Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Sobiech, M.

Teufel, J.

Welzel, U.

Mittemeijer, E. J.

and

Hügel, W.

2011.

Stress Relaxation Mechanisms of Sn and SnPb Coatings Electrodeposited on Cu: Avoidance of Whiskering.

Journal of Electronic Materials,

Vol. 40,

Issue. 11,

p.

2300.

Kwon, Se-Hun

Kwon, Na-Hyun

Song, Pung-Keun

Hui, Kwun Nam

Hui, Kwan-San

and

Cho, Young-Rae

2012.

In-situ electrical resistance measurement for determining minimum continuous thickness of Sn films by DC magnetron sputtering.

Materials Letters,

Vol. 73,

Issue. ,

p.

62.

Horváth, Barbara

Illés, Balázs

Shinohara, Tadashi

and

Harsányi, Gábor

2013.

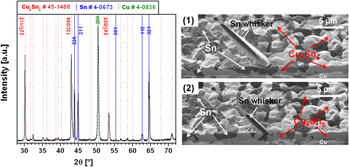

Copper-oxide whisker growth on tin–copper alloy coatings caused by the corrosion of Cu6Sn5 intermetallics.

Journal of Materials Science,

Vol. 48,

Issue. 23,

p.

8052.

Chason, Eric

Jadhav, Nitin

Pei, Fei

Buchovecky, Eric

and

Bower, Allan

2013.

Growth of whiskers from Sn surfaces: Driving forces and growth mechanisms.

Progress in Surface Science,

Vol. 88,

Issue. 2,

p.

103.

Yan, X. L.

Lin, M.

and

Wang, J. Y.

2013.

Equilibrium and kinetic surface segregations in Cu–Sn thin films.

Applied Physics A,

Vol. 113,

Issue. 2,

p.

423.

Stein, Jendrik

Welzel, Udo

Huegel, Werner

Blatt, Sabine

and

Mittemeijer, Eric Jan

2013.

Aging-time-resolvedin situmicrostructural investigation of tin films electroplated on copper substrates, applying two-dimensional-detector X-ray diffraction.

Journal of Applied Crystallography,

Vol. 46,

Issue. 6,

p.

1645.

Huang, Lin

Lin, Xue Nian

Chen, Ren Wu

and

Wang, Jiang Yong

2013.

Sn Whisker Growth in Cu(Top)-Sn(Bottom) Bilayer System upon Room Temperature Aging.

Advanced Materials Research,

Vol. 785-786,

Issue. ,

p.

918.

Steiger, Jens

Kramer, Dominik

and

Mönig, Reiner

2014.

Mechanisms of dendritic growth investigated by in situ light microscopy during electrodeposition and dissolution of lithium.

Journal of Power Sources,

Vol. 261,

Issue. ,

p.

112.

Stein, J.

Rehm, S.

Welzel, U.

Huegel, W.

and

Mittemeijer, E. J.

2014.

The Role of Silver in Mitigation of Whisker Formation on Thin Tin Films.

Journal of Electronic Materials,

Vol. 43,

Issue. 11,

p.

4308.

Chia, Pay Ying

and

Haseeb, A. S. M. A.

2015.

Intermixing reactions in electrodeposited Cu/Sn and Cu/Ni/Sn multilayer interconnects during room temperature and high temperature aging.

Journal of Materials Science: Materials in Electronics,

Vol. 26,

Issue. 1,

p.

294.

Huang, Lin

Jian, Wei

Lin, Bing

Wen, Yuren

Gu, Lin

and

Wang, Jiangyong

2015.

Thermodynamic understanding of Sn whisker growth on the Cu surface in Cu(top)-Sn(bottom) bilayer system upon room temperature aging.

Journal of Applied Physics,

Vol. 117,

Issue. 21,

Molnár, G Y

Katona, G L

Langer, G A

Csík, A

Chen, Y C

and

Beke, D L

2015.

Low temperature homogenization in nanocrystalline PdCu thin film system.

Materials Research Express,

Vol. 2,

Issue. 10,

p.

105012.

Stein, J.

Welzel, U.

Leineweber, A.

Huegel, W.

and

Mittemeijer, E.J.

2015.

The crystallographic growth directions of Sn whiskers.

Acta Materialia,

Vol. 86,

Issue. ,

p.

102.

Samy, N.

Shenouda, S.S.

Fadel, M.

Talaat, H.

Katona, G.L.

Langer, G.A.

Csik, A.

and

Beke, D.L.

2015.

Investigation of solid-state reaction in Ag/Sn nanostructured thin films at room temperature.

Philosophical Magazine,

Vol. 95,

Issue. 27,

p.

2990.

Pei, Fei

Jadhav, Nitin

Buchovecky, Eric

Bower, Allan F.

Chason, Eric

Liu, Wenjun

Tischler, Jonathan Z.

Ice, Gene E.

and

Xu, Ruqing

2016.

In-situ synchrotron micro-diffraction study of surface, interface, grain structure, and strain/stress evolution during Sn whisker/hillock formation.

Journal of Applied Physics,

Vol. 119,

Issue. 10,

Zaka, H.

Shenouda, S.S.

Fouad, S.S.

Medhat, M.

Katona, G.L.

Csik, A.

Langer, G.A.

and

Beke, D.L.

2016.

Formation of Cu6Sn5 phase by cold homogenization in nanocrystalline Cu–Sn bilayers at room temperature.

Microelectronics Reliability,

Vol. 56,

Issue. ,

p.

85.

Chia, Pay

Haseeb, A.

and

Mannan, Samjid

2016.

Reactions in Electrodeposited Cu/Sn and Cu/Ni/Sn Nanoscale Multilayers for Interconnects.

Materials,

Vol. 9,

Issue. 6,

p.

430.

Lin, B.

Jian, W.

and

Wang, J.Y.

2016.

Understanding of phase transformation in Pd/a-Si bilayered system.

Journal of Alloys and Compounds,

Vol. 665,

Issue. ,

p.

42.

Ross, Glenn

Tao, Xiaoma

Broas, Mikael

Mäntyoja, Nikolai

Vuorinen, Vesa

Graff, Andreas

Altmann, Frank

Petzold, Matthias

and

Paulasto-Kröckel, Mervi

2017.

Interfacial void segregation of Cl in Cu-Sn micro-connects.

Electronic Materials Letters,

Vol. 13,

Issue. 4,

p.

307.

Lin, Qiaoli

Li, Fuxiang

and

Wang, Jianbin

2018.

Wetting of Sn/Cu and Sn/Cu-Sn IMCs at 623–723K.

Journal of Alloys and Compounds,

Vol. 767,

Issue. ,

p.

877.