Article contents

Microstructure, texture, and enhanced mechanical properties of an extruded Mg–rare earth alloy after hot compression

Published online by Cambridge University Press: 10 December 2015

Abstract

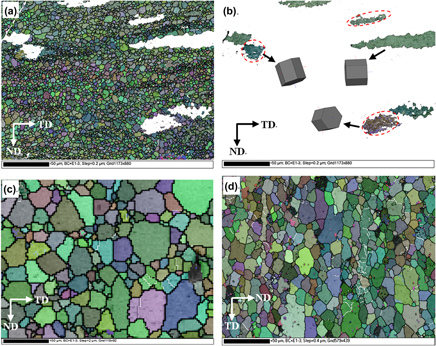

An extruded Mg–8Gd–4Y–1Nd–0.5Zr alloy was preheated at 500 °C for 0.5 h and then subjected to hot compression to a true strain of 0.69 at temperature 450 °C and a strain rate of 0.2 s−1. It is observed that boundaries of small grains (∼3 μm) in the extruded alloy are decorated with irregular-shaped particles; small grains show a weak texture of three main components of

$\left\langle {0001} \right\rangle //{\rm{TD}}$

,

$\left\langle {0001} \right\rangle //{\rm{TD}}$

,

$\left\langle {11\overline 2 1} \right\rangle //{\rm{ND}}$

, and

$\left\langle {11\overline 2 1} \right\rangle //{\rm{ND}}$

, and

$\left\langle {10\overline 1 0} \right\rangle //{\rm{ED}}$

. Dynamic recrystallization is concurrent with dynamic precipitation of particles during hot compression, resulting in both a uniform grain structure and a redistribution of particles. The retained particles before compression keep the texture unchanged during compression, leading to the same texture type of

$\left\langle {10\overline 1 0} \right\rangle //{\rm{ED}}$

. Dynamic recrystallization is concurrent with dynamic precipitation of particles during hot compression, resulting in both a uniform grain structure and a redistribution of particles. The retained particles before compression keep the texture unchanged during compression, leading to the same texture type of

$\left\langle {0001} \right\rangle //{\rm{TD}}$

of the compressed alloy as that of the preheated alloy. The compressed alloy exhibits a better aging hardening ability than the extruded alloy. After peak aging, the compressed alloy presents an ultimate tensile strength of 416 MPa, a yield tensile strength of 317 MPa, and an elongation of 2.7%.

$\left\langle {0001} \right\rangle //{\rm{TD}}$

of the compressed alloy as that of the preheated alloy. The compressed alloy exhibits a better aging hardening ability than the extruded alloy. After peak aging, the compressed alloy presents an ultimate tensile strength of 416 MPa, a yield tensile strength of 317 MPa, and an elongation of 2.7%.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2015

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 4

- Cited by