Article contents

Microstructure evolution in L12 hardened Co-base superalloys during creep

Published online by Cambridge University Press: 18 September 2017

Abstract

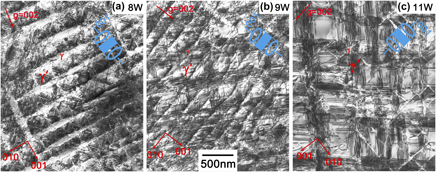

The plastic deformation mechanisms and the microstructure development during creep deformation of L12-hardened Co-base superalloys show a number of unique features. The preferred orientation of rafting is determined by their positive lattice mismatch. In addition, the regular interfacial dislocation networks often found in rafted specimens of other types of superalloys do not form. While the ordered γ′-L12 precipitates are supposed to harden the material, they are actually found to be frequently cut by partial dislocations generating stacking faults. In this work, specimens from creep tests interrupted at different strains were investigated using transmission and scanning electron microscopy. By this, it is possible to find out which of these processes take place in which stage of creep deformation. For a better understanding of creep deformation, the balance between γ′ cutting and dislocation activity within the matrix channels is of special interest.

Keywords

- Type

- Articles

- Information

- Journal of Materials Research , Volume 32 , Issue 24: Focus Issue: Mechanical Properties and Microstructure of Advanced Metallic Alloys—in Honor of Prof. Haël Mughrabi PART B , 28 December 2017 , pp. 4522 - 4530

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Mathias Göken

References

REFERENCES

- 12

- Cited by