Published online by Cambridge University Press: 14 March 2017

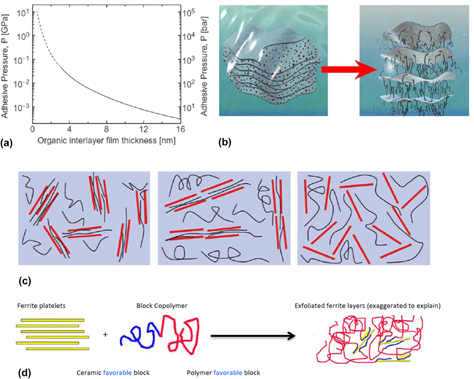

Magneto polymer matrix composites (MPMC) is a new class of magnetic polymer materials which are being developed and under investigation as potential materials for tomorrow’s aircraft structures. It encompasses magnetic, particulate strengthening (dispersion strengthening) as well as fiber reinforcement/strengthening characteristics which are sought out to be utilized toward making efficient future aerospace composite materials. Various types of ferrites including barium, cobalt, iron, and strontium were explored for being used in making new composites. Here a comprehensive review of the synthesis, structure, properties, thermodynamics, surface chemistry, and phase transformations of individual ferrites and clusters of ferrites as fillers is presented. In particular a discussion about the rational control of the mechanical, physical, thermal, electrical, and magnetic properties of magneto polymer matrix composites through surface functionalization, modification, emulsification/compounding/blending, heat treatment (phase transformation and separation), and control of processing conditions (temperature, pressure and geometry of mold) is provided. These smart materials have a wide range of potential applications in medicine, drug delivery, bio imaging, bio marking, tissue engineering, electromagnetic interference (EMI) and electromagnetic force (EMF) shielding, and as competent materials for aerospace structural applications.

Contributing Editor: Michael E. McHenry

This section of Journal of Materials Research is reserved for papers that are reviews of literature in a given area.