Article contents

Investigation of micro-yield strength and coefficient of thermal expansion of Al–Cu–Mg–Li–Sc–Ag alloys with various contents of Li

Published online by Cambridge University Press: 11 April 2019

Abstract

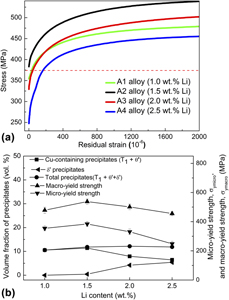

In this study, the effects of lithium(Li) content (1.0, 1.5, 2.0, and 2.5 wt%) on the microstructure, micro-yield strength (MYS) and coefficient of thermal expansion (CTE) of Al–Cu–Mg–Li–Sc–Ag alloys were investigated. The results showed that increased Li content promoted the formation of primary T1 phases and secondary T1 precipitates. While the primary T1 phases decreased the MYS of the Al–Cu–Mg–Li–Sc–Ag alloys due to large residual stress and stress concentration, secondary T1 precipitates increased the MYS due to their excellent pinning and impeding effect on mobile dislocations. In addition, the increase in Li content caused the CTETT (i.e., CTE transition temperature) first increased and then decreased, while the CTEH (CTETT to 300 °C) of alloys to first decrease and then increase. The CTEH and CTETT values were influenced by the MYS rather than by the macro-yield strength of alloys, arising from the differences in the amounts of the T1 precipitates among the four tested alloys; this was due to the superior thermal stability of the T1 precipitates.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 9

- Cited by