Article contents

Recrystallization and cube texture formation in heavily cold-rolled Ni7W alloy substrates for coated conductors

Published online by Cambridge University Press: 21 May 2015

Abstract

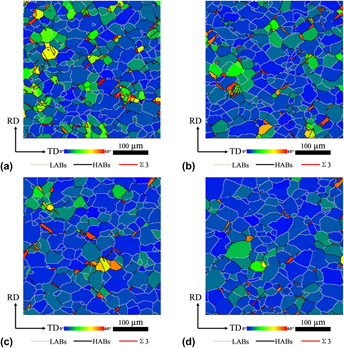

The formation of deformation and recrystallization textures has been investigated in a Ni7W alloy after heavy cold rolling and subsequent annealing at different temperatures. Cold rolling to a von Mises strain of 4.17 produced a mix of rolling texture that lies between classical brass- and copper-type rolling textures, with the fraction of S({123}<634>), brass({110}<112>), and copper({112}<111>) orientations being 33, 28, and 13%, respectively. The fraction of rolling texture for the deformed Ni7W alloy samples increased slightly during recovery, was then consumed significantly during recrystallization, and dropped to 22% after being annealed at 800 °C for 1 h. The fraction of cube({001}<100>) orientation increased to 26% after primary recrystallization, whereas other random orientations of 43% formed in the Ni7W alloy samples. Further annealing promoted cube grain growth, which lead to a significant strengthening of the cube texture and to a significant loss in high angle boundary (HAB). The fractions of cube texture and HAB of the Ni7W alloy substrate were 92.1 and 27.8%, respectively, after annealing at 1200 °C for 1 h.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

References

REFERENCES

- 4

- Cited by