Published online by Cambridge University Press: 22 June 2020

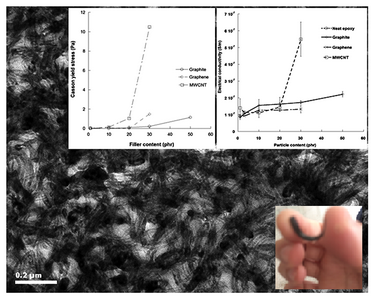

The aim of this research was to develop the UV-cured epoxy/carbon composites. The rheological properties of the uncured neat epoxy and epoxy composite with graphite, graphene, and multi-walled carbon nanotube (MWCNT) were evaluated to observe the macroscopic flow behavior and the microstructure by shear force. The results showed that epoxy/carbon composites at high filler content exhibited shear-thinning behavior with a high yield stress value and epoxy/MWCNT at 30 phr showed this characteristic obviously. The fractured surface and particle dispersion in the epoxy matrix were evaluated by scanning electron microscopy and transmission electron microscopy, respectively. Epoxy/carbon composites at high filler content displayed rough fracture surface with particle agglomeration, thus the electrical conductivity increased. The result showed that the epoxy/MWCNT composites had high potential to use as a conductive adhesive with a 3D printing process due to high electrical conductivity with high viscosity that could be formed easily during processing.