Published online by Cambridge University Press: 17 April 2019

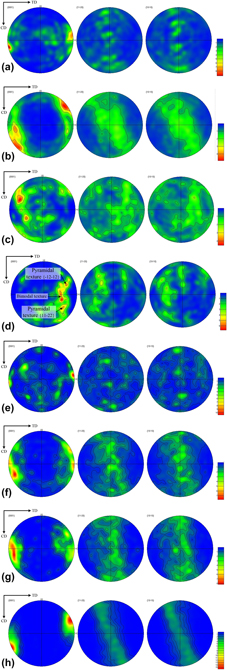

The hot compression behavior of as-extruded AZ31 magnesium alloy was investigated to study the effect of compression temperature and strain on microstructure evolution, grain orientation, and texture evolution. The thermal compression tests of AZ31 Mg alloy were carried out on the Gleeble-3800 simulation device: With constant strain, the temperatures were 250, 300, 400, and 500 °C, respectively; at constant temperature, the strains were 0.2, 0.4, 0.6, and 0.8, respectively. After observation and analysis of compressed samples, it is found that with 0.65 strain and 0.05 s−1 strain rate, grains were equiaxed, well refined, and distributed uniformly at 400 °C. At this temperature, new orientation between {0001} and  $\left{\rm\char123} {12\bar{1}0} {\rm\char125} \right$ or

$\left{\rm\char123} {12\bar{1}0} {\rm\char125} \right$ or  $\left{\rm\char123} {01\bar{1}0} {\rm\char125} \right$ appeared in grains; new texture components close to

$\left{\rm\char123} {01\bar{1}0} {\rm\char125} \right$ appeared in grains; new texture components close to  $\left{\rm\char123} {\bar{1}\bar{1}22} {\rm\char125} \right$ and

$\left{\rm\char123} {\bar{1}\bar{1}22} {\rm\char125} \right$ and  $\left{\rm\char123} {1\bar{2}12} {\rm\char125} \right$ pyramidal textures were formed, but whole texture strength was weakened and anisotropy of the sample was reduced. With the increase of strain, grains became smaller and volume fraction of DRX grain became higher; the original basal texture was replaced by prismatic textures; after 0.4 strain, the increase of strain did not change the texture component, but only the pole density.

$\left{\rm\char123} {1\bar{2}12} {\rm\char125} \right$ pyramidal textures were formed, but whole texture strength was weakened and anisotropy of the sample was reduced. With the increase of strain, grains became smaller and volume fraction of DRX grain became higher; the original basal texture was replaced by prismatic textures; after 0.4 strain, the increase of strain did not change the texture component, but only the pole density.