Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Souier, Tewfik

Santos, Sergio

Al Ghaferi, Amal

Stefancich, Marco

and

Chiesa, Matteo

2012.

Enhanced electrical properties of vertically aligned carbon nanotube-epoxy nanocomposites with high packing density.

Nanoscale Research Letters,

Vol. 7,

Issue. 1,

Souier, Tewfik

Stefancich, Marco

and

Chiesa, Matteo

2012.

Characterization of multi-walled carbon nanotube–polymer nanocomposites by scanning spreading resistance microscopy.

Nanotechnology,

Vol. 23,

Issue. 40,

p.

405704.

Guo, L.Q.

Lin, M.C.

Qiao, L.J.

and

Volinsky, Alex A.

2014.

Duplex stainless steel passive film electrical properties studied by in situ current sensing atomic force microscopy.

Corrosion Science,

Vol. 78,

Issue. ,

p.

55.

Diamanti, M.V.

Souier, T.

Stefancich, M.

Chiesa, M.

and

Pedeferri, M.P.

2014.

Probing anodic oxidation kinetics and nanoscale heterogeneity within TiO2 films by Conductive Atomic Force Microscopy and combined techniques.

Electrochimica Acta,

Vol. 129,

Issue. ,

p.

203.

UZUN, İsmail

GÜLER, Buğra

ÖZYÜREK, Taha

UÇARLI, Okan

BODRUMLU, Emre

and

MENEK, Necati

2014.

Steel and Nickel Titanium Endodontic Instruments.

International Journal of Electrochemical Science,

Vol. 9,

Issue. 10,

p.

5812.

Guo, L.Q.

Yang, B.J.

Liang, D.

and

Qiao, L.J.

2015.

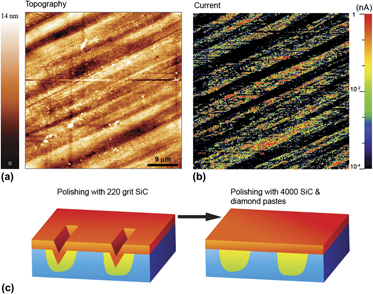

Surface preparation effect on duplex stainless steel passive film electrical properties studied by in situ CSAFM.

Journal of Materials Research,

Vol. 30,

Issue. 20,

p.

3084.

Seita, Matteo

Nimerfroh, Michael M.

and

Demkowicz, Michael J.

2017.

Acquisition of partial grain orientation information using optical microscopy.

Acta Materialia,

Vol. 123,

Issue. ,

p.

70.

Guo, L. Q.

Qin, S. X.

Yang, B. J.

Liang, D.

and

Qiao, L. J.

2017.

Effect of hydrogen on semiconductive properties of passive film on ferrite and austenite phases in a duplex stainless steel.

Scientific Reports,

Vol. 7,

Issue. 1,

Yakubov, Vladislav

Lin, Meichao

Volinsky, Alex A.

Qiao, Lijie

and

Guo, Liqiu

2018.

The hydrogen-induced pitting corrosion mechanism in duplex stainless steel studied by current-sensing atomic force microscopy.

npj Materials Degradation,

Vol. 2,

Issue. 1,

Srinivasan, N.

and

Kumaran, S. Senthil

2019.

Role of Alloy Chemistry on Stability of Passive Films in Austenitic Stainless Steel.

Journal of Materials Engineering and Performance,

Vol. 28,

Issue. 6,

p.

3695.

Krawiec, Halina

and

Vignal, Vincent

2021.

Mechanical and Electro-Chemical Interactions Under Tribocorrosion.

p.

7.

Ahn, Taemin

and

Kim, Tae-Hwan

2023.

Microscopic conductivity of passive films on ferritic stainless steel for hydrogen fuel cells.

Journal of the Korean Physical Society,

Vol. 83,

Issue. 4,

p.

289.

魏, 雨希

2023.

Effect of Milling Residual Stress on Stress Corrosion of Al7075-T6 Alloy.

Modeling and Simulation,

Vol. 12,

Issue. 03,

p.

2141.

Lee, So-Hyeon

Lee, Junsang

Kim, Younghoon

and

Kim, Ju-Young

2024.

Surface residual stress in H-section steel beams processed by quenching and self-tempering using instrumented indentation testing.

Journal of Materials Research and Technology,

Vol. 32,

Issue. ,

p.

177.