No CrossRef data available.

Published online by Cambridge University Press: 27 June 2017

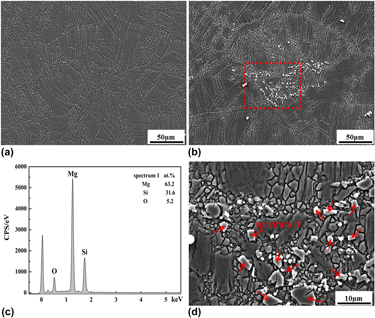

Mg–3Al–Zn alloy with the addition of Al and Si as a eutectic alloy was subjected to conventional hot rolling. The corresponding mechanical properties, microstructure evolution, and dynamic recrystallization mechanism were investigated by optical microscope, scanning electron microscope, electron backscattered diffraction (EBSD), and tensile tests. The experimental results indicated that the Mg–3(Al–Si)–Zn alloy had a microstructure refinement, thus rendering an enhanced mechanical properties in comparison with the Mg–3Al–Zn alloy. The refined Mg2Si particles could act as potential nucleation sites for recrystallization in as-rolled Mg–3(Al–Si)–Zn alloy sheets, which resulted in more completely recrystallized regions through particle stimulated nucleation and a weakened basal texture compared to Mg–3Al–Zn alloy. The improvement in the tensile strength of the as-rolled Mg–3(Al–Si)–Zn alloy can be attributed to grain refinement and second phase strengthening caused by the refined Mg2Si particles.

Contributing Editor: Jürgen Eckert