Article contents

Precipitate phase transformation behavior, microstructure, and properties of Cu–Cr–Co–Si alloy

Published online by Cambridge University Press: 10 February 2020

Abstract

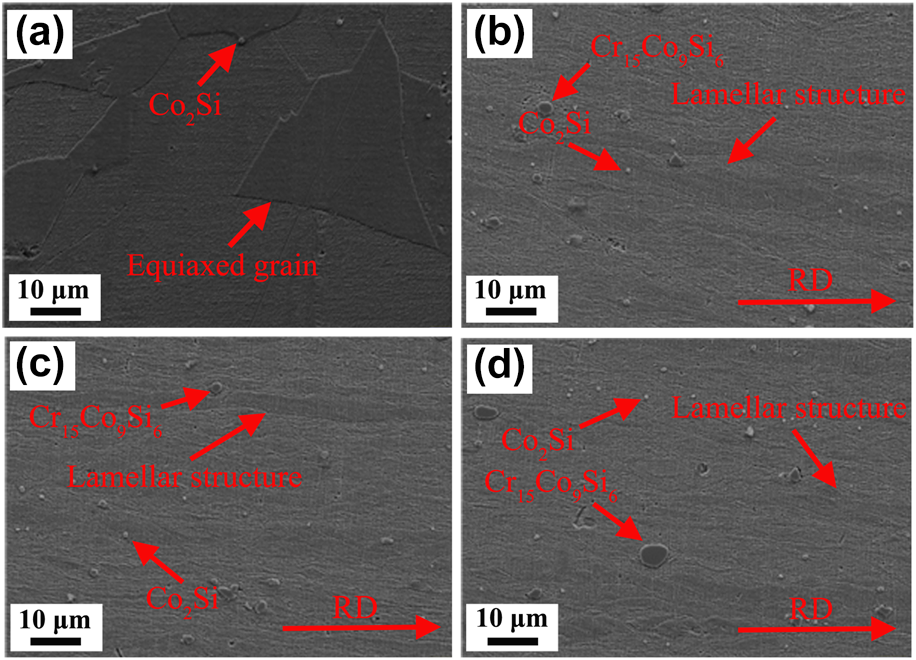

In this study, precipitate phase transformation behavior, microstructure, and properties of the Cu–1Cr–1Co–0.4Si (wt%) alloy were investigated. Precipitate phase transformation kinetic equations of the alloy under room temperature rolling (RTR) 90% deformation and aging at different temperatures (440–520 °C) were established. The alloy yielded excellent mechanical and electrical properties under RTR 90% deformation and aging at 440 °C for 1 h, and the corresponding hardness, yield strength (YS), ultimate tensile strength (UTS), elongation, and electrical conductivity were 181.6 HV, 573.6 MPa, 653.7 MPa, 7.3%, and 51.6% International Annealed Copper Standard, respectively. The precipitate phase transformation behavior determined the size and volume fraction of the precipitate phase fv, which played a key role in improving the YS. Impurity scattering caused by surplus Si atoms was mainly responsible for decreasing the electrical conductivity. Therefore, these results can provide a reliable theoretical guidance to prepare Cu–Cr–based alloys with high strength and high electrical conductivity.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2020

References

- 4

- Cited by