Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Révész, Ádám

Gajdics, Marcell

Schafler, Erhard

Calizzi, Marco

and

Pasquini, Luca

2017.

Dehydrogenation-hydrogenation characteristics of nanocrystalline Mg2Ni powders compacted by high-pressure torsion.

Journal of Alloys and Compounds,

Vol. 702,

Issue. ,

p.

84.

Tran, Xuan Quy

McDonald, Stuart D.

Gu, Qinfen

Tan, Xin Fu

and

Nogita, Kazuhiro

2017.

Effect of trace Na additions on the hydriding kinetics of hypo-eutectic Mg–Ni alloys.

International Journal of Hydrogen Energy,

Vol. 42,

Issue. 10,

p.

6851.

Tran, Xuan Quy

McDonald, Stuart D.

Gu, Qinfen

Yamamoto, Tomokazu

Shigematsu, Koji

Aso, Kohei

Tanaka, Eishi

Matsumura, Syo

and

Nogita, Kazuhiro

2017.

In-situ investigation of the hydrogen release mechanism in bulk Mg2NiH4.

Journal of Power Sources,

Vol. 341,

Issue. ,

p.

130.

Tran, Xuan Quy

McDonald, Stuart D.

Gu, Qinfen

Tan, Xin Fu

and

Nogita, Kazuhiro

2017.

Effect of impurity N2 concentration on the hydriding kinetics of Na-doped Mg–Ni alloys.

International Journal of Hydrogen Energy,

Vol. 42,

Issue. 1,

p.

366.

Wu, Zhen

Zhu, Luying

Yang, Fusheng

Nyamsi, Serge N.

Porpatham, Ekambaram

and

Zhang, Zaoxiao

2018.

Toward the design of interstitial nonmetals co-doping for Mg-based hydrides as hydrogen storage material.

Journal of Materials Research,

Vol. 33,

Issue. 23,

p.

4080.

Gao, Shichao

Wang, Hui

Wang, Xinhua

Liu, Haizhen

He, Ting

Wang, Yuanyuan

Wu, Chen

Li, Shouquan

and

Yan, Mi

2020.

MoSe2 hollow nanospheres decorated with FeNi3 nanoparticles for enhancing the hydrogen storage properties of MgH2.

Journal of Alloys and Compounds,

Vol. 830,

Issue. ,

p.

154631.

Ouyang, Liuzhang

Liu, Fen

Wang, Hui

Liu, Jiangwen

Yang, Xu-Sheng

Sun, Lixian

and

Zhu, Min

2020.

Magnesium-based hydrogen storage compounds: A review.

Journal of Alloys and Compounds,

Vol. 832,

Issue. ,

p.

154865.

Kim, Manjin

Ali, Yahia

McDonald, Stuart D.

Abbott, Trevor B.

and

Nogita, Kazuhiro

2020.

Magnesium Technology 2020.

p.

289.

Kim, Manjin

Gu, Qinfen

Hussain, Tanveer

Ali, Yahia

Abbott, Trevor B.

and

Nogita, Kazuhiro

2021.

The effect of Na addition on the first hydrogen absorption kinetics of cast hypoeutectic Mg–La alloys.

International Journal of Hydrogen Energy,

Vol. 46,

Issue. 53,

p.

27096.

Tan, Xin F.

Kim, Manjin

Gu, Qinfen

Pinzon Piraquive, Julio

Zeng, Guang

McDonald, Stuart D.

and

Nogita, Kazuhiro

2022.

Na-modified cast hypo-eutectic Mg–Mg2Si alloys for solid-state hydrogen storage.

Journal of Power Sources,

Vol. 538,

Issue. ,

p.

231538.

Kim, Manjin

McDonald, Stuart D.

Ali, Yahia

Abbott, Trevor B.

and

Nogita, Kazuhiro

2022.

Magnesium Technology 2022.

p.

69.

Kim, Manjin

Tan, Xin Fu

Gu, Qinfen

McDonald, Stuart D.

Ali, Yahia

Matsumura, Syo

and

Nogita, Kazuhiro

2022.

Hydrogen sorption behaviour of Mg-5wt.%La alloys after the initial hydrogen absorption process.

International Journal of Hydrogen Energy,

Vol. 47,

Issue. 36,

p.

16132.

Tan, Xin F.

Kim, Manjin

Yasuda, Kazuhiro

and

Nogita, Kazuhiro

2023.

Strategies to enhance hydrogen storage performances in bulk Mg-based hydrides.

Journal of Materials Science & Technology,

Vol. 153,

Issue. ,

p.

139.

Maleki, Milad

Jamei, Fatemeh

Emamy, Massoud

and

Mirzadeh, Hamed

2023.

Microstructure and mechanical properties of as-cast and wrought Mg–Ni in-situ formed alloys.

Materials Science and Technology,

Vol. 39,

Issue. 8,

p.

985.

Raza, Hafiz Hamid

Murtaza, G.

and

Shafiq, Maleeha

2023.

Structural, phonon, thermodynamic, and electronic properties of MgFeH3 at different pressures: DFT study.

Computational and Theoretical Chemistry,

Vol. 1221,

Issue. ,

p.

114030.

Yao, Hu

Zeng, Guang

Tan, Xin F.

Gu, Qinfen

Nogita, Kazuhiro

Guo, Jing

and

Li, Qian

2023.

Hydrogen storage performance and phase transformations in as-cast and extruded Mg-Ni-Gd-Y-Zn-Cu alloys.

Journal of Materials Science & Technology,

Vol. 151,

Issue. ,

p.

162.

Shen, Guohong

Kondou, Shinji

Wada, Gakuto

Nakagaki, Hiroki

Watanabe, Masayoshi

Dokko, Kaoru

and

Ueno, Kazuhide

2025.

Interfacially-localized high-concentration electrolytes for high-performance rechargeable aqueous lithium-ion batteries.

EES Batteries,

Vol. 1,

Issue. 2,

p.

273.

Lee, Da Hye

Jung, So Jin

Suh, Byeong-Chan

Kim, Young Min

Kwak, Ryun Ho

Park, Sung-Min

Kang, Jang-Won

Park, Hyung-Ki

and

Ha, Taejun

2025.

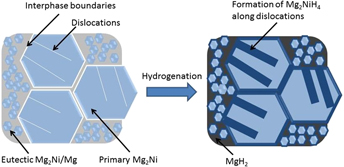

A study on first hydrogenation mechanism and microstructural features of hyper-eutectic Mg–Ni hydrogen storage alloy.

International Journal of Hydrogen Energy,

Vol. 120,

Issue. ,

p.

110.