Published online by Cambridge University Press: 16 February 2017

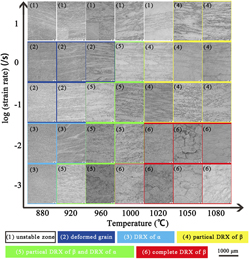

Isothermal compression testing of Ti–5.8Al–3Sn–5Zr–0.5Mo–1.0Nb–1.0Ta–0.4Si–0.2Er titanium alloy is performed on a Gleeble-3500 thermal simulator, and the corresponding microstructures are analyzed to clarify the softening mechanism and participates evolution. A constitutive equation compensated by strain has been established to describe the hot deformation behavior of the alloy. The deformation activation energies are calculated to be 369760.93–699310.86 J/mol in α + β two-phase region and 268030.03–325800.41 J/mol in β single-phase region. At a temperature of 880 °C, the main softening mechanism is the continuous dynamic recrystallization of lamellar α colony, controlled by the mechanical rotation of the sub-grain followed by dislocation climbing and annihilation by diffusion. Meanwhile, the dominant softening mechanism is the discontinuous dynamic recrystallization of β phase during the deformation at temperatures of 920 °C–1080 °C. Silicide containing Er with an average diameter of 20 nm is formed during the water quenching.

Contributing Editor: Jürgen Eckert