Article contents

Electron backscattered diffraction analysis of the effect of deformation temperature on the microstructure evolution in a typical nickel-based superalloy during hot deformation

Published online by Cambridge University Press: 25 April 2016

Abstract

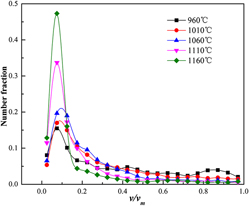

The microstructure evolution of a typical nickel-based superalloy was studied in the temperature range of 960–1160 °C with the strain rate of 0.001 s−1 by using electron backscattered diffraction technique. Based on the grain orientation spread method, the dynamic recrystallization (DRX) grains were distinguished from the deformed grains. The results revealed that the volume fraction and the size of DRX grains increased with the increasing deformation temperatures. Most of the original Σ3 boundaries lost their twin characteristics due to crystal rotations during hot deformation. Meanwhile, lots of new Σ3 boundaries were formed in the DRX grains mainly by growth accidents. Moreover, the deformation temperature had a similar effect on the fraction of Σ3 boundary and the Σ3 boundary density in the DRX domains, which increased firstly and then decreased with the increasing deformation temperature. The Σ3 boundary density was analyzed as a function of grain size, and the critical grain size below which no twin forms was calculated to be 2.06 µm. In addition, the coherent Σ3 boundaries were easier to form at the higher deformation temperature due to their lower boundary energy.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 9

- Cited by