Published online by Cambridge University Press: 12 March 2014

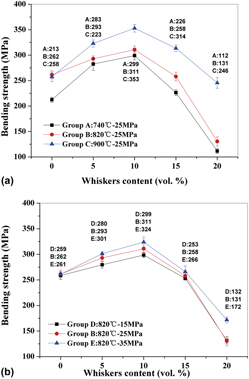

Cu/Sn alloy matrix composites reinforced with β-Si3N4 whiskers (β-Si3N4w/Cu/Sn) were prepared by powder metallurgy method with the aim of improving the mechanical property. Although the β-Si3N4 whisker additions played a side effect on the densification of the composites, the mechanical property was significantly improved. The highest bending strength of β-Si3N4w/Cu/Sn reached up to 353 MPa, and the highest hardness of composites was also improved to 97.13 HRF. β-Si3N4 whiskers could induce the improved work of fracture and grain refinement of composites and thus brought about the enhancement of mechanical performance. However, excessively high β-Si3N4 whisker content was not beneficial to the high mechanical property because of the low densification and the severe aggregation of whiskers. The β-Si3N4w/Cu/Sn still had a quite high thermal conductivity. As a result, the β-Si3N4w/Cu/Sn could be a promising material applied in a severe environment.