Article contents

A robust method for extracting the mechanical properties of thin films with rough surfaces by nanoindentation

Published online by Cambridge University Press: 14 December 2016

Abstract

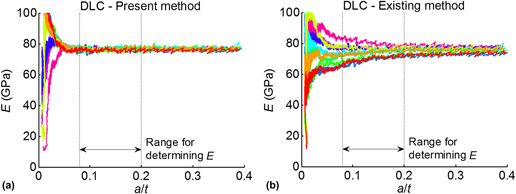

Surface roughness and finite sample thickness are major sources of error in the nanoindentation measurements of thin films as the former makes it difficult to determine the effective contact point between the indenter and sample while the latter limits the usable depth range to be no more than ∼10% of the film thickness. Combining a closed-form model of a film/substrate system with the ability of nanoindentation to monitor the contact depth, the present method defines the two-dimensional shape profile of the indenter contacting the composite system with one unknown constant associated with the model and another unknown constant associated with the effective contact point. On the basis that the obtained shape profile of the rigid indenter is identical to the pre-determined indenter shape profile function, the method extrapolates the two constants simultaneously so as to determine the effective contact point. The method was demonstrated for amorphous diamond-like carbon (DLC) coatings.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 6

- Cited by