{L}$ and ![]() $x_{\alpha,{w}}^{G}$, activity coefficients

$x_{\alpha,{w}}^{G}$, activity coefficients ![]() $\gamma _\alpha$, and

$\gamma _\alpha$, and ![]() $\alpha ={Hep}$ or

$\alpha ={Hep}$ or ![]() $Dod$. The activity coefficients account for the deviation from ideal solution caused by changes in composition. For chemically similar species, the numerical value of

$Dod$. The activity coefficients account for the deviation from ideal solution caused by changes in composition. For chemically similar species, the numerical value of ![]() $\gamma _\alpha$ is close to 1. Activity coefficients can be obtained by using models for the excess Gibbs energy, such as, the Wilson equation, NRTL or UNIQUAC (Gmehling et al. Reference Gmehling, Kolbe, Kleiber and Rarey2012). Recognizing the chemical similarity of alkane species heptane and dodecane, we set

$\gamma _\alpha$ is close to 1. Activity coefficients can be obtained by using models for the excess Gibbs energy, such as, the Wilson equation, NRTL or UNIQUAC (Gmehling et al. Reference Gmehling, Kolbe, Kleiber and Rarey2012). Recognizing the chemical similarity of alkane species heptane and dodecane, we set ![]() $\gamma _\alpha$ to be equal to 1 for simplicity. With

$\gamma _\alpha$ to be equal to 1 for simplicity. With ![]() $\gamma _\alpha = 1$ in (2.19), we obtain Raoult's law. A validation with experimentally measured vapour–liquid equilibria by Maia de Oliveira et al. (Reference Maia de Oliveira, Bezerra Lopes, Dantas Neto and Chiavone-Filho2002) is presented in § A.3.

$\gamma _\alpha = 1$ in (2.19), we obtain Raoult's law. A validation with experimentally measured vapour–liquid equilibria by Maia de Oliveira et al. (Reference Maia de Oliveira, Bezerra Lopes, Dantas Neto and Chiavone-Filho2002) is presented in § A.3.

The heat balance reads

where ![]() $L_{m}$ is the latent heat of the fuel mixture. The heat transport by each of the diffusing components has been neglected in (2.20) because it is small, as was verified by preliminary tests. The heat flux is evaluated by Fourier's law in terms of

$L_{m}$ is the latent heat of the fuel mixture. The heat transport by each of the diffusing components has been neglected in (2.20) because it is small, as was verified by preliminary tests. The heat flux is evaluated by Fourier's law in terms of ![]() $q_{w}^{L} = \lambda _{{m,w}}^{L} ({\partial T^{L}}/{\partial r})|_{w}$ and

$q_{w}^{L} = \lambda _{{m,w}}^{L} ({\partial T^{L}}/{\partial r})|_{w}$ and ![]() $q_{w}^{G} = \lambda _{{m,w}}^{G}({\partial T^{G}}/{\partial r})|_{w}$, and the mixture thermal conductivities

$q_{w}^{G} = \lambda _{{m,w}}^{G}({\partial T^{G}}/{\partial r})|_{w}$, and the mixture thermal conductivities ![]() $\lambda _{m}^{L}$ and

$\lambda _{m}^{L}$ and ![]() $\lambda _{m}^{G}$ are defined in §§ 2.5 and A.4.

$\lambda _{m}^{G}$ are defined in §§ 2.5 and A.4.

The mass balance for species ![]() $\alpha$ at the bubble wall reads, where

$\alpha$ at the bubble wall reads, where ![]() $\alpha = {Hep}$,

$\alpha = {Hep}$, ![]() $Dod$ or

$Dod$ or ![]() $Air$,

$Air$,

The first term on the right-hand side of (2.21) is the convective mass flux ![]() $\dot {m}''_{\alpha,{conv}} = -\rho _{{m,w}}^{{\gamma }} y_{\alpha,{w}}^{{\gamma }} (u_{w}^{{\gamma }} - \dot {R} )$ of species

$\dot {m}''_{\alpha,{conv}} = -\rho _{{m,w}}^{{\gamma }} y_{\alpha,{w}}^{{\gamma }} (u_{w}^{{\gamma }} - \dot {R} )$ of species ![]() $\alpha$ in the relative frame of reference, which means relative to the moving bubble wall. The second term,

$\alpha$ in the relative frame of reference, which means relative to the moving bubble wall. The second term, ![]() $\dot {m}''_{\alpha,{diff}} =\rho _{{m,w}}^{{\gamma }}D_{{\alpha,w}}^{{\gamma }} ({\partial y_{\alpha }^{{\gamma }}}/{\partial r})|_{w}$, corresponds to diffusion of species

$\dot {m}''_{\alpha,{diff}} =\rho _{{m,w}}^{{\gamma }}D_{{\alpha,w}}^{{\gamma }} ({\partial y_{\alpha }^{{\gamma }}}/{\partial r})|_{w}$, corresponds to diffusion of species ![]() $\alpha$. After inserting (2.8) and (2.13) into (2.21) and rearranging, we obtain the mass balance equations for the gas

$\alpha$. After inserting (2.8) and (2.13) into (2.21) and rearranging, we obtain the mass balance equations for the gas ![]() $(\gamma ={G})$ and liquid

$(\gamma ={G})$ and liquid ![]() $(\gamma ={L})$ side, with

$(\gamma ={L})$ side, with ![]() $\alpha$ and

$\alpha$ and ![]() $\beta$ as

$\beta$ as ![]() $Hep$,

$Hep$, ![]() $Dod$ or

$Dod$ or ![]() $Air$:

$Air$:

\begin{equation} \dot{m}''_{\alpha} ( 1 - y_{{\alpha,w}}^{{\gamma}}) - y_{{\alpha,w}}^{{\gamma}} \sum_{\substack{\beta=1\\ \beta \neq\alpha}}^{N_{S}} \dot{m}''_{{\beta}} = \rho_{{m,w}}^{{\gamma}} D_{{\alpha,w}}^{{\gamma}} {\left. \frac{\partial y_{\alpha}^{{\gamma}}}{\partial r} \right|}_{w}. \end{equation}

\begin{equation} \dot{m}''_{\alpha} ( 1 - y_{{\alpha,w}}^{{\gamma}}) - y_{{\alpha,w}}^{{\gamma}} \sum_{\substack{\beta=1\\ \beta \neq\alpha}}^{N_{S}} \dot{m}''_{{\beta}} = \rho_{{m,w}}^{{\gamma}} D_{{\alpha,w}}^{{\gamma}} {\left. \frac{\partial y_{\alpha}^{{\gamma}}}{\partial r} \right|}_{w}. \end{equation}We assume that Henry's law holds. This means that there is a simple linear relation between the concentration of dissolved air and its partial pressure in the gas phase (Sander Reference Sander2015):

where ![]() $H_{m}$ is the Henry coefficient. We formulate (2.23) for the mass fraction

$H_{m}$ is the Henry coefficient. We formulate (2.23) for the mass fraction ![]() $y^{L}_{{Air,w}}$, which is detailed in § A.3.

$y^{L}_{{Air,w}}$, which is detailed in § A.3.

Together with the ideal gas law (2.4), ![]() $p^{G}=\rho ^{G}_{{m,w}}\mathfrak {R}_{{m,w}}T^{G}_{w}$ and the complement (2.1),

$p^{G}=\rho ^{G}_{{m,w}}\mathfrak {R}_{{m,w}}T^{G}_{w}$ and the complement (2.1), ![]() $\sum _{\alpha =1}^{N_{S}} y_{\alpha,{w}}^{G} = 1$ and

$\sum _{\alpha =1}^{N_{S}} y_{\alpha,{w}}^{G} = 1$ and ![]() $\sum _{\alpha =1}^{N_{S}} y_{\alpha,{w}}^{L} = 1$ a closed boundary equation set for the evaluation of the dependent variables at the bubble wall has been obtained.

$\sum _{\alpha =1}^{N_{S}} y_{\alpha,{w}}^{L} = 1$ a closed boundary equation set for the evaluation of the dependent variables at the bubble wall has been obtained.

2.4. Initial conditions

The bubble is initialized (subscript 0) in mechanical and thermal equilibrium in terms of ![]() $R_0$,

$R_0$, ![]() $T_0^{G}=T_0^{L}=T_0$ and

$T_0^{G}=T_0^{L}=T_0$ and ![]() $p_{\infty,0}^{L}$. The mass fractions

$p_{\infty,0}^{L}$. The mass fractions ![]() $y_{\alpha,0}^{G}$ and

$y_{\alpha,0}^{G}$ and ![]() $y_{\alpha,0}^{L}$ are prescribed homogeneously, according to the phase equilibrium equation (2.19) and Henry's law (2.23), together with (2.1). The initial bubble pressure

$y_{\alpha,0}^{L}$ are prescribed homogeneously, according to the phase equilibrium equation (2.19) and Henry's law (2.23), together with (2.1). The initial bubble pressure ![]() $p_0^{G}$ is evaluated by (2.17) by setting

$p_0^{G}$ is evaluated by (2.17) by setting ![]() $p_{{w,0}}^{L} = p_{{\infty,0}}^{L}$,

$p_{{w,0}}^{L} = p_{{\infty,0}}^{L}$, ![]() $\dot {R} =0$,

$\dot {R} =0$, ![]() $\ddot {R} =0$,

$\ddot {R} =0$, ![]() $\dot {m}_0'' = 0$ and

$\dot {m}_0'' = 0$ and ![]() $\ddot {m}_0'' = 0$. It should be noted that by (2.23),

$\ddot {m}_0'' = 0$. It should be noted that by (2.23), ![]() $y_{{Air,0}}^{L}$ is evaluated by

$y_{{Air,0}}^{L}$ is evaluated by ![]() $p_0^{G}$ and thus depends on

$p_0^{G}$ and thus depends on ![]() $R_0$. This initialization might deviate from real situations where the liquid is usually saturated with air at ambient pressure, and not at bubble pressure, which should be considered when comparisons with experimental data are planned. After initialization, the bubble motion is driven by the temporal evolution of

$R_0$. This initialization might deviate from real situations where the liquid is usually saturated with air at ambient pressure, and not at bubble pressure, which should be considered when comparisons with experimental data are planned. After initialization, the bubble motion is driven by the temporal evolution of ![]() $p_{\infty }^{L}$, which will be specified for the particular test cases in § 4.

$p_{\infty }^{L}$, which will be specified for the particular test cases in § 4.

2.5. Thermophysical properties

For pure fluids, thermophysical properties – e.g. thermal conductivity, heat capacity, latent heat, saturation pressure and diffusion coefficients – depend on temperature and pressure. In fluid mixtures, they depend additionally on the local mixture composition. We present a detailed calculus of properties in § A.4. Here, we discuss briefly their dependence on ![]() $T$ and

$T$ and ![]() $p$.

$p$.

In anticipation of the results presented in § 4, this dependence of properties on ![]() $T$ and

$T$ and ![]() $p$ has been assessed by preliminary simulations. On the one hand, properties have been evaluated with their full

$p$ has been assessed by preliminary simulations. On the one hand, properties have been evaluated with their full ![]() $T$ and

$T$ and ![]() $p$ dependence. On the other hand, properties have been evaluated at a fixed reference state, which we chose to be the initial temperature and pressure. Based on a comparison of both variants, we assess the

$p$ dependence. On the other hand, properties have been evaluated at a fixed reference state, which we chose to be the initial temperature and pressure. Based on a comparison of both variants, we assess the ![]() $T$ and

$T$ and ![]() $p$ dependence of each property. We do not present the details here, but summarize that while the

$p$ dependence of each property. We do not present the details here, but summarize that while the ![]() $T$ dependence of the diffusion coefficients in the gas phase

$T$ dependence of the diffusion coefficients in the gas phase ![]() $D^{G}_{\alpha }$ (see (A22) and (A23)) is insignificant, its pressure dependence affects the results significantly. For example, the mass flux at the bubble interface rises by more than 100 % for a rapid pressure drop when

$D^{G}_{\alpha }$ (see (A22) and (A23)) is insignificant, its pressure dependence affects the results significantly. For example, the mass flux at the bubble interface rises by more than 100 % for a rapid pressure drop when ![]() $D^{G}_{\alpha }$ is evaluated at the initial pressure instead of the instantaneous value of

$D^{G}_{\alpha }$ is evaluated at the initial pressure instead of the instantaneous value of ![]() $p^{G}$. Also, the temperature dependence of vapour saturation pressure

$p^{G}$. Also, the temperature dependence of vapour saturation pressure ![]() $p^{Sat}_{m}$ (A27) is important, albeit to a lesser extent. The

$p^{Sat}_{m}$ (A27) is important, albeit to a lesser extent. The ![]() $T$ and

$T$ and ![]() $p$ dependence of all other properties can be neglected. Of course, this assessment of property impact is not general but certainly confined to the particular test cases under consideration. A more in-depth analysis is considered out of scope here. For convenience, all results presented in § 4 have been obtained with full

$p$ dependence of all other properties can be neglected. Of course, this assessment of property impact is not general but certainly confined to the particular test cases under consideration. A more in-depth analysis is considered out of scope here. For convenience, all results presented in § 4 have been obtained with full ![]() $T$ and

$T$ and ![]() $p$ dependence of properties, and details of their evaluation are provided in § A.4.

$p$ dependence of properties, and details of their evaluation are provided in § A.4.

Moreover, we consider the dependence of thermophysical properties on local mixture composition as crucial for alkane mixtures. While in this study we accept the uncertainties on mixture composition that have been introduced by the simple Raoult's law as discussed above, we introduce an even more crude simplification by comparison with a pseudo-fuel whose components cannot segregate. For the pseudo-fuel, properties are evaluated at a reference mixture state in terms of the initial mixture composition. Details of this simplified mathematical model are presented in § 2.6.2.

2.6. Variants of the mathematical model

2.6.1. Discrete fuel model (full model)

In the model presented so far, the full transport processes have been considered. A discrete mixture of heptane and dodecane has been described by different mass fractions ![]() $y_{Hep}^{\gamma }$ and

$y_{Hep}^{\gamma }$ and ![]() $y_{Dod}^{\gamma }$ for both the liquid (

$y_{Dod}^{\gamma }$ for both the liquid (![]() $\gamma ={L}$) and gas (

$\gamma ={L}$) and gas (![]() $\gamma ={G}$) phases. By solving mass fraction equations for each alkane in terms of (2.3), the transport of each individual species is considered so that interdiffusion of both alkanes is enabled, and the fuel may segregate locally. This segregation-prone two-component heptane/dodecane fuel is termed discrete fuel in the following. In the next subsubsection, we introduce a simplification to the discrete fuel model by lumping the fuel species together into one single-component pseudo-fuel.

$\gamma ={G}$) phases. By solving mass fraction equations for each alkane in terms of (2.3), the transport of each individual species is considered so that interdiffusion of both alkanes is enabled, and the fuel may segregate locally. This segregation-prone two-component heptane/dodecane fuel is termed discrete fuel in the following. In the next subsubsection, we introduce a simplification to the discrete fuel model by lumping the fuel species together into one single-component pseudo-fuel.

2.6.2. Pseudo-fuel model (simplified model)

It is interesting to see how bubble dynamics changes when we define a bulk fuel with an invariant mixture composition. In a simplified version of the discrete fuel model, a single-component fuel is introduced with a fuel mass fraction ![]() $y_{Fuel}^{\gamma }$. This is initialized by

$y_{Fuel}^{\gamma }$. This is initialized by ![]() $y_{{Fuel,0}}^{\gamma } = y_{{Hep,0}}^{\gamma } + y_{{Dod,0}}^{\gamma }$, in which

$y_{{Fuel,0}}^{\gamma } = y_{{Hep,0}}^{\gamma } + y_{{Dod,0}}^{\gamma }$, in which ![]() $y_{{Hep,0}}^{\gamma }$ and

$y_{{Hep,0}}^{\gamma }$ and ![]() $y_{{Dod,0}}^{\gamma }$ correspond to the initial mixture composition of heptane and dodecane. This surrogate single-component fuel is termed pseudo-fuel in the following. Per definition, the pseudo-fuel has the same initial composition as the discrete counterpart, but interdiffusion of the alkanes is disabled, and the mixture cannot segregate, which means that its composition is invariable for both the gaseous in-bubble (

$y_{{Dod,0}}^{\gamma }$ correspond to the initial mixture composition of heptane and dodecane. This surrogate single-component fuel is termed pseudo-fuel in the following. Per definition, the pseudo-fuel has the same initial composition as the discrete counterpart, but interdiffusion of the alkanes is disabled, and the mixture cannot segregate, which means that its composition is invariable for both the gaseous in-bubble (![]() $\gamma ={G}$) and the surrounding liquid (

$\gamma ={G}$) and the surrounding liquid (![]() $\gamma ={L}$) phases. For the pseudo-fuel, all mixing rules for the property evaluation specified in § A.4 hold, but in contrast to the discrete fuel, they are evaluated by the invariable, initial mixture state of the pseudo-fuel. It is important to note that as in the liquid phase, also the invariable gaseous phase of the pseudo-fuel model corresponds to the initial composition of the discrete counterpart. Thus the initial bubble content in terms of the fuel/air mixture ratio is the same for both discrete fuel and pseudo-fuel mixtures. The governing equations hardly change compared to the discrete fuel model, with one exception: for the discrete fuel, mass fraction equations (2.3) are solved for each discrete species, i.e.

$\gamma ={L}$) phases. For the pseudo-fuel, all mixing rules for the property evaluation specified in § A.4 hold, but in contrast to the discrete fuel, they are evaluated by the invariable, initial mixture state of the pseudo-fuel. It is important to note that as in the liquid phase, also the invariable gaseous phase of the pseudo-fuel model corresponds to the initial composition of the discrete counterpart. Thus the initial bubble content in terms of the fuel/air mixture ratio is the same for both discrete fuel and pseudo-fuel mixtures. The governing equations hardly change compared to the discrete fuel model, with one exception: for the discrete fuel, mass fraction equations (2.3) are solved for each discrete species, i.e. ![]() $y_{Hep}^{\gamma }$,

$y_{Hep}^{\gamma }$, ![]() $y_{Dod}^{\gamma }$ and

$y_{Dod}^{\gamma }$ and ![]() $y_{Air}^{\gamma }$. For the pseudo-fuel, only one fuel species exists, so the solution of (2.3) is restricted to

$y_{Air}^{\gamma }$. For the pseudo-fuel, only one fuel species exists, so the solution of (2.3) is restricted to ![]() $y_{Fuel}^{\gamma }$ and

$y_{Fuel}^{\gamma }$ and ![]() $y_{Air}^{\gamma }$.

$y_{Air}^{\gamma }$.

2.7. Note on mass conservation and species complement

In case of only two species (![]() $N_{S}=2$), (2.1) and (2.2) are fulfilled readily when we solve (2.3) for both species, assuming equality of binary diffusion coefficients

$N_{S}=2$), (2.1) and (2.2) are fulfilled readily when we solve (2.3) for both species, assuming equality of binary diffusion coefficients ![]() $D^{\gamma }_{\alpha }$. In fact, by summing (2.3), we obtain (2.2). We encounter a two-species system – e.g. for pure heptane or pure dodecane with air – and this is also the case for the single-component pseudo-fuel (introduced in the preceding subsection) with air. In the case of discrete heptane/dodecane mixtures with air, however, we face a three-species system (

$D^{\gamma }_{\alpha }$. In fact, by summing (2.3), we obtain (2.2). We encounter a two-species system – e.g. for pure heptane or pure dodecane with air – and this is also the case for the single-component pseudo-fuel (introduced in the preceding subsection) with air. In the case of discrete heptane/dodecane mixtures with air, however, we face a three-species system (![]() $N_{S}=3$). The diffusion coefficients

$N_{S}=3$). The diffusion coefficients ![]() $D_{\alpha }^{L}$ (see (A17)) and

$D_{\alpha }^{L}$ (see (A17)) and ![]() $D_{\alpha }^{G}$ (see (A22)) correspond to equivalent diffusion of species

$D_{\alpha }^{G}$ (see (A22)) correspond to equivalent diffusion of species ![]() $\alpha$ into the rest of the mixture (Hirschfelder, Curtiss & Byrd Reference Hirschfelder, Curtiss and Byrd1969). Thus generally, summing (2.3) may not result in (2.2), and mass conservation may not be fulfilled. Furthermore, solving (2.3) for all three species may violate the species complement (2.1). In preliminary simulations, we have tested different means to enforce both mass conservation and species complement, and how we calculate mixture density

$\alpha$ into the rest of the mixture (Hirschfelder, Curtiss & Byrd Reference Hirschfelder, Curtiss and Byrd1969). Thus generally, summing (2.3) may not result in (2.2), and mass conservation may not be fulfilled. Furthermore, solving (2.3) for all three species may violate the species complement (2.1). In preliminary simulations, we have tested different means to enforce both mass conservation and species complement, and how we calculate mixture density ![]() $\rho ^{\gamma }_{m}$ and mass fraction

$\rho ^{\gamma }_{m}$ and mass fraction ![]() $y^{\gamma }_{\alpha }$ of species

$y^{\gamma }_{\alpha }$ of species ![]() $\alpha$. Details are provided in § 2 of the supplementary material. Here, we summarize that exact fulfilment of mass conservation by (2.2) has little effect on the results. This means that regardless how we calculate

$\alpha$. Details are provided in § 2 of the supplementary material. Here, we summarize that exact fulfilment of mass conservation by (2.2) has little effect on the results. This means that regardless how we calculate ![]() $\rho ^{\gamma }_{m}$, the effect on the results in § 4 is insignificant. Therefore, gas mixture density

$\rho ^{\gamma }_{m}$, the effect on the results in § 4 is insignificant. Therefore, gas mixture density ![]() $\rho ^{G}_{m}$ is evaluated by the ideal gas law (2.4). Liquid mixture density

$\rho ^{G}_{m}$ is evaluated by the ideal gas law (2.4). Liquid mixture density ![]() $\rho ^{L}_{m}$ is also evaluated by an equation of state in terms of (A8). We have verified that by this procedure, (2.2) is fulfilled approximately. We solve (2.3) for only two of three species and ensure species complement by solving (2.1) for the remaining species.

$\rho ^{L}_{m}$ is also evaluated by an equation of state in terms of (A8). We have verified that by this procedure, (2.2) is fulfilled approximately. We solve (2.3) for only two of three species and ensure species complement by solving (2.1) for the remaining species.

3. Simulation method

The governing equations constitute a coupled nonlinear set of partial differential equations. The numerical scheme and the solution procedure have been presented in detail by Bermudez-Graterol et al. (Reference Bermudez-Graterol, Nickaeen and Skoda2021) for a water–air system. Their extension to alkane mixtures is straightforward, so the simulation method is summarized only briefly here.

The bubble interior and its surrounding liquid are discretized in the radial direction by computational nodes with a grid clustering at the bubble wall to resolve the gradients. In preliminary simulations, an extent of the liquid domain that corresponds to ![]() $r/R=5$ has been found to be adequate for each test case considered. Computational cells are constructed between nodes. A staggered variable arrangement is employed, which means that the velocity is stored at node locations, and all other variables are stored at cell centre locations. Ghost cells are introduced to store the boundary values at the bubble centre, at the bubble interface and in the liquid far field. The bubble wall moves with the velocity

$r/R=5$ has been found to be adequate for each test case considered. Computational cells are constructed between nodes. A staggered variable arrangement is employed, which means that the velocity is stored at node locations, and all other variables are stored at cell centre locations. Ghost cells are introduced to store the boundary values at the bubble centre, at the bubble interface and in the liquid far field. The bubble wall moves with the velocity ![]() $\dot {R}$, and the governing equations are solved by an arbitrary Lagrangian–Eulerian (ALE) method according to e.g. Hirt, Amsden & Cook (Reference Hirt, Amsden and Cook1997), on a grid that moves with the bubble wall.

$\dot {R}$, and the governing equations are solved by an arbitrary Lagrangian–Eulerian (ALE) method according to e.g. Hirt, Amsden & Cook (Reference Hirt, Amsden and Cook1997), on a grid that moves with the bubble wall.

The mass fraction equations are solved in their conservative form by a finite volume discretization and a central scheme, which means a linear interpolation of cell centre values to node locations. For the other equations, a finite difference scheme is used, where the spatial derivatives are approximated by central differences. All integration operations, e.g. in (2.5)–(2.7), are performed by the midpoint rule. By this combined central finite volume/finite difference scheme, we have obtained a simple and robust second-order-accurate scheme. An evaluation of the magnitude of the Péclet number ![]() $Pe^{num}$ has been performed, since large values of

$Pe^{num}$ has been performed, since large values of ![]() $Pe^{num}$ may promote artificial wiggles in the numerical solution. For any simulation result presented in § 4,

$Pe^{num}$ may promote artificial wiggles in the numerical solution. For any simulation result presented in § 4, ![]() $Pe^{num}$ amounts to less than

$Pe^{num}$ amounts to less than ![]() $0.01$ at any location within the bubble and at any time instant. Regarding the liquid side,

$0.01$ at any location within the bubble and at any time instant. Regarding the liquid side, ![]() $Pe^{num}$ is even significantly smaller close to the bubble wall due to a very fine grid, but may grow up to about

$Pe^{num}$ is even significantly smaller close to the bubble wall due to a very fine grid, but may grow up to about ![]() $10^2$ towards the liquid far field for some cases and time instants. In spite of this rather large value, a careful inspection of the numerical solution field did not reveal any wiggles, since far away from the bubble wall, gradients of any flow variable vanish and the solution is homogeneous.

$10^2$ towards the liquid far field for some cases and time instants. In spite of this rather large value, a careful inspection of the numerical solution field did not reveal any wiggles, since far away from the bubble wall, gradients of any flow variable vanish and the solution is homogeneous.

Time integration is performed by an implicit Crank–Nicolson scheme (Crank & Nicolson Reference Crank and Nicolson1996). Time steps correspond to a maximum Courant–Friedrichs–Lewy (CFL) number of about ![]() $100$, and convergence within each time step is achieved when the dimensionless residuals of each equation have dropped below

$100$, and convergence within each time step is achieved when the dimensionless residuals of each equation have dropped below ![]() $1 \times 10^{-8}$.

$1 \times 10^{-8}$.

At the bubble wall, ![]() $12$ unknown boundary quantities in terms

$12$ unknown boundary quantities in terms ![]() $T_{w}^{G}$,

$T_{w}^{G}$, ![]() $T_{w}^{L}$,

$T_{w}^{L}$, ![]() $y_{\alpha,{w}}^{L}$,

$y_{\alpha,{w}}^{L}$, ![]() $y_{\alpha,{w}}^{G}$,

$y_{\alpha,{w}}^{G}$, ![]() $\dot {m}_{\alpha }''$ and

$\dot {m}_{\alpha }''$ and ![]() $\rho _{{m,w}}^{G}$ need to be evaluated, with

$\rho _{{m,w}}^{G}$ need to be evaluated, with ![]() $\alpha = {Hep}$,

$\alpha = {Hep}$, ![]() $Dod$ or

$Dod$ or ![]() $Air$. Heat balance (2.20), mass balance (2.22), Henry's law (A7) and the ideal gas law (2.4), together with (2.18) and (A6), are solved. These

$Air$. Heat balance (2.20), mass balance (2.22), Henry's law (A7) and the ideal gas law (2.4), together with (2.18) and (A6), are solved. These ![]() $12$ equations constitute a closed nonlinear equation set that is solved by a Newton method.

$12$ equations constitute a closed nonlinear equation set that is solved by a Newton method.

The computer program sibub (![]() $=$ single bubble dynamics) is coded by Fortran 90 and run on a conventional Linux workstation. Program sibub has been validated thoroughly for water in our preceding study (Bermudez-Graterol et al. Reference Bermudez-Graterol, Nickaeen and Skoda2021), which is particularly important since no measurement data on bubble dynamics in binary alkane mixtures are available.

$=$ single bubble dynamics) is coded by Fortran 90 and run on a conventional Linux workstation. Program sibub has been validated thoroughly for water in our preceding study (Bermudez-Graterol et al. Reference Bermudez-Graterol, Nickaeen and Skoda2021), which is particularly important since no measurement data on bubble dynamics in binary alkane mixtures are available.

4. Results

4.1. Bubble oscillation after a rapid pressure drop

4.1.1. Case description

A bubble with ![]() $R_0 = 100$

$R_0 = 100$ ![]() $\mathrm {\mu }\mathrm {m}$ at

$\mathrm {\mu }\mathrm {m}$ at ![]() $T_0 = 293.15 \ \mathrm {K}$ is initialized in a liquid fuel mixture with mass fraction ratio

$T_0 = 293.15 \ \mathrm {K}$ is initialized in a liquid fuel mixture with mass fraction ratio ![]() $25 \, \%$ heptane and

$25 \, \%$ heptane and ![]() $75 \, \%$ dodecane, referred to as a

$75 \, \%$ dodecane, referred to as a ![]() $25/75 \, \%$ mixture in what follows. It is important to note that this mixture ratio refers to the liquid fuel mixture outside the bubble, while the mixture ratio of the gaseous phase within the bubble results from the equilibrium initialization. Details on the fuel mixture initialization are provided in § 3 of the supplementary material. The bubble is exposed to a rapid pressure drop from

$25/75 \, \%$ mixture in what follows. It is important to note that this mixture ratio refers to the liquid fuel mixture outside the bubble, while the mixture ratio of the gaseous phase within the bubble results from the equilibrium initialization. Details on the fuel mixture initialization are provided in § 3 of the supplementary material. The bubble is exposed to a rapid pressure drop from ![]() $p_{\infty }^{L} = 10^5$ to

$p_{\infty }^{L} = 10^5$ to ![]() $10^4$ Pa within 100

$10^4$ Pa within 100 ![]() $\mathrm {\mu }$s, which corresponds to a drop rate of

$\mathrm {\mu }$s, which corresponds to a drop rate of ![]() $\mathrm {d}p_{\infty }^{L}/\mathrm {d}t = 9 \times 10^8$ Pa s

$\mathrm {d}p_{\infty }^{L}/\mathrm {d}t = 9 \times 10^8$ Pa s![]() $^{-1}$. The final pressure level is well above the saturation pressure of any mixture component, so no excessive growth by phase change occurs, but the bubble is rather excited to oscillate. A computational grid with

$^{-1}$. The final pressure level is well above the saturation pressure of any mixture component, so no excessive growth by phase change occurs, but the bubble is rather excited to oscillate. A computational grid with ![]() $n^{G} = 200$ and

$n^{G} = 200$ and ![]() $n^{L} = 800$ nodes within and outside the bubble, respectively, with a strong node clustering at the bubble wall, is used, which has been ensured to yield grid-independent results in preliminary simulation runs.

$n^{L} = 800$ nodes within and outside the bubble, respectively, with a strong node clustering at the bubble wall, is used, which has been ensured to yield grid-independent results in preliminary simulation runs.

For an oscillating gas bubble, Prosperetti (Reference Prosperetti1991) used the ratio of the thermal penetration length to the initial bubble radius to assess the effect of heat transfer on bubble motion. This ratio corresponds to the inverse Péclet number ![]() $Pe^{G}$ (not to be confused with

$Pe^{G}$ (not to be confused with ![]() $Pe^{num}$ in § 3, which characterizes the ratio of convective to diffusive flux in a numerical scheme). Here,

$Pe^{num}$ in § 3, which characterizes the ratio of convective to diffusive flux in a numerical scheme). Here, ![]() $Pe^{G}$ is equivalent to the ratio of thermal diffusion time scale to bubble motion, i.e. dynamic time scale. For small values of

$Pe^{G}$ is equivalent to the ratio of thermal diffusion time scale to bubble motion, i.e. dynamic time scale. For small values of ![]() $Pe^{G}$, the bubble temperature variation is insignificant, while for large values, most of the gas in the bubble is thermally insulated from the liquid. Fuster & Montel (Reference Fuster and Montel2015) and Bergamasco & Fuster (Reference Bergamasco and Fuster2017) analysed the influence of mass transfer on the dynamic response of oscillating bubbles. We adopt their evaluation of dynamic and thermal diffusion time scale in terms of

$Pe^{G}$, the bubble temperature variation is insignificant, while for large values, most of the gas in the bubble is thermally insulated from the liquid. Fuster & Montel (Reference Fuster and Montel2015) and Bergamasco & Fuster (Reference Bergamasco and Fuster2017) analysed the influence of mass transfer on the dynamic response of oscillating bubbles. We adopt their evaluation of dynamic and thermal diffusion time scale in terms of ![]() $t_{dyn}=1/f$ and

$t_{dyn}=1/f$ and ![]() $t_{diff}=R_0^2/D^{G}_{T}$, with thermal diffusivity

$t_{diff}=R_0^2/D^{G}_{T}$, with thermal diffusivity ![]() $D^{G}_{T} = \lambda ^{G}_{m}/( \rho ^{G}_{m} c^{G}_{p,{m}} )$. In the studies by Prosperetti (Reference Prosperetti1991), Fuster & Montel (Reference Fuster and Montel2015) and Bergamasco & Fuster (Reference Bergamasco and Fuster2017), bubble oscillation due to an enforcing sinusoidal pressure wave with an angular frequency

$D^{G}_{T} = \lambda ^{G}_{m}/( \rho ^{G}_{m} c^{G}_{p,{m}} )$. In the studies by Prosperetti (Reference Prosperetti1991), Fuster & Montel (Reference Fuster and Montel2015) and Bergamasco & Fuster (Reference Bergamasco and Fuster2017), bubble oscillation due to an enforcing sinusoidal pressure wave with an angular frequency ![]() $\omega$ has been investigated. Since we excite our bubble with a one-time pressure drop, the frequency

$\omega$ has been investigated. Since we excite our bubble with a one-time pressure drop, the frequency ![]() $f$ is evaluated simply by the bubble response frequency. We obtain

$f$ is evaluated simply by the bubble response frequency. We obtain ![]() $Pe^{G}=2$, so according to Bergamasco & Fuster (Reference Bergamasco and Fuster2017), thermal effects will be relevant. When we evaluate

$Pe^{G}=2$, so according to Bergamasco & Fuster (Reference Bergamasco and Fuster2017), thermal effects will be relevant. When we evaluate ![]() $Pe^{G}$ with the mass diffusion coefficient

$Pe^{G}$ with the mass diffusion coefficient ![]() $D_{\alpha }^{G}$ according to (A22), instead of the thermal diffusivity

$D_{\alpha }^{G}$ according to (A22), instead of the thermal diffusivity ![]() $D^{G}_{T}$, and average over all three species and over time, we obtain

$D^{G}_{T}$, and average over all three species and over time, we obtain ![]() $Pe^{G}=0.6$, which is of the same order of magnitude.

$Pe^{G}=0.6$, which is of the same order of magnitude.

4.1.2. Discrete fuel model results

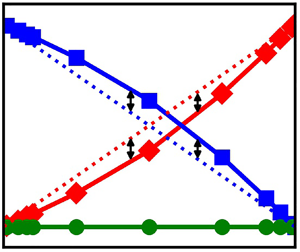

In figure 1(a), the initial phase of the bubble radius oscillation is depicted. The time is related to the thermal diffusion time scale in terms of ![]() $t^* = t/t_{diff}$, where

$t^* = t/t_{diff}$, where ![]() $t_{diff} = 5 \times 10^{-4} \ \mathrm {s}$ for the discrete fuel mixture. As reference, bubbles in pure heptane, pure dodecane and water are considered. Water properties are adopted from Bermudez-Graterol et al. (Reference Bermudez-Graterol, Nickaeen and Skoda2021), and the time axis of any fluid is scaled with the same value

$t_{diff} = 5 \times 10^{-4} \ \mathrm {s}$ for the discrete fuel mixture. As reference, bubbles in pure heptane, pure dodecane and water are considered. Water properties are adopted from Bermudez-Graterol et al. (Reference Bermudez-Graterol, Nickaeen and Skoda2021), and the time axis of any fluid is scaled with the same value ![]() $t_{diff} = 5 \times 10^{-4} \ \mathrm {s}$ for convenience. The oscillation is damped by thermal effects, while viscous damping essentially plays no role. The damping effect is most pronounced for pure heptane, which is traced back to a strong initial liquid temperature drop close to the bubble wall, illustrated in figure 1(b). Bubble oscillation is affected by alternating heat and mass flux over the bubble wall. Similar to what was observed for rectified diffusion processes (Hsieh & Plesset Reference Hsieh and Plesset1961; Crum Reference Crum1984), a net heat and mass flux into the bubble arises. While the initial content of any bubble is dominated by air, evaporation changes the bubble content. This is most pronounced for the heptane bubble due to high volatility of heptane, so that its net vapour mass flux is largest. At

$t_{diff} = 5 \times 10^{-4} \ \mathrm {s}$ for convenience. The oscillation is damped by thermal effects, while viscous damping essentially plays no role. The damping effect is most pronounced for pure heptane, which is traced back to a strong initial liquid temperature drop close to the bubble wall, illustrated in figure 1(b). Bubble oscillation is affected by alternating heat and mass flux over the bubble wall. Similar to what was observed for rectified diffusion processes (Hsieh & Plesset Reference Hsieh and Plesset1961; Crum Reference Crum1984), a net heat and mass flux into the bubble arises. While the initial content of any bubble is dominated by air, evaporation changes the bubble content. This is most pronounced for the heptane bubble due to high volatility of heptane, so that its net vapour mass flux is largest. At ![]() $t^* = 2$, the heptane bubble contains most vapour, and its final radius is thus greater than that of the others.

$t^* = 2$, the heptane bubble contains most vapour, and its final radius is thus greater than that of the others.

Figure 1. Temporal progression of (a) bubble radius and (b) wall temperature, for different fluids. The 25/75 % heptane/dodecane mixture corresponds to the discrete model according to § 2.6.1.

The discrete 25/75 % mixture corresponds to a two-component fuel that is prone to segregation. A more thorough look at the 25/75 % mixture reveals that mass transfer of the different species through the bubble wall is considerably different. According to figure 2(a), the entire mass flow is dominated by ![]() $\dot {m}_{Hep}$, while

$\dot {m}_{Hep}$, while ![]() $\dot {m}_{Dod}$ and

$\dot {m}_{Dod}$ and ![]() $\dot {m}_{Air}$ are approximately two orders of magnitude lower – note the augmented illustration of

$\dot {m}_{Air}$ are approximately two orders of magnitude lower – note the augmented illustration of ![]() $\dot {m}_{Dod}$ and

$\dot {m}_{Dod}$ and ![]() $\dot {m}_{Air}$ by a factor of 50 in figure 2(a). The small mass flow of air illustrates that air release is a relatively slow process, compared to fuel component transfer by evaporation. The small dodecane mass flow comes along with its small content within the bubble: in figure 2(b), the mass fraction at the gaseous side of the bubble wall

$\dot {m}_{Air}$ by a factor of 50 in figure 2(a). The small mass flow of air illustrates that air release is a relatively slow process, compared to fuel component transfer by evaporation. The small dodecane mass flow comes along with its small content within the bubble: in figure 2(b), the mass fraction at the gaseous side of the bubble wall ![]() $y_{{\alpha,w}}^{G}$ is presented, where

$y_{{\alpha,w}}^{G}$ is presented, where ![]() $\alpha = {Hep}$,

$\alpha = {Hep}$, ![]() $Dod$ or

$Dod$ or ![]() $Air$. Heptane and air are present predominantly within the bubble, while dodecane represents only a minor species – note again the augmented illustration of

$Air$. Heptane and air are present predominantly within the bubble, while dodecane represents only a minor species – note again the augmented illustration of ![]() $y_{{Dod,w}}^{G}$. The low amount of dodecane at the inner bubble wall is associated with its low volatility in terms of low vapour saturation pressure