The Intergovernmental Panel on Climate Change report, released in October of this year, warned of the short time left to prevent the worst effects of a warming planet. Making a serious dent in greenhouse gas emissions will require more efficient ways to create and use energy, a transition from fossil fuels to renewables, and greener modes of transport.

Magnetic materials will play a key role in these endeavors. Magnets are at the heart of electric generators in steam turbines and wind turbines, converting mechanical energy into electricity. In the electric motors that drive hybrid and plug-in electric cars, they do the reverse, converting electrical energy to motion. Stronger, lighter magnets would enable efficient turbines and car engines, and powerful, lightweight motors for cars, ships, and industrial robots. In developed nations, nearly 65% of total electrical energy use goes to drive electrical motors. Improving motor efficiency by just 1% would save almost 2.2 million metric tons of carbon equivalent emissions.

A growing “green” economy will require better permanent magnetic materials. Wind power and electric car markets are expected to boom in coming years. Magnets weighing hundreds of kilograms are found in today’s direct-drive wind turbine generators, while each electric vehicle (EV) needs 1–2 kg of magnets. “There are several driving forces that will increase the demand for bulky magnets,” said Matthias Katter of magnet producer VACUUMSCHMELZE GmbH & Co. KG in Germany.

Magnetic materials could also be the answer for next-generation cooling technologies. Air conditioners and refrigerators today rely on 150-year-old vapor compression technology that is energy-intensive. Globally, about 17% of all electric energy spent and 8% of all emitted greenhouse gases are connected with cooling. New methods based on magnetocaloric materials that heat up in a magnetic field promise to be 30% more energy efficient. It would be a sustainable way to meet rising demands for cooling in India and China, which already now use 15 and 68 times more electricity, respectively, for cooling than in 1990.

Researchers around the world are developing promising high-performance magnetic materials for future energy technologies. Yet, the need for novel, low-cost magnetic compounds is huge, and there are many hurdles to cross.

The crucial challenge is to develop compounds that contain less rare-earth metals. Neodymium-iron-boron (NdFeB) magnets, which garner about 70–80% of the permanent magnet market by value, contain about 30% by weight of rare earths, largely neodymium with some dysprosium, which make up half the cost of the magnets. Well-known magnetocaloric materials are based on gadolinium.

Rare-earth elements (REEs) are not necessarily scarce, but prices have temporarily exploded by a factor of 20 in 2011 because of a political dispute between China and Japan, said Katter. Only a third of the world’s rare-earth resources are in China, but because of extensive mining that involves heavy chemical and energy use, the country corners more than 80% of the market share. Around 30,000 tons of REEs are used per year in NdFeB permanent magnets, and production of NdFeB magnets is expected to grow by 10% every year.

To make a permanent magnet, manufacturers start with an intermetallic compound with the right intrinsic properties. A good candidate should get magnetized to at least 1 Tesla (T). It needs a high Curie temperature, beyond which ferromagnetic order breaks down. And it should be hard to demagnetize. Adding rare earths helps to fine-tune properties. Dysprosium, for instance, increases coercivity—the reverse magnetic field needed to demagnetize a material—which is important for high-temperature EV motors.

A magnetic material’s properties also depend on its microstructure. Tuning this structure via steps such as annealing can reduce rare-earth content. Making grain sizes finer or concentrating heavy REEs into grain boundaries can increase coercivity, said Katter.

At the European Commission-funded NOVAMAG program coordinated in Bilbao, Spain, researchers are using theoretical modeling and computational materials design to develop permanent magnets with little rare-earth content. The NOVAMAG consortium, which includes teams from the University of Delaware, Fraunhofer IWKS, Technische Universität Darmstadt (TU Darmstadt), and VACUUMSCHMELZE, is developing a samarium-iron compound with either titanium or vanadium to stabilize the microstructure.

The new magnet will ideally contain 8% REEs by weight. But turning the material into a permanent magnet has been a problem, said George Hadjipanayis, professor of physics at the University of Delaware. “We can compact it and make a bulk magnet, but we’re not able yet to develop significant texture combined with high coercivity.” Making new materials and tailoring magnetic properties is not easy, he added. “There’s no theoretical calculation or computation that will tell you how to do it. It’s an expertise that you acquire.”

Nanocomposite materials are a promising approach to reduce REE use. These contain neodymium-based nanoparticles mixed with nanoparticles of iron or other soft magnetic materials. The nanostructured regions interact to give high energy density, provided they can be aligned at the same time: a problem.

Manufacturers can reduce REE use by decreasing waste. VACUUMSCHMELZE, for instance, makes magnets by pressing powder into the shape close to the final required magnet. “So you need not machine a lot of material away, and yield can be 90% or more,” said Katter. “The standard method in China is to make larger blocks and cut out the desired shape, so yield can be as little as 50%.”

Researchers at Fraunhofer IWKS and TU Darmstadt are looking at cutting mining waste. Mining 1 kg of neodymium produces 2.8 kg of cerium and 1.8 kg of lanthanum, which are discarded, said Jürgen Gassmann, head of the Magnetic Materials Department at Fraunhofer IWKS. So the teams are using these elements in lower performance magnets.

Recycling magnets would significantly reduce the need to mine new material. No commercial magnet recycling exists today partly due to the lack of a system for collecting enough well-qualified waste material. Today’s methods involve dissolving magnetic alloys to separate them into their elements, but this uses a large amount of harsh chemicals and energy.

The Fraunhofer IWKS–TU Darmstadt team is working on a direct-recycling technique to refurbish the entire magnetic alloy. One approach involves casting a melted scrap magnet through a nozzle onto a water-cooled copper wheel. This creates flakes with grain sizes of 5–50 nm that can be pulverized and reprocessed into magnets. “The challenge is to reach magnetic properties at the same level,” said Gassmann. For that, researchers are experimenting with adding traces of either pristine alloy or specific elements. The right recycling technology could have a big economic and environmental impact, he said.

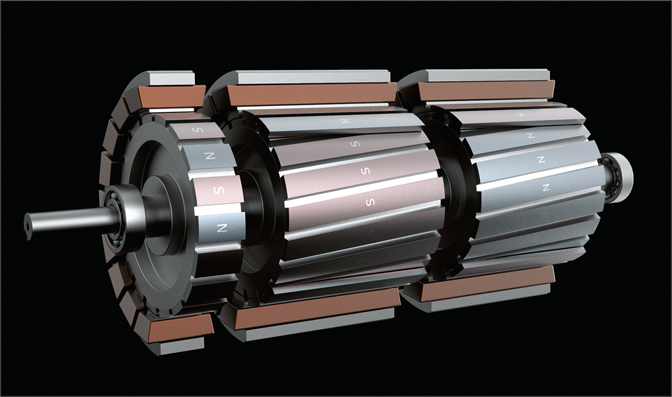

Permanent magnets are located on the rotor of the electric generator. N and S represent the North and South poles. Credit: Serge Alekseenko.

Advances in soft magnetic materials could also have an envir onmental impact by enabling a more energy-efficient power grid. These materials make the cores of induction motors, power transformers, and inverters that are used to generate and transform electricity. About 9% of electricity is lost during transmission. Better magnetic materials could cut some of these losses.

Good soft magnets have high magnetization, and low coercivity and core losses. Core losses increase at higher current frequencies, and there has been much effort to reduce these losses by fine-tuning the microstructures of soft magnetic materials. Amorphous and nanocrystalline materials improve energy efficiency, but these materials carry a hefty price tag. The next generation of soft magnetic materials is needed for modern power electronics operating at even higher frequencies.

The new field of magnetic cooling materials holds tremendous promise for energy savings. Conventional cooling technology uses greenhouse gases such as hydrofluorocarbons or ozone-depleting chemicals such as chlorofluorocarbons in a gas-compression cycle. Magnetic cooling, by contrast, uses a solid as the main working material. Magnetocaloric materials release heat when magnetized by an external field; removing the field randomizes the magnetic moments and cools the material to below ambient temperature. This effect is enhanced in materials such as gadolinium. Researchers are trying to find new materials with even larger magnetocaloric effects that can work in fields of 1 T or less, which can be easily produced by NdFeB magnets.

Lanthanum-iron-silicon and manganese-iron-phosphorus compounds have the largest magnetocaloric effects but become granular after long-term cycling. A key challenge is to go from materials to practical devices. It is difficult to shape the mostly brittle materials into porous regenerators that allow water to flow for fast heat exchange. Another issue is that the cooling effect only lasts as long as the material is in a magnetic field. Even in the best-case scenario, half the coolant needs to be placed inside the magnetic field, said Oliver Gutfleisch of TU Darmstadt. “This means you need four times as much permanent magnet as cooling medium.”

So Gutfleisch and his colleagues are developing a novel cooling technology based on magnetic shape-memory alloys, which remember their magnetization and whose properties such as volume and magnetization change under an external magnetic field. The researchers use a nickel, manganese, and indium alloy. They place the alloy in a 2 T magnetic field to cool it. Then the magnet is removed, and the alloy is put in contact with goods that need to be cooled. The alloy retains its magnetization and comes up to room temperature. Next, a roller compresses the alloy, and the pressure switches it to its non-magnetized state and heats it up. The cooling cycle can start again once the alloy releases its heat. The technology requires far fewer expensive NdFeB magnets than iron-based materials, and next-generation alloys will use no rare earths or other critical raw materials, Gutfleisch said.

The invention of NdFeB magnets has changed our daily lives. Progress in and the development of new magnetic materials has led to stronger magnets with less rare-earth contents and lower losses, enabling many devices that surround us. There is now the need for sustained research investment to achieve a comprehensive understanding of magnetic hysteresis design and to improve other traits such as magnetization, temperature stability, and operation frequency. Such focused research on high-efficiency hard and soft magnetic materials now could help solve the energy crisis.