Article contents

Nucleation and growth of metamorphic epitaxial aluminum on silicon (111) 7 × 7 and  $\sqrt 3 \times \sqrt 3$ surfaces

$\sqrt 3 \times \sqrt 3$ surfaces

Published online by Cambridge University Press: 21 August 2017

Abstract

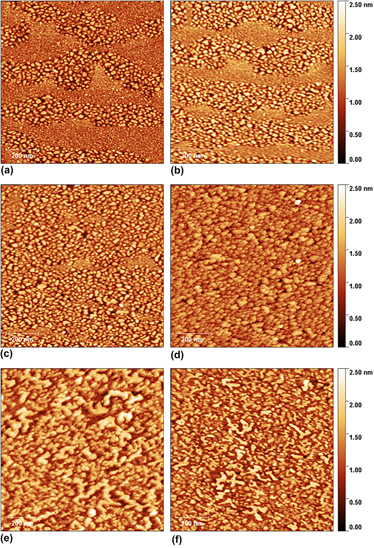

The nucleation and growth of Al on 7 × 7 and  $\sqrt 3 \times \sqrt 3$R30 Al reconstructed Si(111) that result in strain-free Al overgrown films grown with an atomically abrupt metamorphic interface are compared. The reconstructed surfaces and abrupt strain relaxations are verified using reflection high-energy electron diffraction. The topography of evolution is examined with atomic force microscopy. The growth of Al on both the surfaces exhibits 3D island growth, but the island evolution of growth is dramatically different. On the 7 × 7 surface, mounds formed are uniformly distributed across the substrate, and growth appears to proceed uniformly. Alternatively, on the

$\sqrt 3 \times \sqrt 3$R30 Al reconstructed Si(111) that result in strain-free Al overgrown films grown with an atomically abrupt metamorphic interface are compared. The reconstructed surfaces and abrupt strain relaxations are verified using reflection high-energy electron diffraction. The topography of evolution is examined with atomic force microscopy. The growth of Al on both the surfaces exhibits 3D island growth, but the island evolution of growth is dramatically different. On the 7 × 7 surface, mounds formed are uniformly distributed across the substrate, and growth appears to proceed uniformly. Alternatively, on the  $\sqrt 3 \times \sqrt 3$R30 surface, Al atoms exhibit a clear preference to form mounds near the step edges. During Al growth, mounds increase in size and number, expanding out from step edges until they cover the whole substrate. Consistent expression of a mounded nucleation and growth mode imparts a physical limitation to the achievable surface roughness that may impact the ultimate performance of layered devices such as Josephson junctions that are critical components of superconducting quantum circuits.

$\sqrt 3 \times \sqrt 3$R30 surface, Al atoms exhibit a clear preference to form mounds near the step edges. During Al growth, mounds increase in size and number, expanding out from step edges until they cover the whole substrate. Consistent expression of a mounded nucleation and growth mode imparts a physical limitation to the achievable surface roughness that may impact the ultimate performance of layered devices such as Josephson junctions that are critical components of superconducting quantum circuits.

- Type

- Invited Articles

- Information

- Journal of Materials Research , Volume 32 , Issue 21: Focus Issue: Jan van der Merwe: Epitaxy and the Computer Age , 14 November 2017 , pp. 4067 - 4075

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Artur Braun

References

REFERENCES

- 5

- Cited by