I Introduction

The aim of any liability regime is twofold: (1) in the event of an accident the victim shall receive fair compensation; and (2) the liability regime shall allocate responsibilities along the value chain from the producer towards the consumer.Footnote 1 The producers and consumers shall be incentivised to take due care, thereby implementing the optimal care level. Under ideal circumstances a liability regime leads to optimal deterrence of producing or selling defective products. Hence, the socially optimal amount of defective products will be sold.Footnote 2

While liability regimes around the world may differ in detail, it is safe to say that they have always adapted to the technical givens and societal circumstances relevant at a specific moment in time.Footnote 3 Over the last hundred years we see as a general pattern that mass manufacturing led first to the legal innovation of organisational liability and later to mass torts in which whole industries became liable (eg asbestos cases).Footnote 4 Moreover, in the European Union the Product Liability Directive from 1985 accomplished not only the protection of consumers to a high standard, but the Directive also helped to fulfil the Single Market by creating a level playing field and the enforcement of fair competition.Footnote 5

In the past the developments in liability law were challenging mainly from a doctrinal legal point of view. The single developments built upon each other and could rely on an analytical framework in which it was clear who the producers and who the consumers were.Footnote 6 There was also certainty about the properties of the production technology (value chain) and whom to hold responsible in case of wrongdoing. This is also true for the economic analysis of tort law, which requires for an optimal allocation of liability that the single steps in a value chain can be identified and the decision makers at each step in the value chain can be incentivised accordingly.

However, the clear definition of value chains is no longer the case in a world of big data, artificial intelligence and 3D printers.Footnote 7 The new technologies create legal disruptions which make it necessary that jurisdictions reconsider their liability regimes and replace (if necessary) incumbent laws, regulations and procedures.

3D printing technology is a disruptive technology that produces an object layer by layer instructed by a digital file (ie the CAD file).Footnote 8 3D printing was invented in the 1980s, but only in recent years has it been – due to powerful ICT infrastructures – embraced by professional and occasional users. 3D printing has been successfully applied in industrial manufacturing (eg tailor-made ship propellers), medicine (eg artificial hip joints and tissue), toys (eg LEGO bricks), household replacement parts and food (eg pizza) to name only a few applications. In parallel with the technological development and diffusion of 3D printing, specific business models of 3D printing became established. Various electronic platforms give users the access to CAD filesFootnote 9 as well as 3D printersFootnote 10 around the world. While this new technology opens the door to new advanced products with sheer unlimited local availability, it also creates risks and possible harm for users and consumers.

In the following we will highlight the principal challenges that unfold through digitisation for liability regimes in the case of 3D printing. The case of 3D printing is iconic for a better understanding of how far new technologies disrupt our traditional understanding of applying liability law. Our main focus will be on the argument that in the digital world value chains are no longer linear, and as a consequence the informational content associated with a specific step in the value chain becomes blurred. This leads ultimately to a failure when targeting potential wrongdoers. At the end of our contribution we will sketch out an institutional framework within which law and regulations could be further developed to guarantee socially desirable product safety standards, insofar as our article also contributes to the more general question of how a framework for digital governance might look.

II The blurred producer-consumer divide

In incumbent liability regimes it is (rightly) assumed that there is a clear cut distinction between producers and sellers on the one hand and consumers on the other hand.Footnote 11 Indeed, in traditional production regimes value is added along a linear supply chain, and a significant feature of linear supply chains is the division of producers and consumers. As a result we get clear cut roles along the value chain: Producers, sellers and consumers. They can all be separately identified.

Liability regimes typically target producers because they are the ones who profit mostly from business, who can pay out compensation and who – most importantly – are the ones who can make the product safer, with the help of research and development.Footnote 12 Moreover, producers have typically a (large) production site which makes it possible to physically spot the issuer of a defective product and to enforce liability law and safety standards.

In the world of new digital technologies the distinction between producers and consumers is fading away. Some already speak of the prosumer as a new category.Footnote 13 This makes it far more complicated to target the manufacturer of a defective product, which makes the incumbent tort law ultimately a blunt sword to reach optimal safety.

For example, a hobbyist software programmer may engage in co-drafting an open-source CAD file for 3D printing and share the code on a platform.Footnote 14 Afterwards the hobbyist programmer uses the CAD file for 3D printing by herself, and others use the CAD file for commercial purposes. If the CAD file has a bug that leads to accidents, is it then the hobbyist programmer who can be held liable? Or, a hobbyist creator of 3D printed gadgets prints out replacement parts for an espresso machine. With those replacement parts he improves his espresso machine at home. But he also sells a couple of those parts via the internet. Unfortunately the sold parts let the coffee machines explode. Is the hobbyist printer who sold the parts via the internet liable according to product liability?

In both cases it is questionable whether the hobbyist programmer and the hobbyist printer are strictly liable according to product liability, because they are also consumers and have no essential business or financial interest in the activity (besides the fact that the EU Product Liability Directive would not be applicable to software anyway).Footnote 15 Nevertheless, the activity may unfold quite a large impact on business activities. An open source CAD file may become popular for 3D printing and may create widespread potential harm. One need only think about 3D printed LEGO bricks that injure children.

But even if one were of the opinion that the hobbyist 3D printers and CAD file creators can be made strictly liable under incumbent liability law by, for example, amending the EU Product Liability Directive, the two primary goals of liability law would not be accomplished:Footnote 16 (1) typically hobbyist creators or producers do not have the funds to pay compensation to victims as companies do; (2) the deterrence of the liability regime will not and cannot incentivise the hobbyists to engage in systematic research and development, in order to improve product safety, as is the case with companies. Households have typically no research and development department. That means the two main reasons for the incumbent liability law no longer work, because the divide between consumers and producers is fading away in the realm of digitisation.

As a result, the blurred divide between producers and consumers leads to a situation in which it becomes even more important for the lawmaker to establish a regime of product liability that identifies causers of harm and can set proper incentives to bring damages on an optimal level. In the following sections we will identify more closely the disruption of the value chain as the main trigger for these problems.

III The challenge of disrupted value chains for liability

New technologies are constituent for the Internet of Things, Smart Factory or Industry 4.0. The basic idea of these concepts is that manufacturing becomes self-organising, in the sense that all parts involved in manufacturing are communicating with each other, making it possible for tailor-made products to become available at low cost.Footnote 17 The digital infrastructure becomes an enabler to import and export relevant data worldwide. In one country a smart algorithm produces a CAD file which is then directly sent to a 3D printer in another country, where the printed product can be sold instantly.Footnote 18

This example hints at a couple of legal challenges. With regard to liability regimes two issues have the foremost role: law enforcement and safety. The law enforcement problem originates because 3D print technology no longer needs a large production site to produce at low costs, and the product design, the digital CAD file, is independent from the place of printing.Footnote 19 As a consequence small 3D printers may be located at remote places printing out exact copies of a CAD file that has been created at another remote place in the world. The remoteness of creation and production makes it inherently challenging to spot any kind of legal infringement and to enforce legal claims against CAD file creators or 3D printers.Footnote 20 It becomes nearly impossible to trace back to find the perpetrator of an accident and to claim compensation along the contractual relations between the single steps in the value chain.Footnote 21

With regard to safety, the disruption of value chains creates further challenges for society. This is because digital files in combination with 3D printers no longer require the production of intermediate goods which can be physically controlled along the value chain. There are no longer specialised (and maybe certified) sellers of intermediary goods, or retailers which may even have an obligation to insure their business.Footnote 22 Instead a CAD file may go directly from an open source platform to a household that has access to a 3D printer without any contractual formalisation.Footnote 23 More extremely, 3D printing circumvents explicit safety measures, as for example border controls in a harbour. A CAD file can directly go to a 3D printer at a remote place where innocuous raw material becomes transformed into a weapon. This reduces considerably the possibilities for authorities to control or prevent the manufacture of weapons and other hazardous products.Footnote 24

Beyond the mentioned liability and safety issues there are other challenges which underscore the disruptive effect of 3D printing on traditional value chains. One of those challenges is that having less – or even no – intermediate goods in manufacturing implies that there is also less need for shipping (intermediate) products.Footnote 25 As a consequence harbours will possibly play a smaller role for the transhipment of (intermediate) products. At the same time the shipping of raw materials for feeding 3D printers will become more important.Footnote 26 In addition, governments are making revenue by imposing value added tax (VAT) and tariffs on goods, corresponding to the added value of each step in the value chain. But in case of 3D printing it is no longer clear when and where the taxable added value has been created.Footnote 27 Is it the creation of the CAD file (in one country) or is it the 3D printout (in another country) that creates value and accordingly the tax base? If the creation of the CAD file and the 3D printout belong separately to two countries, it is by no means clear to which country the revenue from VAT or tariffs belongs and how value creation can be metered. In any case the disruption of value chains through 3D printing will make it necessary to come up with new tax revenue sharing rules between countries.

IV Safety, liability and the information context of production systems

In the foregoing sections we pointed to two disruptive features of 3D printing which make it difficult to apply the traditional mode of liability rules to 3D printing as well as to maintain the incumbent economic rationality behind the design of liability rules. Thereby the disruption stems from the blurred distinction between producers and consumers on the one hand and from the disbanding of traditional value chains on the other hand.

In this section we will dig deeper into the underlying causes why the application of traditional liability rules in case of 3D printing cannot achieve the two goals of liability regimes: fair compensation and optimal deterrence. It will be shown that this is due to the informational scarcity of 3D printing which makes it very difficult to spot the causer of an accident as well as to set optimal incentives for preventing failures.

1 The disclosure of safety information under modern mass production

Economies of scale are key to competitive advantage in domestic as well as in international trade.Footnote 28 Spreading fixed costs and reducing variable costs by expanding the production scale allows the average costs of production to be brought down and thus to make production processes more profitable. This is standard economic wisdom since Adam Smith’s famous pin factory example.Footnote 29 To be sure, in reality the realisation of economies of scale depends on the concrete case, and also the associated market structures that materialise on a continuum between perfect competition on the one hand and the natural monopoly on the other hand.Footnote 30

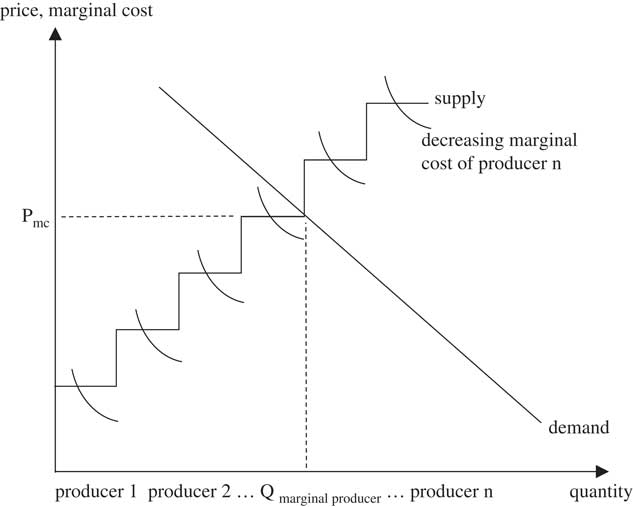

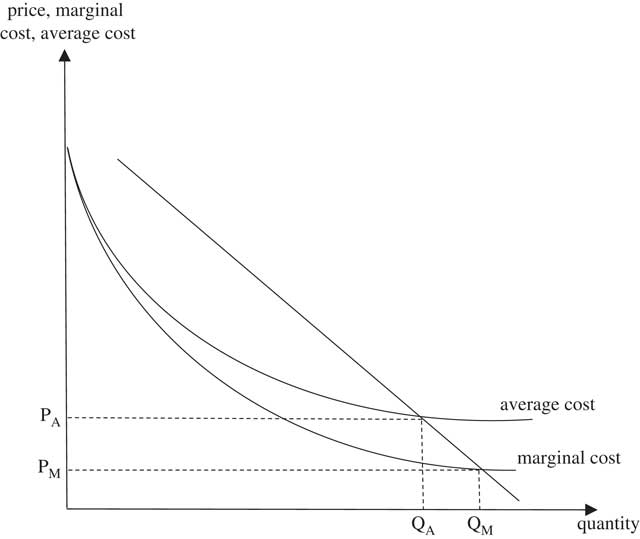

Yet, what is important here is that over the whole continuum of market structures the same economic logic applies: it pays for the manufacturer to bring costs down according to economies of scale. In terms of industrial organisation the model of perfect competition describes then a competitive market in which firms are distinguished from each other according to their ability to bring down marginal costs compared to the so-called marginal producer, which makes no profit anymore (see Figure 1). At the other end of the continuum, the natural monopoly describes a situation in which only one firm can provide the product at the lowest cost level (see Figure 2). The natural monopolist is highly visible within the economic landscape and is typically the target of all kinds of regulatory measures to prevent a distortion of social welfare (see for example the regulation of public utilities with grid infrastructures).

Figure 1 Marginal cost step function under perfect competition

Figure 2 Natural monopoly

Under perfect competition as well as in case of natural monopoly a linear value chain is established. Bulk orders received from downstream distributors and retailers make it profitable to reap the benefits from economies of scale.Footnote 31

A linear value chain implies two important characteristics which are necessary for the workability of incumbent liability law. The first is that the product design, or the basic idea of the product, is closely related to the firm that manufactures and/or distributes the product. The product idea is the scarce resource that drives the firm’s success on the market; it creates the firm’s brand and largely determines the firm’s value as well as the firm’s strategy.Footnote 32 The close relation between the product design and the manufacturing of the product in one firm within the nexus of contracts provided by company law allows the identification of the producer/seller of a specific defective product. The second characteristic is that value chains are established through vertical contracts. For example, a firm receiving a bulk order from downstream retailers will negotiate a better price from upstream input material vendors and may employ more advanced machines to enjoy the benefits from economies of scale. Hence the assembly of the product in a firm under a brand name creates a web of upstream and downstream contracts that allows the pinpointing of a potential trigger of a product failure vis-á-vis the user or consumer of the product. This way, under incumbent liability law, upstream cascades of liability build up, which unfold the right amount of deterrence against producers and sellers bringing defect products to the market.

2 Scarcity and information – the proper scope of traditional liability law

Going analytically a step further, it is the information richness of traditional manufacturing (linear value chains) which makes it possible to detect a specific wrongdoer and at the same time to incentivise the prevention of product failure. Since it is typically firms that produce and sell products, there are legal entities in play that have the means to prevent defective products by systematic research and development. In addition, firms have the capacity to pay out compensation by contracting with appropriate insurance companies and to diversify the risk by producing different products.Footnote 33

Thus the information needed to spot a wrongdoer and to achieve deterrence through liability law stems from the traditional way of organising production, ie the organisation of production in (large) firms to reap the benefits of economies of scale.

This is not saying that there are not all kinds of informational asymmetries around that can hinder (intermediate) producers or consumers from making efficient decisions. However, it can be expected that competition between producers in combination with smart regulations will ultimately pull out products that are on an efficient safety level.

More concretely, for the background of linear value chains a proper legal logic has unfolded, which efficiently allocates risks and responsibilities along the value chain. Here only some basic features of this logic are described, to make the differences clear when compared to a world of 3D printing.

The regime of product liability distinguishes between two generic features: (1) contracted damages; and (2) non-contracted damages. With regard to contracted damages, sales contracts play an important role in combination with product warranties. A possible damage is then compensated to the extent that the warranty foresees. Since those sales contracts are voluntarily signed, they are in the interest of the seller and buyer and therefore efficient.Footnote 34 However, sales contracts are insufficient to bring safety to an optimal level in cases where informational asymmetries are present or bargaining is impossible.Footnote 35 In the latter case the damage is not contracted and is involuntary. For example, a defective car may injure pedestrians, who are not contracted to the car driver or to the manufacturer of the car. The car driver has driven correctly and was not aware that the car was defectively manufactured. In such cases, tort liability is expected to improve product safety, because it makes the manufacturer liable for having sold the defective product. Tort liability imposes the obligation to compensate victims that are not contracted to the tortfeasor. Other (more complex) cases of non-contracted damages can be construed, where a keen eye along the linear value chain helps to determine which party shall be held liable to bring the care level and the activity level of the involved parties as close as possible to economic optimality.

This logic has also been applied by the EU to a large extent. Since the 1960s, with the establishment of the common market, strict product liability has been gradually introduced in Europe to achieve a level playing field between European manufacturers and to reap the benefits of mass production and competition in a common market.Footnote 36 In 1985, the European Product Liability Directive (EPLD) formally established strict product liability in the EU.Footnote 37 The economic rationale behind the introduction of strict liability is that (on average) it supports the goal of efficiency better than other liability rules.Footnote 38

While negligence liability puts the residual liability on consumers, strict liability puts it on the manufacturers. The determination of which party is better suited to be the residual liability bearer depends on who can avoid the accident at the cheapest cost.Footnote 39 Since economies of scale determine largely economic success, firms are regarded as the cheapest cost avoider.Footnote 40 Firms have the expertise as well as advanced machinery to detect and avoid product failures. Moreover, firms control distribution channels and can thus stop the proliferation of defective products.Footnote 41 Finally, compared to consumers firms have a deeper pocket and diverse means of (self-)insurance to bear financial loss.Footnote 42 Therefore, it is reasonable to impose residual liability on manufacturers, and to incentivise them in this way to take the necessary precautions against defective products.

Imposing strict liability on producers also supports the proper identification of product risks by consumers when the product quality cannot fully be assessed. In a competitive market the product price is considered as an important signal to estimate the risk of the product.Footnote 43 Assuming that consumers have at least some knowledge about the product that they intend to buy, then they can trace back from the price the likely precautions undertaken by the manufacturer as well as the expected harm in case of an accident. But even where consumers cannot correlate the product quality with the price level, strict liability sets the most appropriate incentives for the producer to undertake precautionary measures.Footnote 44 That is simply because under strict liability the manufacturer bears the loss whenever an accident occurs. Hence producers will strive to minimise accident costs by targeting the optimal care level as well as activity level. Therefore, even if consumers misperceive the risk of a product through a lack of information, on average they can make proper choices according to market prices.Footnote 45

Besides the (ex post) threat of being held liable in a law suit, specific safety regulations can be employed in order to determine (ex ante) the quality standard of a product. A certain product may only be sold if it fulfils the requirements set by a governmental agency. This is the case, for example, with pharmaceuticals, but also certain professional services may only be offered by certified persons and agencies.

At first glance the setting of specific regulations for product qualities and quantities seems to be an easy way to control product risks. But that is not the case. Quite often it is not clear what the efficient regulation would be, and typically no room is left to deviate to cheaper regulations, ultimately ignoring the diverse preferences of consumers. Moreover, producers and lobby groups may have a strong interest in pressuring the regulator to come forth with specific regulations that pay for them but not for their competitors and/or consumers. Finally, a strong organisation and proper processes are needed to enforce safety regulations. In this regard in recent years the EU has empowered its institutions and in 2008 came up with a particular mechanism called the “New Legislative Framework”, which diminishes the information problem between producers and consumers as well as authorities.Footnote 46 Within this framework market surveillance is centre stage. It comprises a close monitoring of supply chains and the distribution of products to consumers. Whenever an unsafe product is identified, withdrawals and recalls will be enforced to put relevant products out of the market.Footnote 47 In order to ensure information is exchanged rapidly among different authorities, specific regimes like ICSMSFootnote 48 and RAPEXFootnote 49 have been established. In addition, the EU prescribes a couple of information disclosure mechanisms for producers and sellers. A well-known quality label is, for example, the CE certification mark, which states that the product conforms to actual product regulations.Footnote 50

What is important here is that according to the linear value chains of production a complementary regime of laws and regulations has emerged that facilitates not only the market transactions between producers and consumers but also supports the differentiation and specialisation within value chains and the reaping of economies of scale. It does not need much imagination to envisage the disruptive forces on the legal framework if the traditional mode of production within linear value chains collapses. In the event that economies of scale play less of a role for production, then the informational content associated with a specific stage of production will decrease and the applicability of incumbent liability law and safety regulations will become much harder to establish, if not impossible.

3 The end of scarcity and the informational deficits in a world of 3D printing

Different from traditional manufacturing, value creation in 3D printing is not driven by economies of scale.Footnote 51 One author even speaks vividly about a “World without Scarcity”, when a digital design can be used at any place in the world at the same costs for any quantity of production.Footnote 52

More specifically, using 3D printing technology means that the same amount of raw material is always consumed at the same cost level of combined production factors, whereby the combination of production factors is mainly the 3D printer itself.Footnote 53 Hence, if there is any cost reduction in the production process then it is because of lower prices for raw material, a better printer technology or a better digital design (incorporated in the CAD file). Input costs are not unique for a specific company engaged in 3D printing, but industry wide are more or less the same. Also entrepreneurial spirit plays only a minor role when the CAD file and a given printer technology exclusively determine the final product.Footnote 54 In addition, variants of the basic product can easily be printed out without incurring much extra cost. In this regard value is created not by expanding the production scale to get cheaper products, but through producing a more heterogeneous set of products at the same cost level. Thus, with the help of 3D printing, demand from the niche market – no matter how small it is – can be served.Footnote 55

Since in 3D printing economies of scale no longer play a role for capturing value, factors like the lack of advanced machinery, the absence of an effective organisational firm structure or a lack of bargaining power are no longer barriers for a new producer to enter the market.Footnote 56 Also the market exit costs are low when it is easy to react to shifts in demand. Therefore more market entries are possible and actual and potential competition is high. In addition, as mentioned before, the distinction between consumers and producers is blurred when 3D printers become available for households or if hobbyists can co-create CAD files.

As a result 3D printing has broken up linear value chains and has replaced it with a more decentralised or multicentred web of value creation.Footnote 57 This is mainly because of the decoupling of (digital) design from manufacturing, in which independent designers substantially contribute to the final product by providing the product idea.Footnote 58 On the other hand, due to the low market entry threshold, individuals or firms with or without knowledge of manufacturing can engage in designing or manufacturing 3D printed products. The organisation of the activities works via online platforms, replacing a linear value chain with a decentralised web of value creation. Value is created by serving heterogeneous demands instead of bringing down costs by economies of scale.Footnote 59

In summary, in 3D printing: (1) the product design is decoupled from manufacturing; (2) the production process becomes highly standardised; (3) the distinction between producer and consumer is blurred; and (4) the organisation of the activities takes place at online platforms. As a result the information needed to trace the source of a defective 3D printed product becomes very difficult to find. In other words, 3D printing produces only light or no footprints at all, which makes it demanding to identify a culprit in case of harm, damage or wrongdoing.

The technical conditions under which 3D printing takes place translate economically into an extreme form of perfect competition in which it is not possible to distinguish between the atomistic suppliers, because all firms produce at the same marginal cost level. In addition, it is not always possible to separate consumers from producers. The market participants can take over both roles simultaneously or switch between them easily.

The replacement of linear value chains by value creating webs of design and manufacturing in combination with the irrelevancy of economies of scale has a disruptive effect not only on incumbent production processes but also on the incumbent legal frameworks guiding and facilitating manufacturing and trading.

The scarcity of information about identifying the source or cause of a defective product increases misperceptions by consumers and public authorities when they try to adapt to the potential risks associated with a 3D printed product. Additionally, informational scarcity makes it challenging to target liability rules at those who could efficiently prevent damages. In other words, the incentive logic of traditional tort law begins to falter.

V Legal disruptions and the way ahead

In this section we will highlight the legal disruptions which are triggered by 3D printing technology. Our focus will be on liability law and safety regulation. But it is clear that also other legal areas are impacted by this new technology. Intellectual property rights, especially, are challenged when it becomes possible that identical copies of a product can be printed out at remote places.Footnote 60 This leads to the quite fundamental question, asking under which circumstances it may make sense to protect copyrights, patents and trademarks at all, because maintaining high legal fences against infringers becomes very costly for society when digitalisation conquers more and more fields in which human creativity plays a decisive role. Would it not be smarter to employ other means than property rights to compensate inventors?

1 A rugged legal landscape: scale, organisation and contract

If there are economies of scale in production then this has a quite huge effect on the application of law. More precisely, the more economies of scale that are exploited in a production process, the bigger the production site has to become. This typically goes hand in hand with a higher degree of division of labour and more elaborate organisational firm structures reflected in company law. This makes it easy to distinguish between producers and consumers.

For law enforcement it means that the producer of a defective good is physically visible. There is a production site that can be spotted on a map. Even though the production might be at a remote place in the world it can be located and, if necessary, prosecuted. There might well be intriguing international law problems involved in enforcing a legal title, but this is more of a practical problem than one of principle.

In a world of 3D printing law enforcement becomes challenged. The production of a defective product is no longer associated to a physically visible production site.Footnote 61 To make an extreme case: a household at a remote place prints out a considerable number of weapons. This dangerous activity is close to invisible and enforcing a stop of production may take a while, even though there might be international consent to stop the proliferation of 3D printed weapons. A different case, but with similar effect, emerges when the trigger of the defective product is a failure in the program code of the CAD file that has been downloaded from a platform anonymously a thousand times. Independently from the question of what the responsibilities of the platform here might be, it can become very challenging to trace the programmer(s) of the defective code (this is even more a problem if it is an open source code).Footnote 62

Traditionally the very idea of a product determines the success of a firm. It is not necessary that the product design and manufacturing are vertically integrated in one company, and other contractual relations are possible.Footnote 63 But the strategic direction of the value-creation process of the product is in one hand, in order to accrue the profit for the inventor.Footnote 64 As a result, it is reasonable to target firms with strict liability and to expect that firms become optimally deterred from selling defective products, meaning they will bear prevention costs on a socially efficient level.Footnote 65 Firms thus have an incentive to invest in research and development and to come up with safer products.

3D printing breaks up the strategic unity of product design and manufacturing. 3D printing leads to the decoupling of product design and manufacturing, implying that the assignment of liability – as in linear value chains – is no longer possible.Footnote 66 A 3D printing company as well as a hobbyist 3D printer download an appropriate CAD file from a platform. The CAD file can then be adapted or manipulated to the specific needs of the user. The users may have very different capabilities, resources and inclinations to do those manipulations competently.Footnote 67

Unlike risk management under a unitary organisational structure and central strategic direction, a manufacturer of 3D printed products has to take extra efforts to discern the potential risks embedded in the product design. It is questionable whether a manufacturer of 3D printed products will bear those costs.

The CAD file typically comes from a platform which functions as an intermediary for the distribution of the CAD file. The platform does not work as a monitor or guarantor of the quality of the CAD file. That means that even if liability law were targeted at the manufacturer of the 3D printed product, it would not trigger the incumbent logic. A hobbyist printer typically does not have the technological expertise to assess the risk inherent to a specific CAD file. Neither does he or she have the means to run a research and development department to calibrate prevention costs with the potential profits of an improved product. Moreover, individuals and companies can hardly convey the need for improving a CAD file to a platform where very diverse contributors of CAD files meet (anonymously) with each other. To put it differently: an internet platform is an intermediary, and not a sort of research and development department that works under the strategic direction of a boss who has a specific entrepreneurial product idea. For that background it is worthwhile for future research to further explore the role of platforms and to elaborate on their legal design, which possibly should go beyond that of a pure intermediary.

Hierarchy within an organisation is one possibility by which to direct production processes; using the market and contracts is another, to give strategic direction to production processes. In a world of 3D printing contracts do not disappear, but they do not play a central role for the organisation of production. Hence contracts have only a small impact for the control of risks.Footnote 68 Again, this has to do with the decentralised value creation organised via platforms.

Product designs are not developed in specialised research and development centres of firms but put on online platforms for download and possible further improvement, regardless of their origin (households, firms, universities etc). From those platforms users retrieve (anonymously) the CAD file without specifying in a contract what the specific obligations of the user and the platform are. Furthermore, there might be no contractual relationship between the CAD file designers and the manufacturers. Designers place the CAD file online by registration, without substantive review from the platform. The user will only get a safety warning or specification by coincidence, and this information may come from a different source than the platform. For that background the contractual relationship – if there is one at all – becomes empty and it is not a suitable means to tackle product safety issues. As a result platforms claim to be a marketplace for supply and demand but not a contractor and they deny any responsibilities for potential harm. Only where a platform knows or becomes informed that a harmful 3D print design is exchanged on the platform does it have to take steps and remove it according to EU law.Footnote 69

Without sequential contractual relationships along the supply chain 3D printing exposes end-consumers or end-users to large risks. On the one hand online platforms have no incentive to acquire information about product risks from designers and manufacturers, because yet they are not contracted to their customers.Footnote 70 On the other hand, without a formal contractual relationship instituting certain liabilities the identification of specific designers and manufacturers becomes nearly impossible.Footnote 71 Admittedly, online platforms bring designers, manufacturers and consumers directly into contact and they may have the chance to identify each other. However, without sequential contracting in a linear supply chain the risk allocation remains doubtful and the deterrent provided by tort law becomes blunt, especially in a cross-border setting. Future research may come up with proposals for how to rectify the contractual deficits associated to online platforms for CAD files, but for the moment safety issues cannot be tackled within contracts.Footnote 72

The shifts in scale, organisation and contracts leave us with a rugged legal landscape. 3D printing has not only a disruptive effect on the incumbent legal routines which guarantee fair compensation for victims, it also fails to fit into the tort law logic where strict liability of producers leads to optimal deterrence of harmful products. Therefore it comes as no surprise that in summer 2018 the European Commission formed an expert group (Expert Group on Liability and new technologies) to assess the disruptive impact of new technologies on liability issues.Footnote 73 The aim of this expert group is to come up with ideas on how a new product liability directive might look, which take into account the legal disruptions triggered by new technologies.Footnote 74

2 The institutional framework for finding new legal solutions – digital governance

In this article we have identified the technological and economic drivers of 3D printing and their impact on liability law. We could show that the application of incumbent liability regimes to 3D printing becomes a tedious exercise. No one can tell at the moment how future laws and regulations must be structured in order to lift the full economic potential of 3D printing and to guarantee optimal safety for users and consumers at the same time. But what we do know is that the identified drivers are a sort of game changer; we can no longer take for granted that incumbent liability law and safety regulations induce the optimal level of precautions, nor that (fair) compensation to victims can be paid.

The main reason for the misfit between incumbent liability law and 3D printing is the lack of economies of scale which leads to a high degree of technological homogeneity between the products as well as the producers of 3D printed products, in combination with possibly small and scattered producers. The consequence is a lack of information for separating horizontally and vertically between tortfeasors along the value chain. However, the legal system needs exactly this specific information in order to target incentives for deterrence (obligation to pay compensation) at potential causers of harm. Moreover, the separation problem is amplified by online platforms which cut through the contractual relations between CAD file designers and producers. As a result, the incentive logic of incumbent tort law collapses. One can express this even more pointedly: the application of incumbent liability law will lead to improper risks for consumers and/or hindrances for the economy in exploiting the full potential of 3D printing.

Because even looking into a crystal ball will hardly help us to find appropriate laws and regulations for guiding the growing economic importance of 3D printing, in the remainder of this article we will briefly sketch out which institutions have to be brought into play to find proper legal frameworks for 3D printing. Hence, a few words about digital governance will conclude the article.

3D printing and other new technologies, for example robotics and artificial intelligence, not only have an impact on the design of national liability law and safety regulations, or on a possible new Product Liability Directive for the EU. The disruptive nature of digital technologies also gives rise to the question of which institutional setting is the most appropriate forum for a full exploitation of new technologies, such as 3D printing. Is there an appropriate digital governance structure for 3D printing and other new technologies?

The legislator is the political starting point for the design of any regulatory regime. The strength and importance of the legislator comes from its power to address new societal problems, to give them a value-laden debate and finally to give democratic legitimacy to new legal rules. Since any new liability regime needs anchorage and acceptance in society, it is essential that any rule-setting takes place in accordance with the legislator. This is even more important because the legislator can forcefully trigger or stop initiatives. On the other hand, the legislator is often prey to interest groups and has a relative lack of technical competence.Footnote 75

From this, it follows that at the level of the legislator two important things have to be managed in order to raise the likelihood that welfare-increasing laws and regulations are implemented. The first is that the legislator needs the support of (technical) experts, who can explain the ways in which a digital technology produces new risks, and how the technology will affect the incumbent legal setting. This kind of support is not easily achieved, because it is not sufficient to simply assemble engineers, economists, lawyers and other disciplines, all of whom look on the subject matter only from their own methodological and normative perspective. Instead a multi-disciplinary reflection about the chances and risks of digital technologies must be initiated. Moreover, the reflection must be comprehensible for the legislator. Otherwise it will not receive sufficient attention and the drafting of appropriate laws and regulations will be stalled. The second thing that must be managed is a societal discourse about digital technologies. In this discourse the various stakeholders and the electorate must have the opportunity to express their opinions about possible new legal designs. Entering into a sort of public discourse creates not only (extra) legitimacy, but it also serves as an early warning system for possible societal hindrances when the political process has reached the implementation stage of the new law or regulations. In other words, it helps to avoid the situation where, at a relatively late stage of the legislative process, political arguments come into play which thwart a new law that is in principle socially beneficial.

Other than the legislator, tailor-made regulatory agencies can be established for a specific purpose, for example for the regulation of robotics, artificial intelligence, 3D printing or combinations of new technologies. Those agencies are staffed with experts from the field, which are supposed to propose and monitor adequate design regulations for 3D printers. Or the agency analyses the algorithms with which CAD files are programmed. Thus, regulatory agencies are powerful tools to deal with the problems associated with specific technologies. However, they have a “permanent” lack of legitimacy, in the sense that they only gain legitimacy through the legislator who constitutes the agency in a legal act. An agency cannot, by itself, ask the electorate for legitimacy.

A legislature typically fears losing control over agencies (“mission creep”) and therefore it has a tendency to restrict their flexibility. In 3D printing and other new technologies, this leads to a trade-off: on the one hand any agency regulating a new technology needs a strong legitimacy, backed up by the legislature; on the other hand, there must be enough room for flexible regulation. A regulatory agency must react to technological dynamics and has to prevent a situation in which innovation and growth become stifled by improper and outmoded regulations. Thus, a liability regime for 3D printing must strive for sufficient regulatory openness on the one hand and legitimate control on the other hand. This goal might be better achieved by the formulation of relatively open regulatory standards than highly specific rules.Footnote 76

While legislation and regulation have effect ex ante, courts come into play ex post, when harm has already occurred. Liability law has an ex ante deterrent effect, but a case can only be brought to court after the harm has occurred. The court focuses on the risks of a technology in a specific case, and whether due care has been taken by the involved parties. The broader societal aspects of a technology play no role in the court, and courts are also bound to the law and have only limited leeway to come up with new interpretations of the law, insofar as liability law is inherently conservative. This is not necessarily a failure, because judges are neither technology experts nor social engineers. It might even become dangerous to give them too much freedom, but in the case of 3D printing and new technologies, courts may stifle innovation to the detriment of society. Therefore it seems wise to design the liability law which is applicable for new technologies in such a way that the reactive measures taken by courts do not hinder the exploitation of these technologies for society. This includes the avoidance of wrong incentives for plaintiffs’ lawyers who are out to get a “golden” settlement when new technologies enter the court room for the first time. Thus, the strategic behaviour of the courtroom should also be taken into account when new rules for new technologies are designed.Footnote 77 It is, at the moment, by no means clear what a renewed liability law might look like, or how it might perform in specific cases, but it might be handy to have an obligation for the legislator to regularly review liability law. This would strengthen the relationship and exchange between courts and the legislator, and lead to the flexibility and improvements that are much needed by a liability law that has to deal with disruptive innovations.