Article contents

Residual stress in as-deposited Al–Cu–Fe–B quasicrystalline thin films

Published online by Cambridge University Press: 16 December 2011

Abstract

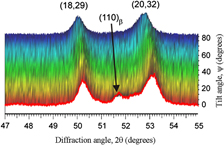

The residual stress in Al–Cu–Fe–B quasicrystalline thin films has been characterized by x-ray diffraction and the curvature method. Films with thicknesses in a range from 0.55 to 2.6 μm were deposited using magnetron sputtering on Si(100) substrates maintained at a temperature of 560 °C. It is found that the tensile stress in uncracked films as determined by the curvature method is close to that measured by a modified sin2ψ method using main diffraction peaks of the icosahedral structure and corresponds approximately to 1.1 GPa. This value is close to that of the thermal stress estimated from the mismatch between thermal expansion coefficients of the film and substrate, suggesting that thermal stress is the main source of residual stress. Increasing film thickness results in the development of cracks and partial delamination of the film, accompanied by the sudden decrease of the stress. The fracture toughness of the quasicrystalline films is estimated between 1.5 and 1.9 MPa .

.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 27 , Issue 5: Focus Issue: Plasma and Ion-Beam Assisted Materials Processing , 14 March 2012 , pp. 837 - 844

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 11

- Cited by