1 Introduction

Polymer blending is used to obtain tailored combinations of properties (Favis, Reference Favis1991; Macosko, Reference Macosko2000; Nofar et al., Reference Nofar, Sacligil, Carreau, Kamal and Heuzey2019b). The morphological characteristics of a binary polymer blend are determined by thermodynamics, processing conditions, type of dispersed phase, and viscoelastic behavior of the polymers under melt blending conditions (Favis & Chalifoux, Reference Favis and Chalifoux1987; Favis & Therrien, Reference Favis and Therrien1991; Nofar et al., Reference Nofar, Heuzey, Carreau, Kamal and Randall2016; Reference Nofar, Tabatabaei, Sojoudiasli, Park, Carreau, Heuzey and Kamal2017; Reference Nofar, Oguz and Ovali2019a; Reference Nofar, Sacligil, Carreau, Kamal and Heuzey2019b; Scott & Macosko, Reference Scott and Macosko1991; Souza & Demarquette, Reference Souza and Demarquette2002; Sundararaj et al., Reference Sundararaj, Macosko, Nakayama and Inoue1995). Blend nanocomposites are systems that exhibit variety of microstructures (Dil & Favis, Reference Dil and Favis2015; Maani & Carreau, Reference Maani and Carreau2016; Nofar et al., Reference Nofar, Heuzey, Carreau and Kamaln.d.). The interfacial interactions, rheological properties and the processing conditions determine the localization of the nanoparticles and influence the final properties (Maani & Carreau, Reference Maani and Carreau2016; Nofar et al., Reference Nofar, Sacligil, Carreau, Kamal and Heuzey2019b; Reference Nofar, Heuzey, Carreau and Kamaln.d.; Sumita et al., Reference Sumita, Sakata, Asai, Miyasaka and Nakagawa1991).

Blending with other flexible biopolymers and the incorporation of nanoparticles has been shown to be a promising approach to overcome several drawbacks of polylactide (PLA) (Keshtkar et al., Reference Keshtkar, Nofar, Park and Carreau2014; Nofar, Reference Nofar2016; Reference Nofar2018; Nofar & Park, Reference Nofar and Park2014; Reference Nofar, Park, Iannace and Park2015; Reference Nofar and Park2017; Nofar et al., Reference Nofar, Tabatabaei and Park2013; Reference Nofar, Sacligil, Carreau, Kamal and Heuzey2019b; Raquez et al., Reference Raquez, Habibi, Murariu and Dubois2013). Few researchers have studied the processing-morphology-property relationships in nanocomposites based on PLA/poly[(butylene adipate)-co-terephthalate] (PBAT) blends (Dil & Favis, Reference Dil and Favis2015; Dil et al., Reference Dil, Virgilio and Favis2016; Jiang et al., Reference Jiang, Liu and Zhang2009; Ko et al., Reference Ko, Hong, Park, Gupta, Choi and Bhattacharya2009; Kumar et al., Reference Kumar, Mohanty, Nayak and Parvaiz2010; Li et al., Reference Li, Cui, Sun, Turng and Huang2011; Nofar et al., Reference Nofar, Sacligil, Carreau, Kamal and Heuzey2019b; Reference Nofar, Heuzey, Carreau and Kamaln.d.; Shi et al., Reference Shi, Zhang, Liu, Ma, Jing and Fan2016). Jiang et al. (Reference Jiang, Liu and Zhang2009) showed when using a twin-screw extruder, the montmorillonite clay was dispersed throughout the whole blend. Kumar et al. (Reference Kumar, Mohanty, Nayak and Parvaiz2010) reported a similar localization for Cloisite 20A. Nofar et al. (Reference Nofar, Heuzey, Carreau and Kamaln.d.) showed that the Cloisite 30B nanoclay was localized at the interface between PLA and PBAT phases and acted as a barrier to droplet coalescence. In all of these studies, the rheological properties are critical parameters in determining the blend morphology and nanoparticle localization (Nofar et al., Reference Nofar, Sacligil, Carreau, Kamal and Heuzey2019b; Reference Nofar, Salehiyan and Ray2019c). In this study, in complement to the results of Nofar et al. (Reference Nofar, Heuzey, Carreau and Kamaln.d.), we present additional SAOS and weighted relaxation spectra data to analyze the nanoparticle interactions with the blend components and the effect of pre-shearing. Investigating the effect of shearing is important since during the melt processing, the applied shear flow could influence the morphology and the properties of a system.

2 Experimental

2–1- Materials and Sample Preparation

A commercial amorphous linear PLA, Ingeo 4060D, PBAT, Ecoflex® F Blend C1200, (Dil et al., Reference Dil, Carreau and Favis2015) and organo-modified nanoclay Cloisite 30B (C30B) were used in this study (Krikorian & Pochan, Reference Krikorian and Pochan2003). The weight-average molecular weight of these PLA and PBAT samples were 180 and 126 kg/mol, respectively. The PBAT possessed around 15% of crystallinity.

Blend nanocomposites were prepared containing 25 wt% PBAT and 1 or 5 wt% C30B based on the total weight. The compounding was conducted using an internal batch mixer, DDRV501 Brabender at 100 rpm and 160 °C for 12 min. Three different strategies were employed for preparing the nanocomposites which are reported in (Nofar et al., Reference Nofar, Heuzey, Carreau and Kamaln.d.) and are referred to as S1, S2, and S3. Disk shape rheological specimens were pressed at 160 °C.

2–2- Rheological Measurements

Rheological measurements were conducted at 160 °C under a nitrogen atmosphere using an Anton Paar MCR-301 rotational rheometer. The thermal stability and the viscoelastic properties of the neat polymers and their blend nanocomposites were examined using time and frequency sweep tests. Stress-growth experiments were carried out at a shear rate of 0.01 s−1. This low shear rate was selected to investigate droplet coalescence in the blends in absence of break up (Nofar et al., Reference Nofar, Maani, Sojoudi, Heuzey and Carreau2015). In order to investigate the effect of morphological changes during shearing on the rheological behavior of the blends, SAOS tests were also performed after stress growth and relaxation of the samples.

3 Results and Discussion

3–1- Thermal Stability

Figure 1 reports the viscosity variations with time of the neat PLA, PLA-PBAT blend and the PLA-PBAT blend nanocomposites containing 1 and 5 wt% C30B. It was depicted that C30B expedited the degradation of PLA (Najafi et al., Reference Najafi, Heuzey, Carreau and Wood-Adams2012; Nofar et al., Reference Nofar, Heuzey, Carreau and Kamaln.d.). As Figure 1 shows, after 910 s the PLA viscosity decreases by about 10%, whereas for the PLA-PBAT blend, the 10% viscosity drop is reached after only 500 s due to the additional effect of PBAT droplet coalescence. In blend nanocomposites with 1 wt% C30B, the 10% viscosity drop occurs after 1,080, 1,010, and 1,180 s in samples prepared through S1, S2, and S3, respectively. As shown in morphological analysis from our previous study (Nofar et al., Reference Nofar, Heuzey, Carreau and Kamaln.d.), the localization of clay at the interface eliminates or seriously reduces the droplet coalescence. Further, the viscosity reduction is more important in the order of S2 > S1 > S3. This is more obvious in the blend nanocomposites containing 5 wt% clay prepared through S1, S2, and S3, as the 10% viscosity drop occurs after 1,130, 930, and 2,230 s, respectively. Obviously, the stability is significantly better for S3 than for the other two samples. This is because the PLA degradation in the presence of nanoclay was minimized as the clay was initially mixed with PBAT and subsequently migrated to the interface (Nofar et al., Reference Nofar, Heuzey, Carreau and Kamaln.d.).

Figure 1. Complex viscosity as a function of time at 160 °C

3–2- Rheological Behavior of PLA/PBAT/C30B Systems Before and After Shearing

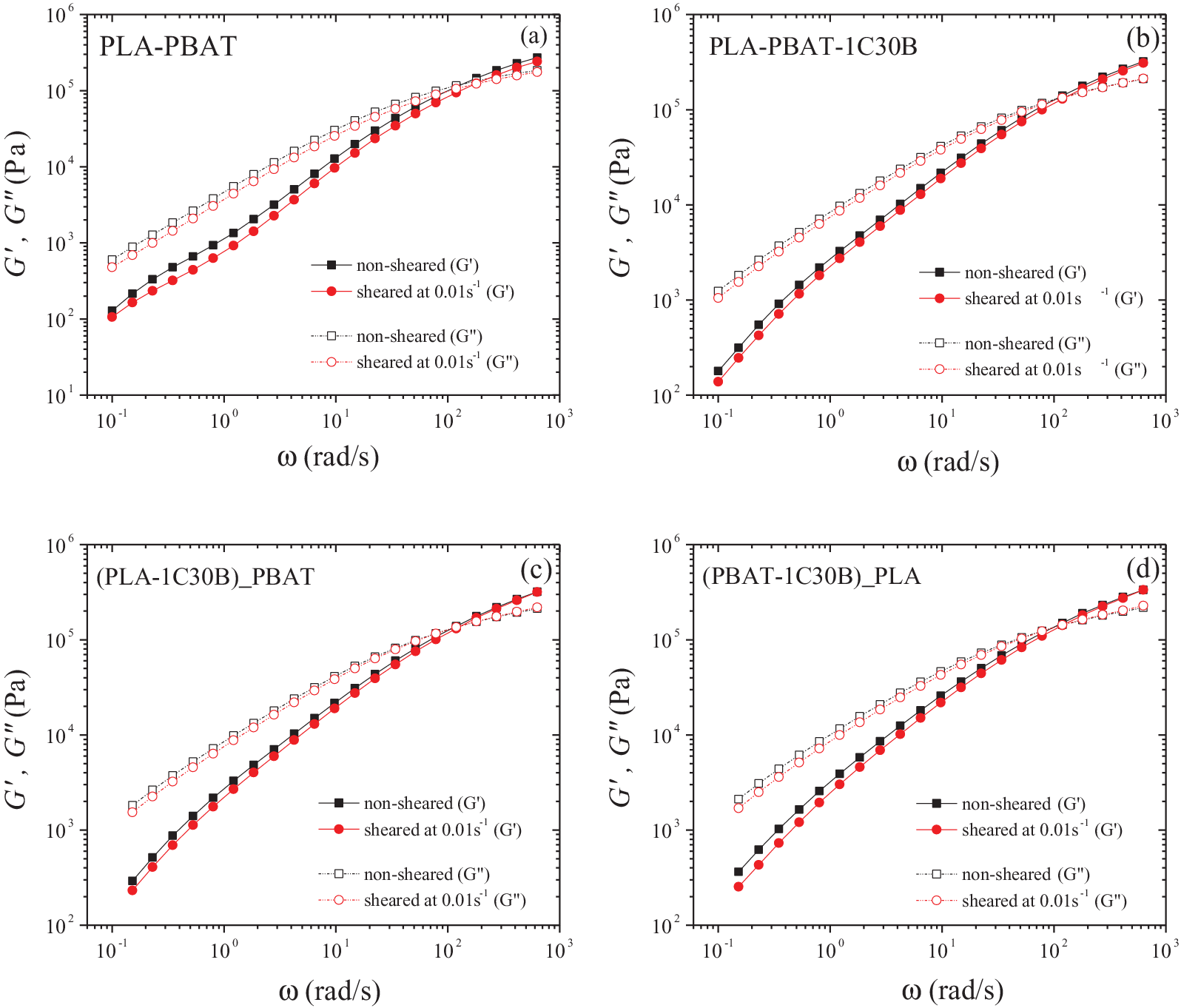

Figures 2a-d present the G’ and G” data of the PLA-PBAT blend and its corresponding nanocomposites with 1 wt% clay before and after shearing at 0.01 s−1. These figures show that both moduli are significantly reduced by shearing mainly due to coalescence as demonstrated in our previous publication (Nofar et al., Reference Nofar, Heuzey, Carreau and Kamaln.d.). The inverse of the G’ and G” crossover frequency at high frequencies is a characteristic relaxation time of the PLA chains in all systems. For PLA-PBAT blend, it is 0.0073 s in the non-sheared sample that reduces to 0.0059 s in sheared sample at 0.01 s−1. This shortened relaxation time can be attributed to the PLA molecular degradation. According to Figures 2b-d, the addition of 1 wt% clay does not affect significantly the molecular relaxation time. Compared to 0.0073 s for the neat blend, the characteristic time is about 0.010 s for all blend nanocomposites independently of the preparation method and shearing. This slight increase is most likely due to the hindering effect of the nanoclay located partly in the matrix (Nofar et al., Reference Nofar, Heuzey, Carreau and Kamaln.d.). The corresponding complex viscosity results and the related discussions are provided in the previous study (Nofar et al., Reference Nofar, Heuzey, Carreau and Kamaln.d.).

Figure 2. Moduli of non-sheared/sheared (a) PLA-PBAT and (b-d) nanocomposites prepared via (b) S1, (c) S2, (d) S3.

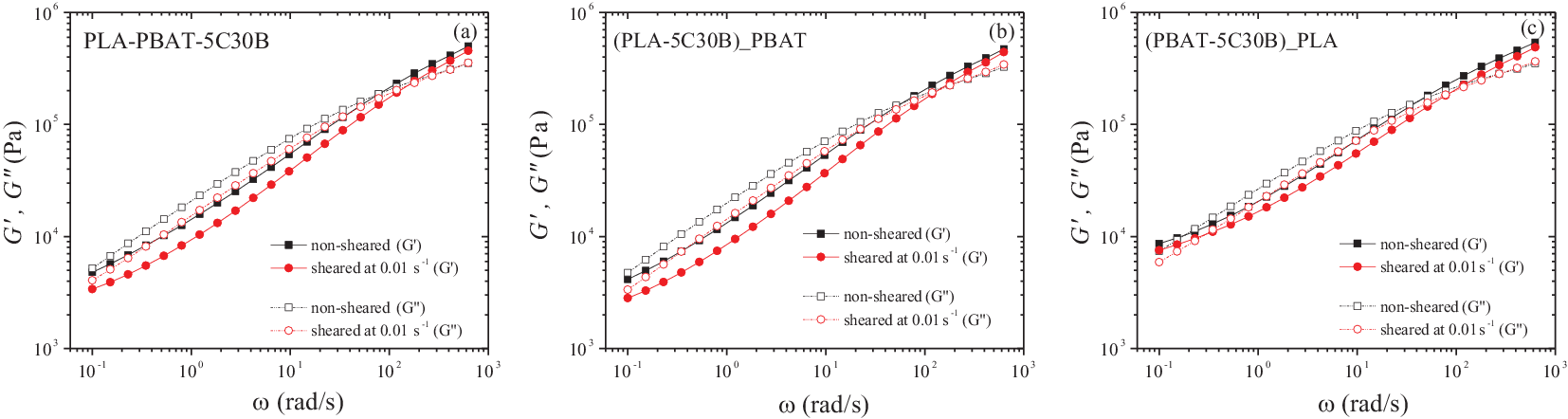

Figures 3a-c report the G’ and G” data of PLA-PBAT blend nanocomposites with 5 wt% clay before and after shearing at 0.01 s−1. In the non-sheared samples, the relaxation time determined for the crossover frequency increases when 5 wt% clay is added and, depending on the preparation strategy, this increase is in the order of S1 < S2 < S3. For example, the relaxation time for (PBAT-5C30B)-PLA is 0.025 s compared to about 0.010 s observed for (PBAT-1C30B)-PLA. This significant increase is attributed to the hindering effect of the nanoparticles that had migrated to the matrix phase under the mixing route S3 (Nofar et al., Reference Nofar, Heuzey, Carreau and Kamaln.d.). The longest relaxation time is observed in the (PBAT-5C30B)-PLA (S3) sample compared to the S1 an S2 cases, due to the reduced PLA degradation as the PLA/clay interactions were minimized when S3 was used as the preparation method. The relaxation time values before and after shearing are as follows: (a) in S1: from 0.0127 to 0.0076 s, (b) in S2: from 0.0167 to 0.0083 s, and (c) in S3: from 0.0250 to 0.0118 s, respectively. In all cases, when shearing is applied, the relaxation time decreases due to the more severe degradation of the PLA molecules in presence of 5 wt% clay.

Figure 3. Moduli of non-sheared and sheared nanocomposites with 5 wt% clay prepared via (a) S1, (b) S2, and (c) S3.

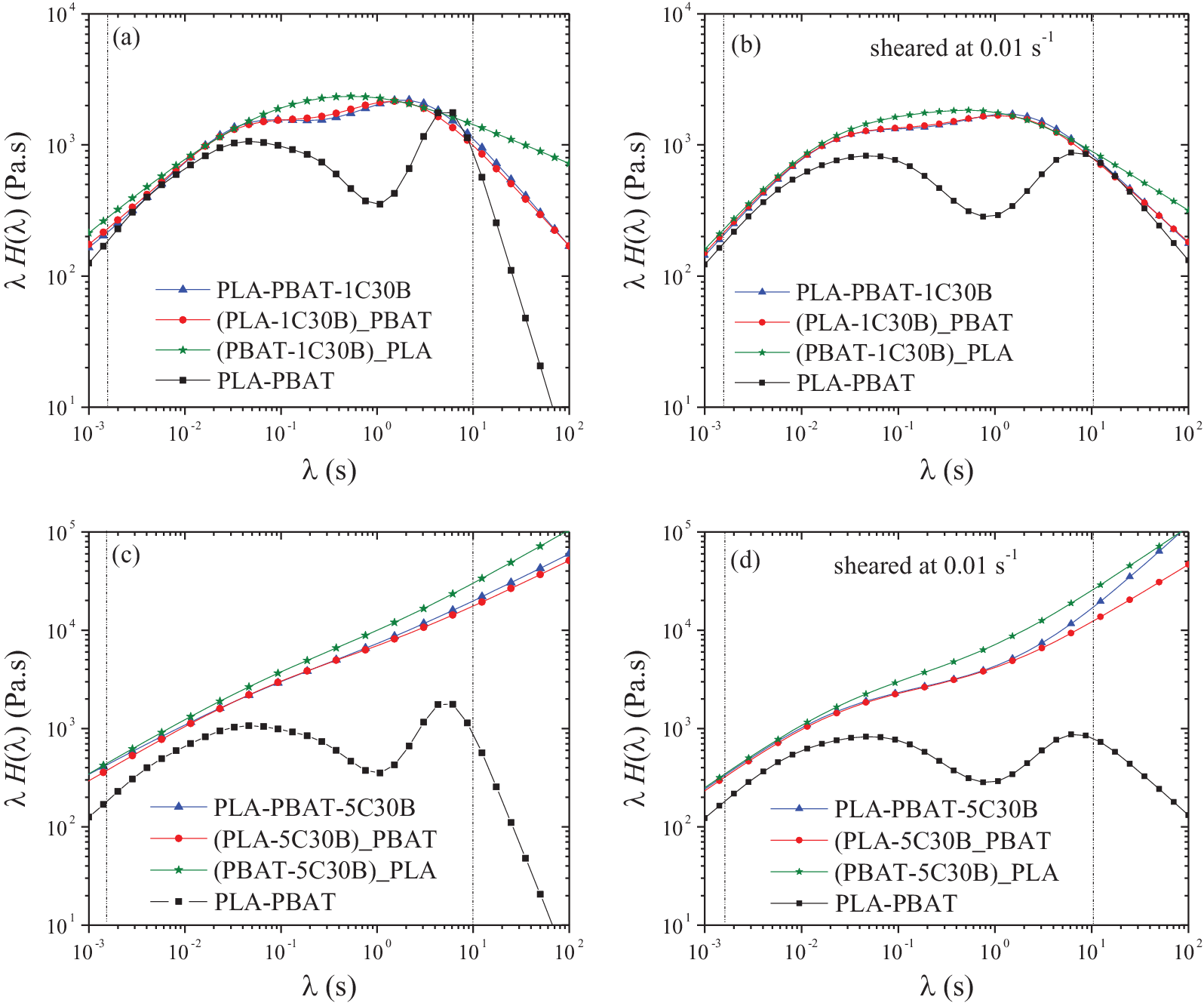

Using the SAOS data, the weighted relaxation spectra of the blends were calculated (Stadler & Bailly, Reference Stadler and Bailly2009; Sherrod, Reference Sherrod2010). In Figure 4, the PLA/PBAT blend reveals two relaxation peaks, where the first peak corresponds to the main relaxation time of the chains of the matrix (0.05 s), which is largely different from that obtained from the crossover frequency (0.0073 s); the second peak characterizes the interfacial relaxation between the two phases (~5 s). After 0.01 s−1 shearing, in PLA-PBAT neat blends, the interfacial relaxation time increases from 5 to around 9 s due to the coalescence of PBAT droplets (Nofar et al., Reference Nofar, Heuzey, Carreau and Kamaln.d.) and the PLA chain molecular relaxation decreases from 0.05 to around 0.04 s, which is a consequence of molecular degradation of PLA. In PLA/PBAT/1C30B systems regardless of the preparation strategy and shearing, wide relaxation merged peaks are observed although for the samples prepared via S1 and S2 two shoulders are also seen within the wide peaks. This is probably because the molecular and shape relaxations occur at a very close range when nanoclay is mainly located at the interface. Another interesting behavior is seen in PLA-PBAT blends containing 5 wt% clay regardless of the preparation strategy (Figures 4c-d). In all these cases, before and after shearing, slight shoulders at short relaxation times are observed followed by unbounded tails at longer times instead of shape relaxation peaks. These tails could be associated with the unfinished relaxation of the continuous solid network structures within the measuring frequency ranges (Kamal & Khoshkava, Reference Kamal and Khoshkava2015).

Figure 4. Weighted relaxation spectra of non-sheared (a, c) and sheared at 0.01 s−1 (b, d) PLA-PBAT blend and its nanocomposites with (a, b) 1 wt% and (c, d) 5 wt% clay.

4 Conclusion

In this study, 1 and 5 wt% nanoclay was incorporated within PLA/PBAT blends prepared via three different melt mixing strategies to investigate nanoclay interactions with the blend components and their effect on the molecular relaxation of the PLA chains. High content of nanoclay increased the relaxation time of the PLA molecules, but also contributed to a more severe PLA degradation depending on the mixing strategy. Shearing also led to more PLA degradation and decreased the relaxation time of the PLA chains. Blend preparation strategy and hence the nanoparticles localization could influence the molecular relaxation of PLA chains differently. Weighted relaxation spectra data of blends with 5 wt% clay exhibited a tail at long relaxation times, which could be related to the unfinished relaxation of the continuous solid network structures.

Acknowledgements

The authors would like to thank Jed Randall from NatureWorks for providing the PLA sample.

Author Contributions

M. Nofar conceived and designed the study, conducted experiments, and wrote the article. M.C Heuzey, P. Carreau and M. Kamal conceived the study and were involved in data analysis and writing the article.

Funding Information

This research received no specific grant from any funding agency, commercial or not-for-profit sectors.

Conflict of Interest

Authors declare none.

Data availability

To view supplementary material for this article, please visit https://doi.org/10.1016/j.polymer.2016.06.044.

Comments

Comments to the Author: The work presented in this manuscript complements the results published previously by the authors, namely in 2016 (ref. [13]). Further rheological studies are presented by the authors concerning two systems prepared from a molten blend of polylactide (PLA) and poly[(butylene adipate)-co-terephthalate] (PBAT) mixed with 1 and 5 wt% of clay nano particles.

While in previous works the authors used different techniques, including morphological studies, to characterize the mixtures prepared the present work is dedicated only to rheological measurements. To understand the rheological results obtained and the analyses performed, in this work, the previous results published by the authors should be accessed.

In this manuscript the authors concluded that PLA behavior and characteristics are influenced not only by the presence of the nanoparticles but also by sample preparation and shearing conditions. Two main points stressed by the authors should be deeply addressed and explained “PLA degradation” and “unfinished relaxation of the continuous solid…” in light of the results presented in this manuscript and previously reported by the authors.