Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Güler, Onur

and

Varol, Temel

2021.

Advanced Surface Coating Techniques for Modern Industrial Applications.

p.

150.

Tian, S. S.

Sun, W. C.

Liu, Y. W.

Xiao, Y.

and

Jia, Y. P.

2021.

Microstructures and corrosion resistance of conversion film-electroless Ni-W-P ternary coatings on AZ91D magnesium alloy.

Transactions of the IMF,

Vol. 99,

Issue. 6,

p.

292.

Fathi, Reham

Wei, Hongyu

Saleh, Bassiouny

Radhika, N.

Jiang, Jinghua

Ma, Aibin

Ahmed, Mahmoud H.

Li, Qin

and

Ostrikov, Kostya Ken

2022.

Past and present of functionally graded coatings: Advancements and future challenges.

Applied Materials Today,

Vol. 26,

Issue. ,

p.

101373.

Li, Zhizhen

Bian, Chaoqun

and

Hu, Lingxia

2023.

Exploration of the Corrosion Behavior of Electroless Plated Ni-P Amorphous Alloys via X-ray Photoelectron Spectroscopy.

Molecules,

Vol. 28,

Issue. 1,

p.

377.

Jia, Ya-Peng

Sun, Wan-Chang

Dong, Ya-Ru

Xiao, Yan

Liu, Jing-Pei

and

Zhang, Cong-Xiao

2023.

Preparation, Microstructures, and Corrosion Resistance of Ni-Mo-P Ternary Amorphous Coating.

Journal of Materials Engineering and Performance,

Vol. 32,

Issue. 5,

p.

2476.

Ding, Ziyu

Yuan, Qianhong

Wang, Hao

Tang, Yinghong

Tan, Yimin

and

He, Quanguo

2023.

Microstructure and properties of Nb2O5/Mg gradient coating on AZ31 magnesium alloy by magnetron sputtering.

Ceramics International,

Vol. 49,

Issue. 1,

p.

154.

Hashemi, Sayed Hamid

Shoja-Razavi, Reza

Ashrafi, Ali

Erfanmanesh, Mohammad

and

Khalili, Sajjad

2023.

Evaluating the Effect of Laser Surface Modification on the Corrosion Behavior of Ni-P-SiC Electroless Coating Deposited on Al356 Alloy.

Transactions of the Indian Ceramic Society,

Vol. 82,

Issue. 1,

p.

14.

Kumar, Sunny

Banerjee, Tushar

and

Patel, Dharmendra

2024.

Structural, mechanical, tribological and corrosion characteristics of dual layer Ni-P/Sr-P coating on AZ91D Mg alloy through environmentally-friendly chemical conversion and electroless routes.

Surface and Coatings Technology,

Vol. 485,

Issue. ,

p.

130922.

Xiao, Xuewen

Xue, Wenjuan

Wang, Shuigen

Chen, Xin

Zheng, Siting

and

Feng, Ke

2024.

Effect of Zinc–Nickel Alloy Gradient Coating Microstructure on the Corrosion Resistance of Steel.

Journal of Materials Engineering and Performance,

Kumar, Sunny

Banerjee, Tushar

and

Patel, Dharmendra

2024.

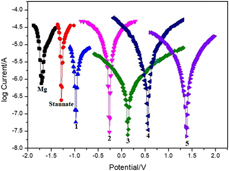

Synthesis and evaluation of tribo-mechanical and corrosion properties of electroless Ni-P coating on AZ91D Mg alloy with stannate conversion underlayer.

Proceedings of the Institution of Mechanical Engineers, Part L: Journal of Materials: Design and Applications,