Published online by Cambridge University Press: 23 March 2015

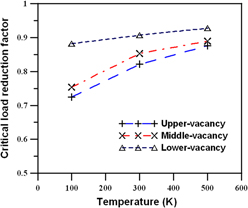

This study investigated influences of vacancy defects on buckling behaviors of open-tip carbon nanocones (CNCs) by molecular dynamics simulations. Effects of vacancy location and temperature on the buckling behaviors were examined in the study. Some interesting findings were attained from the investigations. It was noticed that the CNC with an upper vacancy has comparable degradation in the critical strain and in the critical load with the CNC with a middle vacancy, whereas the CNC with a lower vacancy has lower degradation in the antibuckling ability than the above two CNCs. The antibuckling ability of the CNCs reduces with the growth of the temperature. This temperature effect is more apparent in the perfect CNC than in the vacancy-defect CNCs. It was also observed that the degradation in the antibuckling ability is obvious at a lower temperature, but it decreases as the temperature grows. Besides, all the CNCs (including the perfect and the vacancy-defect CNCs) exhibited a shrinking/swelling buckling mode shape at the studied temperatures. Existence of the vacancies did not alter the buckling mode shape of the CNCs.