Published online by Cambridge University Press: 30 October 2017

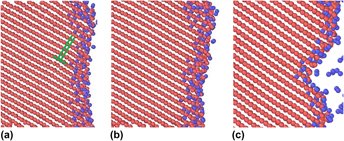

Atomistic simulations are carried out to analyze the influence of oxygen environment on nickel and copper surface roughness and notch initiation. The early stages of oxidation of nickel and copper surfaces are first simulated and compared with experimental observations. Various oxygen superstructures observed on metal surfaces are reproduced as well as the nucleation of small NiO embryos. Nickel and copper surface oxidation mechanisms are different and different “oxide” nano layers are formed. None of these superficial nano layers has a major influence on the mechanical behavior of surface slips as they do not change the surface roughness fatigue evolution and micro-notch production. These atomistic results agree with experimental studies which report similar development of persistent slip band surface relief in inert and in air environment. A general model for the estimation of surface slip irreversibility is also provided and the models of environment-assisted surface relief evolution and microcrack initiation are revisited.

Contributing Editor: Gunther Eggeler