Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

BENHAMOU, Latifa

Giard, Vincent

and

Fénies, Pierre

2021.

Un outil de conception et de production intelligent permettant la personnalisation d’une production continue de masse.

Revue Française de Gestion Industrielle,

Vol. 36,

Issue. 1,

p.

07.

Machado, Natália

and

Morioka, Sandra Naomi

2021.

Contributions of modularity to the circular economy: A systematic review of literature.

Journal of Building Engineering,

Vol. 44,

Issue. ,

p.

103322.

Santato, Clara

and

Alarco, Pierre‐Jean

2022.

The Global Challenge of Electronics: Managing the Present and Preparing the Future.

Advanced Materials Technologies,

Vol. 7,

Issue. 2,

Shi, Lin

Mach, Katharine J.

Suh, Sangwon

and

Brandt, Adam

2022.

Functionality‐based life cycle assessment framework: An information and communication technologies (ICT) product case study.

Journal of Industrial Ecology,

Vol. 26,

Issue. 3,

p.

782.

Schischke, Karsten

Proske, Marina

Pamminger, Rainer

Glaser, Sebastian

Nissen, Nils F.

and

Schneider-Ramelow, Martin

2022.

Towards a Sustainable Future - Life Cycle Management.

p.

15.

Boorsma, Nina

Polat, Esra

Bakker, Conny

Peck, David

and

Balkenende, Ruud

2022.

Development of the Circular Product Readiness Method in Circular Design.

Sustainability,

Vol. 14,

Issue. 15,

p.

9288.

Amend, Clara

Revellio, Ferdinand

Tenner, Isabell

and

Schaltegger, Stefan

2022.

The potential of modular product design on repair behavior and user experience – Evidence from the smartphone industry.

Journal of Cleaner Production,

Vol. 367,

Issue. ,

p.

132770.

Vasalou, Asimina

and

Gauthier, Andrea

2023.

The role of CCI in supporting children’s engagement with environmental sustainability at a time of climate crisis.

International Journal of Child-Computer Interaction,

Vol. 38,

Issue. ,

p.

100605.

de Waal, Ida Mae

2023.

The Legal Transition towards a More Circular Electrical and Electronic Equipment Chain—A Case Study of The Netherlands.

Sustainability,

Vol. 15,

Issue. 2,

p.

935.

Shevchenko, Tetiana

Cluzel, François

Yannou, Bernard

Shams Esfandabadi, Zahra

Ranjbari, Meisam

Saidani, Michael

and

Danko, Yuriy

2024.

Completing the design for product circularity toolkit with hierarchical computation of circularity maturity diagram and redesign circular strategies.

Journal of Cleaner Production,

Vol. 437,

Issue. ,

p.

140742.

Schaltegger, Stefan

Amend, Clara

and

Wüst, Sebastian

2024.

From rebound to reinforcement effects—The role of analyzing underlying mechanisms for accounting.

Journal of Sustainable Finance and Accounting,

Vol. 3,

Issue. ,

p.

100014.

André, Francisco J.

Arguedas, Carmen

and

Rousseau, Sandra

2024.

Strategic pricing, lifespan choices and environmental implications of peer-to-peer sharing.

Journal of Environmental Economics and Management,

Vol. 125,

Issue. ,

p.

102953.

Seliger, Norbert

and

Leirich, Nico

2024.

Reconfigurable Board-to-Board Interconnect Utilizing Bistable Compliant Ribbon Wires.

p.

1.

Marzolla, Rafael Amoroso

and

Zancul, Eduardo

2024.

Upgradable Products for Circularity: a Bibliometric Analysis.

Procedia CIRP,

Vol. 128,

Issue. ,

p.

615.

Jerome, Adeline

and

Ljunggren, Maria

2025.

Product lifetime in life cycle assessments of circular economy strategies — A review and consolidation of methodology.

The International Journal of Life Cycle Assessment,

Harris, Steve

Romare, Mia

and

Zhang, Yuqing

2025.

Comparative life cycle assessment of circular and linear product versions for a motorboat and smartphone.

Sustainable Production and Consumption,

Schomberg, Anna C.

Mostert, Clemens

and

Bringezu, Stefan

2025.

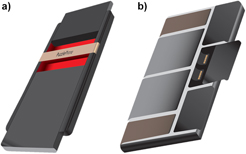

Best Practice for Right to Repair and Supply Chain Regulations: High-reparability Modular Smartphone Usage Model Mitigates Environmental Hotspots.

Highlights of Sustainability,

Vol. 4,

Issue. 1,

p.

38.

Yang, Chaoxiang

Yuan, Bingkun

Yan, Chao

Huang, Zhengyang

Zhang, Yimin

and

Wan, Yongjing

2025.

A product form generative green design method based on consumer aesthetic preference.

Research in Engineering Design,

Vol. 36,

Issue. 2,