Published online by Cambridge University Press: 20 March 2015

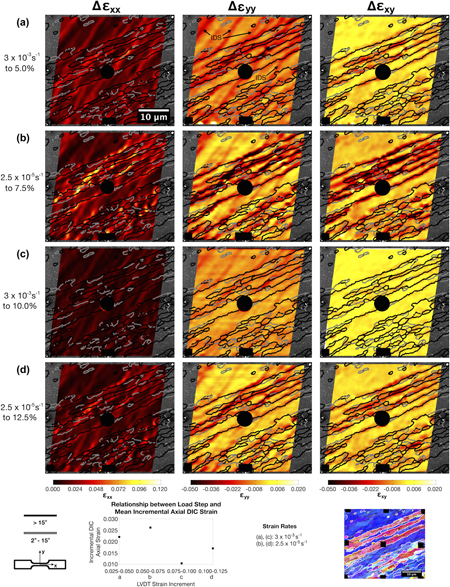

The mechanical properties of ultrafine-grained aluminum produced by equal-channel angular pressing (ECAP) are strongly influenced by strain rate. In this work, an experimental investigation of local strain rate sensitivity as it relates to microstructure was performed using a combination of scanning electron microscopy and digital image correlation. Uniaxial tension tests were carried out at 200 °C and strain rates alternating between 2.5 × 10−5 s−1 and 3.0 × 10−3 s−1. The results demonstrate that the heterogeneous microstructure generated by ECAP has a strong effect on the microstructure scale strain rate sensitivity. Deformation centered at grain boundaries separating regions of banded microstructure exhibits the greatest strain rate sensitivity. Strain rate sensitivity is limited in deformation occurring in regions of microstructure composed of ultrafine grains separated by low-angle grain boundaries. The tensile specimens all failed by shear bands at 200 °C and at room temperature they failed by necking with little plastic deformation apparent outside of the neck.