No CrossRef data available.

Published online by Cambridge University Press: 08 November 2019

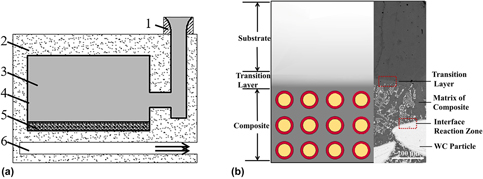

In this study, cast tungsten carbide particle/steel matrix surface composites were fabricated using a vacuum evaporative pattern casting (V-EPC) infiltration process. Through thermal shock tests at 500 °C, the initiation and propagation of cracks at the interface of the composites were investigated. Owing to the mismatch in the coefficients of thermal expansion (CTE), cracks tended to appear at the interface reaction zone (IRZ) between the particles and the matrix. Because there was also a difference in the CTE between the composite and the substrate, the cracks propagated rapidly along the transition layer (TL) between the composite and the substrate, and finally connected to form macro-cracks. Based on the stress analysis and calculation, the maximum thermal stress at the TL was 63.4 MPa, while the maximum thermal stress at the IRZ was 38 MPa. It could thus be inferred that the TL is the weak link under thermal fatigue. In addition, the experimental results were verified and found to be in good agreement with the calculations.