Article contents

Effects of sintering parameters on the microstructure and mechanical properties of carbon nanotubes reinforced aluminum matrix composites

Published online by Cambridge University Press: 28 November 2016

Abstract

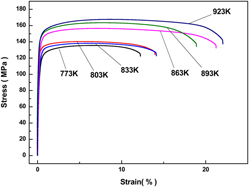

By using high purity aluminum powders and multi-walled carbon nanotubes (MWCNTs) as raw materials, MWCNTs/Al composites were fabricated with ball milling, followed by cold pressing, vacuum sintering, and hot extrusion. It was found that when the sintering temperature was 863 K, MWCNTs/Al composite sintered for 4 h showed good comprehensive properties, and its tensile strength and elongation reached to 156 MPa and 21%, respectively. The comprehensive mechanical properties of the composites became better with raising sintering temperature when the sintering time was 4 h. When the sintering temperature raised to 923 K, the tensile strength of the composite reached to 167 MPa which is three times more than that of annealed high purity aluminum, mainly due to the higher density and better interface bonding resulted from higher sintering temperature. CNTs' pulling out were observed obviously in the fractured surfaces, and load transfer may be the main strengthening mechanism.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 10

- Cited by