I. INTRODUCTION

Discovery of graphene Reference Geim and Novoselov1 led to renewed interest in layered transition metal dichalcogenides (TMDs) like MoS2, ReSe2, WSe2 and MoTe2 as well as post-TMDs like InSe, GaSe, and SnSe2 (Refs. Reference Lotsch2–Reference Zhao, Ribeiro and Eda5) for electronic as well as optical devices. Quasi-two dimensional (2D) materials like Bi2Te3, Bi2Te3, and Sb2Te3 are of great scientific interest as topological insulators as well as thermoelectric materials. Reference Hor, Richardella, Roushan, Xia, Checkelsky, Yazdani, Hasan, Ong and Cava6,Reference Boschker, Momand, Bragaglia, Wang, Perumal, Giussani, Kooi, Riechert and Calarco7 Recently, there has been an enormous number of reports of optical and electronic devices involving different 2D materials and their heterostructures either exfoliated Reference Das and Appenzeller8–Reference Haigh, Gholinia, Jalil, Romani, Britnell, Elias, Novoselov, Ponomarenko, Geim and Gorbachev11 or chemical vapor deposition (CVD) grown. Reference Lin, Lu, Perea-lopez, Li, Lin, Peng, Lee, Sun, Calderin, Browning, Bresnehan, Kim, Mayer, Terrones and Robinson12–Reference Liang, Schmidt and Jin15 Quasi-2D material superlattices (SLs) have been shown to have superior thermoelectric properties. Reference Böttner, Chen and Venkatasubramanian16,Reference Osterhage, Gooth, Hamdou, Gwozdz, Zierold and Nielsch17 Molecular beam epitaxy (MBE) of 2D materials although pioneered in early 1990s Reference Ohuchi, Shimada, Parkinson, Ueno and Koma18–Reference Hammond, Back, Lawrence, Nebesny, Lee, Schlaf and Armstrong22 has been dormant until recently. Reference Hayashi, Ueno, Saiki and Koma23–Reference Liu, Yuan, Wang, Chen, Tang, Zhang and Zhang29 Historically, strength of MBE is growth of abrupt heterostructures at lower temperatures, alloying, delta doping, and in situ monitoring of growth for monolayer control. Geim, in his paper on van der Waals heterostructures, Reference Geim and Grigorieva30 proposes a dreamscape for 2D materials where they can be stacked as lego blocks to realize various structures desirable to probe novel physics and device applications. Reference Gong, Zhang, Wang, Colombo, Wallace and Cho31 In this report we aim to show that we are a step closer to achieving that dreamscape using MBE for growing 2D and quasi-2D materials.

Heterostructures and SLs in 3D materials have opened doors for a myriad of high performance devices like heterojunction bipolar transistors, Reference McCarthy, Smorchkova, Xing, Kozodoy, Fini, Limb, Pulfrey, Speck, Rodwell, DenBaars and Mishra32,Reference Kroemer33 multi quantum well lasers, Reference Goodhue34 etc; also SLs drive home the claim that these materials can be used as lego blocks. Also, this is the first report where MBE growth of MoTe2 has been demonstrated. Due to weak bonding between Mo and arising from similar electronegativity, Reference Bernède, Amory, Assmann and Spiesser35 it has been hard to obtain MoTe2 using CVD. MoTe2 has been obtained using tellurization of e-beam deposited molybdenum films Reference Park, Yun, Kim, Park, Chae, An, Kim, Kim, Kim and Lee36 and bulk crystals by chemical vapor transport (CVT). CVT process involves use of a transport agent and also the transporting agent, usually a halogen, gets incorporated into the crystal. This incorporation is close to 1 % of the CVT grown crystal by weight, which is a very high unintentional doping from a device perspective. Reference Nitsche, Bolsterli and Lichtenstriger37 This is evident from the fact that MoTe2 grown using Te as the transport agent is p-type but when grown using Br it is n-type. Reference Bernede, Kettaf, Khelil and Spiesser38

In a 3D semiconductor system, the growth of heterostructures is limited primarily by the lattice mismatch between various layers. Hence, a figure like Fig. 1(a) plotting band gap versus lattice constant sets the constraints on choice of layers in a heterostructure and the growth substrate. But in case of a layered material grown on a layered material, as we had reported in the case of MBE MoSe2 grown on graphene and highly ordered pyrolytic graphite (HOPG) Reference Vishwanath, Liu, Rouvimov, Mende, Azcatl, McDonnell, Wallace, Feenstra, Furdyna, Jena and Grace Xing24 ; we observe superimposed reflected high electron energy diffraction (RHEED) signals from the underlying substrate and the as grown film in case of an incomplete coverage. This suggests that the growth of 2D materials is by van der Waals epitaxy. This is supported by the fact we do not see any discernable change in lattice constants in monolayers as one moves away from the interface in aberration-corrected scanning transmission electron microscopy (STEM) images shown further below. This gives us an added freedom to design electronic or optical devices solely using the desired band alignments as shown in Fig. 1(b). Promise of few-layer heterostructures has been demonstrated in form of WSe2/MoS2 p–n junctions, Reference Xiao, Li, Seabaugh, Debdeep and Xing39 black phosphorus/SnSe2 tunnel diodes. Reference Yan, Fathipour, Han, Song, Xiao, Li, Ma, Protasenko, Muller, Jena and Xing40 Near broken band alignment for WSe2/SnSe2, MoTe2/SnSe2, GaSe/SnSe2 seen in Fig. 1(b) is very interesting for electronic applications like highly scaled tunnel field effect transistors (Thin-TFET). Reference (Oscar) Li, Esseni, Snider, Jena and Grace Xing41 With the recent observation of direct band gap in few layer MoTe2 (Ref. Reference Lezama, Arora, Ubaldini, Barreteau, Giannini, Potemski and Morpurgo42) and in bulk ReS2, Reference Tongay, Sahin, Ko, Luce, Fan, Liu, Zhou, Huang, Ho, Yan, Ogletree, Aloni, Ji, Li, Li, Peeters and Wu43 few layered materials and heterostructures would likely be in limelight for optoelectronic devices as well. 2D and quasi-2D materials don't yet have uniformly accepted definitions. For this work, we have used the Fig. 1(c), where we plot the lattice constant perpendicular to the cleavage plane of the layered material divided by the sum of the ionic radii of the constituent atoms of the monolayer versus the number of atomic layers comprising the monolayer, to differentiate the two classes of materials among layered materials with multiple atomic layers per monolayer. We see that for layered materials having 3 atomic layers in a monolayer, all materials irrespective of the group in the periodic table to which the cation belongs are clustered together. Whereas in 2 atomic layers or 5 atomic layers, the ratio changes dramatically with change in the group to which the cation belongs. The definition holds good for layered materials having greater than one atomic layer per monolayer. It gives us a rough estimate of the fraction van der Waals gap per monolayer height. Hence, in spite of the quasi-2D materials being layered, the cation in one monolayer likely has more significant interaction with the cation in the next monolayer when compared to 2D materials.

FIG. 1. (a) Plot showing band gap versus lattice constant of various bulk layered materials. Materials in red are the layered 2D materials of interest in this work, in orange are the quasi-2D layered materials presented here, blue lines represent the lattice constant of common bulk 3D substrates with hexagonal symmetry and green lines those with cubic symmetry (http://www.ioffe.ru/). (b) Cumulative plot of experimentally determined Reference Schlaf, Lang, Pettenkofer and Jaegermann20 band gaps (BG) and electron affinity (X) of various layered materials in bulk form, contrasted to common compound semiconductor substrates. (c) The monolayer height [half of the lattice constant perpendicular to the cleavage plane of a bulk crystal (c/2)] divided by the sum of the ionic radii (atomic radii in case of graphene) of constituent atoms in each monolayer is plotted against the number of atomic layers in each monolayer.

It is finally important to stress that MBE is capable of producing monolayer materials Reference Ugeda, Bradley, Shi, da Jornada, Zhang, Qiu, Ruan, Mo, Hussain, Shen, Wang, Louie and Crommie25 and their heterostructures but the growth to date is not self-limiting and hence it needs to be timed using RHEED intensity oscillations. This doesn't give perfect monolayer control as discussed further. Hence, the focus is on few layer SLs and heterostructure in this paper.

II. IN SITU GROWTH OF TMD (MoTe2/MoSe2) SL

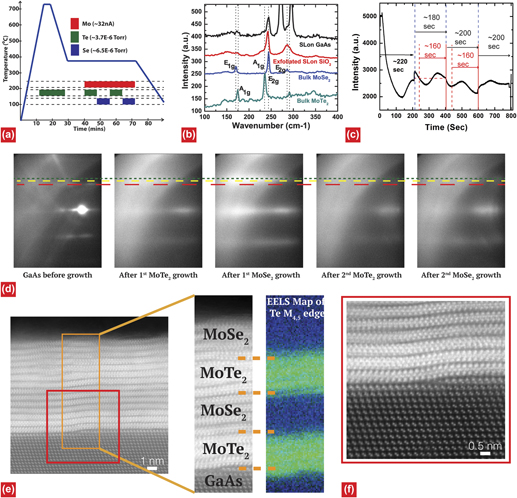

This is the first demonstration of in situ growth of 2D material SLs. As shown in Fig. 2, we demonstrate an MBE MoSe2/MoTe2 SL on GaAs (111)B substrates. GaAs substrate was chosen as high quality epi ready GaAs substrates are commercially available and the surface can be made quasi-van der Waals employing a surface termination with chalcogen atoms. Replacement of surface arsenic with sulfur retaining 1 × 1 reconstruction has been observed in GaAs (111) immersed in NH4S solution Reference Sugiyama, Maeyama and Oshima44 and such sulfur terminated GaAs has been previously used for MBE growth of layered materials like MoSe2. Reference Ueno, Shimada, Saiki and Koma45 In this work, we deoxidize GaAs in situ (at a thermocouple temperature of 730 °C) and then anneal under a Te flux for 5 min, followed by cool down to the growth temperature of 380 °C (thermocouple temperature). The effect of this tellurium treatment is shown in Fig. 3. When the surface is just deoxidized without Te treatment [Fig. 3(a)], the surface is heavily pitted with ∼10 nm deep triangular craters, which results in a broken RHEED pattern from the surface. When the surface treatment is performed [Fig. 3(b)], the surface becomes much smoother showing wider and shallower triangles, which are most likely GaAs/Te islands with atomic step heights as shown in Fig. 2(f). Correspondingly, the RHEED patterns become sharp and streaky as in Fig. 2(d). This shows that there are atomic motions on the surface assisted by Te atoms. Furthermore, the high angle annular dark field-scanning transmission electron microscope (HAADF-STEM) image in Fig. 2(f) shows the very top row of the As–Ga atomic pair of the GaAs substrate appears brighter than the As–Ga pairs below, strengthening the claim of Te replacing As on the GaAs surface.

FIG. 2. (a) Growth diagram of the MoTe2/MoSe2 SL on GaAs (111)B. (b) Raman from the SL (on GaAs as well as exfoliated onto SiO2/Si) compared to Raman signal from CVT grown bulk MoSe2 and bulk MoTe2. (c) RHEED oscillation from a sample grown under the same condition but for a shorter duration for each period. Blue lines show where the chalcogen is switched and the dashed red line to the solid red line mark one period of the oscillation. (d) Evolution of RHEED signal from the sample shown in Fig. 2(c), RHEED streaks from GaAs are superimposed by the red line, MoTe2 in yellow and MoSe2 in green. (e) HAADF-STEM image of the SL and EELS map of Te M4,5 edge, which clearly shows abruptness of different layers. (f) Higher magnification image of the red box in Fig. 2(e) showing how MoTe2 climbs over an atomic step on GaAs.

FIG. 3. AFM images of (a) deoxidized GaAs surface without tellurium treatment, and (b) deoxidized GaAs surface followed by Te treatment.

As shown in the growth diagram in Fig. 2(a), once the substrate is cooled down to the growth temperature and stabilized, Mo and Te molecular beams are simultaneously incident on the substrate. The Mo molecular beam is from an e-beam source and Te and Se are from Kundsen cells. All the data presented in Fig. 2, except for the RHEED oscillations, are for a growth with 480 s for each period. The Mo flux is kept constant and the Te and Se fluxes are alternated. The key point drawn from Fig. 2(b) is that Raman from the SL is superimposition of Raman from both MoSe2 and MoTe2, which is expected but it is interesting to note that the Raman efficiency from MoTe2 is much lower than that from MoSe2. Also, as some of the Raman peaks were masked by peaks from the longitudinal optical (LO) and transverse optical (TO) phonons in GaAs, Reference Abstreiter, Bauser, Fischer and Ploog46 the MoTe2/MoSe2 SL was exfoliated onto a SiO2/Si substrate and Raman was carried out to confirm the peaks. Raman spectroscopy, measured using a 488 nm laser, an incident power of 633 µW and averaged over several scans, shows a MoSe2 A1g peak at 242.02 cm−1 and E2g peak at 286.3 cm−1, which is consistent with the observations on MBE grown MoSe2 on HOPG. Reference Vishwanath, Liu, Rouvimov, Mende, Azcatl, McDonnell, Wallace, Feenstra, Furdyna, Jena and Grace Xing24 The E2g peak seems to comprise of 2 very close peaks, one from MoSe2 and one from MoTe2. Figure 2(d) shows the RHEED evolution along the growth of the SL. It can be clearly seen that the RHEED streak spacing is inverse of the lattice spacing shown in Fig. 1(a). The ratio of the inverse of the RHEED streak spacing closely matches the ratio of reported lattice spacing. Reference Böker, Severin, Müller, Janowitz, Manzke, Voß, Krüger, Mazur and Pollmann47 The ratio of the lattice spacing of (111) GaAs:MoTe2:MoSe2 from the literature is 3.997 (aGaAs/√2):3.522:3.299 (where “a” is lattice constant of GaAs), which is equivalently 1:0.88:0.82. The ratio of the inverse of RHEED streak spacing of the Red, Yellow, and Green lines is 1:0.88:0.81, which is within the error margin given the RHEED patterns from the TMD layers are diffused.

It is also interesting to note that starting from the second MoTe2 layer polycrystalline ring develops along with the streaky RHEED. This is correlated with the waviness in the MoTe2 in the 2nd period of the SL and MoSe2 in the 2nd period of the SL as seen from the cross-sectional HAADF-STEM image in Fig. 2(e). This polycrystallinity deteriorates RHEED oscillations, therefore, the RHEED oscillation presented in Fig. 2(c) is from a different growth under the same growth condition but with thinner layers, which was used to calibrate the growth rate. Since Mo is a refractory metal and the substrate temperature is low, the sticking coefficient of Mo can be safely assumed to be 1 at the surface thus the growth rate is limited by the Mo deposition rate. The RHEED oscillation period is taken to be the duration of one monolayer. From the 2nd and 3rd oscillation in Fig. 2(c), one oscillation period (duration between the dashed red line and the solid red line) can be estimated to be ∼160 s, i.e., a growth rate of 1 monolayer per 160 s. In the 2nd oscillation, it is taken as double of the duration between the minimum and maximum. In the 3rd oscillation, as the duration between the 2 minima. It is an approximation since, Mo flux from e-beam changes slightly between growths and during growth itself. Based on this observation, each half-period of the reported SL growth in Fig. 2(e) is carried out for 480 s, which corresponds to 3 monolayers. However, it is worth noting that in the region in Fig. 2(e) marked by an orange box we can see that there are 3 monolayers of MoTe2 and 4 monolayers of MoSe2 in the 1st period, and there are 4 layers of MoTe2 and MoSe2 in the 2nd period. Together with the substrate surface features of atomic heights, this suggests that observation of RHEED oscillation doesn't necessarily mean a full layer-by-layer growth. In fact, delay in the RHEED intensity and oscillation magnitude is a result of cumulative interference from a roughening film. In spite of that during growth the Se and Te flux is about 3 orders magnitude higher than the Mo flux and there are no breaks between the Se pulse and Te pulse to remove excess Se or Te from the surface, very abrupt MoTe2 and MoSe2 interfaces have been achieved. This is evidenced by the atomic resolution electron energy loss spectroscopy (EELS) map of the Te M4,5 edge of the SL. The sharpness of the map is demonstrated by the fact that the Te signal takes a bend over the GaAs step where the layers bend. Figure 2(f) shows how the MoTe2 layers climb over an atomic step on GaAs and that there is no chemical bond between the 2D material and the 3D substrate treated with Te.

III. IN SITU GROWTH OF TMD/QUASI-2D CRYSTAL (MoX2/Bi2X3) SL

Diced sapphire substrates were first cleaned sequentially in chloroform (30 min), acetone (15 min), methanol (5 min), and hydrofluoric acid (HF) (10%, 2 min). The substrate was then loaded into the MBE chamber, heated to 800 °C and held for 30 min, then cooled to 200 °C. Once the temperature was stabilized the first 2–3 monolayers of Bi2X3 (X denotes Se or Te) was deposited. RHEED from sapphire is observed to disappear; when the substrate is heated gradually to the growth condition of 340 °C (avoiding any overshoot), the Bi2X3 RHEED pattern appears. This is similar to the growth reported for Bi2X3 on GaAs (001). Reference Liu, Smith, Cao, Chen, Fan, Zhang, Pimpinella, Dobrowolska and Furdyna48 Subsequently, the Bi2X3 and MoX2 SL was grown. The reason for this increase in Te flux before MoTe2 growth on Bi2Te3 is presented elsewhere. Reference Vishwanath, Liu, Rouvimov, Azcatl, Wallace, Furdyna, Jena and Grace Xing49

Figures 4(b) and 5(b) shows that Raman from the SL is a superimposition from individual components of respective SLs, Bi2Te3/MoTe2 and Bi2Se3/MoSe2. Again, even though in both SLs the thickness of MoX2 is almost equal, the Raman signal from MoTe2 is much lower and broader than from MoSe2, which is consistent with the observation in the MoTe2/MoSe2 SL (Fig. 2). The MoTe2 A1g peak at ∼171 cm−1 and E2g at ∼230 cm−1 (obtained by Lorentz fitting to the broad peaks) can be better resolved due to the absence of MoSe2 Raman peaks in the neighborhood, which are close to the values from bulk MoTe2 at 174.4 and 235.8 cm−1. 1T-MoTe2 has been reported to have very different peak positions from 2H-MoTe2,

Reference Park, Yun, Kim, Park, Chae, An, Kim, Kim, Kim and Lee36

therefore, this observed shift and broadening in MoTe2 peaks are more likely due to the small grain size in the MBE grown MoTe2 as compared to the bulk. We assume there is no systematic zero error since the E2g peak of Bi2Te3 is at 103.8 cm−1 and the

![]() ${\rm{A}}_{1{\rm{g}}}^2$

peak is at 134.7 cm−1, consistent with the reported values for bulk Bi2Te3.

Reference He, Wang, Qiu, Delaney, Beck, Kidd, Chancey and Gao50,Reference Richter, Kohler and Becker51

The bulk value measured by us is consistent with the reported value for bulk 2H-MoTe2.

Reference Yamamoto, Wang, Ni, Lin, Li, Aikawa, Bin Jian, Ueno, Wakabayashi and Tsukagoshi52

RHEED in Fig. 4(c) is in line with the expectation that Bi2Te3 has a wider lattice spacing than MoTe2 hence a narrower spacing in the reciprocal space. It is worth noting that RHEED from MoTe2 is much more diffused than that from Bi2Te3, pointing toward a greater disorder and smaller grains in MoTe2. This is similar to the small grains reported in MBE MoSe2 on graphene,

Reference Vishwanath, Liu, Rouvimov, Mende, Azcatl, McDonnell, Wallace, Feenstra, Furdyna, Jena and Grace Xing24,Reference Ugeda, Bradley, Shi, da Jornada, Zhang, Qiu, Ruan, Mo, Hussain, Shen, Wang, Louie and Crommie25

owing to the low adatom surface diffusivity of refractory metals. Bi2Te3 RHEED sharpness recovers during the subsequent growth on MoTe2, adding strength to the above claim.

${\rm{A}}_{1{\rm{g}}}^2$

peak is at 134.7 cm−1, consistent with the reported values for bulk Bi2Te3.

Reference He, Wang, Qiu, Delaney, Beck, Kidd, Chancey and Gao50,Reference Richter, Kohler and Becker51

The bulk value measured by us is consistent with the reported value for bulk 2H-MoTe2.

Reference Yamamoto, Wang, Ni, Lin, Li, Aikawa, Bin Jian, Ueno, Wakabayashi and Tsukagoshi52

RHEED in Fig. 4(c) is in line with the expectation that Bi2Te3 has a wider lattice spacing than MoTe2 hence a narrower spacing in the reciprocal space. It is worth noting that RHEED from MoTe2 is much more diffused than that from Bi2Te3, pointing toward a greater disorder and smaller grains in MoTe2. This is similar to the small grains reported in MBE MoSe2 on graphene,

Reference Vishwanath, Liu, Rouvimov, Mende, Azcatl, McDonnell, Wallace, Feenstra, Furdyna, Jena and Grace Xing24,Reference Ugeda, Bradley, Shi, da Jornada, Zhang, Qiu, Ruan, Mo, Hussain, Shen, Wang, Louie and Crommie25

owing to the low adatom surface diffusivity of refractory metals. Bi2Te3 RHEED sharpness recovers during the subsequent growth on MoTe2, adding strength to the above claim.

FIG. 4. (a) Growth diagram of the Bi2Te3/MoTe2 SL, (b) Raman spectrum from the SL compared to that from bulk MoTe2 and the *reported spectrum Reference He, Wang, Qiu, Delaney, Beck, Kidd, Chancey and Gao50 for bulk Bi2Te3, (c) RHEED showing that MoTe2 has a smaller lattice constant than Bi2Te3 hence the reverse in the reciprocal space, (d) HAADF-STEM image of the SL showing the abruptness of different materials, (e) higher magnification image of the red box in Fig. 4(d) showing that the lattice constant of the 2 materials is consistent with that of the bulk and how a MoTe2 layer stitches to a partial layer of Bi2Te3.

FIG. 5. (a) Growth diagram of the Bi2Se3/MoSe2 SL, (b) Raman spectra from the SL compared to that from bulk MoSe2 and MBE grown Bi2Se3 on sapphire, (c) HAADF-STEM image of the SL, (d) EDX line scan of the SL showing abruptness of the Mo and Bi species, the widening of the edge is due to sample motion during imaging, (e) high-resolution transmission electron microscopy (HRTEM) of MoSe2 grown at 340 °C on Bi2Se3, the same growth condition as the SL, (f) HRTEM of MoSe2 grown at 400 °C on Bi2Se3, (g) AFM of Bi2Se3 grown on sapphire at 340 °C, the same growth condition as the first layer in the SL, (h) AFM of MoSe2 grown at 340 °C [sample in Fig. 5(e)], and (i) AFM of MoSe2 grown at 400 °C [sample in Fig. 5(f)].

The most interesting observation in transmission electron microscopy (TEM) imaging of this SL sample is that a lateral junction between a quintuple layer Bi2Te3 and a trilayer MoTe2 is seen, shown in Fig. 4(e). This is the first ever observation of a lateral junction between a quasi-2D layer and a 2D layer. We see that the top 3 layers of the Quintuple (Te–Bi–Te) transition into (Te–Mo–Te). Such a junction might open paths for novel devices not envisioned before involving structurally different layered materials.

A substrate temperature of 340 °C was chosen to grow the Bi2X3/MoX2 SL samples presented in Figs. 4 and 5(a)–5(d) since the growth of Bi2X3 was optimized near 340 °C. In our previous work MBE growth of MoSe2 was carried out at a substrate temperature of 400 °C. To explore the effects of the substrate temperature, growths of MoSe2 at 340 and 400 °C were carried out on Bi2Se3, which was grown on sapphire at 340 °C as described previously. In case of MoSe2 growth at 400 °C, the first layer of MoSe2 was grown at 340 °C and then substrate was heated to 400 °C for subsequent layers to avoid any dissociation of Bi2Se3. Atomic force microscopy (AFM) imaging of the as grown Bi2Se3 at 340 °C [Fig. 5(g)] shows triangular domains consistent with other reports. Reference Liu, Smith, Cao, Chen, Fan, Zhang, Pimpinella, Dobrowolska and Furdyna48 When AFM images from MoSe2 growth at 340 °C [Fig. 5(h)] are contrasted to those at 400 °C [Fig. 5(i)], significant differences in surface morphology are observed. The MoSe2 at 340 °C follows the contours of the underlying Bi2Se3 and hence any pits in Bi2Se3 are also seen after growth of MoSe2. But when the growth is done at 400 °C we observe features similar to that observed on thick MBE MoSe2 on HOPG, Reference Vishwanath, Liu, Rouvimov, Mende, Azcatl, McDonnell, Wallace, Feenstra, Furdyna, Jena and Grace Xing24 i.e., tall protrusions enclosing large smooth regions. TEM imaging of the 2 samples [Figs. 5(e) and 5(f)] reveals that MoSe2 grown at 400 °C has a greater waviness but the interface between Bi2Se3 and MoSe2 is sharp in both cases. Further investigations are necessary to understand the exact mechanisms behind these observations.

Finally, energy dispersive x-ray spectrum (EDX) line scan shown in Fig. 5(d) is consistent with the expected 40% Bi in Bi2Se3 and 33.3% Mo expected in MoSe2. Local variations in the height of Bi2Se3 triangular grain along the width of the TEM sample and slight sample drift during the scan likely contribute to the overlap in the Bi and Mo signals in contrast to the sharp interface in HAADF-STEM [Fig. 5(c)].

IV. IN SITU GROWTH OF HETEROSTRUCTURES INVOLVING MORE THAN 3 MATERIALS

We have grown layered crystals (MoSe2, MoTe2, SnSe2, WSe2) on a 3D substrate (GaAs, CaF2) and quasi-2D crystals (Bi2Se3, Bi2Se3) with very small band gaps (∼200 meV), and growth of quasi-2D materials like SnSe (∼0.86 eV bulk indirect band gap) Reference He, Wang, Qiu, Delaney, Beck, Kidd, Chancey and Gao50 and GaSe on a 2D substrate is equally interesting. Of particular interest is the Sn–Se system, because SnSe has been shown to have exceptional thermoelectric properties Reference Zhao, Lo, Zhang, Sun, Tan, Uher, Wolverton, Dravid and Kanatzidis53 and SnSe2 is a layered material with high work function ideal for tunnel junctions. Monolayer and few layer SnSe has only been demonstrated to date using solution synthesis. Reference Li, Chen, Hu, Wang, Zhang, Chen and Wang54 Taking guidelines from previously reported growth conditions for MBE growth of SnSe and SnSe2 on layered mateials Reference Shimada, Ohuchi and Koma55,Reference Schlaf, Louder, Lang, Pettenkofer, Jaegermann, Nebesny, Lee, Parkinson and Armstrong56 we grew a heterostructure involving 3 materials: Bi2Se3, MoSe2, and SnSe2. The corresponding growth diagram is shown in Fig. 6(a). Raman measurements show superimposition of expected layered materials. The shift of SnSe2 peaks is likely due to difference in stacking order of bulk SnSe2 and MBE SnSe2. Reference Mead and Irwin57–Reference Vishwanath, Liu, Rouvimov, Furdyna, Jena and Grace Xing59 The cross-sectional TEM [Fig. 6(c)] image reveals that majority of the deposited Sn–Se was in form of SnSe2, but there were some regions of SnSe. What is very interesting is that a band of SnSe forms at the interface between MoSe2 and SnSe2. Our hypothesis is that even though the growth temperature was lowered from 340 to 240 °C for the growth of SnSe2, the growth temperature of 240 °C wasn't stabilized for long enough, essentially resulting in a higher than desired growth temperature for the first few layers. Indeed we have consistently observed that SnSe grows at a higher temperature than SnSe2. While a separate manuscript Reference Vishwanath, Liu, Rouvimov, Furdyna, Jena and Grace Xing59 is under preparation to report the MBE growth of SnSe and SnSe2, we present here two sets of growth. Samples in Fig. 6(d) (SnSe x grown at 240 °C on MBE MoSe2/Bi2Se3/Sapphire) and Fig. 6(e) [SnSe grown at 240 °C on exfoliated MoS2/SiO2 (300 nm)/Si] differ primarily by substrate alone. Samples in Figs. 6(e) and 6(f) [SnSe2 grown at 200 °C on exfoliated WSe2/SiO2 (300 nm)/Si] differ primarily by growth temperature. Although using STEM imaging only SnSe is seen on exfoliated MoS2 in Fig. 6(e), inorder to see if there is SnSe2 in other regions of the film, X-ray photoelectron spectroscopy (XPS) was performed on the sample. In agreement with the STEM imagining, the XPS spectra for Fig. 6(e) shows that majority of the as grown film is indeed comprised of the SnSe phase, at a binding energy of 54.3 eV in Se 3d and 485.5 eV in Sn 3d, which are consistent with the values reported in literature. Reference Boscher, Carmalt, Palgrave and Parkin60 Yet, in addition to this phase, a small but significant amount of SnSe2 was also detected, where the corresponding peaks appear at higher binding energy (0.6 eV for Se 3d and 0.8 eV for Sn 3d) than the SnSe peaks. In addition to the SnSe x film, a signal from metallic Se was detected at a binding energy of 54.7 eV, suggesting that some selenium remained unreactive in a metallic form (Se0). Finally, the presence of surface oxides, SnO x and SeO x , were also detected in this sample, which could be generated due to air exposure prior to XPS measurements (Fig. 7).

FIG. 6. (a) Growth diagram of the Bi2Se3/MoSe2/SnSe2 heterostructure, (b) Raman spectrum from the heterostructure compared to those from MBE grown Bi2Se3 on sapphire, bulk MoSe2 and bulk SnSe2, (c) HAADF-STEM image of the heterostructure, (d) higher magnification image of the interface of SnSe2 on MoSe2, (e) HAADF-STEM image of another MBE sample showing that single phase SnSe can be grown on MoS2, (f) HAADF-STEM image of yet another MBE sample showing that single phase SnSe2 can be grown on WSe2.

FIG. 7. XPS on sample in Fig. 6(e) (SnSe on exfoliated MoS2 on SiO2/Si) (a) Se 3d core level showing the presence of SnSe, SnSe2, metallic Se, and SeO x , (b) Sn 3d core level showing the presence of SnSe, SnSe2, and SnO x , (c and e) low intensity signals from Mo–S bonds are detected, however both Mo 3d and S 2p overlap with selenium related regions from SnSe x complicating the deconvolution for MoS2, and (d) the stoichiometry for SnSe and SnSe2 are close to the expected values.

This shows that by optimizing and modeling parameters like growth temperature, interfacial thermal resistance, and the thermal conductivity of the various layers, it is possible to grow single phase SnSe x (x = 1 or 2) or a mixed phase with varying concentrations of SnSe2 and SnSe.

V. CONCLUSION

In summary, we have demonstrated that MBE is a very unique and powerful tool for growth of layered material heterostructures and SLs. Atomically abrupt MoSe2/MoTe2 SLs with RHEED oscillation for ultrathin layer control have been demonstrated. Heterostructures involving Bi2Se3, Bi2Te3, MoSe2, SnSe, and SnSe2 have been grown. Raman and TEM measurements confirm the integrity of the layered materials in these heterostructures. We believe this work serves as a starting point for future optimizations of 2D material MBE heterostructures to probe theoretical predictions Reference Terrones, López-Urías and Terrones61–Reference He, Hummer and Franchini63 of interesting physics in epitaxially aligned heterostructures and SLs.

VI. INSTRUMENTATION DETAILS

A. XPS details

XPS was carried out using a monochromated Al Kα source (hν = 1486.7 eV) and an Omicron EA125 hemispherical 7-channel analyzer (Omicron Electronics, Taunusstein, Germany). The XPS scans were acquired at a take-off angle of 45° with respect to the sample normal and pass energy of 15 eV. The software AAnalyzer was used for peak analysis and deconvolution, where Voigt line shapes and an active Shirley background were used for peak fitting. Reference Herrera-Gómez, Hegedus and Meissner64

ACKNOWLEDGMENTS

L.B. acknowledges the financial support of the National Secretariat of Higher Education, Science, Technology and Innovation of Ecuador (SENESCYT). Microscopy conducted at ORNL's Center for Nanophase Materials Sciences (CNMS), which is a U.S. Department of Energy, Office of Science User Facility (JCI).

This work was supported in part by the NSF/AFOSR EFRI-2DARE program (1433490), NSF Grant DMR1400432 and Center for Low Energy Systems Technology (LEAST), one of six centers of STARnet, a Semiconductor Research Corporation program sponsored by MARCO and DARPA.