Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Peng, Zhuowei

Pan, Qinglin

Cai, Shan

Li, Jinfeng

and

Liang, Wenjie

2019.

Effect of different aging processes on the corrosion behavior of new Al–Cu–Li–Zr–Sc alloys.

Materials and Corrosion,

Vol. 70,

Issue. 12,

p.

2266.

Wang, Qian

Liu, Changzhi

Yao, Ruijuan

Zhu, Hong

Liu, Xiaomin

Wang, Mingliang

Chen, Zhe

and

Wang, Haowei

2020.

First-principles study on the stability and work function of low-index surfaces of TiB2.

Computational Materials Science,

Vol. 172,

Issue. ,

p.

109356.

Snopiński, P.

Król, M.

Wróbel, T.

Matus, K.

Woźniak, A.

Tański, T.

and

Palček, P.

2020.

Effects of modifying the hypoeutectic AlMg5Si2Mn alloy via addition of Al10Sr and/or Al5TiB.

Archives of Civil and Mechanical Engineering,

Vol. 21,

Issue. 1,

Zhang, Jin-Yu

Gao, Yi-Han

Yang, Chong

Zhang, Peng

Kuang, Jie

Liu, Gang

and

Sun, Jun

2020.

Microalloying Al alloys with Sc: a review.

Rare Metals,

Vol. 39,

Issue. 6,

p.

636.

Wang, Qian

Li, Yuanyuan

Chen, Siyi

Liu, Xiaomin

Chen, Zhe

Wang, Mingliang

Zhu, Hong

and

Wang, Haowei

2021.

Interface Alloying Design to Improve the Dispersion of TiB2 Nanoparticles in Al Composites: A First-Principles Study.

The Journal of Physical Chemistry C,

Vol. 125,

Issue. 10,

p.

5937.

Xu, Pian

Lu, Gang

Zhang, Lei

Zhou, Shitong

Yan, Yuping

Yan, Qingsong

and

Jiang, Lihong

2021.

Effect of holding time on the growth morphology of in-situ TiB2 particles.

Materials Today Communications,

Vol. 29,

Issue. ,

p.

102953.

Sun, Jing

Wang, Fei

Liu, Yuwen

Guo, Lijie

and

Wang, Haowei

2021.

The effect of V on the morphology of TiB2 particles in as-cast aluminum composites.

International Journal of Materials Research,

Vol. 112,

Issue. 11,

p.

890.

Mao, Hongkui

Li, Cong

Dong, Yuan

Wang, Yu

Xu, Hong

Yu, Qi

Shang, Yuncong

Li, Xiaofeng

and

Zhao, Zhanyong

2022.

The effect of Mn on particles morphology and property of 5 wt% TiB2/Al-4.5Cu-0.4Mn alloys.

Journal of Alloys and Compounds,

Vol. 904,

Issue. ,

p.

163907.

Li, Cong

Xu, Hong

Mao, Hongkui

Lian, Peng

Wei, Qi

Song, Feng

and

Wang, Yu

2023.

The effect of V on the morphology transformation of TiB2 particles in Al-4.5Cu-0.18 V matrix.

Journal of Materials Research,

Vol. 38,

Issue. 5,

p.

1377.

Kong, Xiang

Wang, Yu

Fan, Haotian

Wu, Junteng

Xu, Hong

and

Mao, Hongkui

2023.

Effect of high cooling rate on the solidification microstructure of Al–Cu/TiB2 alloy fabricated by freeze-ablation casting.

Journal of Materials Research and Technology,

Vol. 25,

Issue. ,

p.

593.

Singh, Chandan

Prywer, Jolanta

and

Yadav, Devinder

2023.

On the Three-Dimensional Morphology of In Situ Grown TiB2 Particles in Molten Aluminum.

Journal of Materials Engineering and Performance,

Vol. 32,

Issue. 20,

p.

9396.

Ma, Siming

Shang, Zhongxia

Shang, Anyu

Zhang, Peter

Tang, Chenglu

Huang, Yuze

Leung, Chu Lun Alex

Lee, Peter D.

Zhang, Xinghang

and

Wang, Xiaoming

2023.

Additive manufacturing enabled synergetic strengthening of bimodal reinforcing particles for aluminum matrix composites.

Additive Manufacturing,

Vol. 70,

Issue. ,

p.

103543.

Wang, Xiaoming

2024.

Additive Manufacturing Using Al-Cu-Mg-Sc-TiB2 Composite Powders to Overcome the Strength–Ductility Trade-Off.

JOM,

Vol. 76,

Issue. 1,

p.

71.

Zhuang, Weibin

Jia, Jing

Liu, Jingfu

Qin, Longjian

Li, Jinghui

and

Meng, Chao

2024.

Microstructure evolution and properties improvement of in-situ TiB2/6061 composites via trace Mn addition.

Journal of Molecular Structure,

Vol. 1301,

Issue. ,

p.

137423.

Zhu, Hongyi

Wang, Qian

Yang, Chen

Wang, Yihao

Xia, Cunjuan

Zhao, Dechao

Zhang, Huawei

Wang, Mingliang

Chen, Zhe

and

Wang, Haowei

2024.

Improving TiB2 dispersion in Al-Si composites by interfacial projection: High-throughput first-principles calculations and experimental verification.

Materials & Design,

Vol. 244,

Issue. ,

p.

113184.

Huang, Ting

Zhao, Lijun

Sun, Xiujuan

Xu, Junhua

Wang, Zhidong

Yu, Lihua

Lu, Zhengping

Ding, Yi

long, Lin

and

Zhang, Hao

2025.

Synergistic strengthening effect of Sc and TiB2 particles on the microstructure and mechanical properties of 7055 aluminum composites.

Journal of Alloys and Compounds,

Vol. 1024,

Issue. ,

p.

179980.

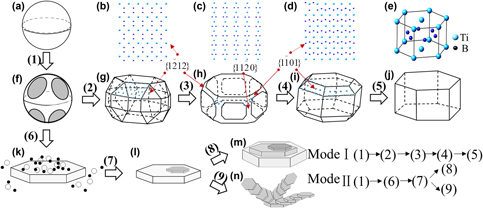

${\bf \left\{ {1{\bf \overline{2}}12} \right\}}$,

${\bf \left\{ {1{\bf \overline{2}}12} \right\}}$,  ${\bf \left\{ {11\overline{2}0} \right\}}$, and

${\bf \left\{ {11\overline{2}0} \right\}}$, and  ${\bf \left\{ {10\overline{1}1} \right\}}$ which would inhibit the growth of these faces effectively and retain a lower-energy state of the polyhedral or quasispherical TiB2 particles in Al–Sc systems.

${\bf \left\{ {10\overline{1}1} \right\}}$ which would inhibit the growth of these faces effectively and retain a lower-energy state of the polyhedral or quasispherical TiB2 particles in Al–Sc systems.