1. Introduction

Human locomotion is one of the most critical physical tasks for an individual to maintain independence and achieve the desired activities of daily living (Spector and Fleishman, Reference Spector and Fleishman1998). The human ankle joint is a critical point of rotation and weight translations, and is one of the major contributing factors to assist in forward locomotion and postural stabilization (Mueller et al., Reference Mueller, Minor, Schaaf, Strube and Sahrmann1995; Sawicki and Ferris, Reference Sawicki and Ferris2009). Two major contributors to successful forward locomotion are plantarflexion and medial/lateral ankle stability for balance throughout walking. Ankle plantarflexion is responsible for 45% of the power behind moving the body forward during walking (Winter, Reference Winter1983; Farris and Sawicki, Reference Farris and Sawicki2011). Push-off is the stage of human gait, which is a major contributor to forward propulsion during walking, and occurs at roughly between 45 and 60% of the gait cycle (Winter, Reference Winter1983; Winter and Sienko, Reference Winter and Sienko1988).

There are many factors that can impact an individual’s ability to achieve natural and comfortable mobility. Among the most common factors are injuries from trips or falls, neuromuscular conditions, and neurological disorders, and many of those with a history of ankle injury (or injuries) face an increased risk of reoccurring injuries (Yeung et al., Reference Yeung, Chan, So and Yuan1994). Chronic ankle instability is a common ankle impairment that affects the medial/lateral ankle stability and increases the risk of future ankle sprains and injuries (Garrick, Reference Garrick1977; Venesky et al., Reference Venesky, Docherty, Dapena and Schrader2006). Ankle sprains usually occur when there is a sudden instance of inversion due to unanticipated lateral ankle buckling (Garrick, Reference Garrick1977; Venesky et al., Reference Venesky, Docherty, Dapena and Schrader2006).

Ankle-foot orthoses (AFOs) are the most commonly used orthoses available to patients, accounting for as many as 26% of all orthoses provided to patients in the United States (Whiteside et al., Reference Whiteside, Allen, Barringer, Beiswenger, Brncick, Bulgarelli and Lin2007; Lusardi et al., Reference Lusardi, Jorge and Nielsen2013). For example, AFOs are commonly prescribed for recovering survivors with symptoms of hemiparesis, which affects around 80% of stroke survivors (Lusardi et al., Reference Lusardi, Jorge and Nielsen2013; Sankaranarayan et al., Reference Sankaranarayan, Gupta, Khanna, Taly and Thennarasu2016; Cogollor et al., Reference Cogollor, Rojo-Lacal, Hermsdörfer, Ferre, Waldmeyer, Giachritsis and Sebastián2018). While there are many versions of AFOs available on the market, they are largely made out of rigid materials like plastics and carbon fiber (Whiteside et al., Reference Whiteside, Allen, Barringer, Beiswenger, Brncick, Bulgarelli and Lin2007; Lusardi et al., Reference Lusardi, Jorge and Nielsen2013).

With the rise in popularity of the wearable robotic industry, new robotic devices are being created to replace existing assistive and rehabilitative technologies (Park et al., Reference Park, Chen, Pérez-Arancibia, Young, Stirling, Wood and Nagpal2014; Lee et al., Reference Lee, Crea, Malcolm, Galiana, Asbeck and Walsh2016; Ren et al., Reference Ren, Wu, Yang, Xu, Harvey and Zhang2017; Chung et al., Reference Chung, Heimgartner, O’Neill, Phipps and Walsh2018; Kwon et al., Reference Kwon, Park, Ku, Jeong, Paik and Park2019; Shi et al., Reference Shi, Chen, Yue, Yin, Weng and Zhang2019). The field of assistive soft robotics has gained popularity within the wearable robotics community (Bao et al., Reference Bao, Fang, Chen, Wan, Xu, Yang and Zhang2018; Thalman and Artemiadis, Reference Thalman and Artemiadis2020). Previous works have made significant advancements to substantiate the recent popularity of the use of soft, compliant materials to create wearable robots that are lightweight, comfortable, and effective in providing assistance to the user (Malcolm et al., Reference Malcolm, Lee, Crea, Siviy, Saucedo, Galiana, Panizzolo, Holt and Walsh2017; Chung et al., Reference Chung, Heimgartner, O’Neill, Phipps and Walsh2018; Kwon et al., Reference Kwon, Park, Ku, Jeong, Paik and Park2019; Thalman et al., Reference Thalman, Hsu, Snyder and Polygerinos2019). Integrating textiles and fabrics into a wearable robot can help eliminate some of the drawbacks seen with rigid exoskeletons such as size, weight, and cost (Asbeck et al., Reference Asbeck, Dyer, Larusson and Walsh2013; Park et al., Reference Park, Chen, Pérez-Arancibia, Young, Stirling, Wood and Nagpal2014; Malcolm et al., Reference Malcolm, Lee, Crea, Siviy, Saucedo, Galiana, Panizzolo, Holt and Walsh2017). This is especially critical when assisting a joint such as the ankle, where gait dynamics can be heavily affected by even slight changes to external conditions (Browning et al., Reference Browning, Modica, Kram and Goswami2007).

This paper presents the SR-AFO exosuit, which integrates soft, pneumatic actuators made of garment-like fabrics. The SR-AFO utilizes principles of soft robotics to help alleviate troublesome attributes of other traditional AFO solutions. It integrates two novel soft actuators and operates in multiple degrees of freedom of the ankle, providing both assistance in ankle plantarflexion in the sagittal plane and medial/lateral ankle support in the frontal plane (Figure 1). The SR-AFO is designed to provide active assistance at the precise intervals where it is needed without impacting the comfort or range of motion of the wearer. This paper presents the design, modeling, analysis, fabrication, and experimental characterization of the two soft actuators for the SR-AFO, and a pilot human study of its use.

Figure 1. (a) The concept illustration of a soft robotic ankle-foot orthosis (SR-AFO) that assists walking with active ankle plantarflexion assistance as well as medial/lateral ankle support. Since the SR-AFO is designed to be used in its current stages as a rehabilitative device in clinical trials, the goal is to have the participant in a rehabilitative space already equipped with pressure lines, and the hardware needed to control pressure, timing, and record data from each session will sit beside the participant. Ideally, in most cases, there would be no compressor in this setup, rather the electropneumatic hardware box would connect directly to line pressure from the wall. (b) The actuators used for plantarflexion assistance are placed on the back of the leg, and contract to pull the heel upward. (c) The actuators to provide lateral ankle support are placed on either side of the ankle joint, and act as a brace when active to provide variable stiffness to the joint.

The goal and motivation of designing the SR-AFO was to create a solution that would provide both the lightweight wearable orthoses such as the rigid ankle braces, with the dynamic support of a robotic ankle orthosis. The focus and novelty of this work is in the design of a device that could provide dynamic support and assistance to the user without adding excessive mass to the ankle during lower extremity tasks, with an easy don/doff process, which is unlike anything else currently used in ankle-targeted or gait rehabilitation.

2. Design, Modeling, Analysis, Characterization, and Fabrication of the SR-AFO

2.1. Actuator Concept and Design

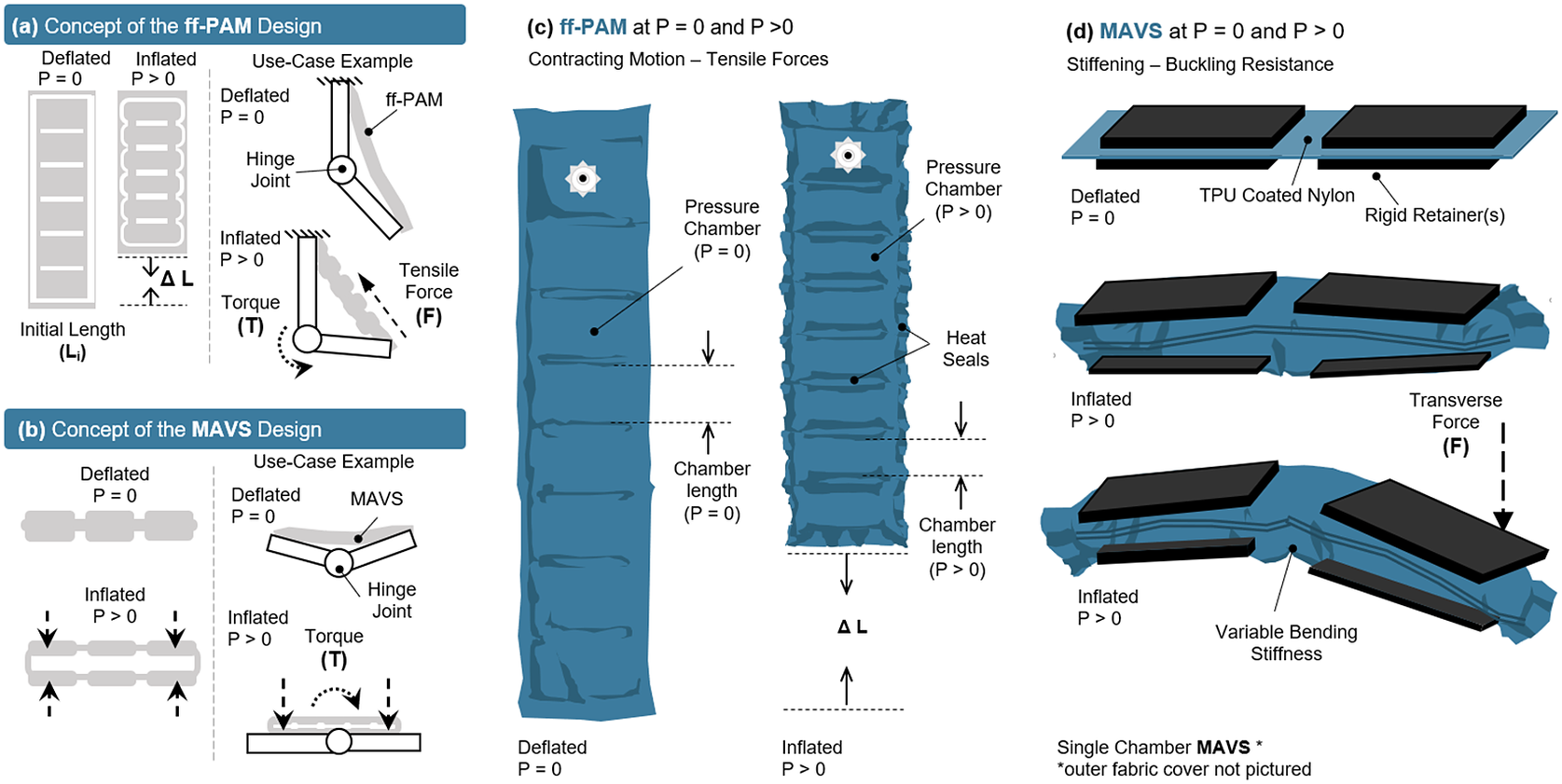

The SR-AFO is a soft, wearable ankle robot that is made entirely of fabric materials such as Neoprene, Spandex, and Nylon. The combination of these materials forms a pattern that creates the main body of the SR-AFO, which can be worn over the user’s athletic shoe and can accommodate most adult shoe sizes. The SR-AFO comprises of two sets of soft actuators, that is, flat fabric pneumatic artificial muscle (ff-PAM) and multi-material actuator for variable stiffness (MAVS) actuators, which serve different primary functions in the overall performance of the soft exosuit. Upon pressurization, the ff-PAM contracts and increases tensile force (Figure 2a,c), whereas the MAVS increases the lateral stiffness (Figure 2b,d).

Figure 2. The concept illustration of (a) the flat fabric pneumatic artificial muscle (ff-PAM) actuator in a simplified geometry to show inflated and deflated states, as well as a basic diagram of how the actuator provides joint torque. (b) The multi-material actuator for variable stiffness (MAVS) is shown in a simplified form in the inflated and deflated states, as well as in a simple diagram showing how the MAVS can brace a joint against buckling. Deflated (

![]() $ P\hskip0.35em =\hskip0.35em 0 $

) and inflated (

$ P\hskip0.35em =\hskip0.35em 0 $

) and inflated (

![]() $ P>0 $

) states of (c) the ff-PAM actuator and (d) the MAVS actuator are shown in more detail, with material layers, seams, and basic function.

$ P>0 $

) states of (c) the ff-PAM actuator and (d) the MAVS actuator are shown in more detail, with material layers, seams, and basic function.

2.2. Analytical Modeling

The analytical models for the ff-PAM and MAVS actuators were created using the geometric programming of materials, which has been shown to be a useful approach for modeling textile-based soft pneumatic actuators (Niiyama et al., Reference Niiyama, Sun, Sung, An, Rus and Kim2015; Thalman et al., Reference Thalman, Hsu, Snyder and Polygerinos2019; Kwon et al., Reference Kwon, Yoon and Park2020). The assumptions used in modeling textile-based actuators include: (a) soft materials are inextensible, (b) soft materials assume common geometric shapes when inflated, and (c) fully inflated soft segments assume a “rigid” behavior at maximum pressure.

2.2.1. Modeling of flat fabric PAM

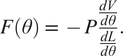

The first actuator introduced was the ff-PAM. The model used to represent the ff-PAM is governed by the following set of equations (Figure 3; Niiyama et al., Reference Niiyama, Sun, Sung, An, Rus and Kim2015):

where

![]() $ F $

is the tensile force,

$ F $

is the tensile force,

![]() $ {L}_i $

is the original length of each chamber,

$ {L}_i $

is the original length of each chamber,

![]() $ L\left(\theta \right) $

is the length of each chamber after inflation,

$ L\left(\theta \right) $

is the length of each chamber after inflation,

![]() $ {L}_{\varepsilon } $

is the contraction ratio of the actuator,

$ {L}_{\varepsilon } $

is the contraction ratio of the actuator,

![]() $ P $

is the supply pressure, and

$ P $

is the supply pressure, and

![]() $ w $

is the width of the actuator. Estimation of force output is based on the laws of conservation of energy. The relation between the supplied pressure and the resultant force output can be expressed as

$ w $

is the width of the actuator. Estimation of force output is based on the laws of conservation of energy. The relation between the supplied pressure and the resultant force output can be expressed as

where

![]() $ V $

is the internal volume of the pneumatic chamber. Both

$ V $

is the internal volume of the pneumatic chamber. Both

![]() $ V $

and

$ V $

and

![]() $ L $

can be expressed as a function of

$ L $

can be expressed as a function of

![]() $ \theta $

, and the expression can be written as

$ \theta $

, and the expression can be written as

$$ F\left(\theta \right)\hskip0.35em =\hskip0.35em -P\frac{\frac{d V}{d\theta}}{\frac{d L}{d\theta}}. $$

$$ F\left(\theta \right)\hskip0.35em =\hskip0.35em -P\frac{\frac{d V}{d\theta}}{\frac{d L}{d\theta}}. $$

Figure 3. (a) The frontal view representation of the ff-PAM at

![]() $ P $

= 0, which indicates its geometries and the path of airflow within the chambers. (b) The frontal view of the ff-PAM at

$ P $

= 0, which indicates its geometries and the path of airflow within the chambers. (b) The frontal view of the ff-PAM at

![]() $ P $

> 0 where the length and geometries are altered as a result of pressurization. (c) The cross section of a single chamber inspired by previous model iteration of inflatable pouches (Niiyama et al., Reference Niiyama, Sun, Sung, An, Rus and Kim2015). (d) The isometric view of the ff-PAM in deflated and inflated states, where

$ P $

> 0 where the length and geometries are altered as a result of pressurization. (c) The cross section of a single chamber inspired by previous model iteration of inflatable pouches (Niiyama et al., Reference Niiyama, Sun, Sung, An, Rus and Kim2015). (d) The isometric view of the ff-PAM in deflated and inflated states, where

![]() $ {L}_i $

and

$ {L}_i $

and

![]() $ {L}_f $

are the initial and final lengths of

$ {L}_f $

are the initial and final lengths of

![]() $ L\left(\theta \right) $

, respectively. (e) The theoretical tensile force versus strain curve for the dual ff-PAM actuator, with eight chambers, at pressure levels of

$ L\left(\theta \right) $

, respectively. (e) The theoretical tensile force versus strain curve for the dual ff-PAM actuator, with eight chambers, at pressure levels of

![]() $ P $

= 50, 100, 150, and 200

$ P $

= 50, 100, 150, and 200

![]() $ \mathrm{k}\mathrm{P}\mathrm{a} $

resulting from the analytical model. Increasing pressure level result in a more stable and linear response in actuator force profile.

$ \mathrm{k}\mathrm{P}\mathrm{a} $

resulting from the analytical model. Increasing pressure level result in a more stable and linear response in actuator force profile.

In order to determine the contraction in terms of strain (

![]() $ {L}_{\varepsilon } $

), a corrected version of

$ {L}_{\varepsilon } $

), a corrected version of

![]() $ {L}_{\varepsilon } $

is used (

$ {L}_{\varepsilon } $

is used (

![]() $ {L}_{\varepsilon C} $

):

$ {L}_{\varepsilon C} $

):

$$ {L}_{\varepsilon C}\hskip0.35em =\hskip0.35em {L}_{\varepsilon}\left(1+\frac{d\pi}{\pi -2}\right)-d, $$

$$ {L}_{\varepsilon C}\hskip0.35em =\hskip0.35em {L}_{\varepsilon}\left(1+\frac{d\pi}{\pi -2}\right)-d, $$

where

![]() $ d $

is a correction coefficient as described in (Niiyama et al., Reference Niiyama, Sun, Sung, An, Rus and Kim2015) to account for some of the flexibility and compliance of the soft, thin textiles used to fabricate the actuator, which can affect the resulting strain. The length of the entire actuator, including all chambers of the actuator, with all chambers of the actuator was later optimized via finite element analysis (FEA) using the following conditions:

$ d $

is a correction coefficient as described in (Niiyama et al., Reference Niiyama, Sun, Sung, An, Rus and Kim2015) to account for some of the flexibility and compliance of the soft, thin textiles used to fabricate the actuator, which can affect the resulting strain. The length of the entire actuator, including all chambers of the actuator, with all chambers of the actuator was later optimized via finite element analysis (FEA) using the following conditions:

where

![]() $ {L}_y $

is the total length of the ff-PAM,

$ {L}_y $

is the total length of the ff-PAM,

![]() $ s $

is the distance between each chamber created by the heat seal, and

$ s $

is the distance between each chamber created by the heat seal, and

![]() $ N $

is the total number of chambers.

$ N $

is the total number of chambers.

The number of chambers used in the ff-PAM was set to 8 (

![]() $ N $

= 8), considering overall length, contraction performance, and robustness of the actuator. In addition, while the dual actuator configuration increased the total volume of the active ff-PAM setup compared to the single actuator, the increase in tensile force output was considered valuable for the application of plantarflexion and push-off assistance, and the SR-AFO exosuit used the dual ff-PAM configuration.

$ N $

= 8), considering overall length, contraction performance, and robustness of the actuator. In addition, while the dual actuator configuration increased the total volume of the active ff-PAM setup compared to the single actuator, the increase in tensile force output was considered valuable for the application of plantarflexion and push-off assistance, and the SR-AFO exosuit used the dual ff-PAM configuration.

The force versus strain curves for the dual ff-PAM design with

![]() $ N\hskip0.35em =\hskip0.35em $

8 is obtained using the analytical model at four pressure levels (50, 100, 150, and 200

$ N\hskip0.35em =\hskip0.35em $

8 is obtained using the analytical model at four pressure levels (50, 100, 150, and 200

![]() $ \mathrm{k}\mathrm{P}\mathrm{a} $

; Figure 3e), which show that the tensile force of the ff-PAM increases with increasing

$ \mathrm{k}\mathrm{P}\mathrm{a} $

; Figure 3e), which show that the tensile force of the ff-PAM increases with increasing

![]() $ P $

. The dual ff-PAM actuators were predicted to reach 307

$ P $

. The dual ff-PAM actuators were predicted to reach 307

![]() $ N $

and 348.3

$ N $

and 348.3

![]() $ N $

at the theoretical point

$ N $

at the theoretical point

![]() $ {L}_{\varepsilon C} $

= 0 at 150 and 200

$ {L}_{\varepsilon C} $

= 0 at 150 and 200

![]() $ \mathrm{k}\mathrm{P}\mathrm{a} $

, respectively.

$ \mathrm{k}\mathrm{P}\mathrm{a} $

, respectively.

2.2.2. Modeling of multi-material actuator for variable stiffness

The second actuator introduced in the SR-AFO was the MAVS, which integrated rigid components into a soft, fabric-based actuator. Inspiration for the integration of multi-segment, multi-material for the MAVS actuator was drawn from several previous works, such as the sliding layer laminate actuator design presented by Jiang and Gravish (Jiang and Gravish, Reference Jiang and Gravish2018). This design focused on a three-layer laminate actuator that varies stiffness based on the ratio of the size of each exposed material when subjected to transverse load. The stiffest condition was achieved when there was a total misalignment of the layers, where the exposed soft material was minimized. Similarly, the smallest stiffness was achieved when the layers were stacked in vertical layers with no human error in fabrication misalignment, where the exposed soft material was maximized. The MAVS design was implemented with these physical characteristic behaviors in mind. The rigid retainers embedded in fabric were placed on the outside of the layer of inflatable actuator. The rigid pieces were aligned on the top and bottom of the actuator. A single segment of the MAVS weighed between 31.2 and 89.3

![]() $ \mathrm{g} $

, depending on the configuration used.

$ \mathrm{g} $

, depending on the configuration used.

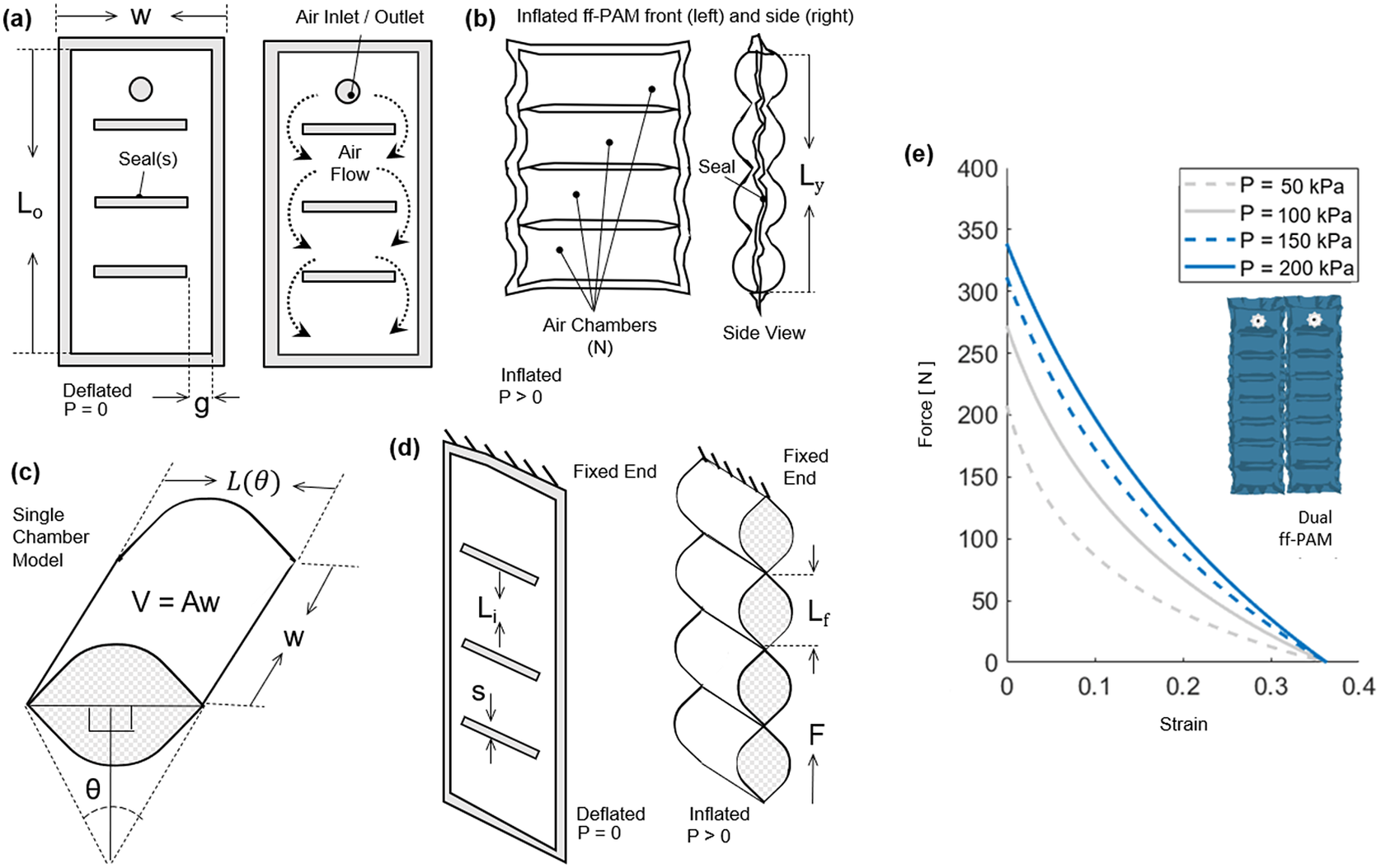

The rigid components of the MAVS actuator were small, thin pieces of custom 3D-printed polylactic acid (PLA), which were embedded into the soft actuator fabric layers during the sewing stages of the fabrication process. The rigid materials limited vertical expansion of the actuator when pressurized and restricted physical internal volume by limiting the cross-sectional area of the MAVS. The rigid retainers were placed along the length of the actuator and alternated with sections of exposed fabric, providing the MAVS with varying levels of compliance. By alternating segments of soft and rigid-bound cross sections, the MAVS obtained varying levels of lateral stiffness that can be adjusted during fabrication and pressurization (Figure 4a).

Figure 4. (a) The multi-material actuator for variable stiffness (MAVS) actuator when deflated and inflated. A cross section view of the MAVS actuator for the rigid and soft parts.

![]() $ {L}_{r,g} $

is the length of each segment, where

$ {L}_{r,g} $

is the length of each segment, where

![]() $ {L}_r $

is representative of the length of the rigid sections, and

$ {L}_r $

is representative of the length of the rigid sections, and

![]() $ {L}_g $

is the length of the soft segment.

$ {L}_g $

is the length of the soft segment.

![]() $ V $

is the deflection of the beam at its total length, inclusive of all segments.

$ V $

is the deflection of the beam at its total length, inclusive of all segments.

![]() $ x $

is the total distance from the origin point at varying lengths depending on which MAVS configuration and combination of

$ x $

is the total distance from the origin point at varying lengths depending on which MAVS configuration and combination of

![]() $ {L}_g $

and

$ {L}_g $

and

![]() $ {L}_r $

are used to create the final ratios. Each length is broken down and specified individually to account for various ratios of rigid surface versus soft surface area. (b) The theoretical force versus displacement relationship, that is, stiffness, of the MAVS for various values of

$ {L}_r $

are used to create the final ratios. Each length is broken down and specified individually to account for various ratios of rigid surface versus soft surface area. (b) The theoretical force versus displacement relationship, that is, stiffness, of the MAVS for various values of

![]() $ N $

, which denotes the quantity of exposed soft actuators segments in MAVS-A2 design, and the front view of the MAVS-A2 design is illustrated with multiple segments of

$ N $

, which denotes the quantity of exposed soft actuators segments in MAVS-A2 design, and the front view of the MAVS-A2 design is illustrated with multiple segments of

![]() $ N $

. The applied transverse load is denoted by

$ N $

. The applied transverse load is denoted by

![]() $ F $

at the free of the MAVS in (a2).

$ F $

at the free of the MAVS in (a2).

The rigid retainers were tested in three sizes, labeled

![]() $ A $

1–

$ A $

1–

![]() $ A $

3 for each size of rigid retainer and soft actuator gaps. In this study, only the type

$ A $

3 for each size of rigid retainer and soft actuator gaps. In this study, only the type

![]() $ A $

was used. The size of the rigid retainer was

$ A $

was used. The size of the rigid retainer was

![]() $ {L}_r $

= 1 cm. The gap length was denoted by the numerical value assigned, with A1 = 0.5 cm, A2 = 1 cm, A1 = 1.5 cm. Based on the previous analysis presented in (Thalman et al., Reference Thalman, Hertzell, Debeurre and Lee2020), the MAVS-A2 was selected for the SR-AFO. The selected ratio between rigid and soft materials allowed for high stiffness for medial/lateral ankle support when pressurized (inflated) without becoming overly stiff when inactive (deflated).

$ {L}_r $

= 1 cm. The gap length was denoted by the numerical value assigned, with A1 = 0.5 cm, A2 = 1 cm, A1 = 1.5 cm. Based on the previous analysis presented in (Thalman et al., Reference Thalman, Hertzell, Debeurre and Lee2020), the MAVS-A2 was selected for the SR-AFO. The selected ratio between rigid and soft materials allowed for high stiffness for medial/lateral ankle support when pressurized (inflated) without becoming overly stiff when inactive (deflated).

The MAVS actuator was modeled as a cantilever beam, fixed and pinned in place across one half of the actuator, with the other half free to move. The cross section of each segment of the MAVS was accounted for in the final equation for deflection of the free end. The total deflection

![]() $ {V}_t\left({L}_t\right) $

of the MAVS with

$ {V}_t\left({L}_t\right) $

of the MAVS with

![]() $ N $

segments of alternating materials was calculated by

$ N $

segments of alternating materials was calculated by

These material types were denoted by the variables

![]() $ {V}_{\mathrm{PLA}} $

and

$ {V}_{\mathrm{PLA}} $

and

![]() $ {V}_{\mathrm{Nylon}} $

, which indicate the deflections using the material properties of PLA and Nylon, respectively. Segments for PLA (

$ {V}_{\mathrm{Nylon}} $

, which indicate the deflections using the material properties of PLA and Nylon, respectively. Segments for PLA (

![]() $ {E}_1{I}_1 $

) and Nylon (

$ {E}_1{I}_1 $

) and Nylon (

![]() $ {E}_2{I}_2 $

) respond differently when subjected to external loads, due to differences in material properties. These were accounted for individually for both

$ {E}_2{I}_2 $

) respond differently when subjected to external loads, due to differences in material properties. These were accounted for individually for both

![]() $ {V}_{\mathrm{PLA}} $

and

$ {V}_{\mathrm{PLA}} $

and

![]() $ {V}_{\mathrm{Nylon}} $

using Young’s elastic modulus (

$ {V}_{\mathrm{Nylon}} $

using Young’s elastic modulus (

![]() $ E $

) and the moment of inertia (

$ E $

) and the moment of inertia (

![]() $ I $

) of each segment. Each of the rigid (PLA) and soft (Nylon) segments was modeled as a simply supported cantilever beam with a single point load at the free end and using Timoshenko’s theory (Wielgosz and Thomas, Reference Wielgosz and Thomas2002; Wielgosz et al., Reference Wielgosz, Thomas and Le Van2008; Thomas and Le Van, Reference Thomas and Le Van2019). Applying this theory, the deflection of each segment (

$ I $

) of each segment. Each of the rigid (PLA) and soft (Nylon) segments was modeled as a simply supported cantilever beam with a single point load at the free end and using Timoshenko’s theory (Wielgosz and Thomas, Reference Wielgosz and Thomas2002; Wielgosz et al., Reference Wielgosz, Thomas and Le Van2008; Thomas and Le Van, Reference Thomas and Le Van2019). Applying this theory, the deflection of each segment (

![]() $ V(x) $

) can be modeled as

$ V(x) $

) can be modeled as

$$ V(x)\hskip0.35em =\hskip0.35em \frac{F}{\left(E+P/{S}_o\right){I}_o}\left(\frac{{L^2}_{r,g}x}{2}-\frac{x^3}{6}\right)+\frac{Fx}{\left(P+{kGS}_o\right)}, $$

$$ V(x)\hskip0.35em =\hskip0.35em \frac{F}{\left(E+P/{S}_o\right){I}_o}\left(\frac{{L^2}_{r,g}x}{2}-\frac{x^3}{6}\right)+\frac{Fx}{\left(P+{kGS}_o\right)}, $$

where

![]() $ {L}_{r,g} $

is the length of each segment (

$ {L}_{r,g} $

is the length of each segment (

![]() $ {L}_r $

for the rigid segment and

$ {L}_r $

for the rigid segment and

![]() $ {L}_g $

for the soft segment), which can be calculated at a length

$ {L}_g $

for the soft segment), which can be calculated at a length

![]() $ x $

away from the fixed end

$ x $

away from the fixed end

![]() $ x\hskip0.35em =\hskip0.35em 0 $

. The beam was subject to an internal pressure

$ x\hskip0.35em =\hskip0.35em 0 $

. The beam was subject to an internal pressure

![]() $ P $

and a transverse force

$ P $

and a transverse force

![]() $ F $

at the free end, where

$ F $

at the free end, where

![]() $ x\hskip0.35em =\hskip0.35em {L}_t $

. The second moment of inertia,

$ x\hskip0.35em =\hskip0.35em {L}_t $

. The second moment of inertia,

![]() $ {I}_o $

, was determined by the shape of the cross-sectional area and the axis about which the actuator was being deflected. The shear coefficient was represented by

$ {I}_o $

, was determined by the shape of the cross-sectional area and the axis about which the actuator was being deflected. The shear coefficient was represented by

![]() $ {kGS}_o $

, where

$ {kGS}_o $

, where

![]() $ {S}_o $

is the cross-sectional area,

$ {S}_o $

is the cross-sectional area,

![]() $ G $

is the shear modulus of the material, and

$ G $

is the shear modulus of the material, and

![]() $ k $

was determined by the cross-sectional shape and Cowper’s formulation (Cowper, Reference Cowper1966).

$ k $

was determined by the cross-sectional shape and Cowper’s formulation (Cowper, Reference Cowper1966).

The maximum deflection was calculated with

![]() $ x\hskip0.35em =\hskip0.35em {L}_t $

(Wielgosz and Thomas, Reference Wielgosz and Thomas2002), which reduced equation (8) to

$ x\hskip0.35em =\hskip0.35em {L}_t $

(Wielgosz and Thomas, Reference Wielgosz and Thomas2002), which reduced equation (8) to

where

![]() $ b $

is the base length of the cross-sectional area (which was kept constant at 4 cm),

$ b $

is the base length of the cross-sectional area (which was kept constant at 4 cm),

![]() $ h $

is the height of the actuator when inflated, and

$ h $

is the height of the actuator when inflated, and

![]() $ {L}_t $

is the total length of the MAVS actuator. The length

$ {L}_t $

is the total length of the MAVS actuator. The length

![]() $ {L}_t $

of the actuator was calculated as

$ {L}_t $

of the actuator was calculated as

where

![]() $ {L}_s $

is the length added by the seam,

$ {L}_s $

is the length added by the seam,

![]() $ {L}_r $

is the length of the rigid piece, and

$ {L}_r $

is the length of the rigid piece, and

![]() $ {L}_g $

is the length of the gap between rigid pieces where the soft actuator was exposed (Figure 4a1). The number of exposed sections of the soft actuator was represented by

$ {L}_g $

is the length of the gap between rigid pieces where the soft actuator was exposed (Figure 4a1). The number of exposed sections of the soft actuator was represented by

![]() $ N $

to account for varying lengths of the MAVS. The effects of varying

$ N $

to account for varying lengths of the MAVS. The effects of varying

![]() $ N $

are shown in Figure 4b, where applied transverse load versus tip deflection are shown for varying

$ N $

are shown in Figure 4b, where applied transverse load versus tip deflection are shown for varying

![]() $ N $

conditions.

$ N $

conditions.

2.3. Finite Element Analysis

In order to investigate the behavior of each actuator prior to fabrication, simulations were performed using FEA. The analysis predicted the accuracy of the analytical models, validated the behavior of the soft and integrated materials, and optimized the geometric parameters of the design. The FEA simulation was performed using an FEA software (ABAQUS, Dassault Systems, Vlizy-Villacoublay, France) in a dynamic explicit environment. The thermoplastic polyurethane (TPU)-coated Nylon was simulated using Young’s Modulus of

![]() $ E $

= 498.9 MPa, the Poisson’s ratio of

$ E $

= 498.9 MPa, the Poisson’s ratio of

![]() $ \nu $

= 0.35, and the material thickness of 0.15 mm. These properties were found in previous studies using the same materials (Thalman et al., Reference Thalman, Hsu, Snyder and Polygerinos2019), utilizing methods from previous works implementing and characterizing TPU-coated Nylon (Adams et al., Reference Adams, Sridar, Thalman, Copenhaver, Elsaad and Polygerinos2018).

$ \nu $

= 0.35, and the material thickness of 0.15 mm. These properties were found in previous studies using the same materials (Thalman et al., Reference Thalman, Hsu, Snyder and Polygerinos2019), utilizing methods from previous works implementing and characterizing TPU-coated Nylon (Adams et al., Reference Adams, Sridar, Thalman, Copenhaver, Elsaad and Polygerinos2018).

For each actuator design, the air chambers were modeled by creating a 2D homogeneous thin shell with the net shape of a single layer of the TPU-coated Nylon. Partitions were created where the heat seals were placed. Two layers of the thin shells were stacked in an assembly, and the innermost facing surfaces of each seam partition were bound using a tie constraint. The innermost facing surfaces of the air chambers were designated as a load-bearing face, and a uniform pressure load was applied outward from the initial plane of the fabric in both directions to simulate pressure. This was done for both the ff-PAM and MAVS actuators, which are described in more detail in the following sections.

Initial simulation setup was critical in ensuring that excessive node or element rotations did not occur through the simulation. For simple shapes, basic translational constraints along the fixed edges proved sufficient to keep the thin shell walls from experiencing high levels of nodal rotation or distortion. For more complicated layers such as the MAVS actuators, layers had to be positioned with small gaps between fabric and fixed rigid components to allow proper inflation of each chamber before removing any constraint on rigid parts, to allow for a more natural interaction between the compliant pressurized surface and the solid rigid surface.

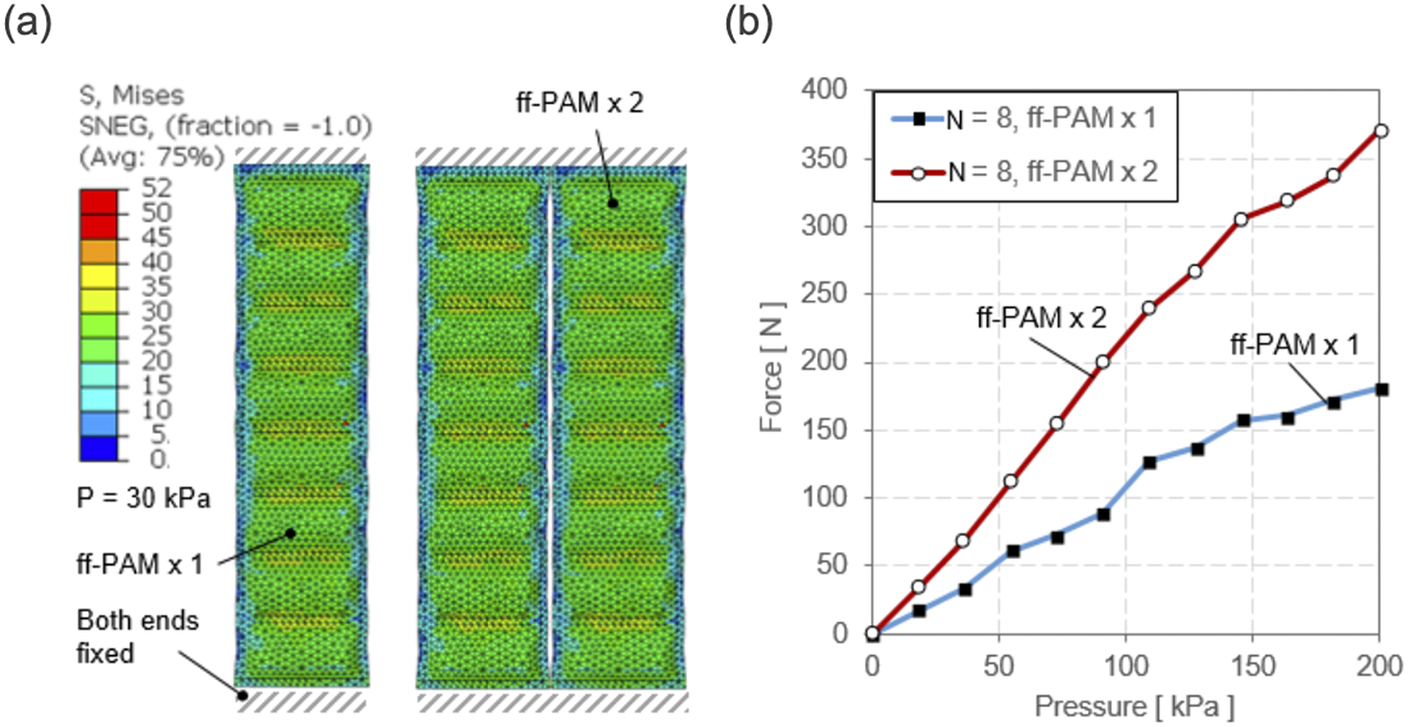

2.3.1. FEA analysis of ff-PAM

An FEA model was created for the ff-PAM using two layers of TPU-coated Nylon stacked and tied at the seams. To investigate the force and pressure relationship at a fixed displacement (0 mm), the simulation was performed when actuator vertical displacement at each end was held constant and the pressure was varied. The constant displacement condition was intended to estimate the theoretical maximum force output of the actuators, which occurs when displacement of the actuator was fixed at its original length (Ching-Ping and Hannaford, Reference Ching-Ping and Hannaford1996; Doumit et al., Reference Doumit, Fahim and Munro2009).

Pressure was incremented with each simulation until the model stabilized and a final maximum force value was obtained. One end was fixed in all directions, whereas the other was fixed vertically and used to evaluate the reaction forces across its surface to estimate the force. The forces in the vertical direction were summed along the width of the top of the actuator to estimate the tensile force generated from the actuator. This was done for varying pressure levels (0–200

![]() $ \mathrm{kPa} $

), as well as for the single and dual ff-PAM actuators (Figure 5a). For the same level of pressure, the dual actuators always exhibited a higher output force than the single actuator (Figure 5b). At the maximum pressure level tested (i.e., 200

$ \mathrm{kPa} $

), as well as for the single and dual ff-PAM actuators (Figure 5a). For the same level of pressure, the dual actuators always exhibited a higher output force than the single actuator (Figure 5b). At the maximum pressure level tested (i.e., 200

![]() $ \mathrm{kPa} $

), the peak force was 180.2

$ \mathrm{kPa} $

), the peak force was 180.2

![]() $ N $

and 373.3

$ N $

and 373.3

![]() $ N $

for the single and dual actuators, respectively. Simulation results of maximum force obtainable at each pressure level can be used to estimate the behavior of the actuator prior to fabrication.

$ N $

for the single and dual actuators, respectively. Simulation results of maximum force obtainable at each pressure level can be used to estimate the behavior of the actuator prior to fabrication.

Figure 5. (a) A sample FEA simulation result. Both ends of the actuator are fixed, and the pressure is varied to obtain the maximum tensile force at each level. The color map shows the stress across the surface of the actuator to show a uniform loading of the internal pressure force. A sample result at 30

![]() $ \mathrm{kPa} $

is shown. (b) Simulation results of the force versus pressure relation at the constant displacement for the single and dual ff-PAM actuators. Forces are the result of the summation of vertical force components along the fixed ends.

$ \mathrm{kPa} $

is shown. (b) Simulation results of the force versus pressure relation at the constant displacement for the single and dual ff-PAM actuators. Forces are the result of the summation of vertical force components along the fixed ends.

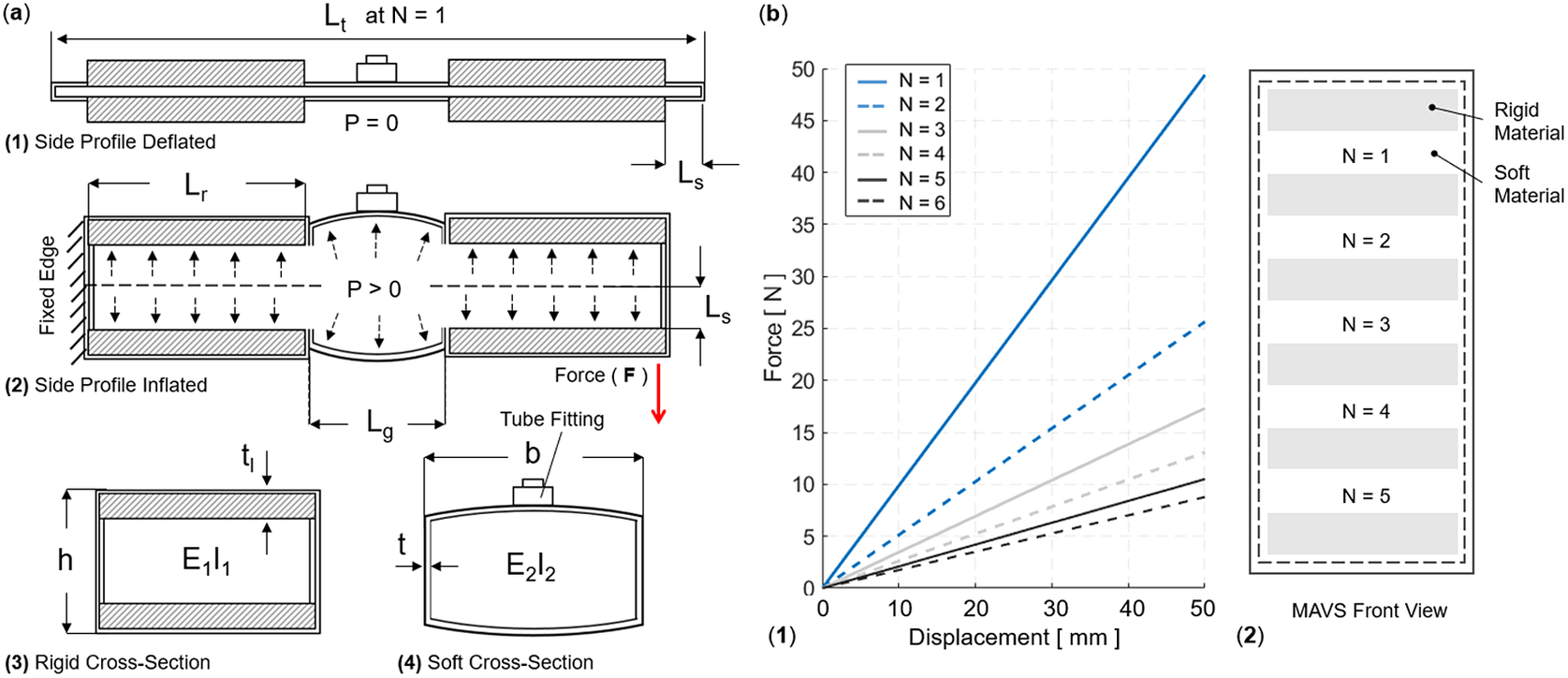

2.3.2. FEA analysis of MAVS

The MAVS was modeled using a combination of simulated materials for both the soft actuator and rigid retainers. Thin 2D homogeneous shells were used in the shape of a hollow rectangle to create the pneumatic chamber, with the length and width of the rectangle the same dimensions as that of the MAVS width and length. The rigid retainers were modeled using solid 3D homogeneous extrusions, and assigned a material property for PLA 3D-printed material, which was modeled using material properties with Young’s Modulus of 3,600

![]() $ \mathrm{MPa} $

and the Poisson’s ratio of 0.3 as used in previous works (Tehrani et al., Reference Tehrani, Akbari and Majumder2014; Pepelnjak et al., Reference Pepelnjak, Karimi, Maček and Mole2020). More thorough explanation of MAVS FEA modeling can be found in previous studies (Thalman et al., Reference Thalman, Hertzell, Debeurre and Lee2020).

$ \mathrm{MPa} $

and the Poisson’s ratio of 0.3 as used in previous works (Tehrani et al., Reference Tehrani, Akbari and Majumder2014; Pepelnjak et al., Reference Pepelnjak, Karimi, Maček and Mole2020). More thorough explanation of MAVS FEA modeling can be found in previous studies (Thalman et al., Reference Thalman, Hertzell, Debeurre and Lee2020).

The pneumatic pouch was sealed by tying the edges of the thin shells around the perimeter of the rectangular parts. The rigid pieces were placed on the top and bottom faces of the rectangular shell, parallel to the face, and spaced according to which MAVS variation was simulated. An additional 2D homogeneous shell of Nylon fabric was placed to encase the stacked soft actuator and rigid retainers. The outward faces of the rigid pieces were tied to the outer shell, and a global interaction property for surface–surface contact was applied to the assembly. A solid 3D homogeneous clamp was created with the PLA material property and fixed to hold the actuator at a fixed point for the cantilever beam example modeled in the previous section. The major benefit of being able to model the MAVS was to show the interaction between multiple layers of several material types, thicknesses, and properties. This allowed the internal chambers of the MAVS to be observed and studied as done in other works with variable stiffness actuators (Sun et al., Reference Sun, Chen, Han, Jiao, Lian and Song2020).

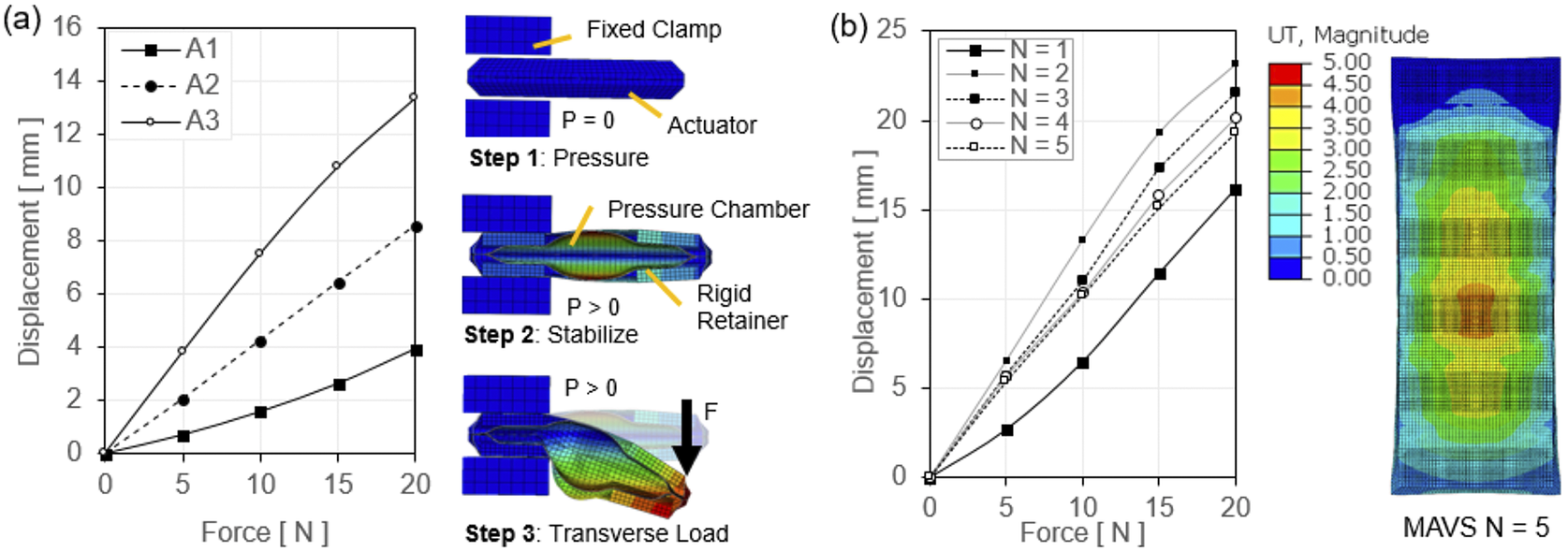

Two loads were applied to the model: (a) a uniform pressure load to the internal faces of the thin shells of the actuator, and (b) a transverse load applied at a fixed point at the end of the actuator. A total of three steps were run for the simulation: (1) pressurization, (2) stabilization, and (3) point loading as depicted in Figure 6a. The deflection of the MAVS was measured by fixing one half of the MAVS and applying a perpendicular force to the free end. Transverse loads of 5, 10, 15, and 20

![]() $ N $

were applied at a fixed point on the free end of the actuator, which was inflated to 100

$ N $

were applied at a fixed point on the free end of the actuator, which was inflated to 100

![]() $ \mathrm{kPa} $

. This was done for the three highest performing MAVS designs (

$ \mathrm{kPa} $

. This was done for the three highest performing MAVS designs (

![]() $ A1-A3 $

) predicted by the analytical model. The deflection at the end of the actuator was measured along the direction of the transverse load. Simulation results showed that stiffness of the MAVS decreased as

$ A1-A3 $

) predicted by the analytical model. The deflection at the end of the actuator was measured along the direction of the transverse load. Simulation results showed that stiffness of the MAVS decreased as

![]() $ {L}_g $

increased (Figure 6a).

$ {L}_g $

increased (Figure 6a).

Figure 6. (a) The force–displacement output of a single multi-material actuator for variable stiffness (MAVS) actuator is evaluated with finite element analysis (FEA) for the MAVS-A1, A2, and A3. Various loads are applied to the free end of the MAVS while in a cantilever orientation and the resulting displacement is recorded as the actuator beam begins to buckle under load. (b) FEA simulation results of the same sequence of steps as (a), with the MAVS-A2 actuator, varying the number of segments (

![]() $ N $

) for each simulation to calculate the total displacement of the free end.

$ N $

) for each simulation to calculate the total displacement of the free end.

Since the MAVS-A2 was selected as the primary MAVS actuator for the SR-AFO, the MAVS-A2 design was evaluated in further detail using FEA to analyze the behavior of the actuator at varying lengths and numbers of segments of alternating materials

![]() $ N $

. The MAVS-A2 actuator was modeled in the FEA simulation as a cantilever beam as done in the previous simulation. One end of the MAVS was constrained between two infinitely stiff, fixed blocks which held the end in place. The other end of the MAVS was subjected to a transverse point load at the end of the actuator perpendicular to the top surface as shown in Step 3 of Figure 6a. The tip deflection of the MAVS was recorded for loads of 5, 10, 15, and 20

$ N $

. The MAVS-A2 actuator was modeled in the FEA simulation as a cantilever beam as done in the previous simulation. One end of the MAVS was constrained between two infinitely stiff, fixed blocks which held the end in place. The other end of the MAVS was subjected to a transverse point load at the end of the actuator perpendicular to the top surface as shown in Step 3 of Figure 6a. The tip deflection of the MAVS was recorded for loads of 5, 10, 15, and 20

![]() $ N $

. The value of

$ N $

. The value of

![]() $ N $

was also increased after each set of point loads was applied from

$ N $

was also increased after each set of point loads was applied from

![]() $ N $

= 1–5 with the internal pressure of the MAVS fixed at a constant 50

$ N $

= 1–5 with the internal pressure of the MAVS fixed at a constant 50

![]() $ \mathrm{kPa} $

for each simulation (Figure 6b).

$ \mathrm{kPa} $

for each simulation (Figure 6b).

Simulation results showed the least deflection with

![]() $ N $

= 1 across all loading conditions, likely due to the small net size of the actuator. However, as

$ N $

= 1 across all loading conditions, likely due to the small net size of the actuator. However, as

![]() $ N $

increased more than one, the degree of deflection was comparable for each loading condition. This result helps to validate that, even at longer lengths, the MAVS-A2 actuator can maintain relatively constant bending stiffness and resist deflection against medial and lateral loads. This is a critical point as a single MAVS-A2 chamber is not long enough to cross the length of the human ankle, whereas the MAVS-A2 at

$ N $

increased more than one, the degree of deflection was comparable for each loading condition. This result helps to validate that, even at longer lengths, the MAVS-A2 actuator can maintain relatively constant bending stiffness and resist deflection against medial and lateral loads. This is a critical point as a single MAVS-A2 chamber is not long enough to cross the length of the human ankle, whereas the MAVS-A2 at

![]() $ N $

= 5 is able to cross the ankle joint effectively.

$ N $

= 5 is able to cross the ankle joint effectively.

2.4. Actuator Characterization

A universal testing machine (UTM; Instron 5565, Instron Corporation, High Wycombe, United Kingdom) was used to experimentally characterize both the ff-PAM and MAVS actuators of the SR-AFO exosuit and evaluate their performance.

2.4.1. Characterization of ff-PAM

Three different types of experiments were performed to evaluate (a) tensile force versus contraction at varying pressure levels; (b) tensile force versus pressure at a fixed displacement at 0

![]() $ \mathrm{mm} $

(i.e., zero contraction); and (c) dynamic response of tensile force generation.

$ \mathrm{mm} $

(i.e., zero contraction); and (c) dynamic response of tensile force generation.

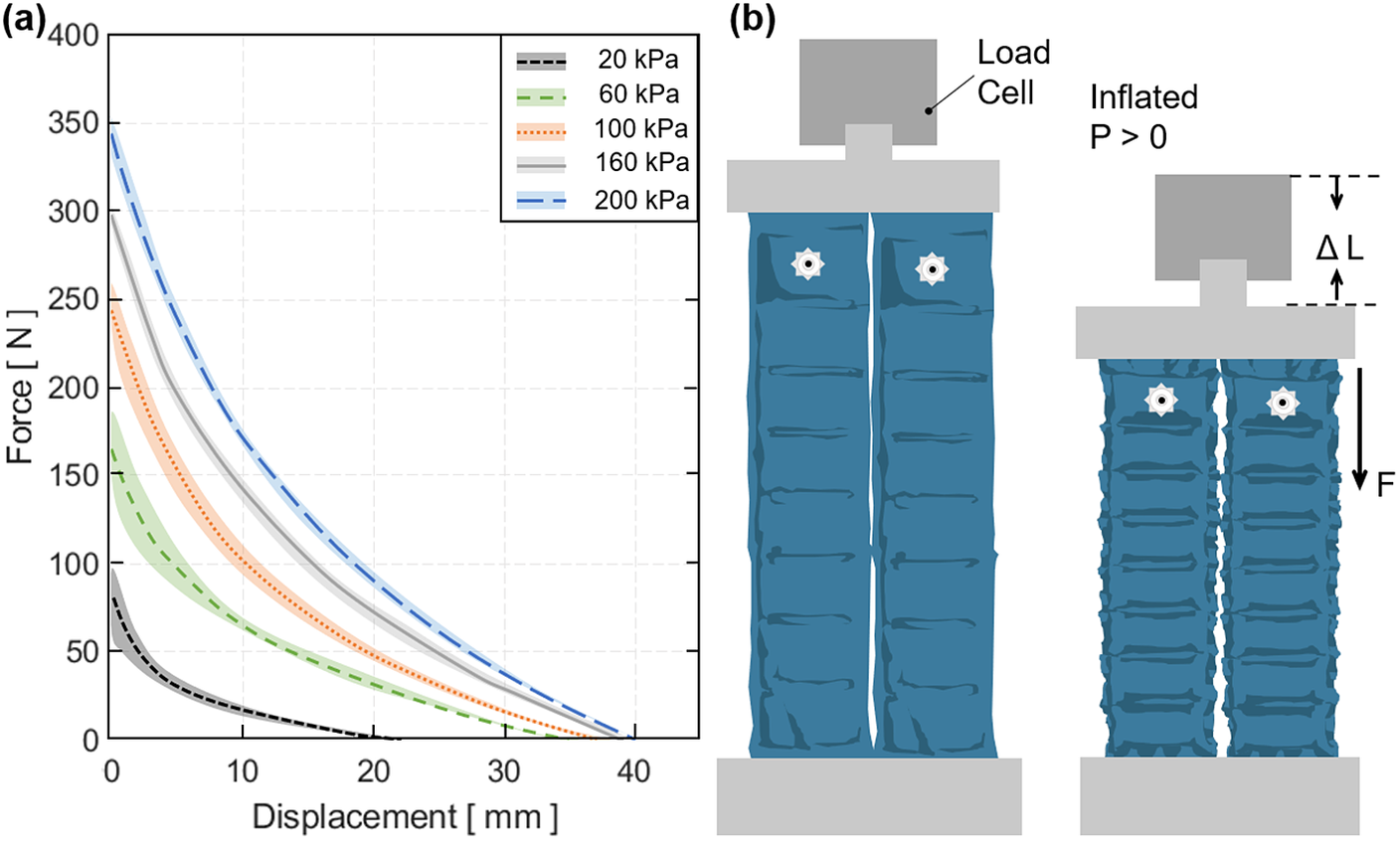

In the first quasi-static experiment, the output tensile force versus actuator contraction (or displacement) relation was evaluated under varying pressure levels. The experiment was performed at five different pressure levels (20, 60, 100, 160, and 200

![]() $ \mathrm{kPa} $

) with five repetitions per each pressure condition. The UTM was programmed to induce a controlled vertical translation and measure actuator force versus contraction. Each measurement was completed once the load cell reading was 0

$ \mathrm{kPa} $

) with five repetitions per each pressure condition. The UTM was programmed to induce a controlled vertical translation and measure actuator force versus contraction. Each measurement was completed once the load cell reading was 0

![]() $ N $

, indicating full actuator contraction. The load cell increased the uniaxial compression at 5 mm/s until it read 0

$ N $

, indicating full actuator contraction. The load cell increased the uniaxial compression at 5 mm/s until it read 0

![]() $ N $

of force. The load cell was returned to the zero position, and the test was run cyclically for five repetitions. The average result (mean and mean

$ N $

of force. The load cell was returned to the zero position, and the test was run cyclically for five repetitions. The average result (mean and mean

![]() $ \pm $

standard deviation [std]) and the test condition are shown in Figure 7a.

$ \pm $

standard deviation [std]) and the test condition are shown in Figure 7a.

Figure 7. (a) The tensile force output versus contraction of the dual flat fabric pneumatic artificial muscle (ff-PAM) actuator in the quasi-static experiment. Five constant pressure levels are tested, and mean and mean

![]() $ \pm $

standard deviation are shown. (b) The test conditions and setup of the dual ff-PAM actuator in the UTM before and after pressurization.

$ \pm $

standard deviation are shown. (b) The test conditions and setup of the dual ff-PAM actuator in the UTM before and after pressurization.

Tensile force of the ff-PAM was maximized when the actuator length was maximized (zero contraction), and the force approached 0

![]() $ N $

as the actuator fully contracted. In addition, as the pressure level increased, the force output was less variable. At 200

$ N $

as the actuator fully contracted. In addition, as the pressure level increased, the force output was less variable. At 200

![]() $ \mathrm{kPa} $

, the maximum force output was 346.5 ± 1.4

$ \mathrm{kPa} $

, the maximum force output was 346.5 ± 1.4

![]() $ N $

, whereas at 100

$ N $

, whereas at 100

![]() $ \mathrm{kPa} $

, it was 245.4 ± 15.8

$ \mathrm{kPa} $

, it was 245.4 ± 15.8

![]() $ N $

, decreasing the output by 100

$ N $

, decreasing the output by 100

![]() $ N $

and increasing the variability drastically. Following this trend, at 20

$ N $

and increasing the variability drastically. Following this trend, at 20

![]() $ \mathrm{kPa} $

, the maximum force output was 83.0 ± 16.5

$ \mathrm{kPa} $

, the maximum force output was 83.0 ± 16.5

![]() $ N $

. The variability was close to that at 100

$ N $

. The variability was close to that at 100

![]() $ \mathrm{kPa} $

, yet the force dropped drastically.

$ \mathrm{kPa} $

, yet the force dropped drastically.

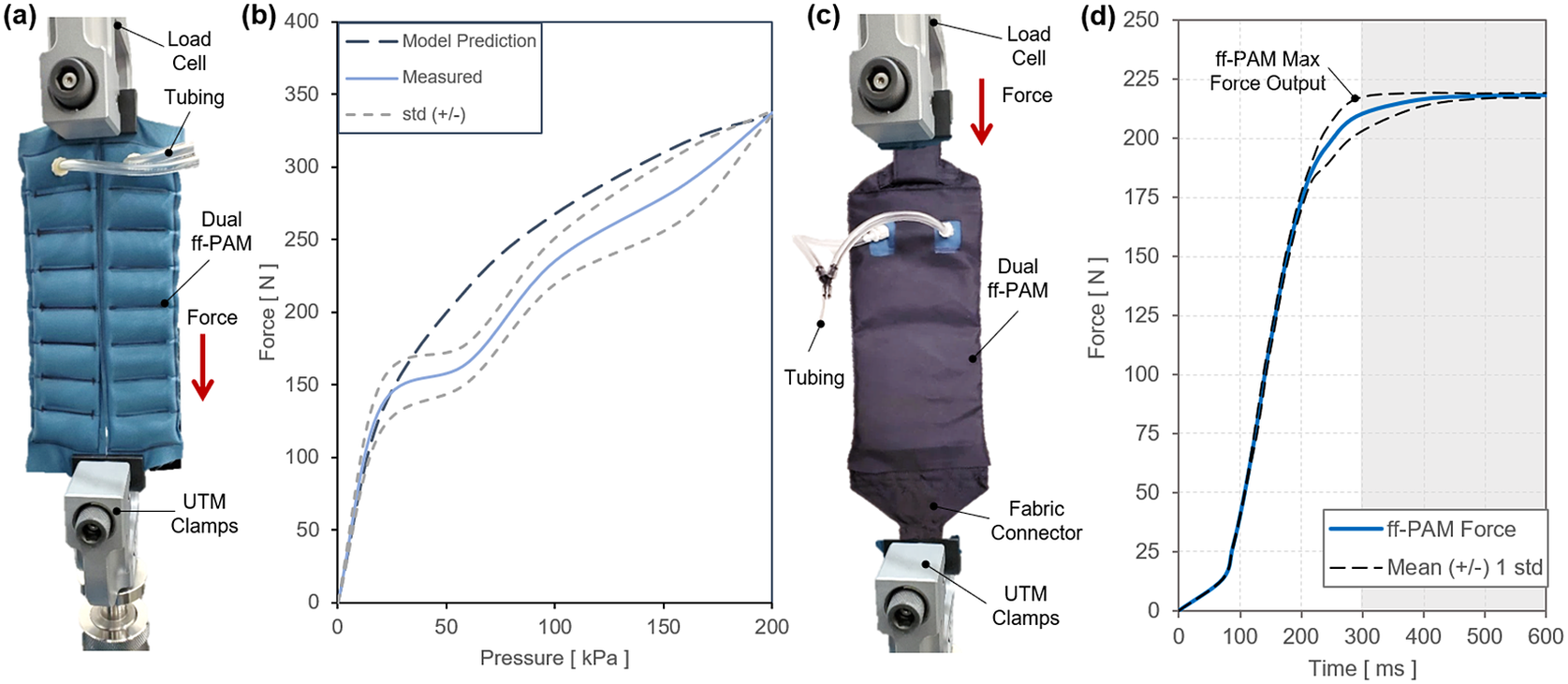

In the second static experiment, the output tensile force versus pressure relation was evaluated when displacement was fixed at 0 mm. This relation was compared with the predictions from the analytical model and the FEA simulated maximum force threshold. The dual ff-PAM was placed in a vice clamp with the UTM displacement fixed at 0 mm. The actuators we placed in the UTM are shown in Figure 8a. The pressure increased quasi-statically from 0 to 200

![]() $ \mathrm{kPa} $

in fixed increments of 10

$ \mathrm{kPa} $

in fixed increments of 10

![]() $ \mathrm{kPa} $

until a stable load could be read from the UTM. Three repeated measurements were performed. The final maximum tensile force output of the ff-PAM actuator at 200

$ \mathrm{kPa} $

until a stable load could be read from the UTM. Three repeated measurements were performed. The final maximum tensile force output of the ff-PAM actuator at 200

![]() $ \mathrm{kPa} $

measured by the UTM was 337.1 ± 1.4

$ \mathrm{kPa} $

measured by the UTM was 337.1 ± 1.4

![]() $ N $

(Figure 8b).

$ N $

(Figure 8b).

Figure 8. (a) The test setup for experimental characterization of the flat fabric pneumatic artificial muscle (ff-PAM) actuator. The ff-PAM is fixed in the vice clamp of the universal testing machine (UTM). (b) The tensile force output of the dual ff-PAM actuator versus pressure input in the static experiment. Experimental results are compared with the analytic model prediction. (c) The experimental setup of the dual ff-PAM actuator in the casing that attaches the actuators to the soft robotic ankle-foot orthosis. This includes two fabric connectors that affix the ends of the actuators to a single anchoring point. (d) The dynamic response of the dual ff-PAM actuators, while clamped at maximum length in the UTM interface. The response is measured for the time required to achieve maximum force output at 150

![]() $ \mathrm{kPa} $

.

$ \mathrm{kPa} $

.

In the third experimental characterization, a dynamic test was performed to obtain a force versus time relation to measure how quickly the actuator reacts to pressurized input. A fabric connector was affixed to the top and bottom of the ff-PAMs to secure both actuators together with a tapered fabric component used to transfer the force from pressurization to a single point (Figure 8c). By allowing the actuator to interface with a fabric anchor, it is assumed that a more realistic force output can be measured to represent the behavior of the actuator when worn on the SR-AFO exosuit. The dynamic response was initiated by rapidly opening a three-way, two-channeled solenoid valve (320-12 VDC, Humphrey, Kalamazoo, MI, USA) to quickly deliver pre-set pressure to the internal air chambers of the ff-PAM. This characterization is important since the ff-PAM actuator is designed to provide a tensile force through uniaxial contraction to the posterior end of the foot to assist plantarflexion during the push-off phase of human gait, and the actuator must be able to provide sufficient force output within a time window that allows the user to feel each controlled perturbation. At a fixed pressure of 150

![]() $ \mathrm{kPa} $

, the valve was opened to provide rapid pressurization. The actuator was able to provide 212.3 ± 7.7

$ \mathrm{kPa} $

, the valve was opened to provide rapid pressurization. The actuator was able to provide 212.3 ± 7.7

![]() $ N $

of tensile force in 0.29 s (Figure 8d).

$ N $

of tensile force in 0.29 s (Figure 8d).

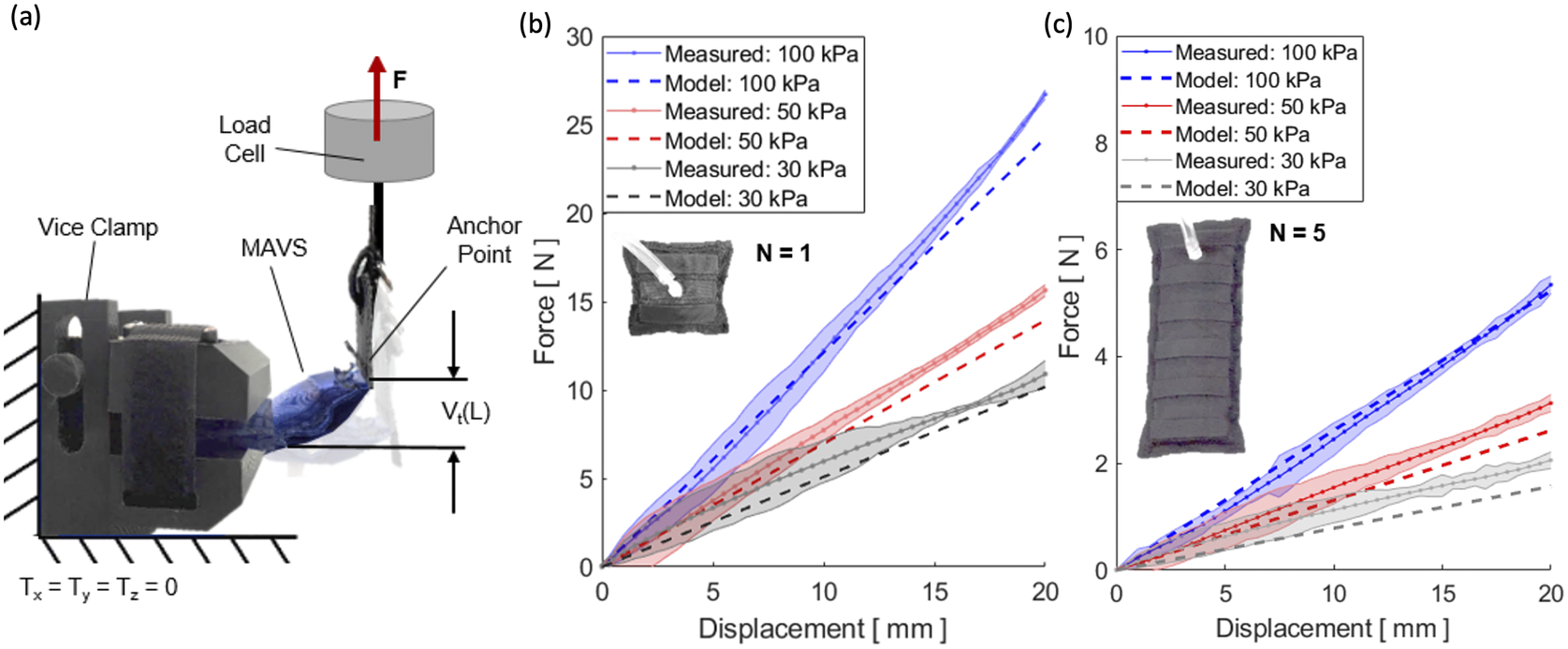

2.4.2. Characterization of MAVS

The MAVS actuators were tested using a custom clamp which was fabricated to fix the actuators in place while being subjected to deflection testing. The MAVS had a tab sewn into the free end to interface with the clamps paired with the load cell of UTM (Figure 9a). This allowed for the UTM to apply a point load to the MAVS, while it was fixed in a cantilever position. The UTM pulled the free end of the MAVS upward 20 mm. The tab acted as a constant point of contact so that the lever arm distance did not change. Each iteration was deflected upward, and the force was measured so that the stiffness of each MAVS could be determined.

Figure 9. (a) The test setup for experimental characterization of the multi-material actuator for variable stiffness (MAVS) actuator. The universal testing machine is shown from the side view, with the custom 3D-printed clamp and the MAVS actuator fixed to the load cell. (b) Measured force versus displacement/deflection relationship for a single unit of the MAVS-A2 actuator (

![]() $ N= $

1). A maximum 20-mm deflection was tested at three pressure input levels (30, 50, and 100

$ N= $

1). A maximum 20-mm deflection was tested at three pressure input levels (30, 50, and 100

![]() $ \mathrm{kPa} $

). Model predictions of the force required to deflect the same distance (20 mm) is shown with dotted lines. (c) Measured force versus the displacement/deflection relationship for a longer MAVS-A2 actuator (

$ \mathrm{kPa} $

). Model predictions of the force required to deflect the same distance (20 mm) is shown with dotted lines. (c) Measured force versus the displacement/deflection relationship for a longer MAVS-A2 actuator (

![]() $ N= $

5) used in the soft robotic ankle-foot orthosis.

$ N= $

5) used in the soft robotic ankle-foot orthosis.

The MAVS-A2 actuator, our selection for the SR-AFO, was evaluated for pressure levels of 30, 50, and 100

![]() $ \mathrm{kPa} $

in the cantilever orientation and compared to the analytical model. The rationale for these pressure level selections was based on two factors: (a) accuracy of higher pressures and (b) comfort of the user. With the MAVS actuator integrated into the SR-AFO design, user feedback indicated pressure levels of above 100

$ \mathrm{kPa} $

in the cantilever orientation and compared to the analytical model. The rationale for these pressure level selections was based on two factors: (a) accuracy of higher pressures and (b) comfort of the user. With the MAVS actuator integrated into the SR-AFO design, user feedback indicated pressure levels of above 100

![]() $ \mathrm{kPa} $

were not comfortable during walking. This evaluation was performed for the original MAVS-A2 design where

$ \mathrm{kPa} $

were not comfortable during walking. This evaluation was performed for the original MAVS-A2 design where

![]() $ N\hskip0.35em =\hskip0.35em $

1, and performed a second time for MAVS-A2 for

$ N\hskip0.35em =\hskip0.35em $

1, and performed a second time for MAVS-A2 for

![]() $ N\hskip0.35em =\hskip0.35em $

5, the latter of which is the version of the MAVS-A2 actuator embedded into the SR-AFO exosuit.

$ N\hskip0.35em =\hskip0.35em $

5, the latter of which is the version of the MAVS-A2 actuator embedded into the SR-AFO exosuit.

The MAVS-A2 actuator with

![]() $ N\hskip0.35em =\hskip0.35em $

1 experienced 20 mm of deflection with an applied load of 12.1 ± 0.2

$ N\hskip0.35em =\hskip0.35em $

1 experienced 20 mm of deflection with an applied load of 12.1 ± 0.2

![]() $ N $

, 15.6 ± 0.1

$ N $

, 15.6 ± 0.1

![]() $ N $

, and 26.7 ± 0.1

$ N $

, and 26.7 ± 0.1

![]() $ N $

at 30, 50, and 100

$ N $

at 30, 50, and 100

![]() $ \mathrm{kPa} $

, respectively (Figure 9b). It was observed that as pressure decreased, so did the applied load required to reach the fixed displacement threshold. The variability increased with lower pressures, although this was anticipated as lower pressure would result in higher changes of buckling at unpredictable locations. Increasing the length to

$ \mathrm{kPa} $

, respectively (Figure 9b). It was observed that as pressure decreased, so did the applied load required to reach the fixed displacement threshold. The variability increased with lower pressures, although this was anticipated as lower pressure would result in higher changes of buckling at unpredictable locations. Increasing the length to

![]() $ N\hskip0.35em =\hskip0.35em $

5 showed similar trends. While the overall deflection had less resistance to bending observed than the

$ N\hskip0.35em =\hskip0.35em $

5 showed similar trends. While the overall deflection had less resistance to bending observed than the

![]() $ N\hskip0.35em =\hskip0.35em $

1 condition, this was an expected result since the MAVS-A2 had an increased length. The MAVS-A2 with

$ N\hskip0.35em =\hskip0.35em $

1 condition, this was an expected result since the MAVS-A2 had an increased length. The MAVS-A2 with

![]() $ N\hskip0.35em =\hskip0.35em $

5 required 2.4 ± 0.2

$ N\hskip0.35em =\hskip0.35em $

5 required 2.4 ± 0.2

![]() $ N $

, 3.1 ± 0.2

$ N $

, 3.1 ± 0.2

![]() $ N $

, and 5.3 ± 0.2

$ N $

, and 5.3 ± 0.2

![]() $ N $

, for 30, 50, and 100

$ N $

, for 30, 50, and 100

![]() $ \mathrm{kPa} $

, respectively, to reach 20 mm of deflection (Figure 9c).

$ \mathrm{kPa} $

, respectively, to reach 20 mm of deflection (Figure 9c).

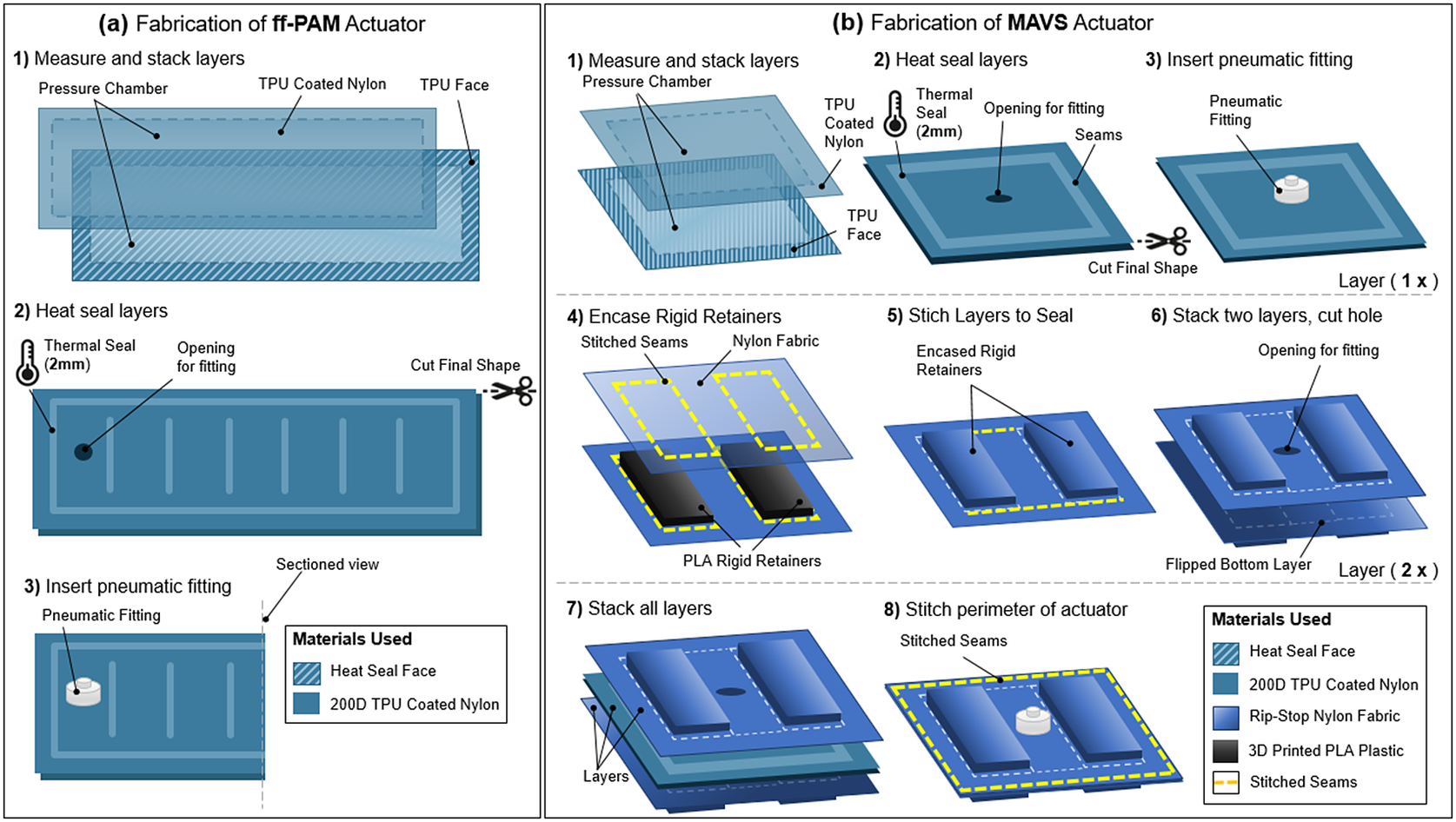

2.5. Actuator Fabrication

The pneumatic chambers of the ff-PAM and MAVS actuators were fabricated using TPU-coated Nylon fabric (200 Denier Rockywoods Fabrics), which was thermally bonded with a 2-mm heat impulse sealer (AIE-500 2-mm Impulse Sealer, American International Electric Inc., City of Industry, CA, USA). The heat impulse sealer applied uniform heat and pressure to the seam to create an air-tight seal (Thalman et al., Reference Thalman, Hsu, Snyder and Polygerinos2019).

2.5.1. Fabrication of ff-PAM

The ff-PAM actuator was fabricated primarily following the procedures for soft fabric actuators listed above; however, there were a few additional details that made the actuator design unique. Two layers of TPU-coated Nylon were first stacked and sealed (Figure 10a1). Once three sides were sealed, thick card-stock stencils were placed over the heat sealer with a gap size of the inner seams (Figure 10a2). This ensured that the seal was only formed for the segment in the center and left the gaps open and unsealed on either side of the ff-PAM to allow airflow to the subsequent segments. Each segment was sealed using this technique until the eight chambers were created. A hole was created in the last chamber (Figure 10a2), and a fitting was inserted (Figure 10a3). The last side was then sealed to create one ff-PAM actuator.

Figure 10. (a) The fabrication process of the flat fabric pneumatic artificial muscle actuator. The formation of the air-tight chamber using thermoplastic polyurethane (TPU)-coated Nylon and a heat seal (a1), the creation of the ribs and placement of the pneumatic fitting (a2), and the final fitting placement (a3) are illustrated. (b) The fabrication process of the MAVS actuator. Heat sealing and fitting placement of the soft actuator using TPU-coated Nylon to form the air-tight chamber (b1–b3), the laying and placement of the rigid retainers in the out layers of the MAVS by embedding polylactic acid (PLA) into Nylon fabric layers (b4–b6), and the final stages of integrating and stacking the MAVS layers (b7 and b8) are shown where the air-tight chamber is placed in between two layers of PLA embedded in Nylon. All components are stitched together around the perimeter to form the MAVS.

For the dual ff-PAM, two actuators were fabricated using this process and laid out in parallel. Nylon fabric (uncoated) was cut to sew the two actuators to one another along the length of the top and bottom seams. A standard tabletop sewing machine (SE-400 Brother, Bridgewater, NJ, USA) was used to create these seams and stitch the fabric connector onto the ff-PAMs. The Nylon fabric connector was cut into a pre-defined pattern that matched the width of the dual ff-PAM and tapered to a single thin strap. This allowed for the dual ff-PAM to be affixed firmly to the SR-AFO at the base of the heel and at the back of the knee with Velcro.

2.5.2. Fabrication of MAVS

The first of the three layer design was composed of rigid PLA 3D Printer Filament (1.75-mm diameter PLA 3D Printer Filament, HATCHBOX, Pomona, CA, USA) sewn between two layers of fabric. Two layers of the embedded rigid retainers were used to encase an inflatable actuator in between. A sewing machine was used to create stitching to hold the rigid retainers in place, as well as to hold the layers together.

The MAVS consisted of a total of three main layers as shown in Figure 10b: a single fabric-based inflatable actuator and two layers of Nylon material with the rigid retainers embedded into the layers. The inflatable chamber was sealed at the designated location to create a rectangular shape using the heat impulse sealer on three of the four sides (Figure 10b1). The fourth side was left open for the installation of the pneumatic fitting (Figure 10b2). A small hole was cut into the fabric, and the threaded Nylon barbed nozzle and nut fitting were secured onto the TPU-coated Nylon (Figure 10b3). The final side was sealed with the impulse sealer to create an air-tight seal that is the same net shape as the entire actuator.

The additional two layers were fabricated using the same method for each (Figure 10b4–b6). The rigid retainers were 3D-printed using PLA and have a thickness of 2 mm and a width of 40 mm, whereas the length as well as the distance between the rigid retainers were 10 mm for the selected MAVS-A2 actuator. Each of the constraining layers was made from two pieces of Nylon fabric, which were stacked with the rigid retainers placed in between at fixed distances. A sewing machine was used to create a stitched seam around the net shape of the rigid retainers, encasing the parts between the two Nylon layers. This was done to create the top and bottom constraining layers. A hole was cut into the top constraining layer to allow the tube fitting from the soft actuator to fit in between the rigid retainers. The sealed soft actuator was placed in between the two constraining layers (Figure 10b7), with the fitting centered within the hole cut previously into the top constraining layer. A final seam was sewn in a rectangular shape around the rigid retainers, at a 5-mm offset. This seam allowance provided a buffer to avoid sewing into the sealed soft actuator and to provide an offset that constrained vertical expansion during inflation (Figure 10b8).

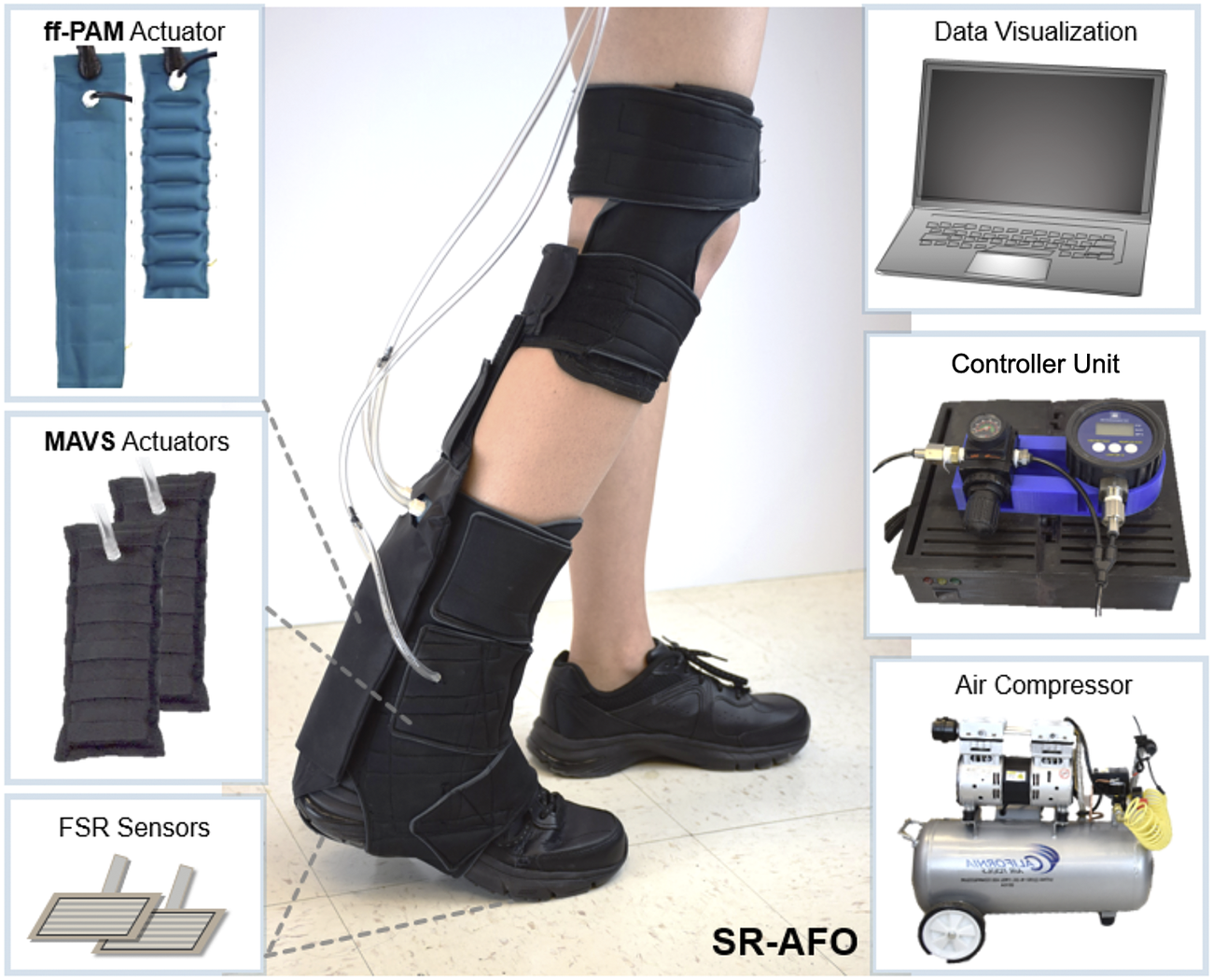

2.6. SR-AFO Hardware Design

The SR-AFO was designed to be worn in a variety of applications, and is shown with all critical components in Figure 11. The hardware used to control the exosuit is housed within a lightweight fabric belt, which can be adjusted to be worn on the hips, or worn as a backpack depending on the user preference. The cables are long enough to allow the hardware to be set aside and placed next to the test platform if on-board hardware is not ideal for the test conditions. The tabletop version of the design was used in this study. The total worn mass of the SR-AFO system is 0.203

![]() $ \mathrm{kg} $

. The compressor is not worn during use. The compressor and all hardware sit beside the treadmill and/or walking path with a tether to the participant.

$ \mathrm{kg} $

. The compressor is not worn during use. The compressor and all hardware sit beside the treadmill and/or walking path with a tether to the participant.

Figure 11. (Middle) The final assembly of the soft robotic ankle-foot orthosis and its components. (Left) The flat fabric pneumatic artificial muscle and multi-material actuator for variable stiffness actuators and the force-sensitive resistor sensors for gait detection. (Right) The controller, pneumatic source (air compressor), and visual feedback for system operation.

The hardware logic controller used an Arduino Mega 2560 Rev3, which connected all analog inputs and digital outputs of the SR-AFO to monitor the status of the system. These I/O were categorized by the force-sensitive resistor sensors (Interlink 406, Adafruit, New York, NY, USA), which were embedded in the user’s shoe to detect gait phase. Pressure sensors (ASDXAVX 100PGAA5, Honeywell Sensing and Productivity Solutions, Charlotte, NC, USA) were used to monitor actuator pressure throughout the operation of the SR-AFO, and three-way, two-channeled solenoid valves (320-12 VDC, Humphrey) MOSFETs (IRF520 MOSFET Driver Module) were used to actuate the SR-AFO exosuit at various times. The control pouch was connected to a portable air compressor (Model 8010A, California Air Tools, San Diego, CA, USA), which can be easily placed next to the current test site or facility and provided a pneumatic power source for the actuators.

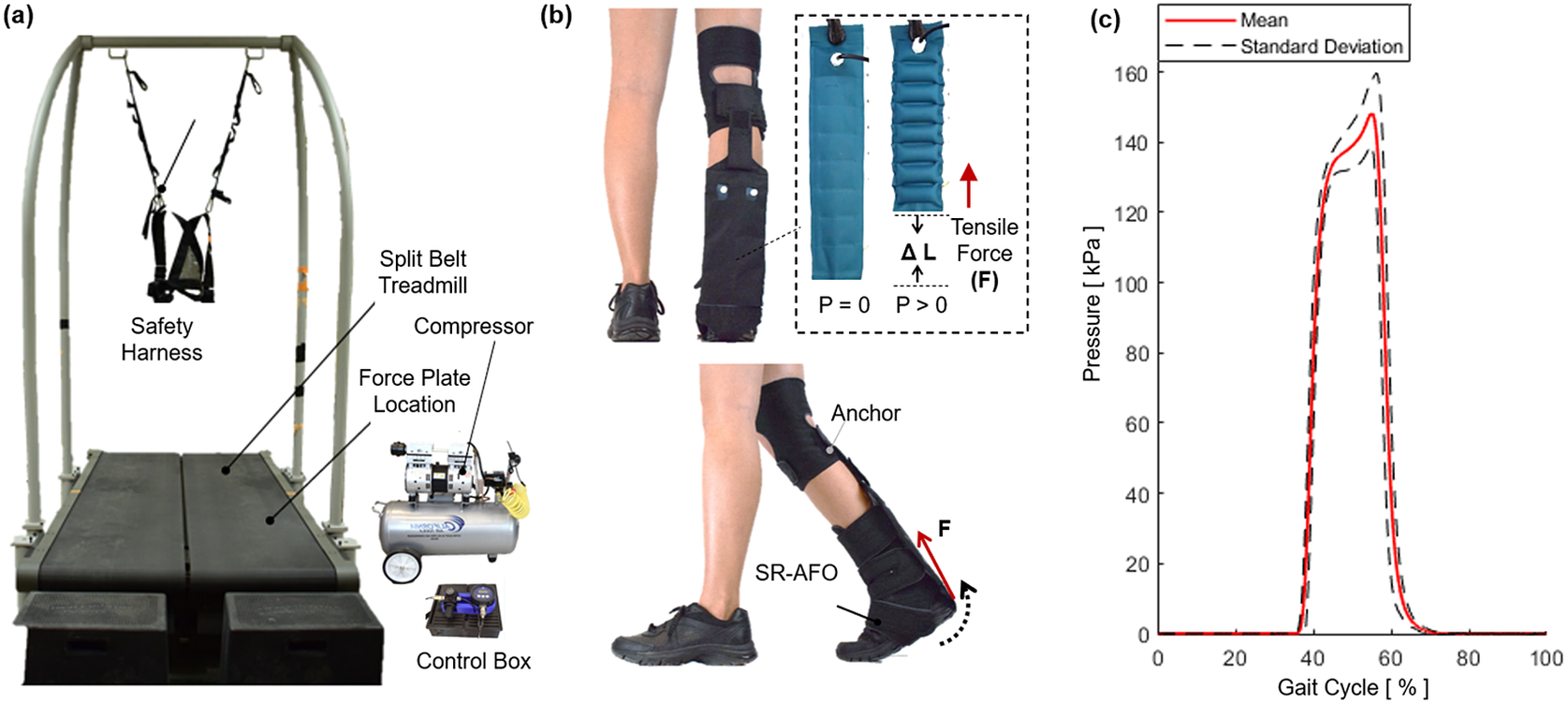

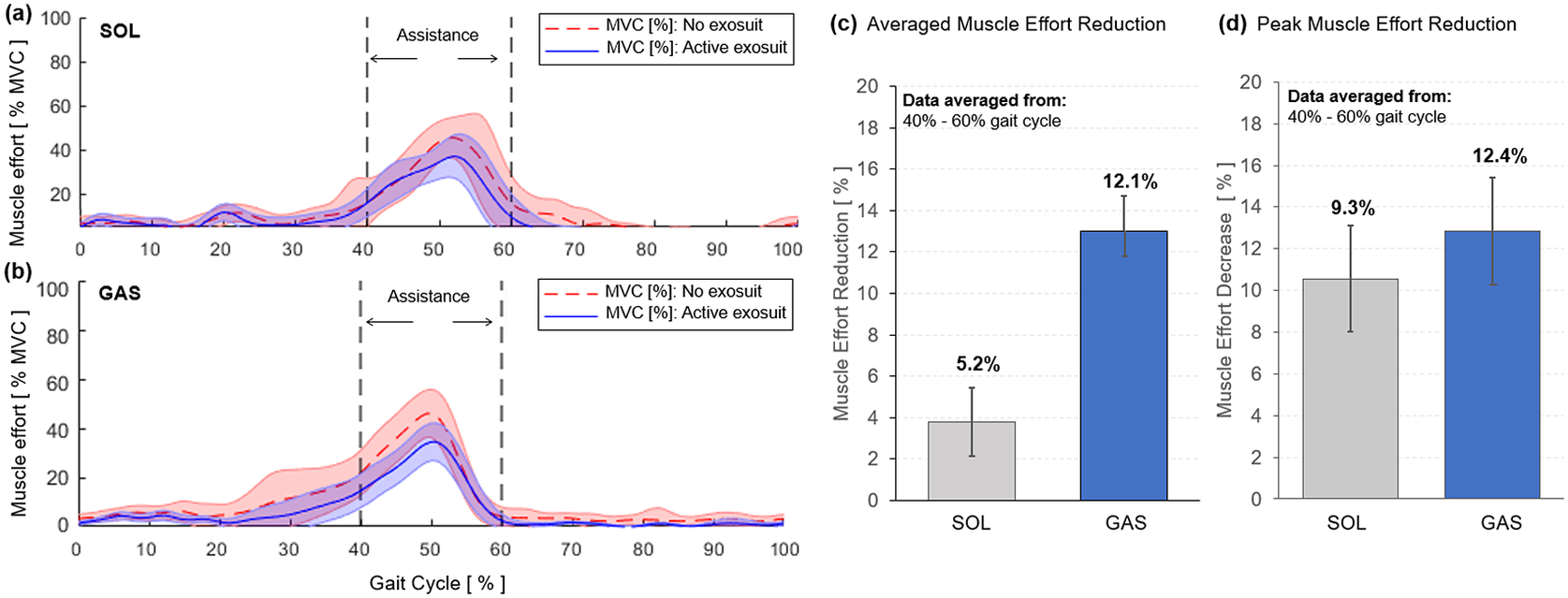

3. Human Trials and Experimental Evaluation of the SR-AFO

In order to evaluate the effectiveness of the SR-AFO, specifically the MAVS for lateral ankle support and the ff-PAM for plantarflexion assistance, three different human experiments were designed and performed: (a) quiet standing; (b) walking over compliant surfaces; and (c) treadmill walking. A total of six able-bodied participants (

![]() $ N $

= 6) participated in the experiments (male = 4, female = 2, age = 23–29 years, height = 1.68–1.88 m, weight = 47.6–72.9 kg, BMI = 16.9–23.0, and leg length = 0.81–1.05 m). All the participants gave informed consent prior to participation, and the study was approved by the ASU Institutional Review Board (STUDY00012099). A screening process was used to ensure this study included only able-bodied individuals, with no diagnosed musculoskeletal disorders, gait impairments, or past or current injuries to the lower limbs. Participants with any active illness or symptoms were also excluded.

$ N $

= 6) participated in the experiments (male = 4, female = 2, age = 23–29 years, height = 1.68–1.88 m, weight = 47.6–72.9 kg, BMI = 16.9–23.0, and leg length = 0.81–1.05 m). All the participants gave informed consent prior to participation, and the study was approved by the ASU Institutional Review Board (STUDY00012099). A screening process was used to ensure this study included only able-bodied individuals, with no diagnosed musculoskeletal disorders, gait impairments, or past or current injuries to the lower limbs. Participants with any active illness or symptoms were also excluded.

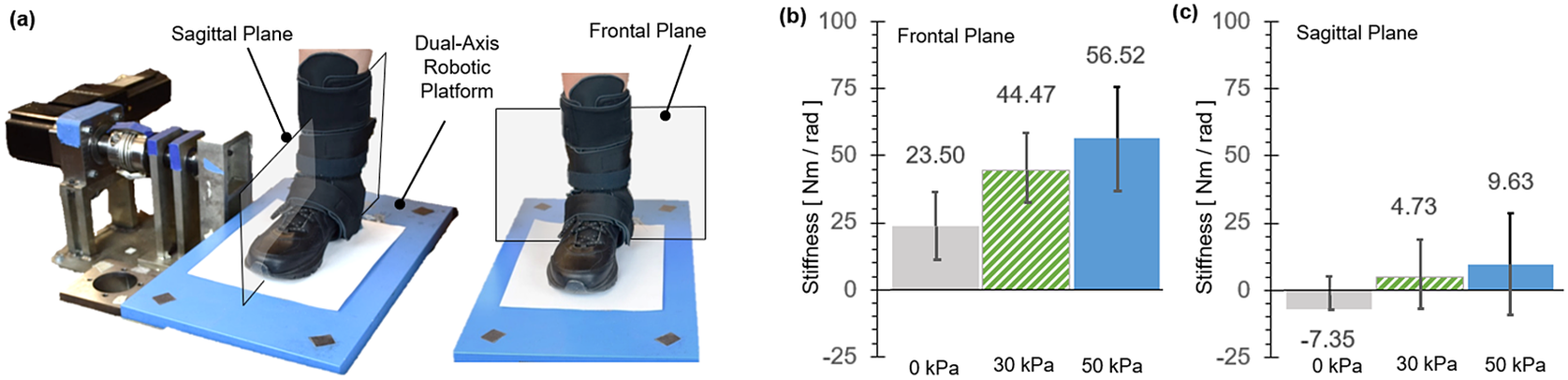

3.1. Lateral Ankle Support during Standing: MAVS

3.1.1. Experimental setup and protocol

The objective of this experiment was to evaluate the effectiveness of the MAVS of the SR-AFO to support lateral ankle stability during standing. The degree of stiffness increase in the frontal plane with MAVS actuation was quantified and compared with natural ankle stiffness in the frontal plane without the exosuit. Sagittal plane stiffness was also quantified to evaluate the potential impact of MAVS actuation on ankle movement in the sagittal plane.

Each subject wore a pair of custom athletic shoes, and a dual-axis goniometer (SG110, Biometrics Ltd., Ynysddu, UK) was placed on the right foot-ankle complex to measure 2D ankle kinematics. The dual-axis robotic platform (Figure 12a), capable of applying position perturbations to the ankle in the sagittal and frontal planes and measuring the corresponding ankle torques, was used to quantify 2D ankle stiffness in both the sagittal and frontal planes. The platform was validated to accurately quantify 2D ankle stiffness during upright standing (Nalam and Lee, Reference Nalam and Lee2018; Nalam and Lee, Reference Nalam and Lee2019; Adjei et al., Reference Adjei, Nalam and Lee2020; Nalam et al., Reference Nalam, Adjei and Lee2020). The subject was asked to stand with the right foot placed on the robotic platform and the left foot on the elevated ground right next to the platform. The right foot was placed in a fashion to ensure that the axes of rotation of the robotic platform were as closely aligned as possible with those of the ankle. Our previous study confirmed that any potential misalignment in the foot placement has a minimal impact on the quantification of ankle stiffness in the sagittal and frontal planes (Nalam and Lee, Reference Nalam and Lee2019).

A fast ramp-and-hold position perturbation of 3° and a duration of 100

![]() $ \mathrm{ms} $

was randomly applied either in the dorsiflexion direction or the eversion direction to quantify sagittal plane stiffness and frontal plane stiffness, respectively. A total of 30 perturbations was applied in each direction. The experiment was performed under four conditions: (a) no exosuit; (b) passive exosuit (at 0

$ \mathrm{ms} $

was randomly applied either in the dorsiflexion direction or the eversion direction to quantify sagittal plane stiffness and frontal plane stiffness, respectively. A total of 30 perturbations was applied in each direction. The experiment was performed under four conditions: (a) no exosuit; (b) passive exosuit (at 0

![]() $ \mathrm{kPa} $

); (c) active exosuit (30

$ \mathrm{kPa} $

); (c) active exosuit (30

![]() $ \mathrm{kPa} $

); and (d) active exosuit (50

$ \mathrm{kPa} $

); and (d) active exosuit (50

![]() $ \mathrm{kPa} $

).

$ \mathrm{kPa} $

).

3.1.2. Data analysis

Ankle stiffness was quantified by fitting a linear second-order model, consisting of ankle stiffness, ankle damping, and foot inertia, to the measured ankle kinematics and torques due to perturbation for a window of 100

![]() $ \mathrm{ms} $

starting from the onset of the perturbation. To check the reliability of stiffness estimation with the second-order model, the percentage variance accounted for (%VAF) between the estimated ankle torque from the best-fit second-order model and the measured ankle torque due to perturbation was calculated (Lee et al., Reference Lee, Krebs and Hogan2014; Nalam et al., Reference Nalam, Adjei and Lee2020). For each subject, stiffness increase with the exosuit was calculated with respect to the baseline measurement without the exosuit, that is, no exosuit condition. Group average results (mean ± std) of the six subjects were reported.

$ \mathrm{ms} $

starting from the onset of the perturbation. To check the reliability of stiffness estimation with the second-order model, the percentage variance accounted for (%VAF) between the estimated ankle torque from the best-fit second-order model and the measured ankle torque due to perturbation was calculated (Lee et al., Reference Lee, Krebs and Hogan2014; Nalam et al., Reference Nalam, Adjei and Lee2020). For each subject, stiffness increase with the exosuit was calculated with respect to the baseline measurement without the exosuit, that is, no exosuit condition. Group average results (mean ± std) of the six subjects were reported.

3.1.3. Results

The MAVS of the SR-AFO effectively increased ankle stiffness in the frontal plane with a minimal impact on the stiffness in the sagittal plane (Figure 12). Ankle stiffness was reliably quantified and successfully estimated by the second-order model in all experimental conditions, evidenced by high %VAF, which was greater than 97.5% in any of the eight experimental conditions and in any subjects.

Figure 12. The dual-axis robotic platform setup (Nalam and Lee, Reference Nalam and Lee2019) is shown with the user wearing the soft robotic ankle-foot orthosis exosuit for the quantification of ankle stiffness in (a) the sagittal plane and the frontal plane. (b) Average ankle stiffness in the frontal plane (with eversion perturbations) and the sagittal plane (with dorsiflexion perturbations) under different exosuit support conditions. The recorded findings are all in reference to the baseline measurement without the exosuit.

In the frontal plane, simply donning the exosuit (passive exosuit condition) increased ankle stiffness by 23.5 ± 12.6

![]() $ \mathrm{Nm}/\mathrm{rad} $

from the free-foot baseline. Activating MAVS of the exosuit significantly increased the ankle stiffness. At the pressure level of 30

$ \mathrm{Nm}/\mathrm{rad} $

from the free-foot baseline. Activating MAVS of the exosuit significantly increased the ankle stiffness. At the pressure level of 30

![]() $ \mathrm{kPa} $

, the increase from the baseline was 44.5 ± 13.8

$ \mathrm{kPa} $

, the increase from the baseline was 44.5 ± 13.8

![]() $ \mathrm{Nm}/\mathrm{rad} $

. The stiffness increased with increasing pressure. At 50

$ \mathrm{Nm}/\mathrm{rad} $

. The stiffness increased with increasing pressure. At 50

![]() $ \mathrm{kPa} $

, the increase was 56.5 ± 18.6

$ \mathrm{kPa} $

, the increase was 56.5 ± 18.6

![]() $ \mathrm{Nm}/\mathrm{rad} $

. In the sagittal plane, the change in ankle stiffness was minimal. In average across subjects, even activating MAVS increased the ankle stiffness less than 10

$ \mathrm{Nm}/\mathrm{rad} $

. In the sagittal plane, the change in ankle stiffness was minimal. In average across subjects, even activating MAVS increased the ankle stiffness less than 10

![]() $ \mathrm{Nm}/\mathrm{rad} $

. At the pressure level of 30 and 50

$ \mathrm{Nm}/\mathrm{rad} $

. At the pressure level of 30 and 50

![]() $ \mathrm{kPa} $

, the stiffness increase from the baseline was only 4.7 ± 14.8 and 9.6 ± 17.4

$ \mathrm{kPa} $

, the stiffness increase from the baseline was only 4.7 ± 14.8 and 9.6 ± 17.4

![]() $ \mathrm{Nm}/\mathrm{rad} $

, respectively.

$ \mathrm{Nm}/\mathrm{rad} $

, respectively.

3.2. Lateral Ankle Support during Walking: MAVS

3.2.1. Experimental setup and protocol

The objective of this experiment was to evaluate the effectiveness of the MAVS of the SR-AFO to support lateral ankle stability during walking over compliant surfaces. The degree of lateral ankle deflection with MAVS actuation was quantified and compared with the ankle deflection without the exosuit.

The dual-axis robotic platform was used to simulate compliant surfaces in the frontal plane. Our previous study confirmed that the robotic platform was capable of accurately simulating a wide range of compliance (inverse of stiffness) in both the sagittal and frontal planes (Nalam and Lee, Reference Nalam and Lee2019). In this experiment, two different compliant surfaces were simulated with stiffness of 100

![]() $ \mathrm{Nm}/\mathrm{rad} $

(compliant) and 50

$ \mathrm{Nm}/\mathrm{rad} $

(compliant) and 50

![]() $ \mathrm{Nm}/\mathrm{rad} $

(more compliant) in the frontal plane, whereas a rigid surface (stiffness of 10,000

$ \mathrm{Nm}/\mathrm{rad} $

(more compliant) in the frontal plane, whereas a rigid surface (stiffness of 10,000

![]() $ \mathrm{Nm}/\mathrm{rad} $

) was simulated in the sagittal plane.

$ \mathrm{Nm}/\mathrm{rad} $

) was simulated in the sagittal plane.

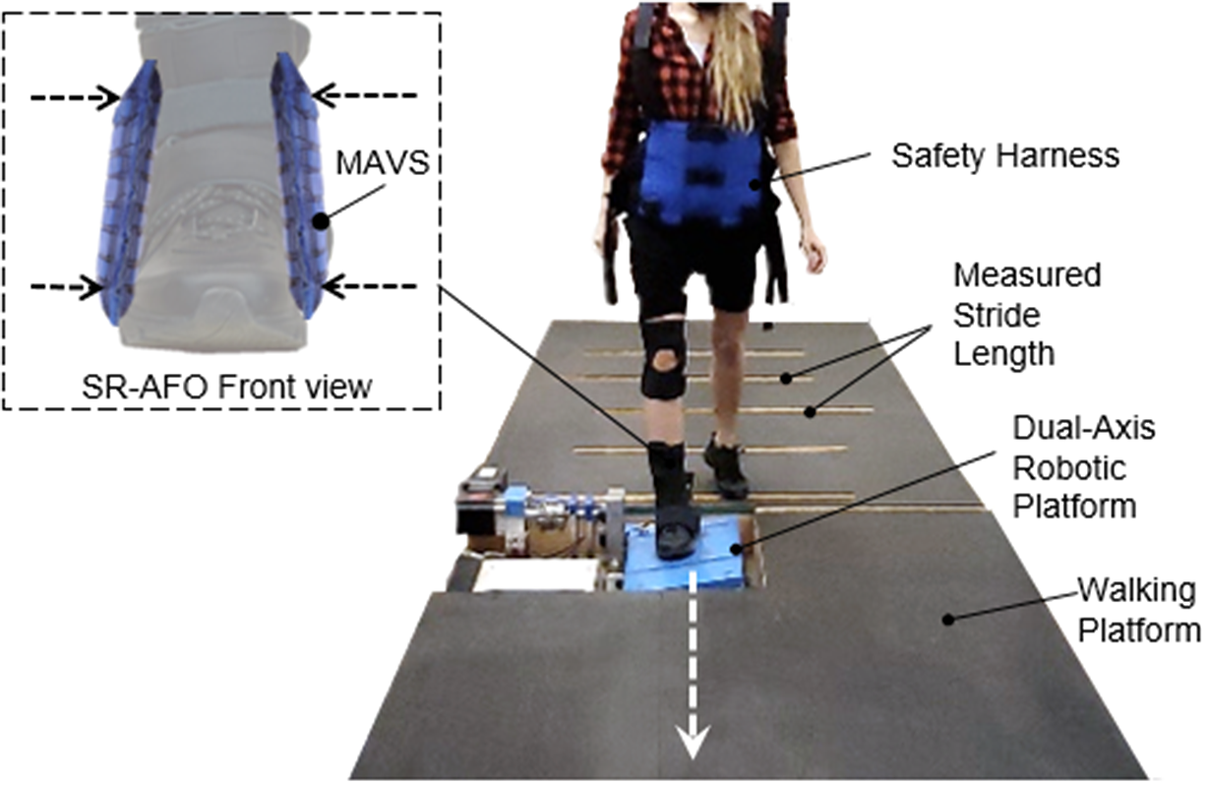

The subject was instructed to walk on the elevated walkway (approximately 6 m in length; Figure 13). A metronome was played at 100 bits per minute to encourage a consistent walking cadence. In addition, the subject’s stride length was measured and marked along the walkway leading up to the platform to ensure consistent foot landing on the platform. The experiment was performed under six conditions: 2 surface conditions (compliant and more compliant) × 3 exosuit conditions (no exosuit, passive exosuit (0

![]() $ \mathrm{kPa} $

), and active exosuit (30

$ \mathrm{kPa} $

), and active exosuit (30

![]() $ \mathrm{kPa} $

)). In each of the six experimental conditions, 30 walking trials were completed, resulting in a total of 180 walking trials. The order of the surface conditions was fully randomized.

$ \mathrm{kPa} $

)). In each of the six experimental conditions, 30 walking trials were completed, resulting in a total of 180 walking trials. The order of the surface conditions was fully randomized.

Figure 13. The instrumented walkway setup to investigate the effectiveness of the soft robotic ankle-foot orthosis with multi-material actuator for variable support (MAVS) actuation for lateral ankle support during walking over compliant surfaces. The dual-axis robotic platform utilized two conditions for compliance in the lateral direction for the ankle as the participant walked across the platform, providing randomized levels of surface compliance each time the participant steps on the platform.

3.2.2. Data analysis

Lateral ankle deflection in the frontal plane was measured using the goniometer from the moment of heel strike to toe-off (0–60% of the gait cycle). To remove outlier data due to simple human error in foot placement on the platform during walking, only the data with the foot center of pressure within 0 (the axis of rotation of the platform) and 5

![]() $ \mathrm{cm} $

lateral offset were included in data analysis. For each subject, peak-to-peak ankle deflection in the frontal plane was quantified throughout the stance phase, and group average results of the six subjects for this measure were compared across the different support conditions.

$ \mathrm{cm} $

lateral offset were included in data analysis. For each subject, peak-to-peak ankle deflection in the frontal plane was quantified throughout the stance phase, and group average results of the six subjects for this measure were compared across the different support conditions.

3.2.3. Results

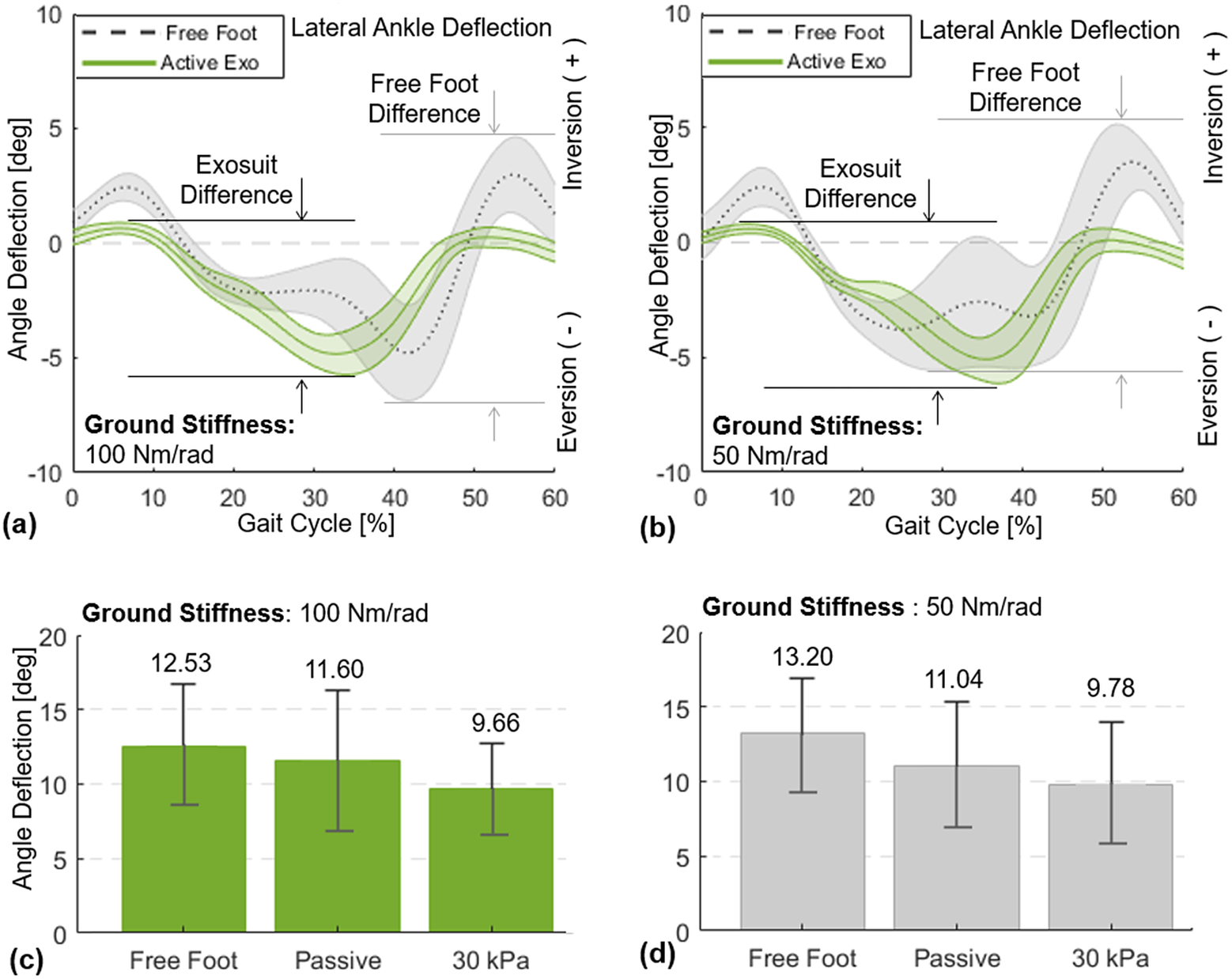

The SR-AFO with MAVS actuation effectively supported lateral ankle stability during walking over the compliant surfaces (Figure 14). Results from a representative subject confirmed a notable reduction in the peak-to-peak ankle deflection in the frontal plane (Figure 14a,b). Group results further demonstrated that these trends were consistent across subjects (Figure 14c,d). In the compliant surface condition (100

![]() $ \mathrm{Nm}/\mathrm{rad} $

), the peak-to-peak ankle deflection was 12.5 ± 4.1° with free foot, 11.6 ± 4.7° after donning the SR-AFO (passive exosuit), which was only a minor decrease. However, MAVS actuation with 30

$ \mathrm{Nm}/\mathrm{rad} $

), the peak-to-peak ankle deflection was 12.5 ± 4.1° with free foot, 11.6 ± 4.7° after donning the SR-AFO (passive exosuit), which was only a minor decrease. However, MAVS actuation with 30

![]() $ \mathrm{kPa} $