Introduction

Herbicides are the most extensively used pesticide applied to agronomic crops in the United States. Since 2013, more than 93% of the planted hectares for corn (Zea mays L.), cotton (Gossypium hirsutum L.), peanut (Arachis hypogaea L.), rice (Oryza sativa L.), and soybean [Glycine max (L.) Merr.] have received a herbicide application (USDA-NASS 2020). In contrast, the next most frequently used pesticides were fungicides in peanut (88% of planted hectares) followed by other chemicals (65%) and insecticides (56%) in cotton. All other pesticide applications were reported on less than 50% of the planted hectares for the respective crop (USDA-NASS 2020).

Although herbicide applications are common occurrences, the specific application techniques and delivery methods are often overlooked fundamental steps required for optimizing herbicide performance (Kudsk Reference Kudsk, Hatcher and Froud-Williams2017). The herbicide application process is complex with numerous opportunities for failure even before spray deposits reach the intended target (Ebert et al. Reference Ebert, Taylor, Downer and Hall1999). Improper herbicide application practices, such as incorrect nozzle selection, boom or flight height, equipment setup, spray volume, and sprayer speed, can lead to increased drift potential (Alves et al. Reference Alves, Kruger, da Cunha, de Santana, Pinto, Guimaraes and Zaric2017; Bueno et al. Reference Bueno, da Cunha and de Santana2017; Hewitt et al. Reference Hewitt, Johnson, Fish, Hermansky and Valcore2002; Nordby and Skuterud Reference Nordby and Skuterud1974), reduced spray pattern uniformity (Azimi et al. Reference Azimi, Carpenter and Reichard1985; Forney et al. Reference Forney, Luck, Kocher and Pitla2017), reduced coverage (Ferguson et al. Reference Ferguson, Hewitt and O’Donnell2016; Legleiter and Johnson Reference Legleiter and Johnson2016), and reduced weed control (Butts et al. Reference Butts, Samples, Franca, Dodds, Reynolds, Adams, Zollinger, Howatt, Fritz, Hoffmann and Kruger2018; Knoche Reference Knoche1994; Meyer et al. Reference Meyer, Norsworthy, Kruger and Barber2016). Herbicide drift to roadsides and field borders caused by application miscues has led to the evolution of herbicide resistance within two generations of Amaranthus spp. (Vieira et al. Reference Vieira, Luck, Amundsen, Werle, Gaines and Kruger2020). As a result, focus should be placed on using precise application procedures to maximize efficacy of herbicide applications while maintaining environmental safety (Matthews et al. Reference Matthews, Bateman and Miller2014).

Droplet size is often one of the primary management decisions for herbicide applications because increasing droplet size has been shown to reduce drift potential (Hewitt Reference Hewitt1997). Numerous application practices and decisions influence droplet size from both ground and aerial spray equipment including herbicide formulations (Fritz et al. Reference Fritz, Hoffmann and Bagley2009; Miller and Butler Ellis Reference Miller and Butler Ellis2000), spray mixtures (Bouse et al. Reference Bouse, Kirk and Bode1990; Butler Ellis et al. Reference Butler Ellis, Tuck and Miller1997), spray pressure (Nuyttens et al. Reference Nuyttens, Baetens, de Schampheleire and Sonck2007), and nozzle type and size (Bouse Reference Bouse1994; Creech et al. Reference Creech, Henry, Fritz and Kruger2015a; Nuyttens et al. Reference Nuyttens, Baetens, de Schampheleire and Sonck2007). Droplet size can be increased on ground spray equipment, and particle drift potential can be decreased by changing the nozzle type (venturi nozzles), increasing the orifice size, decreasing the pressure, and reducing the boom height (Anonymous 2014; Matthews et al. Reference Matthews, Bateman and Miller2014). On aerial spray equipment, managing droplet size and particle drift potential is different as wind shear becomes the driving force for spray atomization (Matthews et al. Reference Matthews, Bateman and Miller2014; O’Connor-Marer Reference O’Connor-Marer2014). Droplet size can be increased by increasing pressure, equipping straight-stream nozzles, using a zero-degree deflection angle, and decreasing flight speed, which results in reduced particle drift potential (Bouse Reference Bouse1994; Hewitt et al. Reference Hewitt, Johnson, Fish, Hermansky and Valcore2002; O’Connor-Marer Reference O’Connor-Marer2014). However, it is unknown how prevalent these application practices are among current herbicide applicators.

New technologies have also been developed in recent years that can improve application efficiency. A wide range of nozzle types and designs are now available that influence numerous spray characteristics such as droplet size, velocity, and spray angle to suit specific herbicide application requirements (Greenleaf Technologies 2020; Pentair Hypro 2018; TeeJet Technologies 2014; Transland 2020; Wilger 2017). The adoption of global positioning system (GPS)-driven automatic boom section control on ground spray equipment has been shown to reduce the area applied by up to 17.5% compared to no section control (Luck et al. Reference Luck, Pitla, Shearer, Mueller, Dillon, Fulton and Higgins2010a), and reduced over-application from 12.4% to 6.2% when compared to manual boom section control (Luck et al. Reference Luck, Zandonadi, Luck and Shearer2010b). Pulse-width modulation (PWM) sprayers provide application flexibility because they allow for several factors, including application pressure and spray droplet size, to be held constant across a range of sprayer speeds while still precisely maintaining the required flow output (Butts et al. Reference Butts, Butts, Luck, Fritz, Hoffmann and Kruger2019a; Butts and Kruger Reference Butts and Kruger2018). Weed sensing technologies with the ability to selectively apply herbicides to detected weeds are becoming commercially available (Blue River Technology 2019; Weed-It 2020). With the abundance of new technologies available, there is a need to identify the levels of adoption and understanding of these technologies by applicators. Research and educational efforts revolving around precision weed control techniques can then be implemented toward ensuring effective future applications of herbicides (Westwood et al. Reference Westwood, Charudattan, Duke, Fennimore, Marrone, Slaughter, Swanton and Zollinger2018).

A survey of consultants in the mid-South of the United States indicated a need for research to evaluate various herbicide application practices, including coverage and efficacy as a function of nozzle selection, hooded sprayers, adjuvant selection, and application techniques to minimize spray drift and maximize herbicide performance (Norsworthy et al. Reference Norsworthy, Bond and Scott2013; Riar et al. Reference Riar, Norsworthy, Steckel, Stephenson, Eubank and Scott2013; Schwartz-Lazaro et al. Reference Schwartz-Lazaro, Norsworthy, Steckel, Stephenson, Bish, Bradley and Bond2018). For application research to be applicable, a baseline of current herbicide application practices and technologies used needs to be established. The objective of this survey was to determine common ground and aerial herbicide application practices and technologies used in Arkansas agronomic crop production. A more thorough understanding of commonly used herbicide application practices and technologies would help to correctly diagnose misapplication errors quicker, direct future research methods to account for standard practices, and assist with determining necessary education efforts.

Materials and Methods

A survey to determine and assess commonly used ground and aerial herbicide application practices in Arkansas was made available online in spring 2019. The online survey was conducted using the Qualtrics survey platform (Qualtrics, Provo, UT) and was distributed through multiple vectors. A link to the survey and a short description of it was direct-emailed to 272 agricultural aviators and 831 certified commercial pesticide applicators; email addresses were obtained from the Arkansas Agricultural Aviation Association and the Arkansas State Plant Board Pesticide Division, respectively. Additionally, the survey link was distributed and publicized through multiple online media sources. Specific survey questions can be found in Supplementary Appendix S1.

The survey included 24 questions divided into five sections according to requested information. The first section consisted of demographic and background information such as age of respondent, years as a certified applicator, county location and number of hectares under supervision, and the percentage of those hectares under various agronomic cropping systems. The second section focused on the prevalence of ground versus aerial herbicide applications and the use of precision sprayer equipment. The premise of the third section was to gather in-depth nozzle and spray volume information for herbicide applications. The fourth section determined details on ground equipment boom height or agricultural aircraft flight height and ground or flight speed. The final section included several open-ended opinion questions to identify respondent views on the benefits of application technology, herbicide application challenges, and future application research needs.

Data collected from the online survey software were directly imported into a spreadsheet software (Microsoft Excel for Office 365, version 2002, Redmond, WA) for analysis (Shaw et al. Reference Shaw, Givens, Farno, Gerard, Jordan, Johnson, Weller, Young, Wilson and Owen2009). Individual responses for the open-ended opinion questions were reduced to one keyword to summarize each respondent’s statement. Keywords were then analyzed for word frequency using the “tm” and “SnowballC” packages in R 3.5.1 statistical software (R Core Team 2018). Not all respondents provided an answer to every survey question. The total number of observations (n) are included for each survey question presented in the results and discussion.

Results and Discussion

Demographic and Background Information

A total of 124 survey responses were recorded, which resulted in about an 11% response rate to the emailed survey. However, because of publicizing the survey openly on multiple online media sources, it is not possible to determine the total pool of survey recipients. Of the 124 total survey responses, 75 were primarily associated with Arkansas agronomic crops, and are the focus of the research presented here.

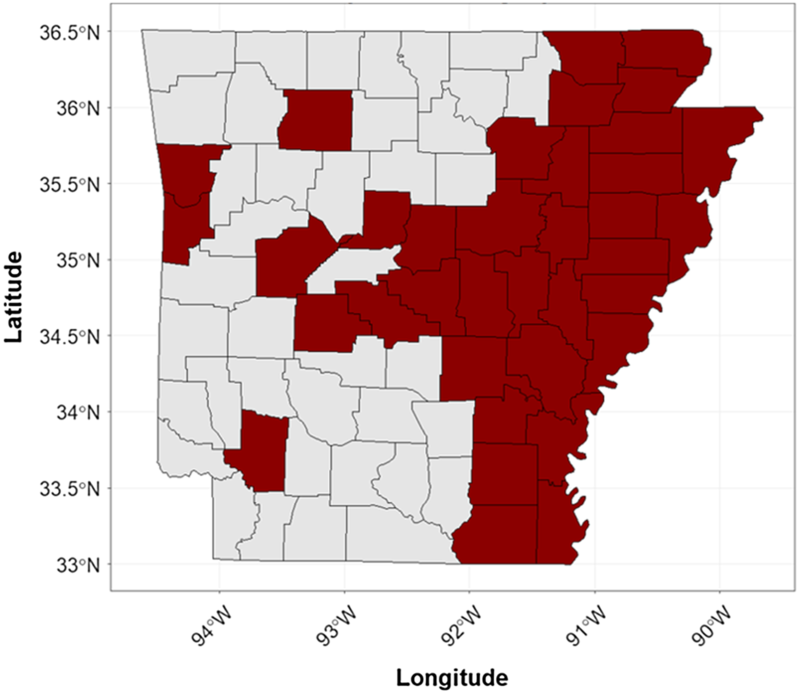

Survey responses were recorded from 36 counties in Arkansas representing nearly all agronomic crop-producing counties in the state (Figure 1). Respondents accounted for a total of 1,057,000 Arkansas agronomic crop hectares planted with corn, cotton, grain sorghum [Sorghum bicolor (L.) Moench ssp. bicolor], peanut, rice, soybean, and wheat (Triticum aestivum L.). The reported hectares accounted for approximately 49% of Arkansas’ planted agronomic hectares in 2019 (USDA-NASS 2019). The key demographic for this survey was well represented because the primary role of respondents was pesticide applicator (54%) followed by farmer (28%), agronomist/salesperson (9%), and crop consultant (8%), respectively. Although some respondents indicated a primary role other than a pesticide applicator, all respondents indicated holding a pesticide applicator certification, and therefore, were included in the subsequent discussions.

Figure 1. Counties of Arkansas that were represented by survey respondents for agronomic crop herbicide applications (red shading).

Respondent age and years as a certified applicator elucidate several intriguing aspects of the Arkansas pesticide applicator industry because both response variables exhibited a skewed left distribution (Figure 2). Because most applicators had significant herbicide application experience (68% had more than 15 years as a certified applicator), applications should be more accurate and efficacious with reduced errors. Conversely, the skewed left distribution of applicator age can have negative consequences for the herbicide application industry. As more applicators near retirement, data suggest fewer younger certified applicators are being effectively trained first-hand to replace the workforce, which may lead to improper applicators due to insufficient training and experience of the younger workforce. Additionally, the lack of younger professionals in the industry may lead to a deficiency in available certified applicators to cover all hectares requiring a herbicide application, especially in a timely, safe, and effective manner. Similar results and industry concerns emerged from a survey of National Agricultural Aviation Association members as 67% of operators were 50 years of age or older (SM Bretthauer, personal communication).

Figure 2. Age (A) and years as a certified applicator (B) of survey respondents for Arkansas agronomic crop herbicide applications. Percentages may not total 100% due to rounding. The number of total observations is noted in the boxes at top left.

Technologies Used in Ground and Aerial Applications

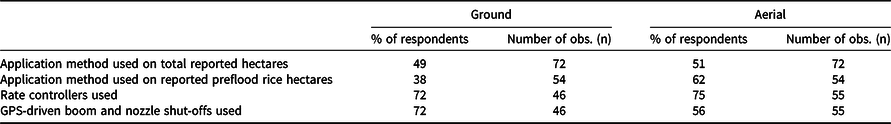

Averaged across respondents and crops, it was reported that herbicides were applied nearly equally from ground and aerial equipment in Arkansas (Table 1). Respondents indicated ground spray equipment and aerial application equipment were used for 49% and 51% of the herbicide applications on reported hectares, respectively. Of the 72 respondents who answered this question, 14 (19%) and 23 (32%) individuals indicated that ground equipment or agricultural aircraft were exclusively used for herbicide applications, respectively. Therefore, approximately 49% of respondents used a combination of ground and aerial equipment to apply herbicides across agronomic crops throughout a growing season.

Table 1. Application method used on total reported hectares and pre-flood rice hectares, rate controllers used, and global positioning system-driven boom and nozzle shut-offs used from ground and aerial spray equipment as reported by Arkansas certified pesticide applicators in a 2019 survey. a

a Abbreviation: GPS, global positioning system.

It is expected that rice hectares account for most of the aerial herbicide applications in the state due to the flooded environment. A large proportion of the preflood rice area (62%) received an aerial herbicide application; however, the use of ground spray equipment for preflood treatment is likely to increase with changing irrigation practices. As furrow-irrigated rice hectares continue to increase (Hardke Reference Hardke, Norman and Moldenhauer2019), ground equipment may become more popular among rice growers to apply herbicides.

Survey respondents were asked about usage of application technologies such as rate controllers, GPS-driven boom and nozzle control, and specialty-type sprayers. Survey results indicated rate controllers were commonly used with both ground and aerial application equipment (Table 1). Seventy-two percent of ground equipment respondents (n = 46) and 75% of aerial equipment respondents (n = 55) reported using rate controllers. Although rate controllers were common for both ground and aerial equipment, the use of GPS-driven technology with automatic boom and nozzle shut-offs differed between the two application methods.

The use of ground spray equipment with GPS-driven automatic boom and nozzle shut-offs was reported by 72% of the respondents (n = 46; Table 1). The high use rates of these technologies on ground spray equipment was expected as other research has reported high adoption rates (Sharda et al. Reference Sharda, Fulton, McDonald and Brodbeck2011, Reference Sharda, Luck, Fulton, McDonald and Shearer2013), but it is a positive attribute for Arkansas agriculture that these technologies are readily available to help improve the accuracy of herbicide applications. In contrast, only 56% of respondents indicated the use of GPS-driven automatic boom and nozzle shut-offs on aerial spray equipment (n = 55). It is unclear why GPS-driven automatic shutoffs are not as common on agricultural aircraft because the technology is available. One possible reason for the lack of adoption of GPS-driven automatic boom and nozzle shutoffs by agricultural pilots may be because the technology is still relatively new to aerial application equipment compared with ground sprayer equipment (SM Bretthauer, personal communication).

Specialty-type sprayers such as PWM, electrostatic, and direct injection, are application technologies that may affect the outcome of herbicide applications (Figure 3). More than 70% of respondents did not use any specialty-type sprayer. However, 23% of total respondents (n = 71) used PWM, and when aerial application-only respondents were removed, 35% of the remaining respondents used PWM (n = 46). Therefore, a substantial number of agronomic crop hectares received herbicide applications from PWM ground spray equipment. Pulse-width modulation spray equipment has numerous benefits including individual nozzle control, overlap and turn compensation, and capability to make real-time flow rate adjustments that minimally affect droplet size (Butts and Kruger Reference Butts and Kruger2018); however, specific application parameters need to be followed to achieve the most effective application possible (Butts et al. Reference Butts, Butts, Luck, Fritz, Hoffmann and Kruger2019a, Reference Butts, Luck, Fritz, Hoffmann and Kruger2019b). Direct injection and electrostatic technologies were not widely used, with only four and two respondents indicating use of these types of sprayers, respectively.

Figure 3. The percentage of survey respondents using specific specialty-type sprayers for Arkansas agronomic crop herbicide applications. Percent total is greater than 100% due to some respondents indicating more than one type of specialty sprayer was used. The number of total observations is noted in the box at the top right. PWM, pulse-width modulation.

Nozzles and Spray Volume

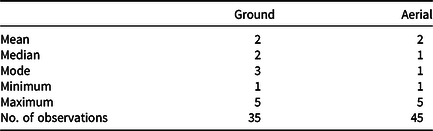

Survey results indicated that few nozzle types were used for ground and aerial herbicide applications during a typical growing season (Table 2). A range of 1 to 5 (mean, 2) nozzle types were used for both ground and aerial spray equipment. However, the median and mode indicated two and three different nozzle types, respectively, were used in a growing season on ground spray equipment, while the median and mode of nozzle types used for aerial spray equipment was one each. Findings indicate ground spray equipment operators use more nozzle types in a growing season than aerial applicators; however, the total number of nozzle types used is still limited. The hesitancy to change nozzle types on ground spray equipment is puzzling with the relative ease of switching between nozzle types on current ground sprayers due to quick attach nozzle caps and turret nozzle bodies. In contrast, changing nozzles on agricultural aircraft tends to be more time-consuming and complex due to threading individual nozzles directly onto the spray boom outlets.

Table 2. Mean, median, mode, minimum, and maximum number of nozzle types used in a growing season from ground and aerial spray equipment as reported by Arkansas certified pesticide applicators in a 2019 survey.

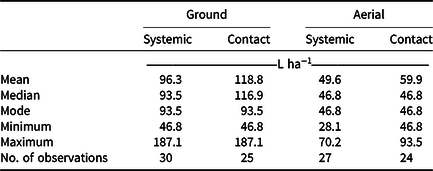

Survey results revealed spray carrier volumes of 96.3 and 118.8 L ha−1 were used on average (mean) for systemic and contact herbicides, respectively, by ground spray equipment operators (Table 3). A range of 46.8 to 187.1 L ha−1 was reported for spray carrier volumes used for both systemic and contact herbicide applications from ground spray equipment. Survey respondents indicated an average (mean) spray carrier volume of 49.6 and 59.9 L ha−1 for systemic and contact herbicides, respectively, using agricultural aircraft. A range of 28.1 to 70.2 L ha−1 and 46.8 to 93.5 L ha−1 aerial application spray carrier volumes were used for systemic and contact herbicides, respectively. The increase in average spray carrier volume regardless of ground or aerial application equipment when switching from systemic to contact herbicides indicates a working knowledge of the importance coverage plays in herbicide efficacy. By increasing the spray volume, a greater number of herbicide spray droplets are available for potential impaction and retention on weed surfaces, thereby increasing weed control (Creech et al. Reference Creech, Henry, Werle, Sandell, Hewitt and Kruger2015b; Knoche Reference Knoche1994).

Table 3. Mean, median, mode, minimum, and maximum spray carrier volumes for systemic and contact herbicides applied from ground and aerial application equipment reported by Arkansas certified pesticide applicators in a 2019 survey.

Limited data was available on the specific types of nozzles used by Arkansas applicators. Only 28% of respondents provided information on a specific nozzle type used across ground and aerial spray equipment. Specifically, 35% of respondents who indicated that at least a portion of reported hectares were sprayed with ground equipment (n = 49) provided a nozzle type used, and 22% of respondents who indicated that at least a portion of reported hectares were sprayed with aerial equipment (n = 58) provided a nozzle type used. From these data we assume that the absence of nozzle type information indicates a lack of knowledge on nozzles used by both ground and aerial applicators because the Qualtrics survey required respondents to input information for each question prior to proceeding to the next question in the survey. Previous survey research from Missouri also concluded an apparent lack of knowledge by applicators was evident regarding technologies that may help reduce herbicide drift including nozzles and drift control agents (Bish and Bradley Reference Bish and Bradley2017). The deficiency in understanding nozzles is problematic because nozzles affect numerous herbicide application outcomes, including spray drift potential (Bueno et al. Reference Bueno, da Cunha and de Santana2017; Vieira et al. Reference Vieira, Butts, Rodrigues, Golus, Schroeder and Kruger2018), coverage (Ferguson et al. Reference Ferguson, Hewitt and O’Donnell2016), and weed control (Butts et al. Reference Butts, Samples, Franca, Dodds, Reynolds, Adams, Zollinger, Howatt, Fritz, Hoffmann and Kruger2018; Creech et al. Reference Creech, Moraes, Henry, Luck and Kruger2016; Meyer et al. Reference Meyer, Norsworthy, Kruger and Barber2016). Educational efforts should be undertaken to increase knowledge and awareness about nozzle types and their importance in herbicide applications.

From the nozzle types reportedly used on ground spray equipment, 47% were non-venturi nozzles, whereas the other 53% were venturi nozzles (Table 4). However, a large portion of the non-venturi nozzles (75%) were used on PWM spray equipment. Because most non-venturi nozzles were reported on PWM spray equipment, the use rate was biased as venturi nozzles are not recommended for use on PWM sprayers (Butts et al. Reference Butts, Butts, Luck, Fritz, Hoffmann and Kruger2019a, Reference Butts, Luck, Fritz, Hoffmann and Kruger2019b). Therefore, venturi nozzles were more commonly used for ground spray applications overall, because PWM sprayers accounted for only 23% of the ground spray equipment. The nozzle types reported to be used on aerial application equipment were nearly evenly split between non-venturi flat-fan nozzles (46%) and straight-stream nozzles (54%; Table 4). Straight-stream nozzles may be slightly more popular due to the coarser droplet size produced compared to non-venturi flat-fan nozzles, which results in reduced drift potential (Hewitt et al. Reference Hewitt, Johnson, Fish, Hermansky and Valcore2002).

Table 4. Nozzle types used on ground and aerial spray equipment as reported by Arkansas certified pesticide applicators in a 2019 survey.

The limited nozzle information provided by survey participants indicated minimal instances of applicators changing nozzle types when switching from systemic to contact herbicides. Only two of the respondents who use ground spray equipment and provided nozzle type information (n = 17) noted using different nozzles when applying a contact herbicide compared to a systemic herbicide. None of the aerial applicator respondents who provided nozzle type information (n = 13) stated nozzle type or deflection angle were changed when switching herbicides. The low proclivity for changing nozzles when applying different herbicides corroborates previous survey research from Missouri (Bish and Bradley Reference Bish and Bradley2017). The result is troublesome because previous research has indicated nozzle selection was the most important factor affecting spray droplet size (Creech et al. Reference Creech, Henry, Fritz and Kruger2015a), and droplet size should be tailored for the herbicide being used and the targeted weed species to optimize efficacy (Butts et al. Reference Butts, Samples, Franca, Dodds, Reynolds, Adams, Zollinger, Howatt, Fritz, Hoffmann and Kruger2018; Creech et al. Reference Creech, Moraes, Henry, Luck and Kruger2016). It should be noted that other application parameters (spray pressure, spray equipment speed, nozzle orifice size) can be changed to achieve the increase in average spray volume without changing nozzles when switching from systemic to contact herbicides. Further survey research should be conducted to evaluate changes in other application parameters that would also influence droplet size and may still result in acceptable droplet sizes for use without changing nozzles.

Other Common Herbicide Application Parameters

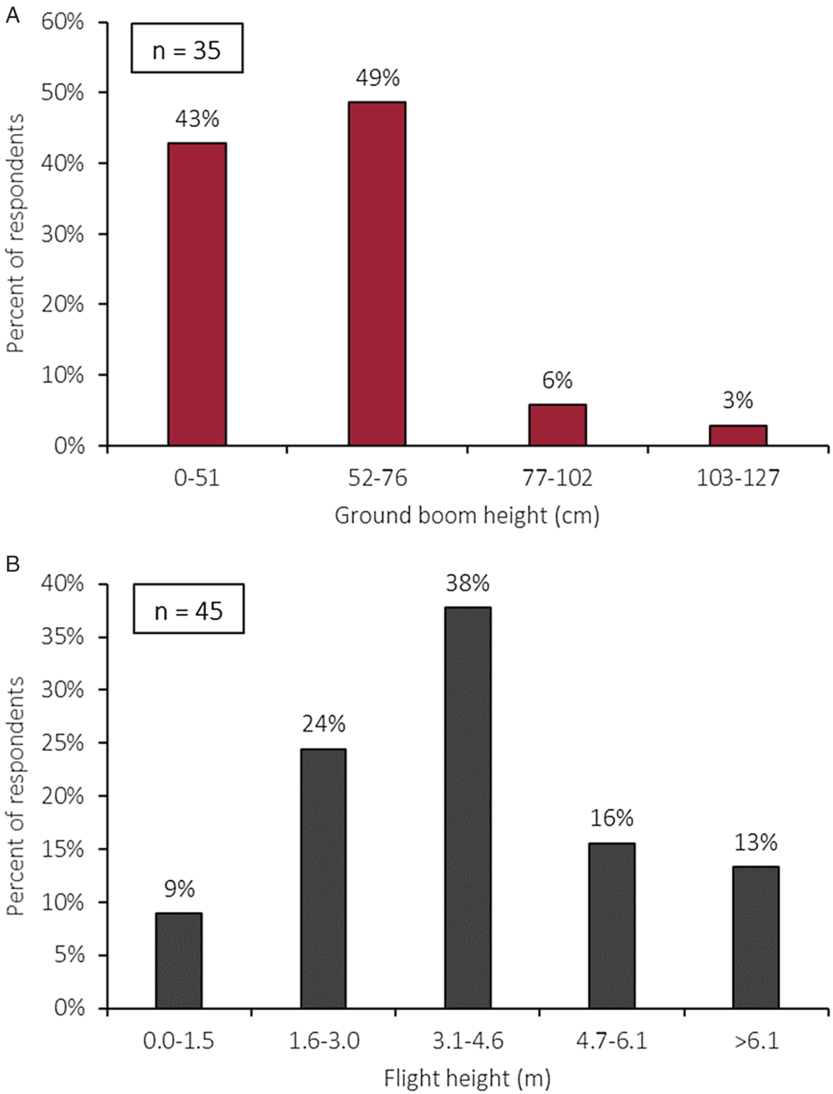

The effectiveness of herbicide applications is further influenced by application parameters such as the sprayer boom or flight height and the equipment’s travel speed. Survey participants were asked to report typical spray heights and travel speeds for both ground and aerial spray equipment. Of the 35 survey participants who used ground spray equipment, 92% reported a boom height of less than 76 cm (Figure 4). Boom height less than 76 cm is very advantageous for drift mitigation purposes by reducing the distance between spray emission and the target, thereby limiting the potential for wind to carry spray droplets off target. Additionally, for most broadcast nozzles and nozzle spacings used on commercial ground sprayers today, 51 cm to 76 cm is the recommended boom height to optimize overlap between nozzles and maximize spray coverage (TeeJet Technologies 2014). Flight heights reported for agricultural aircraft were much more diverse than ground sprayer boom heights. The most frequently reported flight height (38%) was 3.1 m to 4.6 m from the ground (Figure 4). Flight heights between 3.1 m to 4.6 m from the ground are commonly recommended for aerial applications to maximize effectiveness. Additionally, when the nearest flight heights reported were summed, a total of 78% of respondents indicated agricultural aircraft flight heights of 1.6 m to 6.1 m, all of which are still advisable for successful aerial herbicide applications. A minimal percentage of reported ground boom heights (9%) and aerial flight heights (22%) would be inadvisable for use as increased drift potential or unsafe application conditions may result.

Figure 4. Ground spray equipment boom height (A) and agricultural aircraft flight height (B) used for Arkansas agronomic crop herbicide applications as measured by percentage of survey respondents. Percentages may not total 100% due to rounding. The number of total observations is noted in boxes at top left.

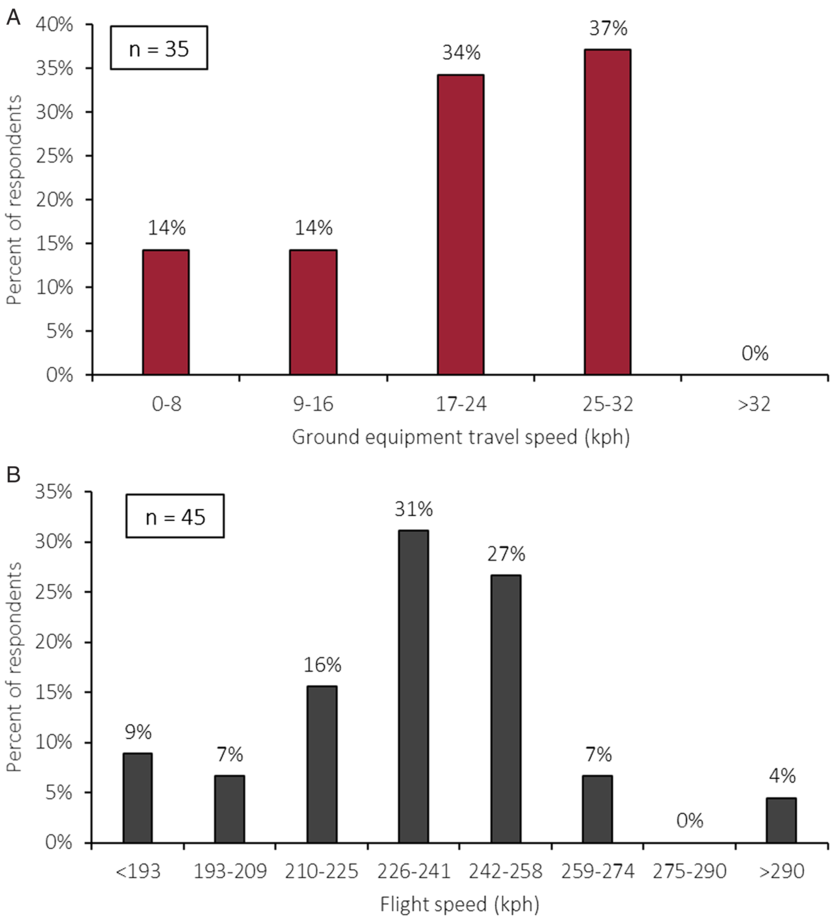

Ground travel and flight speeds are important facets to indicate the safety and accuracy potential of herbicide applications. Survey results indicated that 71% of respondents using ground spray equipment reported travel speeds of 17 kph to 32 kph (Figure 5). Sixty-two percent of respondents reported ground sprayer speeds (<25 kph) that would be considered acceptable for safe and accurate application procedures in the Arkansas delta region to maintain uniformity (Womac et al. Reference Womac, Etheridge, Seibert, Hogan and Ray2001). Agricultural aircraft flight speeds were reported to be less than 193 kph to greater than 290 kph (Figure 5). The diversity of flight speeds may be partially explained by the type of aircraft used for applying the herbicide. It is highly probable that aircraft with a flight speed reported less than 193 kph were rotary wing aircraft (helicopter). Conversely, all other flight speeds greater than 193 kph were likely fixed-wing aircraft (airplane). The greatest percentage of respondents (58%) indicated flight speeds between 226 kph and 258 kph, which is a commonly recommended flight speed range for the types of fixed wing agricultural aircraft typically used to apply herbicides (SM Bretthauer, personal communication). Additionally, flight speeds between 226 kph and 258 kph allow applicators to achieve safe operating conditions by maintaining the necessary amount of lift to carry the high payload capacity of current agricultural aircraft (Air Tractor 2020). Collectively, 0% and 11% of the reported ground travel and flight speeds, respectively, would not be recommended because the speeds may be too great for safe, accurate, and consistent herbicide applications.

Figure 5. Ground spray equipment travel speed (A) and agricultural aircraft flight speed (B) used for Arkansas agronomic crop herbicide applications as measured by percentage of survey respondents. Percentages may not total 100% due to rounding. The number of total observations is noted in boxes at top left.

Benefits of Technologies, Challenges, and Future Research

Survey participants were asked three open-ended opinion questions about herbicide applications. The first was, “What do you feel is the biggest advantage of using newer application technologies?” Fifty responses were received, and when responses were summarized into one-word descriptions, the four most frequent narratives for biggest advantages of newer technologies were drift-control (26%), accuracy (14%), coverage (8%), and flow-control (8%; Figure 6). As spray drift has become an increasing concern for all of agriculture, the ability of new technologies to assist with mitigation of this concern is a necessity. It is positive that new application technologies being used by Arkansas applicators have provided assurance with spray drift mitigation efforts. Overall, responses indicated that survey participants believed newer application technologies assisted with the optimization of herbicide applications as evidenced by descriptive words such as accuracy, precision, efficiency, quality, productivity, and consistency.

Figure 6. Word frequency analysis results from a survey of Arkansas agronomic crop herbicide applicators for the question, “What do you feel is the biggest advantage of using newer application technologies?” The total number of observations was 50.

The second question was, “What is your biggest herbicide application challenge?” Drift (34%), weather (14%), timeliness (12%), regulations (8%), and spray volume (3%) were the top five most frequent descriptors from a total of 65 respondents (Figure 7). The concepts presented were commonly reiterated as challenges from farmers, applicators, and crop consultants across the state at various Extension related activities. It was not surprising that drift was the most frequently cited challenge. Due to the variety of cropping systems and herbicide traits found across the Arkansas delta, symptoms of off-target movement are more readily visible as a wider range of herbicides are utilized. Additionally, the nationwide focus on auxin herbicide movement in recent years has brought spray drift problems to the forefront of agriculture for many herbicide applicators.

Figure 7. Word frequency analysis results from a survey of Arkansas agronomic crop herbicide applicators for the question, “What is your biggest herbicide application challenge?” The total number of observations was 65.

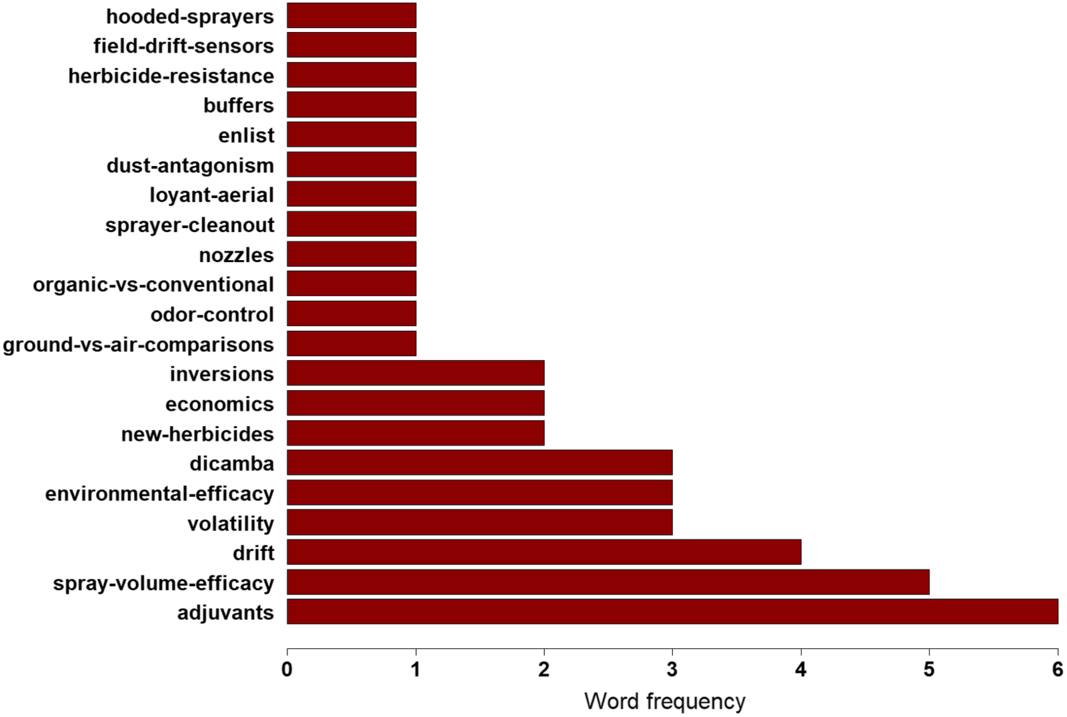

The third opinion question was, “What application research would you like to see the University of Arkansas conduct in the next three years to address your concerns?” Forty-two responses were received. Responses included adjuvants (14%), spray volume efficacy (12%), drift (10%), volatility (7%), environmental efficacy (7%), and dicamba (7%; Figure 8). Adjuvant research requested typically involved drift reduction adjuvants and how drift, pattern development, and weed control may be influenced. The term “environmental efficacy” grouped together responses that included factors such as temperature, relative humidity, soil moisture, and wind speed effects on herbicide efficacy. Responses provided an insight into the needs of current Arkansas herbicide applicators.

Figure 8. Word frequency analysis results from a survey of Arkansas agronomic crop herbicide applicators for the question, “What application research would you like to see the University of Arkansas conduct in the next three years to address your concerns?” The total number of observations was 42.

Current herbicide application practices and technologies used by Arkansas applicators including nozzles, spray volumes, equipment travel speed, boom heights, specialty-type sprayers, and other application technologies were documented for ground and aerial spray equipment in this research. Most of the applicator survey participants had significant herbicide application experience (68% had more than 15 years of experience as a certified applicator); however, as a result, fewer younger certified applicators may be effectively trained to replace the workforce. Respondents reported herbicides were applied using ground versus aerial application equipment in nearly equal percentages. Rate controllers were commonly used in both ground and aerial application equipment. In contrast, GPS-driven automatic nozzle and boom shut-offs were much more common on ground spray equipment than aerial equipment. Specialty-type sprayer technologies were uncommon among respondents with PWM being the most used (23%). The majority of reported boom heights and equipment travel speeds for both ground and aerial application equipment were in recommended ranges for effective herbicide applications. Overall, applicator knowledge of nozzles and usage was limited as minimal respondents reported specific nozzle information used, regardless of ground or aerial applicators, indicating a need for nozzle educational efforts. Venturi nozzles and straight-stream nozzles were most commonly used with ground and aerial spray equipment, respectively. Ground and aerial applicator survey participants alike reported using greater spray carrier volumes when switching to contact herbicides from systemic herbicides. Respondents indicated that optimization of applications was a major benefit of using newer application technologies, and herbicide drift was highlighted as a primary challenge. Research needs expressed by survey participants included adjuvants, spray volume efficacy, and herbicide drift. The results of this survey provided critical insight into current practices, technologies, and needs of Arkansas herbicide applicators. Research and education efforts focused on aforementioned needs can be developed and implemented while also providing applied, research-based information to applicators based on current practices.

Acknowledgments

This project was supported through Checkoff funding provided by the Arkansas Rice Research and Promotion Board and Arkansas Soybean Promotion Board. We thank the University of Arkansas System Division of Agriculture for their support of this research. We also thank the Arkansas State Plant Board Pesticide Division and Arkansas Agricultural Aviation Association for providing contact information of applicators and for their efforts in publicizing the survey. Finally, we thank all Arkansas certified pesticide applicators, farmers, crop consultants, and agronomists that took time to complete the survey. No conflicts of interest have been declared.

Supplementary material

To view supplementary material for this article, please visit https://doi.org/10.1017/wet.2020.81