Published online by Cambridge University Press: 04 May 2020

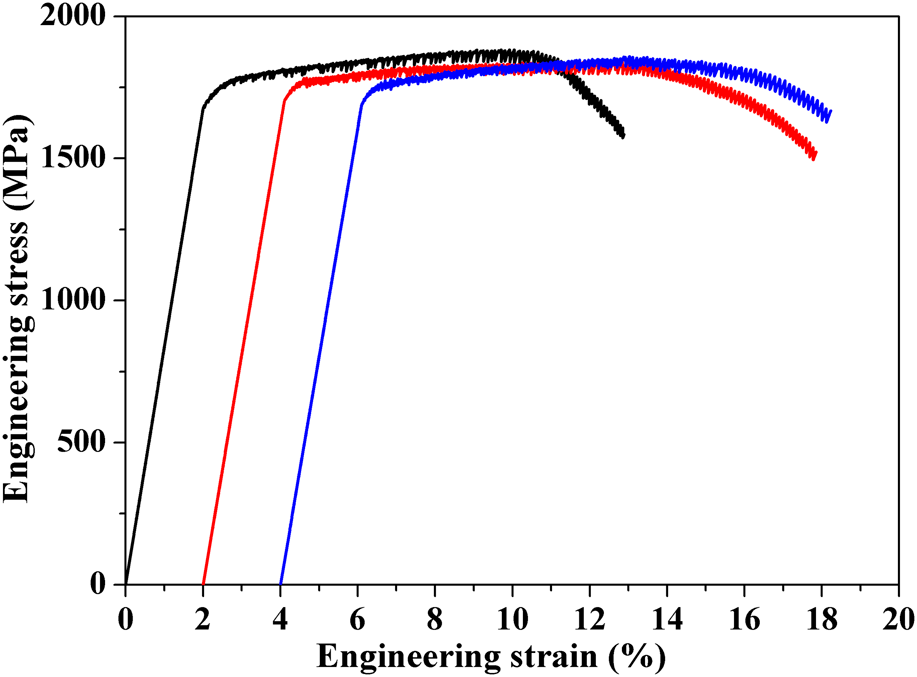

In this study, the glass forming ability, thermal stability, and room-temperature mechanical behavior of a high Zr-containing Zr71Cu11Ni10.5Al7Ti0.5 bulk glassy alloy were investigated. The glassy alloy exhibits a high glass-forming ability with a critical casting diameter of 5 mm using copper mold injection casting, and its critical cooling rate is estimated to be smaller than 40 K/s. A small kinetic fragility index m of 32 indicates its good thermodynamic stability and glass-forming ability. Compressive tests indicate that the glassy alloy displays a significant average plastic strain of 12.3%, a high fracture strength of 1592 MPa, and Young's modulus of 74.5 GPa. The good ductility is attributed to the introduction of more free volume and local compositional inhomogeneity with increasing Zr addition. This finding may provide useful guidelines for the development of novel high Zr-containing glassy alloys.