No CrossRef data available.

Published online by Cambridge University Press: 02 November 2016

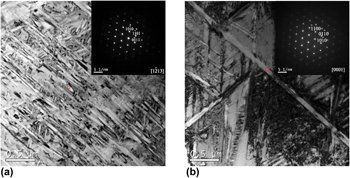

The electric field-assisted extrusion process is applied in Zr–45Ti–5Al–3V alloy. A transition from phase α to phase β is observed at various zones during the extrusion, and a complete transition is achieved by the considerable shear deformation. When subjected to the electric field-assisted extrusion, the continuous dynamic recrystallization is significant at the edges and the major shear deformation zones, and the equiaxed phase β grain structure is refined to a size of 250–300 µm. In addition, the phase β grains contain a minor amount of large residual lath-shaped phase α structures. The edges and the major shear deformation zones form a cubic texture along the {100}〈001〉 direction with a slightly weak polarity, while the polarity of the texture at the center is strong. The extrusion is found to decrease the edge strength from 1580 MPa to 1185 MPa and to increase the elongation up to 7.2%.