Published online by Cambridge University Press: 24 June 2020

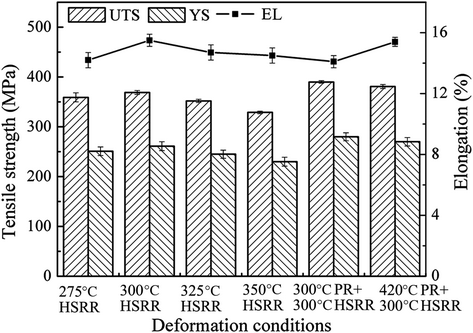

The microstructure evolution, dynamic recrystallization (DRX) and precipitation of the ZM61 alloy sheets prepared with different rolling conditions were studied. The DRX grain sizes (dDRX) at four high strain rate rolling (HSRR) temperatures (275–350 °C) are 1.9, 2.3, 2.6 and 3.1 μm, respectively, while the DRX volume fractions (fVDRX) are 69, 73, 76 and 82%, respectively. 300 °C is selected as the optimal HSRR temperature. The dDRX and fVDRX of the alloys prepared by pre-rolling (PR) at 300 °C + HSRR are 1.0 μm and 91%, respectively. The PR treatment does not change the types of the precipitates but promotes the precipitation. The tensile strength (UTS) of 369 MPa and yield strength (YS) of 261 MPa can be achieved by HSRR at 300 °C, while a further increase in both UTS and YS can be obtained by PR treatment.