Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Salaev, M.A.

Salaeva, A.A.

Kharlamova, T.S.

and

Mamontov, G.V.

2021.

Pt–CeO2-based composites in environmental catalysis: A review.

Applied Catalysis B: Environmental,

Vol. 295,

Issue. ,

p.

120286.

Yang, Min

Li, Guangshe

Li, Huixia

Ding, Junfang

Wang, Yan

and

Li, Liping

2021.

Growth kinetic control over MgFe2O4 to tune Fe occupancy and metal–support interactions for optimum catalytic performance.

CrystEngComm,

Vol. 23,

Issue. 13,

p.

2538.

Mužina, Katarina

Kurajica, Stanislav

Guggenberger, Patrick

Duplančić, Marina

and

Dražić, Goran

2022.

Catalytic activity and properties of copper-doped ceria nanocatalyst for VOCs oxidation.

Journal of Materials Research,

Vol. 37,

Issue. 11,

p.

1929.

Woźniak, Piotr

Małecka, Małgorzata A.

Chinchilla, Lidia

and

Trasobares, Susana

2022.

3D hierarchically structured Ce1-xGdxO2-x/2 mixed oxide particles: the role of microstructure, porosity and multi-level architecture stability in soot and propane oxidation..

Materials Research Bulletin,

Vol. 151,

Issue. ,

p.

111816.

Bezkrovnyi, Oleksii

Vorokhta, Mykhailo

Pawlyta, Mirosława

Ptak, Maciej

Piliai, Lesia

Xie, Xianxian

Dinhová, Thu Ngan

Khalakhan, Ivan

Matolínová, Iva

and

Kepinski, Leszek

2022.

In situ observation of highly oxidized Ru species in Ru/CeO2 catalyst under propane oxidation.

Journal of Materials Chemistry A,

Vol. 10,

Issue. 31,

p.

16675.

Wang, Haiyang

Duan, Wenyuan

Zhang, Ruiyin

Ma, Hao

Ma, Cheng

Liang, Miaomiao

Zhao, Yuzhen

and

Miao, Zongcheng

2023.

Fabrication and catalytic properties of nanorod-shaped (Pt–Pd)/CeO2 composites.

RSC Advances,

Vol. 13,

Issue. 5,

p.

2811.

Wang, Haiyang

Zhang, Dongxia

Zhang, Ruiyin

Ma, Hao

Zhang, Huimin

Yao, Ruijuan

Liang, Miaomiao

Zhao, Yuzhen

and

Miao, Zongcheng

2023.

Dealloying Synthesis of Bimetallic (Au–Pd)/CeO2 Catalysts for CO Oxidation.

ACS Omega,

Vol. 8,

Issue. 13,

p.

11889.

Ascencio, Francisco

Rangel-Gamboa, Lucia

Maqueda-Cabrera, Brayan

Zorrilla, Cristina

Herrera, Raúl

and

Mendoza-Cruz, Rubén

2024.

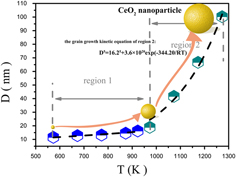

Structural and vibrational study of porous CeO2 nanoparticles.

Materials Chemistry and Physics,

Vol. 311,

Issue. ,

p.

128492.

Palwai, Sharvare

2024.

Electrospinning - Theory, Applications, and Update Challenges.

Zhang, Zhijia

Cui, Ruirui

Zhang, Jun

Tai, Youfa

Linghu, Peng

and

Deng, Chaoyong

2024.

A novel bright and thermally stable red phosphor Mg2YVO6:Eu3+.

Optical Materials,

Vol. 152,

Issue. ,

p.

115487.

Bezkrovnyi, Oleksii

Szymczak, Maja

Marciniak, Lukasz

Seminko, Vladyslav

Kraszkiewicz, Piotr

Małecka, Małgorzata

Pawlyta, Mirosława

Vorochta, Michael

and

Matolínová, Iva

2025.

Advances and Limitations of the Eu3+ Luminescent Probe for Monitoring Ce4+/Ce3+ Transitions in Ceria.

The Journal of Physical Chemistry C,

Vol. 129,

Issue. 3,

p.

1724.