1. Introduction

Cavitation commonly occurs on marine lifting surfaces, such as propellers, hydrofoils, turbines, and energy harvesting and energy saving devices during high-speed operation near the free surface. Cavitation occurs when the absolute local fluid pressure drops to the saturated vapour pressure, which leads to the formation of vapour bubbles. When the local pressure falls below the saturated vapour pressure, the fluid is subject to tension at the magnitude of the difference between the local pressure and saturated fluid pressure. When the tension is greater than the tensile strength of the fluid, the fluid ruptures and a cavity is formed (Brennen Reference Brennen1995). The interface between the fluid and body also contains voids that can serve as a rupture point for bubbles to grow. This formation of rupture, as well as rupture around a solid contaminant particle in the fluid, is known as heterogeneous nucleation (Brennen Reference Brennen1995). Rupture can also occur when there is a void in the fluid, which is known as homogeneous nucleation (Brennen Reference Brennen1995). A similar but different phenomenon is ventilation, during which cavities filled with a non-condensible gas are entrained from a nearby free surface (atmospheric ventilation) or injected by force (forced or artificial ventilation) (Acosta Reference Acosta1973; Faltinsen Reference Faltinsen2005; Young et al. Reference Young, Harwood, Montero, Ward and Ceccio2017). Although there is much similarity between cavitation and ventilation, the formation and collapse mechanisms are different between the two phenomena owing to the differences in condensibility and compressibility of the vapour versus gas within the cavities. This paper focuses primarily on vaporous cavitation.

Vaporous cavitation on the body can be categorized as bubbly cavitation, partial cavitation or supercavitation. Bubbly cavitation occurs during the initial stages of cavitation, during which individual bubbles form in the low-pressure region of the suction side of the body and travel downstream, where they collapse as the local pressure increases. Partial cavitation occurs when the cavity collapses onto the body surface, while supercavitation occurs when the cavity collapses aft of the body. Vaporous cavitation can also be categorized by their form, including sheet cavitation and cloud cavitation. Sheet cavitation occurs when the the separated flow region is filled with vapour, and the cavities remain attached to the body, giving a sheet like appearance. Cloud cavitation occurs when there is unsteady or periodic formation, detachment and collapse of sheet cavities, giving the cavitation a cloud like appearance (Brandner et al. Reference Brandner, Walker, Niekamp and Anderson2010). Cavitation can lead to reduction in lift and thrust, increase in drag, strong vibrations, noise and material damage. Cloud cavitation can cause heavy periodic damage with maximum pressures of the order of 133 bar, as the series of collapsing cavities create energy that propagates towards the centre of the cluster, which can lead to greater damage (van Terwisga et al. Reference van Terwisga, Fitzsimmon, Li and Foeth2009). The collapse of cloud cavitation results in erosion pitting, during which material on the surface of the lifting body is removed (Franc et al. Reference Franc, Riondet, Karimi and Chahine2012). Cavitation damage can be especially harmful to composite marine lifting surfaces. Hammond, Amateau & Queeny (Reference Hammond, Amateau and Queeny1993) compared the cavitation damage of several composites (E-Glass/5920, AS4/APC-2, IM7/977-2 T and Scotch Ply 1002) with that of a nickel aluminium bronze (NAB) specimen, and found that all composites sustained higher cavitation erosion damage compared with the NAB specimen. Over time, cavitation can strongly degrade maritime operation performance.

Shedding from cloud cavitation can be driven by Kelvin–Helmholtz wave instabilities, the formation of the re-entrant jet and the shock-wave mechanism. Kelvin–Helmholtz instabilities occur at the interface of two streams of fluid travelling at different velocities. Any small disturbance of the interface results in a wave reaction, which can encourage the shedding of cavities (Brandner et al. Reference Brandner, Walker, Niekamp and Anderson2010). The re-entrant jet phenomenon leads to cavity shedding commonly known as Type II oscillations (Kawanami et al. Reference Kawanami, Kato, Yamaguchi, Tanimura and Tagaya1997; De Lange & De Bruin Reference De Lange and De Bruin1998; Pham, Larrarte & Fruman Reference Pham, Larrarte and Fruman1999). The re-entrant jet is a liquid flow driven by the adverse pressure gradient from the cavity trailing edge to upstream underneath the attached cavity on the body surface (Kawanami et al. Reference Kawanami, Kato, Yamaguchi, Tanimura and Tagaya1997). The jet pinches the sheet cavity interface near the leading edge, which allows cavities to detach and travel downstream to form a cloud-like appearance (Pham et al. Reference Pham, Larrarte and Fruman1999). The Strouhal number of re-entrant jet cavity shedding, which is dependent on the maximum cavity length, lies constant at approximately 0.2 to 0.4 for different hydrofoil geometries and test conditions (Callenaere et al. Reference Callenaere, Franc, Michel and Riondet2001). As such, the cavity shedding frequency is dependent on the maximum cavity length, which in turn is dependent on cavitation number and effective angle of incidence. However, it is important to recognize that this only estimates the dominant cavity shedding frequency. The actual frequency response may contain other frequencies, as the cavities tend to shed in multiple small clouds and the cavity length is typically not uniform along the span of the body owing to three-dimensional (3-D) effects. After the collapse of cavities, remnant micro-bubbles remain and can be carried upstream in the re-entrant jet owing to the high adverse pressure, which serve as re-nucleation sites for the development of new attached cavities (Barbaca et al. Reference Barbaca, Venning, Russell, Russell, Pearce and Brandner2020; Ram, Agrawal & Katz Reference Ram, Agrawal and Katz2020; Russell & Brandner Reference Russell and Brandner2021). The leading edge cavity grows to the maximum cavity length to repeat the process of re-entrant jet formation and cavity shedding.

As the cavitation number decreases, the cloud cavitation length grows toward the trailing edge and the re-entrant jet loses the ability to pinch off cavities owing to a loss of momentum while travelling towards the leading edge (Bhatt et al. Reference Bhatt, Wu, Ganesh and Ceccio2018). This usually occurs when the maximum cavity length is larger than approximately 75 % of the chord length (Fujii et al. Reference Fujii, Kawakami, Tsujimoto and Arndt2007). The cavity shedding mechanism transforms to a shock-wave-induced mechanism, known as Type I oscillations. A shock occurs when the local speed of sound drops below the flow speed of the bubbly mixture in the cavity (Ganesh, Mäkiharju & Ceccio Reference Ganesh, Mäkiharju and Ceccio2016). Although the speed of sound is approximately ![]() $1500\,\textrm {m}\,\textrm {s}^{-1}$ in water, it varies significantly with local void fraction, or the fraction of gas and vapour in a given volume. In vaporous cavitation, the vapour volume fraction varies between 0 and 1. The speed of sound can drop drastically owing to high compressibility and density variation, including to levels of approximately

$1500\,\textrm {m}\,\textrm {s}^{-1}$ in water, it varies significantly with local void fraction, or the fraction of gas and vapour in a given volume. In vaporous cavitation, the vapour volume fraction varies between 0 and 1. The speed of sound can drop drastically owing to high compressibility and density variation, including to levels of approximately ![]() $6\,\textrm {m}\,\textrm {s}^{-1}$ at void fractions between 50 % and 60 %; at higher void fractions, the speed of sound rises to its speed of gas, near

$6\,\textrm {m}\,\textrm {s}^{-1}$ at void fractions between 50 % and 60 %; at higher void fractions, the speed of sound rises to its speed of gas, near ![]() $350\,\textrm {m}\,\textrm {s}^{-1}$ (Shamsborhan et al. Reference Shamsborhan, Coutier-Delgosha, Caignaert and Nour2010). A shock condensation front develops at the trailing edge of the cavity and moves upstream towards the leading edge, pinching off cavities, which result in strong periodic shedding clouds (Ganesh et al. Reference Ganesh, Mäkiharju and Ceccio2016; Wu, Maheux & Chahine Reference Wu, Maheux and Chahine2017; Bhatt et al. Reference Bhatt, Wu, Ganesh and Ceccio2018). Shock-wave-based shedding is governed by the change in the local speed of sound of the fluid mixture, and usually occurs at a constant frequency of 10–12 Hz regardless of geometry or facility (Fujii et al. Reference Fujii, Kawakami, Tsujimoto and Arndt2007; Ganesh et al. Reference Ganesh, Mäkiharju and Ceccio2016; Bhatt et al. Reference Bhatt, Wu, Ganesh and Ceccio2018; Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a,Reference Smith, Venning, Pearce, Young and Brandnerb). It has also recently been shown that re-entrant jet shedding and shock-wave shedding can occur simultaneously, and has been recorded to occur when the cavity length to chord length ratio,

$350\,\textrm {m}\,\textrm {s}^{-1}$ (Shamsborhan et al. Reference Shamsborhan, Coutier-Delgosha, Caignaert and Nour2010). A shock condensation front develops at the trailing edge of the cavity and moves upstream towards the leading edge, pinching off cavities, which result in strong periodic shedding clouds (Ganesh et al. Reference Ganesh, Mäkiharju and Ceccio2016; Wu, Maheux & Chahine Reference Wu, Maheux and Chahine2017; Bhatt et al. Reference Bhatt, Wu, Ganesh and Ceccio2018). Shock-wave-based shedding is governed by the change in the local speed of sound of the fluid mixture, and usually occurs at a constant frequency of 10–12 Hz regardless of geometry or facility (Fujii et al. Reference Fujii, Kawakami, Tsujimoto and Arndt2007; Ganesh et al. Reference Ganesh, Mäkiharju and Ceccio2016; Bhatt et al. Reference Bhatt, Wu, Ganesh and Ceccio2018; Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a,Reference Smith, Venning, Pearce, Young and Brandnerb). It has also recently been shown that re-entrant jet shedding and shock-wave shedding can occur simultaneously, and has been recorded to occur when the cavity length to chord length ratio, ![]() $L_c/c$, is between 1 and 1.25 (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a,Reference Smith, Venning, Pearce, Young and Brandnerb). The two shedding mechanisms can also occur simultaneously as a coupled mechanism in bluff-body flow about a sphere (de Graaf, Brandner & Pearce Reference de Graaf, Brandner and Pearce2017).

$L_c/c$, is between 1 and 1.25 (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a,Reference Smith, Venning, Pearce, Young and Brandnerb). The two shedding mechanisms can also occur simultaneously as a coupled mechanism in bluff-body flow about a sphere (de Graaf, Brandner & Pearce Reference de Graaf, Brandner and Pearce2017).

Many structures are deformable owing to flexibility of the material or connections. In response to fluid flow, deformable structures may bend and twist. The resulting deformation can interact with fluid flow, and this is known as fluid–structure interaction (FSI). FSI can lead to flow-induced vibrations, which can cause dynamic load oscillations, vibrations, noise and accelerated fatigue. Hydrodynamic instabilities such as divergence (unbounded deformation until material failure develops owing to fluid disturbing forces/moments equal to or exceeding elastic restoring forces/moments), flutter (sustained or growing oscillations owing to zero or negative damping) (Chae, Akcabay & Young Reference Chae, Akcabay and Young2013; Chae et al. Reference Chae, Akcabay, Lelong, Astolfi and Young2016; Chae, Akcabay & Young Reference Chae, Akcabay and Young2017; Harwood et al. Reference Harwood, Felli, Falchi, Ceccio and Young2019) and parametric resonance (exponential growth in vibrations caused by the periodic fluid force modulation at two times the system resonance frequency) (Akcabay & Young Reference Akcabay and Young2015) may develop. While flow-induced vibrations and associated dynamic load amplifications are unwanted for most lift-generating devices, it can be used to harvest flow kinetic energy. Sample studies exploring the energy harvesting potential of flexible piezoelectric plates in air and in water can be found in Akcabay & Young (Reference Akcabay and Young2012) and Wang et al. (Reference Wang, Alben, Li and Young2016). A better understanding of the FSI can also lead to design optimization, as the load-dependent anisotropic deformations can be tailored to delay flow separation, stall, cavitation, static divergence and avoid material failure (Young et al. Reference Young, Harwood, Montero, Ward and Ceccio2017; Liao, Martins & Young Reference Liao, Martins and Young2019). The FSI has also facilitated the development of flow and structural health monitoring techniques with embedded strain gauging or fibre optic techniques (Rajan & Prusty Reference Rajan and Prusty2017; Ward, Harwood & Young Reference Ward, Harwood and Young2018; Di Napoli et al. Reference Di Napoli, Young, Ceccio and Harwood2019). This is especially relevant with the movement towards autonomous marine operations.

The fluid–structure interaction in multiphase flow is currently not well understood. In cavitation and ventilation, the FSI response and stability are difficult to predict. The fluid forces (with fluid inertia, damping and disturbing/restoring force terms proportional to the acceleration, velocity and displacement, respectively, as well as cavity excitation forces caused by unsteady cavity shedding) can all change with the cavitation and ventilation. Because the water and vapour densities are different by five orders of magnitude, the fluid forcing terms are directly impacted and are time dependent in unsteady cavitating and ventilating flows (Akcabay & Young Reference Akcabay and Young2015; Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020). The periodic changes in fluid forces caused by cavity shedding and fluctuating fluid-mixture density can induce parametric excitation of the hydrofoil (Chae et al. Reference Chae, Akcabay and Young2013; Akcabay & Young Reference Akcabay and Young2015; Chae et al. Reference Chae, Akcabay, Lelong, Astolfi and Young2016, Reference Chae, Akcabay and Young2017). There has been very little work on the quantification of the effects of cavitation and ventilation on the fluid forces. Fluid added mass in fully ventilated and partially cavitating regimes is generally lower than that in a fully wetted regime owing to a drop in the local fluid density (Akcabay & Young Reference Akcabay and Young2015; Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020). Through empirical mode decomposition, it has also been shown that oscillating cavity length along the fluid–structure interface can cause fluctuations in the added mass (Rajaomazava et al. Reference Rajaomazava, Benaouicha, Astolfi and Boudraa2021). The system natural frequency is dependent on the fluid added mass, so system natural frequencies are also altered in multiphase flows (De La Torre et al. Reference De La Torre, Escaler, Egusquiza and Farhat2013; Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020; Young et al. Reference Young, Wright, Yoon and Harwood2020). The bandwidth of the system mode frequency tends to increase owing to a decrease in the added mass (Lelong, Guiffant & André Astolfi Reference Lelong, Guiffant and André Astolfi2017). There are many sources of damping, such as radiation, viscous, wake and cavity damping, so the change in damping is generally nonlinear and dependent on the mode of motion and extent of cavitation or ventilation (Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020). Generally, damping increases with the submergence of the hydrofoil and with increasing forward speed. Hydrodynamic damping is typically much higher than structural damping, particularly for the lower-ordered modes (Blake & Maga Reference Blake and Maga1975; Chae et al. Reference Chae, Akcabay and Young2017; Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020). The rate of change of the fluid density also induces added damping on the structure (Rajaomazava et al. Reference Rajaomazava, Benaouicha, Astolfi and Boudraa2021). Moreover, both the fluid added mass and damping depend on the direction of motion, i.e. mode dependent. Although there has been some qualitative work completed, very little work has been done to quantify how the fluid inertial, damping and disturbing forces change with flow conditions, such as speed, angle of incidence and multiphase flow. The cavity shedding frequency during cloud cavitation can also be affected by the FSI. As reviewed above, the frequency of Type II cavity shedding is a function of the cavity length. Deformable hydrofoils with nose-up bend–twist coupling showed an increased cavity length, which reduced the Type II cavity shedding frequency (Pearce et al. Reference Pearce, Brandner, Garg, Young, Phillips and Clarke2017; Young et al. Reference Young, Garg, Brandner, Pearce, Butler, Clarke and Phillips2018; Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020b). Hence, the presence of ventilation or cavitation can lead to very different dynamic responses from fully wetted flow (Young et al. Reference Young, Wright, Yoon and Harwood2020).

Another interesting FSI phenomenon involving unsteady cavitating flow is lock-in, which occurs when one of the cavity shedding frequencies is close to one of the system natural frequencies (primary lock-in), its harmonics (super-harmonic lock-in) or subharmonics (subharmonic lock-in). When lock-in occurs, the cavity shedding frequency deviates from the trend typically observed for rigid hydrofoils, such as constant Strouhal number based on cavity length for Type II re-entrant jet shedding, and synchronizes with the adjacent system natural frequency, harmonic or subharmonic, causing an amplification in the system response (Kato, Dan & Matsudaira Reference Kato, Dan and Matsudaira2006; Ausoni et al. Reference Ausoni, Farhat, Escaler, Egusquiza and Avellan2007; Akcabay et al. Reference Akcabay, Chae, Young, Ducoin and Astolfi2014a; Young et al. Reference Young, Harwood, Montero, Ward and Ceccio2017; Náprstek & Fishcer Reference Náprstek and Fishcer2019). The system natural frequency or harmonic may also deviate slightly towards the cavity shedding frequency during lock-in (Lelong et al. Reference Lelong, Guiffant and André Astolfi2017). Super-harmonic and subharmonic lock-ins are heavily reliant on the form of the damping (which is usually nonlinear) as well as the specific damping parameters. Systems with high damping have a wider zone of lock-in, which means that the cavity shedding frequency can be farther away from the subharmonic of the system natural frequency, and lock-in will still occur, but the dynamic load amplification tends to be limited owing to the high hydrodynamic damping. In general, the zone of resonance for subharmonic lock-in is greater than that for super-harmonic lock-in (Náprstek & Fishcer Reference Náprstek and Fishcer2019). Fluctuating hydrodynamic forces may also excite resonant frequencies, which leads to dynamic load amplification for cases with low damping (Ducoin, Astolfi & Sigrist Reference Ducoin, Astolfi and Sigrist2012; Harwood et al. Reference Harwood, Felli, Falchi, Ceccio and Young2019). Unsteady cavity shedding also leads to frequency modulation, which results in a more broad-banded frequency response spectrum (Harwood et al. Reference Harwood, Felli, Falchi, Ceccio and Young2019).

Another FSI phenomenon that is possible in unsteady cavitating flow is the development of heterodyne frequencies. Heterodyne frequencies are generated as the sum and difference of two frequencies when they are input into an oscillating system. The generation and application of heterodyne frequencies are studied in fields such as sonochemistry (Reno, Korremula & Casadonte Reference Reno, Korremula and Casadonte2019), defect detection (Tashakor et al. Reference Tashakor, Baghalian, Senyurek, Unal, McDaniel and Tansei2018) and radio transmission (Weng, Lin & Way Reference Weng, Lin and Way2008). However, heterodyne frequencies generated by the mixing of two cavity shedding mechanisms (i.e. re-entrant jet-driven and shock-wave-driven cavity shedding), where the local fluid medium and/or the flexible hydrofoil can act as a nonlinear oscillator/mixer, have not been discussed in the previous literature. Such an effect is important, as the heterodyne frequencies change the frequency spectra of the response, which can be important for identification of cavitation phenomena, and for prediction of cavity-induced vibrations, load oscillations, accelerated fatigue and potential instabilities.

Owing to the computational cost of performing computational fluid dynamics and/or computational structure dynamics (CFD/CSD) techniques, and the compatibility of control law design with reduced-order models (ROMs), there has been an increase in the modelling of unsteady flows with ROMs. ROMs are useful not only to predict, explain and control responses, but they can also be used to determine scaling relations and identify when lock-in or instabilities may develop.

Gao et al. (Reference Gao, Zhang, Kou, Liu and Ye2017) presented a linear ROM to model the unsteady flow interactions of transonic buffet flow. The ROM was developed through recording the output (lift and moment coefficient) signal induced by a chirp input (airfoil flap angle) signal obtained through CFD, developing a linear model using the input and output signal through system identification, and then reducing the order of the model through a balanced truncation method. The outputs of a linear ROM modelling transonic buffet flow over a NACA0012 airfoil were compared with the outputs of a full-order model from CFD/CSD simulation by Gao, Zhang & Li (Reference Gao, Zhang and Li2019), and it was found that the outputs of the ROM compared well with those of the full-order models. An additional advantage of using ROMs is that the coupled patterns between the fluid mode and structural mode in unsteady flow can be clearly captured (Gao & Zhang Reference Gao and Zhang2020). Other studies of ROMs on unsteady flow include the development of ROMs for the analysis of vortex-induced vibrations about a long flexible cylinder in both the in-line and cross-flow directions. A forced van der Pol oscillator was used along the cross-flow direction and a linear state space model was used in the inflow direction, the results of which were validated with experimental data from a wave tank (Stabile, Matthies & Borri Reference Stabile, Matthies and Borri2018). A simplified ROM based on the van der Pol equation was also proposed to model turbulent flow around a NACA0015 airfoil, the results of which compared well with high-fidelity simulation results (Siddiqui, Rasheed & Kvamsdal Reference Siddiqui, Rasheed and Kvamsdal2020).

While much work can be found on the development of ROMs for single-phase flows, much less work can be found on the development of ROMs for cavitating flows. Simulation of unsteady cavitating flow using CFD is expensive, particularly if the effects of viscosity, turbulence and compressibility all need to be considered in addition to phase change to simulate both re-entrant jet and shock-wave-driven cavity shedding mechanisms. The problem becomes even more complicated when the FSI effects are important. Hence, it is important to develop and validate a ROM based on the physics of experimental data to predict and control unsteady cavitation on flexible lifting surfaces.

Akcabay & Young (Reference Akcabay and Young2015) developed a simple ROM to predict the effects of parametric excitations of flexible hydrofoils in unsteady cavitating flow. The model was developed using data from two sets of experiments of cavity-induced vibrations of cantilevered hydrofoils in the high-speed cavitation tunnel at the French Naval Academy (Ducoin et al. Reference Ducoin, Astolfi and Sigrist2012; Akcabay et al. Reference Akcabay, Young, Lelong and Astolfi2014b; Chae et al. Reference Chae, Akcabay, Lelong, Astolfi and Young2016). Ducoin et al. (Reference Ducoin, Astolfi and Sigrist2012) performed the experiment on a NACA66-213 hydrofoil made of a polyoxymethylene (POM) polyacetate, while Akcabay et al. (Reference Akcabay, Young, Lelong and Astolfi2014b) and Chae et al. (Reference Chae, Akcabay, Lelong, Astolfi and Young2016) presented experimental and numerical data on a NACA0015 hydrofoil made of the same POM polyacetate. Using a simplified one-degree-of-freedom (1-DOF) model for spanwise bending coupled with a van der Pol model capturing the unsteady Type II re-entrant jet cavity excitation forces with the foil bending vibrations, the ROM modelled the frequency response of flexible hydrofoils. The estimations from the ROM were compared with experimental results from Ducoin et al. (Reference Ducoin, Astolfi and Sigrist2012), Akcabay et al. (Reference Akcabay, Young, Lelong and Astolfi2014b) and Chae et al. (Reference Chae, Akcabay, Lelong, Astolfi and Young2016). It was shown that the ROM could accurately predict the primary frequency response, including primary lock-in and modulations. However, the ROM was limited in that it only considered the Type II re-entrant jet cavity shedding frequency but not the Type I shock-wave-driven cavity shedding frequency, and could not predict subharmonic excitations. Moreover, while the predicted frequency response matched well with the measurements, there were large deviations in the amplitude of the oscillations.

In Alavi, Haddadpour & Firouz-Abadi (Reference Alavi, Haddadpour and Firouz-Abadi2018b), a ROM was developed for hydroelastic analysis of a hydrofoil in partial sheet cavitation by first assuming constant cavity length and then imposing velocity perturbation terms to model the unsteady flow. The unsteady hydrodynamic terms were approximated through a finite element solution. The ROM could accurately model cavity length as a function of cavitation number, variations in damping and frequency of different hydrodynamic modes, and flutter speed with and without the presence of cavities. The ROM was used to model the hydroelastic analysis of supercavitation effects in Alavi, Haddadpour & Firouz-Abadi (Reference Alavi, Haddadpour and Firouz-Abadi2018a), where steady pressure distribution and ROM were used to predict flutter velocity. However, there was little discussion in these two works regarding the modelling of cloud cavitation.

Smith et al. (Reference Smith, Venning, Pearce, Young and Brandner2020a) (Part I) and Smith et al. (Reference Smith, Venning, Pearce, Young and Brandner2020b) (Part II) discussed the FSI of a stiff hydrofoil manufactured from Type 316 stainless steel (SS) and a flexible hydrofoil manufactured from a carbon/glass-epoxy composite (CF) structure, respectively. Part II (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020b) also compared the FSI of the two hydrofoils. Both hydrofoils experienced cloud cavitation and supercavitation, and the SS hydrofoil experienced sheet cavitation at higher cavitation numbers. It was found that at higher cavitation numbers, the CF hydrofoil experienced a higher ratio of cavity length, ![]() $ {L_{c}}$, over the local chord,

$ {L_{c}}$, over the local chord, ![]() $ {c}$, owing to a nose-up twist. This caused an early transformation from the sheet cavitation regime to the cloud cavitation regime, longer cavity and a reduced Type II cavity shedding frequency. Similar observations were made by Young et al. (Reference Young, Harwood, Montero, Ward and Ceccio2017). In addition, multiple lock-in modes occurred at different cavity shedding frequencies on the CF hydrofoil, whereas fewer lock-in modes occurred on the SS hydrofoil. Similar observations were made by Pearce et al. (Reference Pearce, Brandner, Garg, Young, Phillips and Clarke2017) and Young et al. (Reference Young, Garg, Brandner, Pearce, Butler, Clarke and Phillips2018). Lock-ins were frequently observed at subharmonic frequencies of the wetted natural frequencies of the CF hydrofoil. This is supported by findings by Akcabay et al. (Reference Akcabay, Chae, Young, Ducoin and Astolfi2014a). The cavity and the response of the CF hydrofoil became much more stable once the supercavitation regime was achieved. This result was also predicted through numerical methods (Akcabay & Young Reference Akcabay and Young2014, Reference Akcabay and Young2015).

$ {c}$, owing to a nose-up twist. This caused an early transformation from the sheet cavitation regime to the cloud cavitation regime, longer cavity and a reduced Type II cavity shedding frequency. Similar observations were made by Young et al. (Reference Young, Harwood, Montero, Ward and Ceccio2017). In addition, multiple lock-in modes occurred at different cavity shedding frequencies on the CF hydrofoil, whereas fewer lock-in modes occurred on the SS hydrofoil. Similar observations were made by Pearce et al. (Reference Pearce, Brandner, Garg, Young, Phillips and Clarke2017) and Young et al. (Reference Young, Garg, Brandner, Pearce, Butler, Clarke and Phillips2018). Lock-ins were frequently observed at subharmonic frequencies of the wetted natural frequencies of the CF hydrofoil. This is supported by findings by Akcabay et al. (Reference Akcabay, Chae, Young, Ducoin and Astolfi2014a). The cavity and the response of the CF hydrofoil became much more stable once the supercavitation regime was achieved. This result was also predicted through numerical methods (Akcabay & Young Reference Akcabay and Young2014, Reference Akcabay and Young2015).

1.1. Objectives

Although much work has been done, the FSI of flexible hydrofoils in cloud cavitation is still not well understood and the dynamic response is not well predicted. Complementing the experimental results presented in Parts I and II (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a,Reference Smith, Venning, Pearce, Young and Brandnerb), this paper aims to further examine the experimental measurements, develop and use ROM predictions to explain the complex FSI response. The novel contributions include: (1) developing and validating ROMs to predict and explain the steady-state and dynamic hydroelastic response of hydrofoils in cloud cavitation; (2) quantifying the variation of the measured probability density function of hydrodynamic loads and deformations with cavitation numbers; (3) quantifying the variation in added mass and modal frequencies in fully wetted and cavitating flows, as well as the change in the bandwidth of modal frequency variations with different cavitation numbers; (4) identifying the presence of heterodyne frequencies arising from mixing of re-entrant jet driven and shock-wave driven cavity shedding frequencies when both mechanisms are present; and (5) explaining the dynamic load amplification and frequency at subharmonic lock-in, as well as the lack of dynamic load amplification at the primary lock-in for both the model-scale SS and CF hydrofoils.

2. Experimental overview

The experimental set-up and techniques used in this investigation are described in Parts I (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a) and II (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020b). As such, this section only briefly summarizes the set-up and techniques for completeness. Readers interested in the details of the experiment set-up and results for the stainless steel and composite hydrofoils should refer to Parts I (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a) and II (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020b), respectively.

2.1. Model set-up and foil geometry

The experiment was conducted at the Australian Maritime College in the Cavitation Research Laboratory water tunnel. A detailed description of the facility can be found in Brandner, Lecoffre & Walker (Reference Brandner, Lecoffre and Walker2007). The chord-based Reynolds number, ![]() $ {Re} = {U_{\infty }} {c}$/

$ {Re} = {U_{\infty }} {c}$/![]() $\nu$, was held constant at

$\nu$, was held constant at ![]() $0.8\times 10^{6}$, where

$0.8\times 10^{6}$, where ![]() $ {U_{\infty }}$ is the free-stream velocity,

$ {U_{\infty }}$ is the free-stream velocity, ![]() $ {c}$ is the mean chord and

$ {c}$ is the mean chord and ![]() $\nu$ is the kinematic viscosity of water. The hydrofoils were mounted at a fixed angle of incidence,

$\nu$ is the kinematic viscosity of water. The hydrofoils were mounted at a fixed angle of incidence, ![]() $\alpha _o$, of 6

$\alpha _o$, of 6![]() $ {{}^{\circ }}$. The cavitation number,

$ {{}^{\circ }}$. The cavitation number, ![]() $\sigma= 2$ (

$\sigma= 2$ (![]() $ {p_{\infty }-p_{v}})$/

$ {p_{\infty }-p_{v}})$/![]() $\rho _{f} {U_{\infty }}^{2}$, was varied between 1.2 and 0.2, where

$\rho _{f} {U_{\infty }}^{2}$, was varied between 1.2 and 0.2, where ![]() $ {p_{\infty }}$ is the absolute static pressure at the hydrofoil tip,

$ {p_{\infty }}$ is the absolute static pressure at the hydrofoil tip, ![]() $ {p_{v}}$ is the vapour pressure and

$ {p_{v}}$ is the vapour pressure and ![]() $\rho _{f}$ is the fluid density. The

$\rho _{f}$ is the fluid density. The ![]() $\sigma$ range was selected to examine partial leading edge sheet cavitation to cloud cavitation to supercavitation. The dissolved oxygen levels of the fluid were kept between 3 and 4 p.p.m. for all measurements. The experiments were conducted with natural nuclei content, which is a relatively deplete population (Venning et al. Reference Venning, Khoo, Pearce and Brandner2018b). Cloud cavitation modes and frequencies about a thick rigid hydrofoil have been shown to vary significantly with nuclei content. An abundant nuclei population reduces cavity shedding frequencies, and there may be an intermediate nuclei population that significantly reduces the coherence through random bubble activation and breakup, thus minimizing the resultant lift force amplitudes (Venning et al. Reference Venning, Giosio, Smith, Pearce and Brandner2018a; Venning, Pearce & Brandner Reference Venning, Pearce and Brandner2020). To the authors’ knowledge, there has been no study regarding the effects of nuclei content on cavity dynamics regarding a composite hydrofoil specifically.

$\sigma$ range was selected to examine partial leading edge sheet cavitation to cloud cavitation to supercavitation. The dissolved oxygen levels of the fluid were kept between 3 and 4 p.p.m. for all measurements. The experiments were conducted with natural nuclei content, which is a relatively deplete population (Venning et al. Reference Venning, Khoo, Pearce and Brandner2018b). Cloud cavitation modes and frequencies about a thick rigid hydrofoil have been shown to vary significantly with nuclei content. An abundant nuclei population reduces cavity shedding frequencies, and there may be an intermediate nuclei population that significantly reduces the coherence through random bubble activation and breakup, thus minimizing the resultant lift force amplitudes (Venning et al. Reference Venning, Giosio, Smith, Pearce and Brandner2018a; Venning, Pearce & Brandner Reference Venning, Pearce and Brandner2020). To the authors’ knowledge, there has been no study regarding the effects of nuclei content on cavity dynamics regarding a composite hydrofoil specifically.

The hydrofoils have a linearly tapered, unswept, trapezoidal planform with a span of ![]() $s=300$ mm, a tip chord of

$s=300$ mm, a tip chord of ![]() $c_{min}=60$ mm and a root chord of

$c_{min}=60$ mm and a root chord of ![]() $c_{max}=120$ mm. The mean chord is

$c_{max}=120$ mm. The mean chord is ![]() $c=90$ mm. A modified NACA0009 cross-section with a thicker trailing edge (to accommodate the composite layup) was used throughout the span, the details of which can be found in Zarruk et al. (Reference Zarruk, Brandner, Pearce and Phillips2014). The stiff hydrofoil was manufactured from stainless steel and will be denoted as the SS hydrofoil hereafter. The flexible hydrofoil was manufactured from a carbon/glass-epoxy hybrid composite, and will be denoted as the CF hydrofoil hereafter. The SS hydrofoil was made out of Type 316 stainless steel and the CF hydrofoil was made out of a two-part epoxy system, T700 unidirectional carbon fibre (Carbon-UD), non-crimp biaxial E-glass fabrics (Glass-[

$c=90$ mm. A modified NACA0009 cross-section with a thicker trailing edge (to accommodate the composite layup) was used throughout the span, the details of which can be found in Zarruk et al. (Reference Zarruk, Brandner, Pearce and Phillips2014). The stiff hydrofoil was manufactured from stainless steel and will be denoted as the SS hydrofoil hereafter. The flexible hydrofoil was manufactured from a carbon/glass-epoxy hybrid composite, and will be denoted as the CF hydrofoil hereafter. The SS hydrofoil was made out of Type 316 stainless steel and the CF hydrofoil was made out of a two-part epoxy system, T700 unidirectional carbon fibre (Carbon-UD), non-crimp biaxial E-glass fabrics (Glass-[![]() $0^{\circ }/90^{\circ }$]) and a light basket weave E-glass fabric. The two-part epoxy system was used for the matrix resin. The structural layers of the CF hydrofoil consisted of alternating layers of Glass-[

$0^{\circ }/90^{\circ }$]) and a light basket weave E-glass fabric. The two-part epoxy system was used for the matrix resin. The structural layers of the CF hydrofoil consisted of alternating layers of Glass-[![]() $0^{\circ }/90^{\circ }$] and carbon fibre laid unidirectionally in the direction of the spanwise axis. The structural sequence consisted of a single Glass-[

$0^{\circ }/90^{\circ }$] and carbon fibre laid unidirectionally in the direction of the spanwise axis. The structural sequence consisted of a single Glass-[![]() $0^{\circ }/90^{\circ }$] layer, five Carbon-UD layers, two Glass-[

$0^{\circ }/90^{\circ }$] layer, five Carbon-UD layers, two Glass-[![]() $0^{\circ }/90^{\circ }$] layers and four Carbon-UD layers. The light basket weave E-glass fabric was used as the outermost layer to protect the structure from damage. A quasi-isotropic response was expected for the CF hydrofoil owing to the symmetric layering and alternating

$0^{\circ }/90^{\circ }$] layers and four Carbon-UD layers. The light basket weave E-glass fabric was used as the outermost layer to protect the structure from damage. A quasi-isotropic response was expected for the CF hydrofoil owing to the symmetric layering and alternating ![]() $0^{\circ }/90^{\circ }$ layup about the hydrofoil midplane (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020b). Please refer to Parts I (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a) and II (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020b) for the manufacturing details of the stiff and flexible hydrofoils, respectively.

$0^{\circ }/90^{\circ }$ layup about the hydrofoil midplane (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020b). Please refer to Parts I (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a) and II (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020b) for the manufacturing details of the stiff and flexible hydrofoils, respectively.

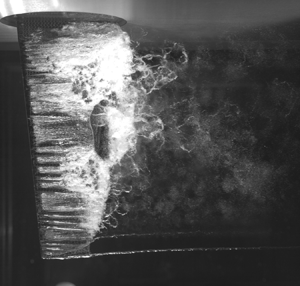

A photo of the CF hydrofoil along with the major dimensions is shown in figure 1. Owing to manufacturing challenges associated with the construction of the small-scale CF hydrofoil, the carbon fibre layers had to be dropped off by approximately 2.5 % of the local chord forward of the trailing edge (TE) at the root, and increased to 11 % of the local chord at the tip, because of thickness limitations. Hence, the glassy-white portion near the TE indicative of the absence of the black carbon fibre layers was larger towards the tip than the root, as observed in figure 1.

Figure 1. (a) CF hydrofoil, labelled with the span and the chord lengths. The coordinate system used for the ROM is also shown, with the origin at the intersection of the EA and the root of the hydrofoil. The black carbon fibre layer is dropped off prior to the foil trailing edge, and the drop off location is increasingly forward of the trailing edge in the outboard portion because of thickness limitations. (b) Diagram of the sectional view of the hydrofoil, along with the definition of the key geometric variables as well as the arrows indicating the positive directions. The variable ![]() $b=c/2$ denotes the semi-chord.

$b=c/2$ denotes the semi-chord.

Static testing was performed on the CF hydrofoil to determine the spanwise variation of the elastic axis (EA) relative to the midchord (MC), ![]() $ac$, as defined in figure 1. The test procedure involved placing a weight of 4.3861 kg at different points along the chord and span of the CF hydrofoil and measuring the deflections with a high-resolution camera. At each spanwise coordinate, the EA was determine as the location along the chord where the measured twist was zero. The measured variation of

$ac$, as defined in figure 1. The test procedure involved placing a weight of 4.3861 kg at different points along the chord and span of the CF hydrofoil and measuring the deflections with a high-resolution camera. At each spanwise coordinate, the EA was determine as the location along the chord where the measured twist was zero. The measured variation of ![]() $a$ as a function of the normalized span

$a$ as a function of the normalized span ![]() $\bar {y}=y/s$ is shown in figure 2, where

$\bar {y}=y/s$ is shown in figure 2, where ![]() $\bar {y} = 0$ is the root of the hydrofoil and

$\bar {y} = 0$ is the root of the hydrofoil and ![]() $\bar {y} = 1$ is the tip. The results showed that the EA of the CF hydrofoil shifted from

$\bar {y} = 1$ is the tip. The results showed that the EA of the CF hydrofoil shifted from ![]() $0.18c$ aft of the midchord at the root to

$0.18c$ aft of the midchord at the root to ![]() $0.12c$ forward of the midchord at the tip. The spanwise-averaged value of the EA was

$0.12c$ forward of the midchord at the tip. The spanwise-averaged value of the EA was ![]() $\bar {a} =\int _0^{1} a(\bar {y})=-0.0464$, and is used later in the two-degrees-of-freedom (2-DOF) ROM prediction of the steady-state FSI response. Using the same static load measurement procedure, the bending and twisting mode shapes,

$\bar {a} =\int _0^{1} a(\bar {y})=-0.0464$, and is used later in the two-degrees-of-freedom (2-DOF) ROM prediction of the steady-state FSI response. Using the same static load measurement procedure, the bending and twisting mode shapes, ![]() $f(\bar {y})$ and

$f(\bar {y})$ and ![]() $g(\bar {y})$, respectively, of the CF hydrofoil were obtained over a trapezoidal grid with 11 chordwise

$g(\bar {y})$, respectively, of the CF hydrofoil were obtained over a trapezoidal grid with 11 chordwise ![]() $\times$ 4 spanwise measurement points. As shown in figure 3, the measured mode shapes were independent of chord position, which suggested negligible chordwise deformations. The EA and mode shapes were not measured for the SS hydrofoil because of its high twisting stiffness. Nevertheless, the same fitted functions of the mode shapes,

$\times$ 4 spanwise measurement points. As shown in figure 3, the measured mode shapes were independent of chord position, which suggested negligible chordwise deformations. The EA and mode shapes were not measured for the SS hydrofoil because of its high twisting stiffness. Nevertheless, the same fitted functions of the mode shapes, ![]() $f(\bar {y})$ and

$f(\bar {y})$ and ![]() $g(\bar {y})$, as shown in the line legends in figure 3, were used for the SS hydrofoil, as it shares the same undeformed geometry and boundary condition as the CF hydrofoil, and both hydrofoils behaved as linear elastic, isotropic or quasi-isotropic bodies. Here,

$g(\bar {y})$, as shown in the line legends in figure 3, were used for the SS hydrofoil, as it shares the same undeformed geometry and boundary condition as the CF hydrofoil, and both hydrofoils behaved as linear elastic, isotropic or quasi-isotropic bodies. Here, ![]() $a(\bar {y})=0$ was assumed for the SS hydrofoil for simplicity, as it exhibited negligible twist owing to the high twisting stiffness.

$a(\bar {y})=0$ was assumed for the SS hydrofoil for simplicity, as it exhibited negligible twist owing to the high twisting stiffness.

Figure 2. Measured variation of the position of the EA from the midchord normalized by the mean chord (![]() $c = 90$ mm),

$c = 90$ mm), ![]() $a$, of the CF hydrofoil along the normalized spanwise coordinate

$a$, of the CF hydrofoil along the normalized spanwise coordinate ![]() $\bar {y}$. Forward of the midchord is denoted as negative. The magenta circles denote measurements made along the span. The blue solid line indicates the curve fit (with the equation given in the line legend) of the elastic axis position, while the blue dash–dotted line indicates the spanwise averaged value. It can be seen that the elastic axis is aft of the midchord at the root and moves forward of the midchord at the tip because the carbon fibre layer had to be dropped off forward of the trailing edge owing to thickness limitations. The spanwise-averaged EA value,

$\bar {y}$. Forward of the midchord is denoted as negative. The magenta circles denote measurements made along the span. The blue solid line indicates the curve fit (with the equation given in the line legend) of the elastic axis position, while the blue dash–dotted line indicates the spanwise averaged value. It can be seen that the elastic axis is aft of the midchord at the root and moves forward of the midchord at the tip because the carbon fibre layer had to be dropped off forward of the trailing edge owing to thickness limitations. The spanwise-averaged EA value, ![]() $\bar {a}$, was used in the ROM predictions.

$\bar {a}$, was used in the ROM predictions.

Figure 3. (a) The bending mode shape, ![]() $f(\bar {y})$, of the CF hydrofoil and (b) the twisting mode shape,

$f(\bar {y})$, of the CF hydrofoil and (b) the twisting mode shape, ![]() $g(\bar {y})$, of the CF hydrofoil. The magenta circles denote the measurements made along the span and the blue lines indicate the fitted mode shapes (with the equation given in the line legend). At each spanwise location, multiple measurements are made along the chord and the data points nearly overlap, which suggests independence from the chordwise coordinate.

$g(\bar {y})$, of the CF hydrofoil. The magenta circles denote the measurements made along the span and the blue lines indicate the fitted mode shapes (with the equation given in the line legend). At each spanwise location, multiple measurements are made along the chord and the data points nearly overlap, which suggests independence from the chordwise coordinate.

Both hydrofoils were manufactured to a ![]() $\pm$0.01 mm surface tolerance and a

$\pm$0.01 mm surface tolerance and a ![]() $0.8\,\mathrm {\mu }\textrm {m}$ surface finish. The composite hydrofoil showed evidence of very minor imperfections on its surface owing to challenges in the moulding process of a relatively thin structure. The minor surface imperfections lead to slightly earlier local cavitation inception in the form of a small bubble streak near the imperfection spot, but it did not affect the developed cavitation response such as in the cloud and supercavitation regimes that are the focus of this work. The effective structural properties of the stiff and flexible hydrofoil can be found in table 1.

$0.8\,\mathrm {\mu }\textrm {m}$ surface finish. The composite hydrofoil showed evidence of very minor imperfections on its surface owing to challenges in the moulding process of a relatively thin structure. The minor surface imperfections lead to slightly earlier local cavitation inception in the form of a small bubble streak near the imperfection spot, but it did not affect the developed cavitation response such as in the cloud and supercavitation regimes that are the focus of this work. The effective structural properties of the stiff and flexible hydrofoil can be found in table 1.

Table 1. Summary of the material and structural properties of the SS and CF hydrofoils (Zarruk et al. Reference Zarruk, Brandner, Pearce and Phillips2014).

2.2. Measurement and data processing techniques

Three different run types, labelled Long, Medium and Short, were conducted for measurement collections. The details of the three run types are summarized in table 2, and detailed information regarding the run types can be found in Part I (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a). Forces were measured in all three run types, while videos for tip deflection and cavitation behaviour were taken in the Medium and Short run types.

Table 2. Test matrix of the hydrofoils for the various run types detailing the ![]() $\sigma$ range, run duration,

$\sigma$ range, run duration, ![]() $T$, high-speed photography frame rate,

$T$, high-speed photography frame rate, ![]() $\,f_{{HSP}}$, and force balance sampling rate,

$\,f_{{HSP}}$, and force balance sampling rate, ![]() $\,f_{{FBS}}$. Long run types provide accurate high frequency resolution loading behaviour with

$\,f_{{FBS}}$. Long run types provide accurate high frequency resolution loading behaviour with ![]() $\sigma$, whereas both statistical and high temporal resolution data of the cavitation behaviour and tip deflection are obtained efficiently with the medium and short run types, respectively.

$\sigma$, whereas both statistical and high temporal resolution data of the cavitation behaviour and tip deflection are obtained efficiently with the medium and short run types, respectively. ![]() $^{*}$Only conducted for flexible CF hydrofoil.

$^{*}$Only conducted for flexible CF hydrofoil.

Tip deflection was measured using a Phantom v2640 high-speed camera with a Nikkor 105 mm f/2.8G lens, operating with a ![]() $512 \times 1504$ pixel resolution for the stiff SS hydrofoil and a

$512 \times 1504$ pixel resolution for the stiff SS hydrofoil and a ![]() $896\times 1504$ pixel resolution for the flexible CF hydrofoil. The spatial resolution of both cases was 0.049 mm px

$896\times 1504$ pixel resolution for the flexible CF hydrofoil. The spatial resolution of both cases was 0.049 mm px![]() $^{-1}$. Tip deflection was calculated by detecting the edge of the hydrofoil based on peaks in the pixel intensity gradient along each row and comparing the detected edge with that of the hydrofoil under zero load, assuming that the local cross-section of the hydrofoil did not deform. When cavitating tip vortices were observed, the length of the edge was adjusted to exclude the sections of the chord obstructed by the tip vortices to maintain accuracy of the tip deformation measurements. Further details of the edge detection process can be found in Part I (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a). The tip twist,

$^{-1}$. Tip deflection was calculated by detecting the edge of the hydrofoil based on peaks in the pixel intensity gradient along each row and comparing the detected edge with that of the hydrofoil under zero load, assuming that the local cross-section of the hydrofoil did not deform. When cavitating tip vortices were observed, the length of the edge was adjusted to exclude the sections of the chord obstructed by the tip vortices to maintain accuracy of the tip deformation measurements. Further details of the edge detection process can be found in Part I (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a). The tip twist, ![]() $\theta$, was determined by fitting a line through the detected edge of the hydrofoil tip and subtracting the line from a similar line fitted under the unloaded condition. Tip bending displacement,

$\theta$, was determined by fitting a line through the detected edge of the hydrofoil tip and subtracting the line from a similar line fitted under the unloaded condition. Tip bending displacement, ![]() $\delta$, was obtained as the average distance of each point after twist was subtracted. Positive

$\delta$, was obtained as the average distance of each point after twist was subtracted. Positive ![]() $\delta$ was defined as bending towards the suction side, and positive

$\delta$ was defined as bending towards the suction side, and positive ![]() $\theta$ was defined as nose-up twist about the midchord.

$\theta$ was defined as nose-up twist about the midchord.

Cavitation behaviour was recorded using a side-mounted Phantom v2640 high-speed camera with a resolution of ![]() $2048\times 1952$ pixels and a spatial resolution of 0.185 mm px

$2048\times 1952$ pixels and a spatial resolution of 0.185 mm px![]() $^{-1}$. Spectral proper orthogonal decomposition (SPOD) was used to identify coherent structures in dynamic cloud cavitation behaviour, using the technique outlined by Towne, Schmidt & Colonius (Reference Towne, Schmidt and Colonius2018). The SPOD method and results have been presented in Parts I (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a) and II (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020b) and were obtained by processing a total of 18 000 snapshots for each run.

$^{-1}$. Spectral proper orthogonal decomposition (SPOD) was used to identify coherent structures in dynamic cloud cavitation behaviour, using the technique outlined by Towne, Schmidt & Colonius (Reference Towne, Schmidt and Colonius2018). The SPOD method and results have been presented in Parts I (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020a) and II (Smith et al. Reference Smith, Venning, Pearce, Young and Brandner2020b) and were obtained by processing a total of 18 000 snapshots for each run.

3. Reduced-order models

To complement the experimental studies, simple ROMs are presented in this section to predict the steady and dynamic FSI response of the hydrofoils. The novelty in the present ROM includes consideration of (1) parametrically oscillating added mass arising from periodic cavity growth and collapse cycles and (2) presence of both re-entrant jet and shock-wave driven cavity shedding frequencies, and random variations in the phase of the unsteady cavity excitation forces arising from the simultaneous presence of two different shedding mechanisms.

The SS and CF hydrofoils are assumed to behave linear elastically and undergo negligible chordwise deformation. Both assumptions are supported by experimental observations reported by Young et al. (Reference Young, Garg, Brandner, Pearce, Butler, Clarke and Phillips2018) and Smith et al. (Reference Smith, Venning, Pearce, Young and Brandner2020a,Reference Smith, Venning, Pearce, Young and Brandnerb). Material bend–twist coupling effects are ignored as the SS hydrofoil is isotropic, and a quasi-isotropic response is expected for the CF hydrofoil. The objective of this section is to present the simplest ROMs that capture the dominant FSI response. Errors arising from the simplified assumptions will be discussed in § 4.

The ROM was derived by decomposing the generalized spanwise bending and twisting deformations, ![]() $\tilde {\delta }(\bar {y},t)$ and

$\tilde {\delta }(\bar {y},t)$ and ![]() $\tilde {\theta }(\bar {y},t)$ as a function of the mode shapes (

$\tilde {\theta }(\bar {y},t)$ as a function of the mode shapes (![]() $f(\bar {y}$) and

$f(\bar {y}$) and ![]() $g(\bar {y})$ given in the line legend in figure 3) and time (

$g(\bar {y})$ given in the line legend in figure 3) and time (![]() $t$):

$t$):

\begin{equation} \left. \begin{gathered} \tilde{\delta}(\bar{y},t)=\delta(t)f(\bar{y}),\\ \tilde{\theta}(\bar{y},t)=\theta(t)g(\bar{y}), \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \tilde{\delta}(\bar{y},t)=\delta(t)f(\bar{y}),\\ \tilde{\theta}(\bar{y},t)=\theta(t)g(\bar{y}), \end{gathered} \right\} \end{equation}

where ![]() $\delta (t)$ and

$\delta (t)$ and ![]() $\theta (t)$ are the tip bending and twisting deformations, respectively, defined at the elastic axis, EA, as shown in figure 1. Using the decomposition shown in (3.1), the generalized equation of motion for

$\theta (t)$ are the tip bending and twisting deformations, respectively, defined at the elastic axis, EA, as shown in figure 1. Using the decomposition shown in (3.1), the generalized equation of motion for ![]() $\delta$ and

$\delta$ and ![]() $\theta$ can be derived based on the principle of virtual work, and can be found in Bisplinghoff, Ashley & Halfman (Reference Bisplinghoff, Ashley and Halfman1955) and Akcabay et al. (Reference Akcabay, Chae, Young, Ducoin and Astolfi2014a).

$\theta$ can be derived based on the principle of virtual work, and can be found in Bisplinghoff, Ashley & Halfman (Reference Bisplinghoff, Ashley and Halfman1955) and Akcabay et al. (Reference Akcabay, Chae, Young, Ducoin and Astolfi2014a).

A 2-DOF model was developed to model the steady-state spanwise bending and twisting FSI response, while a 1-DOF model considering only the spanwise bending fluctuations was developed to model the dynamic FSI response. The 1-DOF model was used for the dynamic response because the bending and twisting frequencies were well separated and the twist measurements were contaminated by force balance excitations.

It should be noted that the force balance measurements were about the midchord. The normal force (![]() $F_N$) was independent of the chordwise position. Equation (3.2) was used to relate the pitch moment at the EA,

$F_N$) was independent of the chordwise position. Equation (3.2) was used to relate the pitch moment at the EA, ![]() $F_P^{EA}$, to the value at the midchord,

$F_P^{EA}$, to the value at the midchord, ![]() $F_P$:

$F_P$:

The tip bending and twisting displacements were made about the midchord, but the values were practically the same as at the EA because ![]() $\sin (\theta )\approx 0$ for both hydrofoils. Hence, no effort was made to distinguish the tip deformations about the midchord versus the EA.

$\sin (\theta )\approx 0$ for both hydrofoils. Hence, no effort was made to distinguish the tip deformations about the midchord versus the EA.

3.1. 2-DOF steady-state FSI model

The generalized steady-state 2-DOF model for the spanwise bending and twisting deformations can be written as follows:

where ![]() $\widetilde {K_s}^{\delta \delta }=({EI }/{L^{3}}) \int _0^{1} [ f^{\prime \prime }(\bar {y}) ]^{2}\, \textrm {d}\bar {y}=({EI }/{L^{3}}) \tilde {\beta }_{k \delta }$ and

$\widetilde {K_s}^{\delta \delta }=({EI }/{L^{3}}) \int _0^{1} [ f^{\prime \prime }(\bar {y}) ]^{2}\, \textrm {d}\bar {y}=({EI }/{L^{3}}) \tilde {\beta }_{k \delta }$ and ![]() $\widetilde {K_s}^{\theta \theta }=({GJ }/{L}) \int _0^{1} [ g^{\prime }(\bar {y}) ]^{2}\,\textrm {d}\bar {y}=({GJ }/{L}) \tilde {\beta }_{k \theta }$ are the generalized bending and twisting stiffness.

$\widetilde {K_s}^{\theta \theta }=({GJ }/{L}) \int _0^{1} [ g^{\prime }(\bar {y}) ]^{2}\,\textrm {d}\bar {y}=({GJ }/{L}) \tilde {\beta }_{k \theta }$ are the generalized bending and twisting stiffness.

Here, ![]() $E$,

$E$, ![]() $I$,

$I$, ![]() $G$ and

$G$ and ![]() $J$ are the material Young's modulus, bending moment of inertia, shear modulus and torsional moment of inertia, as given in table 1. The hydrofoil structural span is

$J$ are the material Young's modulus, bending moment of inertia, shear modulus and torsional moment of inertia, as given in table 1. The hydrofoil structural span is ![]() $L=316$ mm, which is slightly higher than the hydrodynamic span of

$L=316$ mm, which is slightly higher than the hydrodynamic span of ![]() $s=300$ mm because of a nominal radial clearance of 0.5 mm between the fairing disk and the test section ceiling penetration to avoid interference with the force measurements (Young et al. Reference Young, Garg, Brandner, Pearce, Butler, Clarke and Phillips2018). Additionally,

$s=300$ mm because of a nominal radial clearance of 0.5 mm between the fairing disk and the test section ceiling penetration to avoid interference with the force measurements (Young et al. Reference Young, Garg, Brandner, Pearce, Butler, Clarke and Phillips2018). Additionally, ![]() $\tilde {F}_N=F_N\tilde {\beta }_{fN}$ and

$\tilde {F}_N=F_N\tilde {\beta }_{fN}$ and ![]() $\tilde {F}_P^{EA}=F_P^{EA}\tilde {\beta }_{fP}$ are the generalized normal force (positive upwards) and pitching moment (positive nose-up) defined about the EA.

$\tilde {F}_P^{EA}=F_P^{EA}\tilde {\beta }_{fP}$ are the generalized normal force (positive upwards) and pitching moment (positive nose-up) defined about the EA.

Defining the combined bending and twisting shape factor as ![]() $\beta _{k \delta }=\tilde {\beta }_{k \delta } /\tilde {\beta }_{fN}$ and

$\beta _{k \delta }=\tilde {\beta }_{k \delta } /\tilde {\beta }_{fN}$ and ![]() $\beta _{k\theta }=\tilde {\beta }_{k \theta }/\tilde {\beta }_{fP}$, (3.3) can be rewritten as follows:

$\beta _{k\theta }=\tilde {\beta }_{k \theta }/\tilde {\beta }_{fP}$, (3.3) can be rewritten as follows:

\begin{equation} \begin{bmatrix} K_s^{\delta \delta} & 0 \\ 0 & K_s^{\theta \theta} \end{bmatrix} \begin{bmatrix} \delta \\ \theta \end{bmatrix} = \begin{bmatrix} F_N=C_N qsc \\ F_P^{EA}=C_P^{EA} qsc^{2} \end{bmatrix}, \end{equation}

\begin{equation} \begin{bmatrix} K_s^{\delta \delta} & 0 \\ 0 & K_s^{\theta \theta} \end{bmatrix} \begin{bmatrix} \delta \\ \theta \end{bmatrix} = \begin{bmatrix} F_N=C_N qsc \\ F_P^{EA}=C_P^{EA} qsc^{2} \end{bmatrix}, \end{equation}

where ![]() $K_s^{\delta \delta }=\beta _{k \delta }EI/L^{3}$ and

$K_s^{\delta \delta }=\beta _{k \delta }EI/L^{3}$ and ![]() $K_s^{\theta \theta }=\beta _{k\theta }GJ/L$ are the effective structural bending and twisting stiffness, respectively.

$K_s^{\theta \theta }=\beta _{k\theta }GJ/L$ are the effective structural bending and twisting stiffness, respectively.

Here, ![]() $\beta _{k \delta }$ and

$\beta _{k \delta }$ and ![]() $\beta _{k\theta }$ are non-dimensional constants that depend on the geometry only, and account for the spanwise variations of the elastic axis, chord length, load shape distribution and mode shape. Because

$\beta _{k\theta }$ are non-dimensional constants that depend on the geometry only, and account for the spanwise variations of the elastic axis, chord length, load shape distribution and mode shape. Because ![]() $EI/L^{3}$ and

$EI/L^{3}$ and ![]() $GJ/L$ are known for both hydrofoils,

$GJ/L$ are known for both hydrofoils, ![]() $\beta _{k \delta }=5.31$ and

$\beta _{k \delta }=5.31$ and ![]() $\beta _{k\theta }=0.026$ are determined by taking the slope of the measured normal force (

$\beta _{k\theta }=0.026$ are determined by taking the slope of the measured normal force (![]() $F_N$) versus the tip displacement (

$F_N$) versus the tip displacement (![]() $\delta$) and the pitching moment (

$\delta$) and the pitching moment (![]() $F_P^{EA}$) versus the tip twist angle (

$F_P^{EA}$) versus the tip twist angle (![]() $\theta$) about the elastic axis. The resultant values for

$\theta$) about the elastic axis. The resultant values for ![]() $K_s^{\delta \delta }$ and

$K_s^{\delta \delta }$ and ![]() $K_s^{\theta \theta }$ are given in table 3.

$K_s^{\theta \theta }$ are given in table 3.

Table 3. Model parameters used in the reduced-order models. The ![]() $K_s^{\delta \delta }$ and

$K_s^{\delta \delta }$ and ![]() $K_s^{\theta \theta }$ are the effective bending and twisting stiffnesses, respectively,

$K_s^{\theta \theta }$ are the effective bending and twisting stiffnesses, respectively, ![]() $M_s$ is the hydrofoil mass,

$M_s$ is the hydrofoil mass, ![]() $\,f_{n1,dry}$ and

$\,f_{n1,dry}$ and ![]() $\,f_{n1,FW}$ are the dry and fully wetted bending modal frequencies, and

$\,f_{n1,FW}$ are the dry and fully wetted bending modal frequencies, and ![]() $\,f_{n2,dry}$ and

$\,f_{n2,dry}$ and ![]() $\,f_{n2,FW}$ are the dry and fully wetted twisting modal frequencies.

$\,f_{n2,FW}$ are the dry and fully wetted twisting modal frequencies.

The mean 3-D normal force and pitching moment coefficients about the EA (![]() $C_N$ and

$C_N$ and ![]() $C_P^{EA}$) are calculated using (3.5) and (3.6):

$C_P^{EA}$) are calculated using (3.5) and (3.6):

where ![]() $a_o^{3D} = \partial C_N/\partial \alpha _{e}=a_o^{2D}/( 1+a_o^{2D}/{\rm \pi} A_R )$ is the 3-D lift slope and

$a_o^{3D} = \partial C_N/\partial \alpha _{e}=a_o^{2D}/( 1+a_o^{2D}/{\rm \pi} A_R )$ is the 3-D lift slope and ![]() $a_o^{2D}$ is the two-dimensional (2-D) lift slope,

$a_o^{2D}$ is the two-dimensional (2-D) lift slope, ![]() $A_R=2s/c=6.67$ is the effective aspect ratio accounting for the image effect created by the top tunnel boundary at the fixed end of the cantilevered hydrofoil,

$A_R=2s/c=6.67$ is the effective aspect ratio accounting for the image effect created by the top tunnel boundary at the fixed end of the cantilevered hydrofoil, ![]() $\epsilon =e+\bar {a}$ is the spanwise-averaged distance from the CP to the EA normalized by the mean chord,

$\epsilon =e+\bar {a}$ is the spanwise-averaged distance from the CP to the EA normalized by the mean chord, ![]() $q=0.5\rho _fU_\infty ^{2}$ is the dynamic fluid pressure, and

$q=0.5\rho _fU_\infty ^{2}$ is the dynamic fluid pressure, and ![]() $\alpha _e=\alpha _o+\theta S_g$ is the effective angle of attack, with

$\alpha _e=\alpha _o+\theta S_g$ is the effective angle of attack, with ![]() $S_g=\int _0^{1} g(\bar {y}) \,\textrm {d}\bar {y}=1/3$.

$S_g=\int _0^{1} g(\bar {y}) \,\textrm {d}\bar {y}=1/3$.

A semi-empirical equation (3.7) is used to predict the variation of the 2-D lift slope with the effective cavitation parameter ![]() $\psi _e=\sigma /(2\alpha _e)$, where

$\psi _e=\sigma /(2\alpha _e)$, where ![]() $\sigma =2(p_\infty -p_v)/\rho _f U_\infty ^{2}$:

$\sigma =2(p_\infty -p_v)/\rho _f U_\infty ^{2}$:

Note that ![]() $a_o^{2D} \rightarrow 2{\rm \pi}$ for fully wetted flow as

$a_o^{2D} \rightarrow 2{\rm \pi}$ for fully wetted flow as ![]() $\psi _e \rightarrow \infty$ and

$\psi _e \rightarrow \infty$ and ![]() $a_o^{2D} \rightarrow {\rm \pi}/2$ for supercavitating flow as

$a_o^{2D} \rightarrow {\rm \pi}/2$ for supercavitating flow as ![]() $\psi _e \rightarrow 0$. Equation (3.7) is similar in spirit as equation (10) presented by Akcabay & Young (Reference Akcabay and Young2015), and is a simpler mathematical model that follows the trend of experimental data for the 2-D lift slope.

$\psi _e \rightarrow 0$. Equation (3.7) is similar in spirit as equation (10) presented by Akcabay & Young (Reference Akcabay and Young2015), and is a simpler mathematical model that follows the trend of experimental data for the 2-D lift slope.

The variation of the maximum attached cavity length to chord length ratio (![]() $L_c/c$) can be modelled using (3.8), which is obtained by fitting the measured cavity length versus

$L_c/c$) can be modelled using (3.8), which is obtained by fitting the measured cavity length versus ![]() $\psi _e$ of the SS hydrofoil:

$\psi _e$ of the SS hydrofoil:

where ![]() $e$ is required for the calculation of

$e$ is required for the calculation of ![]() $\epsilon$ in (3.6), and is the normalized distance from the midchord to the CP, as defined in figure 1. Experimental measurements suggest that

$\epsilon$ in (3.6), and is the normalized distance from the midchord to the CP, as defined in figure 1. Experimental measurements suggest that ![]() $e$ is a function of

$e$ is a function of ![]() $L_c/c$ and can be expressed in terms of

$L_c/c$ and can be expressed in terms of ![]() $\psi _e$:

$\psi _e$:

where ![]() $e_{FW}=0.26$ is the normalized CP from the midchord in fully wetted flow. Equation (3.9) is obtained by curve fitting the measured CP location of both the SS and CF hydrofoils, as shown later in figure 12.

$e_{FW}=0.26$ is the normalized CP from the midchord in fully wetted flow. Equation (3.9) is obtained by curve fitting the measured CP location of both the SS and CF hydrofoils, as shown later in figure 12.

Defining the fluid stiffness terms as ![]() $K_f^{\delta \theta }=-a_o^{3D}qscS_g$ and

$K_f^{\delta \theta }=-a_o^{3D}qscS_g$ and ![]() $K_f^{\theta \theta }=-a_o^{3D}\epsilon qsc^{2}S_g$, (3.4) can finally be rewritten as follows with all the terms dependent on the unknown tip deformations (

$K_f^{\theta \theta }=-a_o^{3D}\epsilon qsc^{2}S_g$, (3.4) can finally be rewritten as follows with all the terms dependent on the unknown tip deformations (![]() $\delta$ and

$\delta$ and ![]() $\theta$) on the left-hand side:

$\theta$) on the left-hand side:

\begin{equation} \left( \begin{bmatrix} K_s^{\delta \delta} & 0 \\ 0 & K_s^{\theta \theta} \end{bmatrix} + \begin{bmatrix} 0 & K_f^{\delta \theta} \\ 0 & K_f^{\theta \theta}\end{bmatrix} \right) \begin{bmatrix} \delta \\ \theta \end{bmatrix} = \begin{bmatrix} F_{N,R}=a_o^{3D} \alpha_o q sc \\ F_{P,R}^{EA}=a_o^{3D}\epsilon \alpha_o q sc^{2} \end{bmatrix} , \end{equation}

\begin{equation} \left( \begin{bmatrix} K_s^{\delta \delta} & 0 \\ 0 & K_s^{\theta \theta} \end{bmatrix} + \begin{bmatrix} 0 & K_f^{\delta \theta} \\ 0 & K_f^{\theta \theta}\end{bmatrix} \right) \begin{bmatrix} \delta \\ \theta \end{bmatrix} = \begin{bmatrix} F_{N,R}=a_o^{3D} \alpha_o q sc \\ F_{P,R}^{EA}=a_o^{3D}\epsilon \alpha_o q sc^{2} \end{bmatrix} , \end{equation}

where ![]() $F_{N,R}$ and

$F_{N,R}$ and ![]() $F_{P,R}^{EA}$ are the mean hydrodynamic normal force and pitching moment about the EA for an equivalent rigid hydrofoil at a geometric angle of incidence of

$F_{P,R}^{EA}$ are the mean hydrodynamic normal force and pitching moment about the EA for an equivalent rigid hydrofoil at a geometric angle of incidence of ![]() $\alpha _{o}$.

$\alpha _{o}$.

3.2. 1-DOF dynamic FSI model

As will be shown later in § 4, the mean tip twist deformation, ![]() $\theta$, is negligible for the SS hydrofoil and very limited (

$\theta$, is negligible for the SS hydrofoil and very limited (![]() $\theta <1^{\circ }$) for the CF hydrofoil because of the high stiffness of the small-scale models. In addition, as shown in table 3, the fully wetted twisting modal frequency,

$\theta <1^{\circ }$) for the CF hydrofoil because of the high stiffness of the small-scale models. In addition, as shown in table 3, the fully wetted twisting modal frequency, ![]() $\,f_{n2,FW}$, is much higher and well separated from the fully wetted bending modal frequency,

$\,f_{n2,FW}$, is much higher and well separated from the fully wetted bending modal frequency, ![]() $\,f_{n1,FW}$. Moreover, the twisting modal frequency in water is also higher than the fundamental natural frequency of the force balance,

$\,f_{n1,FW}$. Moreover, the twisting modal frequency in water is also higher than the fundamental natural frequency of the force balance, ![]() $\,f_{FB}=122$ Hz, used to measure the normal force and pitch moments. Hence, a 1-DOF model is used to simulate the bending fluctuations of the hydrofoils only. The twisting vibrations were neglected, as they were contaminated by the force balance natural frequency.

$\,f_{FB}=122$ Hz, used to measure the normal force and pitch moments. Hence, a 1-DOF model is used to simulate the bending fluctuations of the hydrofoils only. The twisting vibrations were neglected, as they were contaminated by the force balance natural frequency.

The tip bending fluctuations (![]() $\delta ^{\prime }$) are defined as the mean tip bending (

$\delta ^{\prime }$) are defined as the mean tip bending (![]() $\delta$) subtracted from the instantaneous tip bending displacement (

$\delta$) subtracted from the instantaneous tip bending displacement (![]() $\tilde {\delta }$):

$\tilde {\delta }$):

Following the same decomposition as explained above, the equation of motion for the bending fluctuations can be written as follows:

where ![]() $M_s=f_{ms}\rho _s c^{2} s \tau _c$ and

$M_s=f_{ms}\rho _s c^{2} s \tau _c$ and ![]() $C_s$ are the effective structural mass and damping, respectively,

$C_s$ are the effective structural mass and damping, respectively, ![]() $\rho _s$ is the solid density as given in table 1,

$\rho _s$ is the solid density as given in table 1, ![]() $\tau _c=0.09$ is the maximum thickness-to-chord ratio for the modified NACA0009 cross-section,

$\tau _c=0.09$ is the maximum thickness-to-chord ratio for the modified NACA0009 cross-section, ![]() $\,f_{ms}=0.334$ is a constant shape factor that is the same for both the SS and CF hydrofoils, and

$\,f_{ms}=0.334$ is a constant shape factor that is the same for both the SS and CF hydrofoils, and ![]() $K_s=K_s^{\delta \delta }$ is the effective structural bending stiffness. The values of

$K_s=K_s^{\delta \delta }$ is the effective structural bending stiffness. The values of ![]() $M_s$ and

$M_s$ and ![]() $K_s$ are given in table 3, and

$K_s$ are given in table 3, and ![]() $C_s$ is assumed to be zero for the sake of simplicity, as structural damping is typically negligible compared with fluid damping. Experimental measurements of the structural damping coefficients (

$C_s$ is assumed to be zero for the sake of simplicity, as structural damping is typically negligible compared with fluid damping. Experimental measurements of the structural damping coefficients (![]() $\zeta _s=C_s/2\sqrt {K_sMs}$) of different composite, aluminium and PVC hydrofoils were found to be between 1 % and 2 % (Phillips et al. Reference Phillips, Cairns, Davis, Norman, Brandner, Pearce and Young2017; Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020). However, the fully wetted damping coefficients for the first (bending) mode were more than an order of magnitude higher than the structural damping coefficients according to experimental measurements presented by Blake & Maga (Reference Blake and Maga1975), Phillips et al. (Reference Phillips, Cairns, Davis, Norman, Brandner, Pearce and Young2017) and Harwood et al. (Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020).

$\zeta _s=C_s/2\sqrt {K_sMs}$) of different composite, aluminium and PVC hydrofoils were found to be between 1 % and 2 % (Phillips et al. Reference Phillips, Cairns, Davis, Norman, Brandner, Pearce and Young2017; Harwood et al. Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020). However, the fully wetted damping coefficients for the first (bending) mode were more than an order of magnitude higher than the structural damping coefficients according to experimental measurements presented by Blake & Maga (Reference Blake and Maga1975), Phillips et al. (Reference Phillips, Cairns, Davis, Norman, Brandner, Pearce and Young2017) and Harwood et al. (Reference Harwood, Felli, Falchi, Garg, Ceccio and Young2020).

The ![]() $F_N^{\prime }$ in (3.12) is the fluctuating normal hydrodynamic force, which is linearly decomposed into a component associated with unsteady cavity shedding on an equivalent rigid hydrofoil,

$F_N^{\prime }$ in (3.12) is the fluctuating normal hydrodynamic force, which is linearly decomposed into a component associated with unsteady cavity shedding on an equivalent rigid hydrofoil, ![]() $F_{R}^{\prime }$, and a component arising from the FSI,

$F_{R}^{\prime }$, and a component arising from the FSI, ![]() $F_{FSI}^{\prime }$:

$F_{FSI}^{\prime }$:

where ![]() $\hat {M}_f$,

$\hat {M}_f$, ![]() $C_f$ and

$C_f$ and ![]() $K_f$ are the fluid inertial, damping and disturbing force terms in phase with the fluctuating bending acceleration, velocity and displacement, respectively, and

$K_f$ are the fluid inertial, damping and disturbing force terms in phase with the fluctuating bending acceleration, velocity and displacement, respectively, and ![]() $C_N^{\prime }$ is the fluctuating normal force coefficient for the flexible hydrofoil.

$C_N^{\prime }$ is the fluctuating normal force coefficient for the flexible hydrofoil.

By moving the FSI forces to the left-hand side, (3.12) can be rewritten as follows:

Because only the bending DOF is considered, ![]() $K_f=0$ according to (3.10) and potential flow, i.e. pure bending or heave displacement perpendicular to the flow, does not affect the normal force.

$K_f=0$ according to (3.10) and potential flow, i.e. pure bending or heave displacement perpendicular to the flow, does not affect the normal force.

The fluctuating normal force arising from unsteady cavity shedding on a rigid hydrofoil can be modelled as simple sinusoidal oscillations at the cavity shedding frequencies:

where ![]() $\,f_{c1}$ and

$\,f_{c1}$ and ![]() $\,f_{c2}$ are the Type I shock-wave-driven and Type II re-entrant jet-driven cavity shedding frequencies, respectively,

$\,f_{c2}$ are the Type I shock-wave-driven and Type II re-entrant jet-driven cavity shedding frequencies, respectively, ![]() $\phi _1$ and

$\phi _1$ and ![]() $\phi _2$ are random phase variations between

$\phi _2$ are random phase variations between ![]() $0$ and

$0$ and ![]() ${\rm \pi}$, and

${\rm \pi}$, and ![]() $C_R^{\prime }$ is the fluctuating normal force coefficient for an equivalent rigid hydrofoil. The cavity oscillation force is typically not exactly a sinusoid, but rather a biased wave form with a longer cavity growing process than the breakdown process. However, a sinusoid is used as it is the simplest and lowest order function that captures the dominant frequency. This is desired as there are two cavity shedding frequencies, one associated with the re-entrant jet and the other with the shock-wave. A more complicated wave form would require more empirical coefficients.