Published online by Cambridge University Press: 18 June 2020

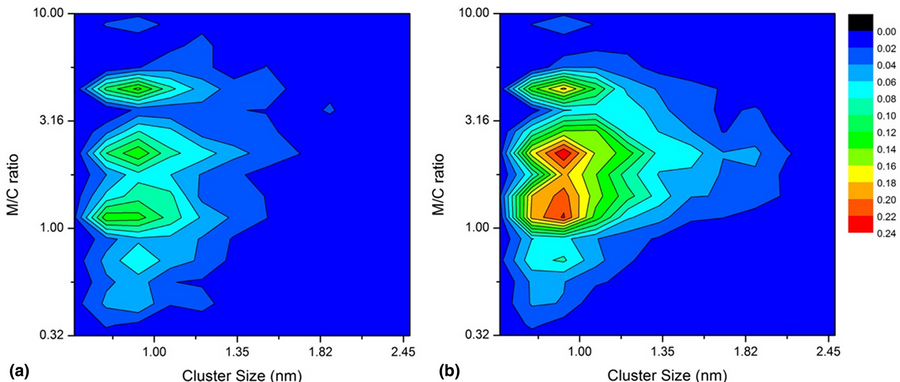

In the present study, 3D atom probe was used to study the effect of increased Mo (1–3 wt%) on clustering in secondary hardening ultra-high strength steels. Clusters have been classified into three categories, namely, Type I, Type II, and Type III with the (Cr + Mo)/C ratio of <1.5, 1.5–3.25, and >3.25, respectively. Cluster evolution suggests that size and volume fraction (Vf) of Type II clusters increase continuously from as-quenched to aged samples, while the number density (Nv) increases in 400 °C aged sample and decreases in 450 and 500 °C samples. On the other hand, Nv and Vf of both Type I and Type III clusters decrease on aging. This work clearly suggests that on aging, Type II clusters, which are close to M2C stoichiometry, become most stable, which may eventually either become M2C precipitates upon prolonged aging or act as potential nuclei for the precipitation of equilibrium M2C precipitates.