To promote the practical applications of organic photovoltaic (OPV) cells, manufacturing techniques allowing rapid and high-throughput production of highly uniform organic thin films are needed. Stephen R. Forrest of the University of Michigan and co-workers have now developed a continuous roll-to-roll vapor-phase growth system for OPV cells. This work was published in a recent issue of Applied Physics Letters (doi: 10.1063/1.5039701).

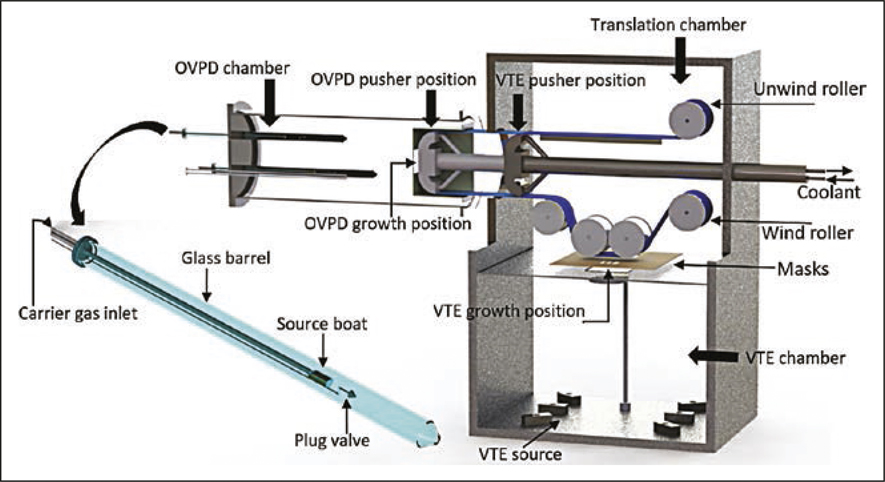

According to Forrest, the motivation of this work was to “test whether vacuum deposition could be combined with organic vapor-phase deposition (OVPD) in a single integrated system to produce high-performance organic photovoltaics.” The core components of their apparatus include a low-pressure OVPD chamber upstream, and a high-vacuum vapor thermal evaporation (VTE) chamber downstream. Both chambers deposit active thin films from gas-phase precursors but under very different pressure conditions. Flexible indium tin oxide-coated poly(ethylene terephthalate) sheets as conveyor belts serve as the device substrate.

OPV cells were fabricated in a sequential deposition manner. First, a thin molybdenum oxide bottom layer was deposited on the substrate in the VTE chamber. An 80-nm-thick film composed of C70 fullerene-blended 2-((7-(4-(diptolylamino)phenyl)benzo[c][1,2,5]thiadiazol-4-yl)methylene)malononitrile (DTDCPB) was then deposited on top of the oxide in the same reactor. The substrate was then moved into the OVPD compartment via rollers where a buffer layer of bathophenanthroline (BPhen) with a thickness of 6 nm was deposited. The top of the multilayered film was finally capped with a 100-nm-thick Ag layer back in the VTE chamber.

The roll-to-roll manufactured OPV cell showed excellent energy-conversion performance. It achieved a power-conversion efficiency (the ratio of output electrical energy to input optical energy) of 8.5 ± 0.2%. This value is nearly identical to those of devices produced by high-vacuum thermal evaporation, the conventional small-scale fabrication method.

Additionally, this integrated system was able to generate highly uniform films; the thickness nonuniformity of the BPhen buffer layer was <3% and the root-mean-square surface roughness was as low as 0.66 nm. This thickness-homogeneity is critical for reproducible performance and reliable long-term operation. The same setup was also demonstrated to be suitable for producing tandem photovoltaic cells with sophisticated, multilayer structures but enhanced output voltage.

Alexander Ayzner of the University of California, Santa Cruz, who was not involved in this study, says that this work “is a very encouraging demonstration that roll-to-roll processing of organic photovoltaic devices can be accomplished with nearly no loss in performance relative to conventional, small-scale fabrication methods. As the OPV field has become more mature, rapid and large-scale processing techniques are extremely important for the broad adoption of organic solar cells in industry.”

The structure of the roll-to-roll manufacturing system. It integrates organic vapor-phase deposition (OVPD) with vapor thermal evaporation (VTE) techniques. Credit: American Institute of Physics.

The research team is interested in investigating the possibility of making other organic electronics, such as organic light-emitting diodes, with their system. “Growth dynamics under a range of manufacturing conditions [e.g., throughput, materials dependence on film properties] are all the parameters that need to be better understood in growing controlled films,” Forrest says.