Article contents

Preparation and microstructural characteristics of solar-grade multicrystalline silicon by directional solidification in an axial magnetic field

Published online by Cambridge University Press: 22 November 2019

Abstract

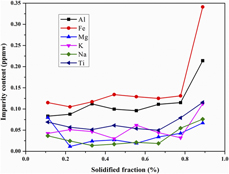

Solar-grade multicrystalline silicon ingots as raw material for solar cells were obtained from upgraded metallurgical silicon by directional solidification in an axial magnetic field. The influence of preparation technology on the microstructural characteristics of silicon ingots was investigated. Governing equations were used to simulate the silicon fluid flow and thermal fields during directional solidification. The results show that appropriately increasing melt temperature and/or decreasing pulling-down rate can be conductive to the growth of a coarse columnar grain. Meanwhile, the axial magnetic field promotes the formation of low-energy ∑3 twin boundaries and reduces the dislocations and impurities, where the total concentration of major metal impurities is with a mean of 0.459 ppmw in the range of 1/9 to 8/9 of height along the growth direction. It is shown from the simulation results that suppressing silicon melt flow in both radial and azimuthal directions and reducing the growth rate in the edge regions contribute to the formation of a flat solid–liquid interface, which is more consistent with the experimental results. Moreover, the formation mechanism of the twins and removal mechanism of the impurities were discussed.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 1

- Cited by