Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Li, Qin

Chen, Weimin

Zhong, Jing

Zhang, Lijun

Chen, Qing

and

Liu, Zi-Kui

2017.

On Sluggish Diffusion in Fcc Al–Co–Cr–Fe–Ni High-Entropy Alloys: An Experimental and Numerical Study.

Metals,

Vol. 8,

Issue. 1,

p.

16.

Zhang, Li Jun

Chen, Juan

Chen, Wei Min

Ta, Na

and

Li, Qin

2017.

Interdiffusion Databanks of γ, γ′ and β Phases in NiAl-Based Ternary Systems.

Diffusion Foundations,

Vol. 13,

Issue. ,

p.

136.

Chen, Juan

Zhang, Lijun

and

Lu, Xiao-Gang

2018.

Diffusion behaviors of Rh, Ta, W, Re, Os and Ir in ternary L12-Ni3Al alloys.

Intermetallics,

Vol. 102,

Issue. ,

p.

11.

Zhong, Jing

Chen, Weimin

and

Zhang, Lijun

2018.

HitDIC: A free-accessible code for high-throughput determination of interdiffusion coefficients in single solution phase.

Calphad,

Vol. 60,

Issue. ,

p.

177.

Chen, Juan

and

Zhang, Lijun

2018.

Composition-dependent interdiffusivity matrices in face centered cubic Ni–Al–X (X = Rh and W) alloys at 1423, 1473 and 1523 K: A high-throughput experimental measurement.

Calphad,

Vol. 60,

Issue. ,

p.

106.

Chen, Juan

Zhang, Lijun

and

Lu, Xiao-Gang

2018.

Screening of Possible Re-Substitutional Elements in Single-Crystal Ni-Based Superalloys: A Viewpoint From Interdiffusion Coefficients in Ni-Al-X Ternaries.

Metallurgical and Materials Transactions A,

Vol. 49,

Issue. 7,

p.

2999.

Lin, Yan

Wei, Ming

Li, Guodong

and

Zhang, Lijun

2018.

Phase Equilibria and Microhardness of As-Cast and Annealed Ni-Al-Os Alloys in Ni-Rich Region.

Journal of Phase Equilibria and Diffusion,

Vol. 39,

Issue. 6,

p.

944.

Wang, Rui

Chen, Weimin

Zhong, Jing

and

Zhang, Lijun

2018.

Experimental and numerical studies on the sluggish diffusion in face centered cubic Co-Cr-Cu-Fe-Ni high-entropy alloys.

Journal of Materials Science & Technology,

Vol. 34,

Issue. 10,

p.

1791.

Chen, Juan

Zhao, Jingrui

Zhang, Lijun

Lu, Xiao-Gang

and

Liu, Libin

2019.

Atomic mobilities in fcc Ni–rich Ni−X (X=Rh, Ta, W, Re, and Ir) systems.

Calphad,

Vol. 65,

Issue. ,

p.

316.

Chen, Shiyao

Li, Qin

Zhong, Jing

Xing, Fangzhou

and

Zhang, Lijun

2019.

On diffusion behaviors in face centered cubic phase of Al-Co-Cr-Fe-Ni-Ti high-entropy superalloys.

Journal of Alloys and Compounds,

Vol. 791,

Issue. ,

p.

255.

Chen, Juan

and

Zhang, Lijun

2019.

Composition-dependent hardness and Young’s modulus in fcc Ni–X (X = Rh, Ta, W, Re, Os, and Ir) alloys: Experimental measurements and CALPHAD modeling.

Journal of Materials Research,

Vol. 34,

Issue. 18,

p.

3104.

Zhong, Jing

Zhang, Lijun

Wu, Xiaoke

Chen, Li

and

Deng, Chunming

2020.

A novel computational framework for establishment of atomic mobility database directly from composition profiles and its uncertainty quantification.

Journal of Materials Science & Technology,

Vol. 48,

Issue. ,

p.

163.

Zhong, Jing

Chen, Li

and

Zhang, Lijun

2020.

High-throughput determination of high-quality interdiffusion coefficients in metallic solids: a review.

Journal of Materials Science,

Vol. 55,

Issue. 24,

p.

10303.

Liu, Feng

Wang, Zexin

Wang, Zi

Zhong, Jing

Wu, Xiaoke

Qin, Zijun

Li, Zihang

Tan, Liming

Zhao, Lei

Zhu, Lilong

Jiang, Liang

Huang, Lan

Zhang, Lijun

and

Liu, Yong

2020.

High-throughput determination of interdiffusivity matrices in Ni-Al-Ti-Cr-Co-Mo-Ta-W multicomponent superalloys and their application in optimization of creep resistance.

Materials Today Communications,

Vol. 24,

Issue. ,

p.

101018.

Tripathi, Aparna

Kumar, K.C. Hari

and

Kulkarni, Kaustubh N.

2020.

Kinetic modeling of β-BCC phase in Ti–Al–Nb system in the temperature range of 1060–1200 °C.

Calphad,

Vol. 68,

Issue. ,

p.

101725.

Liu, Feng

Wang, Zexin

Wang, Zi

Zhong, Jing

Zhao, Lei

Jiang, Liang

Zhou, Runhua

Liu, Yong

Huang, Lan

Tan, Liming

Tian, Yujia

Zheng, Han

Fang, Qihong

Zhang, Lijun

Zhang, Lina

Wu, Hong

Bai, Lichun

and

Zhou, Kun

2022.

High‐Throughput Method–Accelerated Design of Ni‐Based Superalloys.

Advanced Functional Materials,

Vol. 32,

Issue. 28,

Liu, Huixin

Liu, Yuling

Du, Changfa

Du, Yong

Zheng, Zhoushun

Liu, Shuhong

Premovic, Milena

Hu, Jieqiong

and

Xie, Ming

2022.

Diffusivity and atomic mobility in fcc Cu–Mn–Si alloys: measurements and modeling by CALTPP program.

Journal of Materials Science,

Vol. 57,

Issue. 8,

p.

5241.

Liu, Huixin

Wen, Shiyi

Liu, Yuling

Du, Changfa

Min, Qianhui

Zheng, Zhoushun

and

Du, Yong

2023.

Interdiffusivity matrices and atomic mobilities in fcc Co–Ni–Si and Cu–Co–Ni–Si alloys: Experiment and modeling.

Calphad,

Vol. 80,

Issue. ,

p.

102501.

Geng, Lilun

Zhao, Wenyue

Ru, Yi

Li, Mingzhe

Yang, Fan

Hu, Yunpeng

Du, Boxuan

Cao, Yang

Pei, Yanling

Li, Shusuo

and

Gong, Shengkai

2024.

Liberalizing the effects of Al and Cr in coatings for enhanced interface stability with Mo-rich Ni3Al-based superalloys.

Journal of Materials Research and Technology,

Vol. 32,

Issue. ,

p.

2830.

Zhang, Haobo

Liu, Yuan

Zhou, Ruhao

Kang, Jie

Song, Shuang

Chen, Dongping

Zhang, Heng

Ru, Yi

Pei, Yanling

Li, Shusuo

and

Gong, Shengkai

2025.

Effects of Cr and Mo in substrate on the oxidation behavior of (Ni,Pt)Al coatings at 1200 °C.

Journal of Materials Research and Technology,

Vol. 35,

Issue. ,

p.

6431.

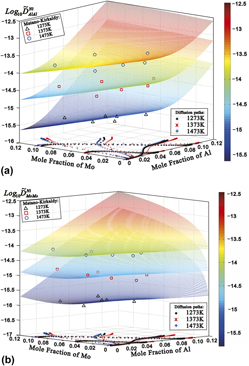

$\tilde D_{{\rm{AlAl}}}^{{\rm{Ni}}}$

is generally larger than

$\tilde D_{{\rm{AlAl}}}^{{\rm{Ni}}}$

is generally larger than

$\tilde D_{{\rm{MoMo}}}^{{\rm{Ni}}}$

. Moreover,

$\tilde D_{{\rm{MoMo}}}^{{\rm{Ni}}}$

. Moreover,

$\tilde D_{{\rm{AlAl}}}^{{\rm{Ni}}}$

generally increases with concentration of Al, while

$\tilde D_{{\rm{AlAl}}}^{{\rm{Ni}}}$

generally increases with concentration of Al, while

$\tilde D_{{\rm{MoMo}}}^{{\rm{Ni}}}$

increases with concentrations of both Al and Mo. In contrast, the cross interdiffusivities can be either positive or negative. Average relative errors of

$\tilde D_{{\rm{MoMo}}}^{{\rm{Ni}}}$

increases with concentrations of both Al and Mo. In contrast, the cross interdiffusivities can be either positive or negative. Average relative errors of

$\tilde D_{{\rm{AlAl}}}^{{\rm{Ni}}}$

,

$\tilde D_{{\rm{AlAl}}}^{{\rm{Ni}}}$

,

$\tilde D_{{\rm{AlMo}}}^{{\rm{Ni}}}$

,

$\tilde D_{{\rm{AlMo}}}^{{\rm{Ni}}}$

,

$\tilde D_{{\rm{MoAl}}}^{{\rm{Ni}}}$

, and

$\tilde D_{{\rm{MoAl}}}^{{\rm{Ni}}}$

, and

$\tilde D_{{\rm{MoMo}}}^{{\rm{Ni}}}$

were evaluated to be 2.4, 5.1, 16.1, and 1.7% using error propagation. Furthermore, our prediction of composition profiles and interdiffusion fluxes based on evaluated interdiffusivity matrices agrees quite well with measured data. Traditional Matano–Kirkaldy method was also applied to further verify the reliability of obtained interdiffusivities. Besides, three-dimensional planes of activation energies of main interdiffusivities were also evaluated using the Arrhenius equation.

$\tilde D_{{\rm{MoMo}}}^{{\rm{Ni}}}$

were evaluated to be 2.4, 5.1, 16.1, and 1.7% using error propagation. Furthermore, our prediction of composition profiles and interdiffusion fluxes based on evaluated interdiffusivity matrices agrees quite well with measured data. Traditional Matano–Kirkaldy method was also applied to further verify the reliability of obtained interdiffusivities. Besides, three-dimensional planes of activation energies of main interdiffusivities were also evaluated using the Arrhenius equation.